|

Thread Number: 1475

Micro twin-tubs |

[Down to Last] |

|

Post# 59483 , Reply# 3 3/8/2005 at 19:31 (6,981 days old) by Pulsator  (Saint Joseph, MI) (Saint Joseph, MI) |

||

| ||

| Post# 59488 , Reply# 5 3/8/2005 at 20:19 (6,981 days old) by mrcleanjeans (milwaukee wi) | ||

|

mini twini that Koblenz twin-tub looks virtually identical to the twin tub Danbys sold here. | ||

Post# 59583 , Reply# 10 3/9/2005 at 20:15 (6,980 days old) by Pulsator  (Saint Joseph, MI) (Saint Joseph, MI) |

||

| ||

| Post# 59606 , Reply# 11 3/9/2005 at 23:10 (6,980 days old) by kenmore1978 () | ||

|

25 Hz Here's the story. Very interesting CLICK HERE TO GO TO kenmore1978's LINK | ||

Post# 59642 , Reply# 14 3/10/2005 at 11:33 (6,979 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Pulsator Twinnies!!!!

A pity that so many of the original machines and companies have now gone, I wouldnt want to use one all the time but are great fun for a trip down memory lane. It really does depend on how you use it as to the efficiency of them, have myself done numerous tests with the front loader v twinnies and have come to the conclusion that modern FL have the edge of washing rinsing and spinning effeciency on the 1200 + machines. Just posted some pics of Hoover Pulsator Action Machines in the clubs album, see link below... Its interesting that the design of this small twinny is the same principle as the Rolls machines from the 60`s etc... Take a look and let me know what you think??? p.s. The pic is from a 1960 AEG twinny CLICK HERE TO GO TO chestermikeuk's LINK

| ||

Post# 59764 , Reply# 18 3/11/2005 at 14:55 (6,978 days old) by Pulsator  (Saint Joseph, MI) (Saint Joseph, MI) |

||

I have a friend of the family who knows a lot about this voltage stuff and he said that there are special transformers you can buy for running a larger peice of equipment than a hairdryer or something, like a washing machine. Anyway, he said that they are probably about $100.00. What do you guys think? Would it work?

| ||

Post# 59831 , Reply# 19 3/12/2005 at 10:44 (6,978 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

A Big Bob Load!!!!....NOT......LOL....!!!!!!!

Could resist taking the Micro Compact for a spin.... Its a fab little washer, and yes I mean little, the laundry basket is a big as it....performs well, the wash action is very strong, certainly wizzes the clothes around.. Spinner very quiet and water spun into the outer tub, then you place the pipe in a bucket or sink and away you go.. See through Tubs are great to watch the washing swirling round and the spin water hitting the side of the outer tub... BUT....A BIG BOB LOAD WASHER IT AINT.....(Hi Appnut!!!) ....lol Take a look and see what you think, I`ve loaded them onto my yahoo pics so you might have to log on there.... Cheers, Mike CLICK HERE TO GO TO chestermikeuk's LINK

| ||

| Post# 59835 , Reply# 20 3/12/2005 at 11:03 (6,977 days old) by westytoploader () | ||

|

Cool machine but I like the big Servis SuperTwin better!!! | ||

Post# 59841 , Reply# 21 3/12/2005 at 12:45 (6,977 days old) by Pulsator  (Saint Joseph, MI) (Saint Joseph, MI) |

||

| ||

Post# 59844 , Reply# 22 3/12/2005 at 13:54 (6,977 days old) by foraloysius  (Leeuwarden, Friesland, the Netherlands) (Leeuwarden, Friesland, the Netherlands) |

||

| ||

Post# 59889 , Reply# 23 3/13/2005 at 16:23 (6,976 days old) by arrrooohhh  (Sydney Australia) (Sydney Australia) |

||

|

OHHH I WANT ONE!!!! I sound like a little kid I know. Loved your pictures Chestermike! Thank you so much for sharing. It really looks like fun, and its allwasy nice to see those Servis twinnies, reminds me of Nan and her Wilkins Servis twinnie :) | ||

| Post# 60012 , Reply# 27 3/15/2005 at 00:12 (6,975 days old) by kenmore1978 () | ||

|

50 Hz/60 Hz Didn't WP and Maytag offer 50 Hz pulleys, using the same 60 Hz motor? Didn't seem to hurt those motors, and they had to start under load. | ||

| Post# 60186 , Reply# 29 3/16/2005 at 20:17 (6,973 days old) by doityrselfguy () | ||

|

Ugh! I want one of those small twin tubs...loved the pictures!! I wish there was a way to purchase internationally for home delivery. | ||

