|

Thread Number: 21061

No oil for 1-18! well mabie some... |

[Down to Last] |

|

| Post# 333173 , Reply# 1 3/2/2009 at 12:08 (5,524 days old) by fltcoils (South Bend, Indiana) | ||

|

another pic

| ||

| Post# 333174 , Reply# 2 3/2/2009 at 12:10 (5,524 days old) by fltcoils (South Bend, Indiana) | ||

|

and rebuild instr

| ||

| Post# 333175 , Reply# 3 3/2/2009 at 12:11 (5,524 days old) by fltcoils (South Bend, Indiana) | ||

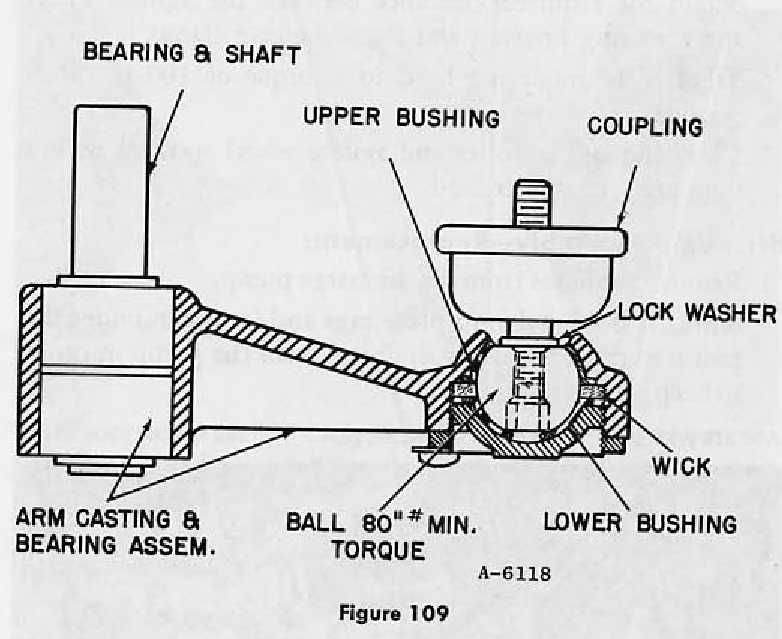

|

pic of arm, showing wick

| ||

Post# 333214 , Reply# 4 3/2/2009 at 14:04 (5,524 days old) by joelippard  (Hickory) (Hickory) |

||

How interesting. | ||

Comes to the Rescue!

Comes to the Rescue!