|

Thread Number: 17593

beggin for a KA part |

[Down to Last] |

| Post# 287841 6/29/2008 at 17:51 (5,773 days old) by christfr (st louis mo) | ||

| ||

|

| Post# 287842 , Reply# 1 6/29/2008 at 17:54 (5,773 days old) by christfr (st louis mo) | ||

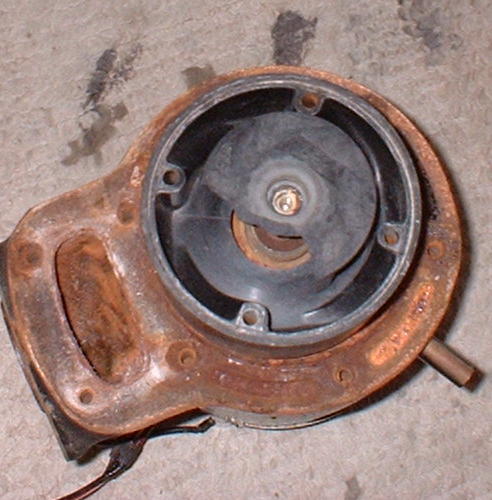

and well got everything apart and cleaned the went after the pump and well i broke the impeller.. this is a KA12P does anyone have a source or spare or good used one to sell?? also have a question about the seal under the impeller? is that a rubber seal or stack washer type seal? should i replace the seal there too? does anyone have a seal??

| ||

| Post# 288057 , Reply# 3 7/1/2008 at 06:16 (5,772 days old) by christfr (st louis mo) | ||

thanks so so much.. let me know.. i took the machine apart to clean and reseal the motor to the cabnet and when the motor was out i heard something in the pump so i took the top off and it was a dried up noodle ha ha. so i thought i take the impeller off and clean it all up and reinstall it but it was stuck on the shaft and when i pulled it broke.. uggg..if you can find something that will work ill be more than happy to buy it from you.. let me know when you have time.. thanks again chris

| ||

| Post# 288137 , Reply# 5 7/1/2008 at 19:51 (5,771 days old) by stevet (West Melbourne, FL) | ||

|

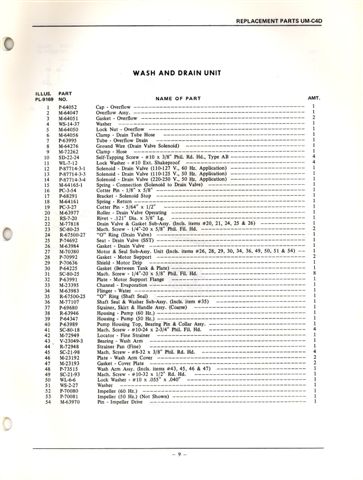

part numbers This is the page with the Hobart part numbers. BTW, Just remembered..if you want, you can contact your own local Hobart office and order them yourself. That way you may be able to save the shipping from Florida to you.

| ||

| Post# 288203 , Reply# 6 7/2/2008 at 06:29 (5,771 days old) by christfr (st louis mo) | ||

oh my gosh.. wow.. well i didnt have time to tinker last night to much yard work and this eve is clean the house nighta before i leave for vacation and then ill be gone for a week so let me mull this over and i can mail you when i get back and go from there. ill have to see how broke i am when i get back ha ha.. is there any way to tell if the seal is bad?? id hate to rebuild the machine and find out later that the seal is shot.. is that little tube on the upper side of the motor an oil port of is that some sort of drain? if there is a way to test the seal let me know ill try that.. i do want to save this one its way to cool to let go of.. thanks so so much

| ||

| Post# 288414 , Reply# 8 7/3/2008 at 06:29 (5,770 days old) by christfr (st louis mo) | ||

| ||

Post# 288509 , Reply# 9 7/3/2008 at 16:39 (5,769 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

| ||

| Post# 290615 , Reply# 10 7/14/2008 at 06:13 (5,759 days old) by christfr (st louis mo) | ||

well im back.. i prob could try and glue the impeller back but not sure how long that would last. and im not sure if the seal is bad or not. and to change the seal the impeller has to come out.. so question for steve-- do you think i could find the parts online? or should i start saving up the big bucks, ha ha

| ||

| Post# 290791 , Reply# 13 7/15/2008 at 06:08 (5,758 days old) by christfr (st louis mo) | ||

well i give that a try this weekend. ill install the motor and see if it holds water. i did get gasket material to make new gaskets so ill go from there and see.. let me know if you find an impeller. one of these days she will run again.. i prob should have never taken it apart but i guess you live and learn ha ha

| ||

| Post# 290951 , Reply# 15 7/16/2008 at 06:16 (5,757 days old) by christfr (st louis mo) | ||

well i did check out the car type impellers that we have here at work but none come close so im gonna wait and see if steve can come up with one.. oh yes and dear mr togg.. i would not mind seeing a few pretty colors but dont think id enjoy the brain damage to much.. i did buy some type of glue stuff but i will read the lable before i use it

| ||

Comes to the Rescue!

Comes to the Rescue!