|

Thread Number: 18832

That project |

[Down to Last] |

| Post# 305233 9/23/2008 at 13:12 (5,686 days old) by hotpoint95622 (Powys) | ||

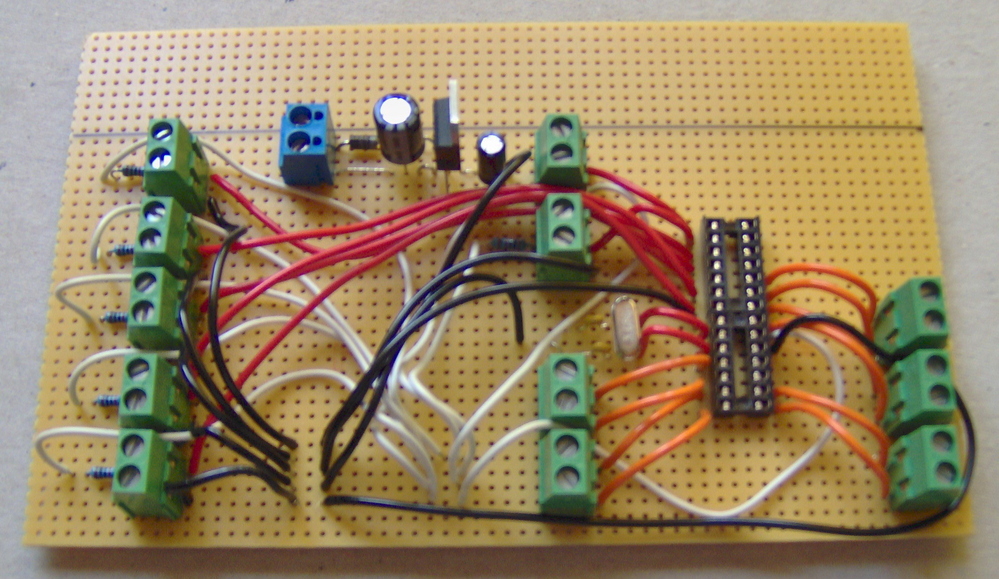

An up date of that project, if any one is interested. Well the program is written (lots of coffee and lots of bad swearing) and blown onto the chip (PIC 16F872) using the PC, would not work to start with as I donít know how to program any thing, itís amazing that it works, hours of reading books and copying examples and trying again and again. Most of the timings I have based on the Hotpoint 95622, spent hours watching it and counting the second between wash actions, main wash 12sec tumble with 6sec pause and 6sec tumble with 12sec pause for heating, spin times ect. I have made a circuit board to hold chip and its power supply and used a quarts crystal as a clock, same thing as in your battery watch or wall clock, and some connecters to the outside world.

| ||

|

| Post# 305234 , Reply# 1 9/23/2008 at 13:14 (5,686 days old) by hotpoint95622 (Powys) | ||

that project | ||

| Post# 305235 , Reply# 2 9/23/2008 at 13:16 (5,686 days old) by hotpoint95622 (Powys) | ||

that project | ||

| Post# 305237 , Reply# 3 9/23/2008 at 13:23 (5,686 days old) by hotpoint95622 (Powys) | ||

that project | ||

| Post# 305238 , Reply# 4 9/23/2008 at 13:33 (5,686 days old) by hotpoint95622 (Powys) | ||

that project | ||

| Post# 305239 , Reply# 5 9/23/2008 at 13:35 (5,686 days old) by hotpoint95622 (Powys) | ||

that project | ||

| Post# 305251 , Reply# 6 9/23/2008 at 14:25 (5,686 days old) by matchboxpaul (U.K) | ||

|

really intrigued to see how the project pans out. i take it you will be mounting it all in/on the carcass of a washing machine - any plans as to what type? keep us posted. cheers paul | ||

| Post# 305269 , Reply# 7 9/23/2008 at 16:21 (5,686 days old) by funguy10 () | ||

|

So you are building your dream washer? Mr. Unimatic1140, site owner & founder also built one but it didn't have its own control panel. A computer ran it. | ||

| Post# 305379 , Reply# 8 9/24/2008 at 05:24 (5,686 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

Wow | ||

| Post# 305384 , Reply# 9 9/24/2008 at 07:09 (5,686 days old) by hotpoint95622 (Powys) | ||

Hotpoint 95622

Yes, paul Iím looking for a host machine for the project, I would like to use a Hotpoint, maybe a 95 or the range after ( I can here the gasps, especially when Iím going to strip all the wiring out of it, like the Texas chain saw massacre ) or a tricity bendix like the aw1053 that we use everyday. But I donít think it would be appreciated if I pull that apart, it relay doesnít mater but it must have a separate speed module and motor that are in good order (so that basically means it must have had a mechanical trimmer ) as I donít yet have the knowledge to built the speed control that is required. I have used a zanussi studio compact machine but it was to small for the purpose, I have kept all the components including the motor and speed module, but it works at a different ratio to a full size machine, but it did prove that my program will work and that I got the valves and pump working at the right time and controlled the motor. Lee | ||

Comes to the Rescue!

Comes to the Rescue!