Post# 60387 , Reply# 30 3/18/2005 at 05:46 (6,972 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

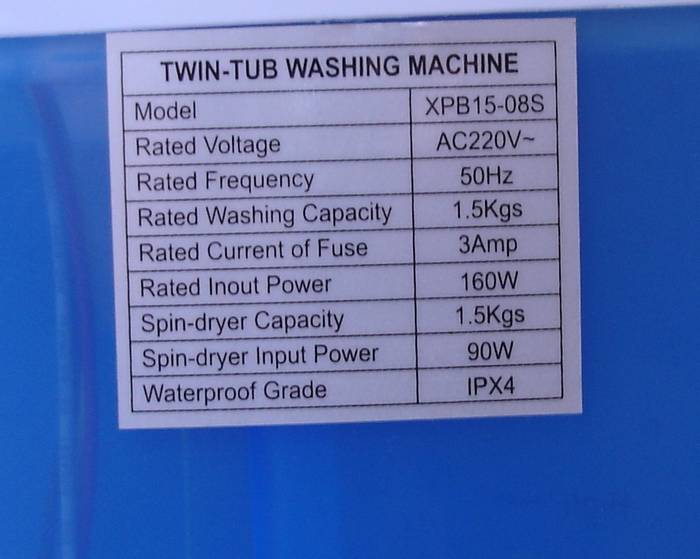

Micro Twinny Rating

Have posted a pic of the rating plate if this helps... It certainly is a fast washer, the disc impellar spins one way then the other, gentle action is a pause in between the reverse etc... The spin can does have perfs. you can just see the spray on the outer blue tub in one of the pics.. I fill it using a Hoover twinny pipe, quicker than the very thin flimsy pipe that comes with it and connects to the top next to the controls, (when you remove the cover) It will drain easily into a bucket, but what a chore.... It will take one pair of jeans, but really splashes about etc...not sure you could use it as a regular washer, fine for one off camping etc..small items....bedding, fleeces, large items , I think a no no... Glad you guys like the servis....its a very rare model..was the second produced in 1960 and is called "The AutoWash", it has 3 automatic linked heater / timer programmes which automatically heat the water and switch on to agitate for a set number of minutes... It also has a spin timer as well, which is unheard of on most machines, very advanced for its day, defies me why Servis never kept it in production & updated it to match the Hoover & Hotpoint...which still dont have as many features...the next model in 1961 looks the same but has a wash timer, seperate heater & no spin timer.. CLICK HERE TO GO TO chestermikeuk's LINK

| ||

| Post# 61529 , Reply# 32 3/28/2005 at 19:39 (6,961 days old) by bpetersxx (laf in on the banks of the Wabash River) | ||

A new way to twin tub

I tried my haier washers that I got a short time ago as a twin tub setup. I started one load in the electronic haier then drained the water out into my pulsator haier model. Then started a second load in the pulsator haier model while the first load finished in the electronic haier This way I get a twin tub washer like a regular twin tub but can configure them how I want to wash today. I can use any of my haier washers in any configuration that works best for the task. | ||

Post# 61783 , Reply# 38 3/30/2005 at 21:59 (6,959 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Don't know much about this, but do know 3000 is about the safe level to pull with a step up transformer in the United States. Higher than that and one really should hardwire the transformer into the electrical system. Case in point my Pfaff ironer runs 220/240 at 50hz according to the plate, with total watts of 3100. Heater alone pulls about 2000, the steam boiler and pump 1,100. Ironer works fine on a step up transformer (convertering 120v to 220), and heats evenly up to "high" max power. If I start the steam boiler while using the high heat setting, the transformer's circut breaker will trip, and or the fuse. In one case the entire transformer fried. Was warned never to exceed max voltage even by a little, and it is better to oversize a transformer than under. In other words I could use a 4000 or 5000 watt transformer and run both steam and heat with no problems, but pulling that much power really requires hard wiring. IIRC our electrican told us most homes in the United States have outlets whose wiring only allows up to about 3000 watts. Over that and one runs the risk of burning down the house as the wiring simply gets too hot handling such a load. Usually it is not the motor on washing machines that is bothered by going from 50hz to 60hz but the electronics. You'll notice most home computers can be switched to run on either 50hz or 60hz depending upon what country they are sold/used in. Washing machines do not have this. True the motor will run faster, as probably the timer. Someone over on THS was running his AEG washers in the States on a transformer with 60hz, with no problems. Cycles just ran a bit faster,but AEG Canada provided him with a chart showing the adjustments for faster cycle times. Launderess | ||

Post# 61799 , Reply# 42 3/30/2005 at 23:09 (6,959 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

| ||

Comes to the Rescue!

Comes to the Rescue!