|

Thread Number: 21167

KD-12 TIMER MOTOR NEEDED! |

[Down to Last] |

|

| Post# 334386 , Reply# 1 3/8/2009 at 20:56 (5,525 days old) by soberleaf () | ||

|

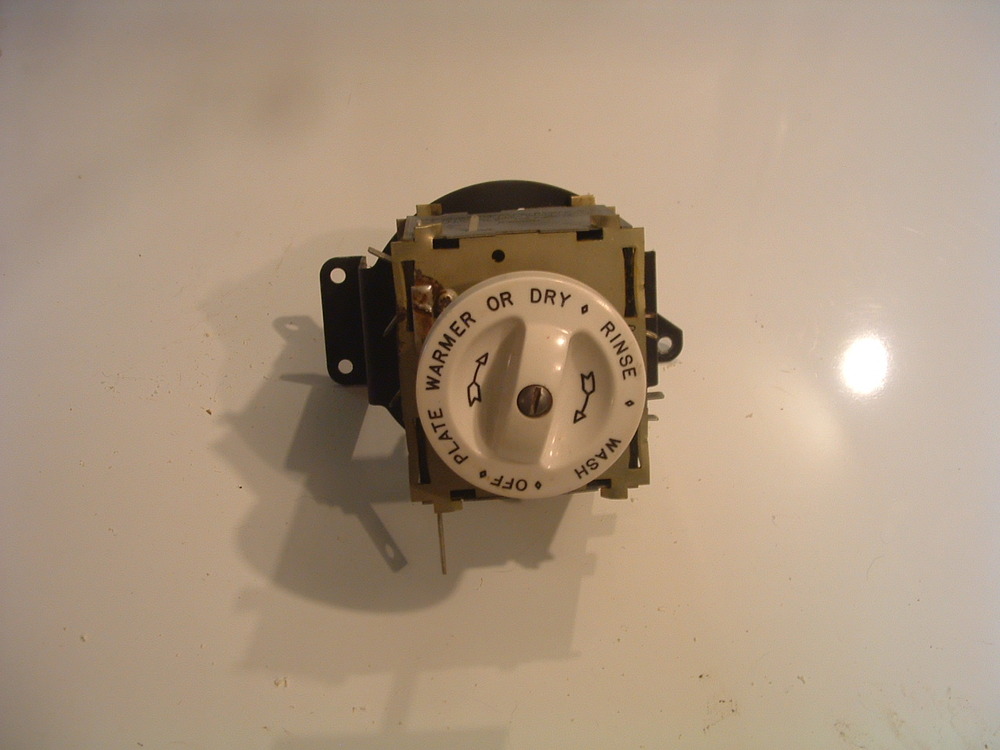

more timer again

| ||

| Post# 334388 , Reply# 2 3/8/2009 at 20:56 (5,525 days old) by soberleaf () | ||

|

more more timer

| ||

| Post# 334389 , Reply# 3 3/8/2009 at 20:58 (5,525 days old) by soberleaf () | ||

|

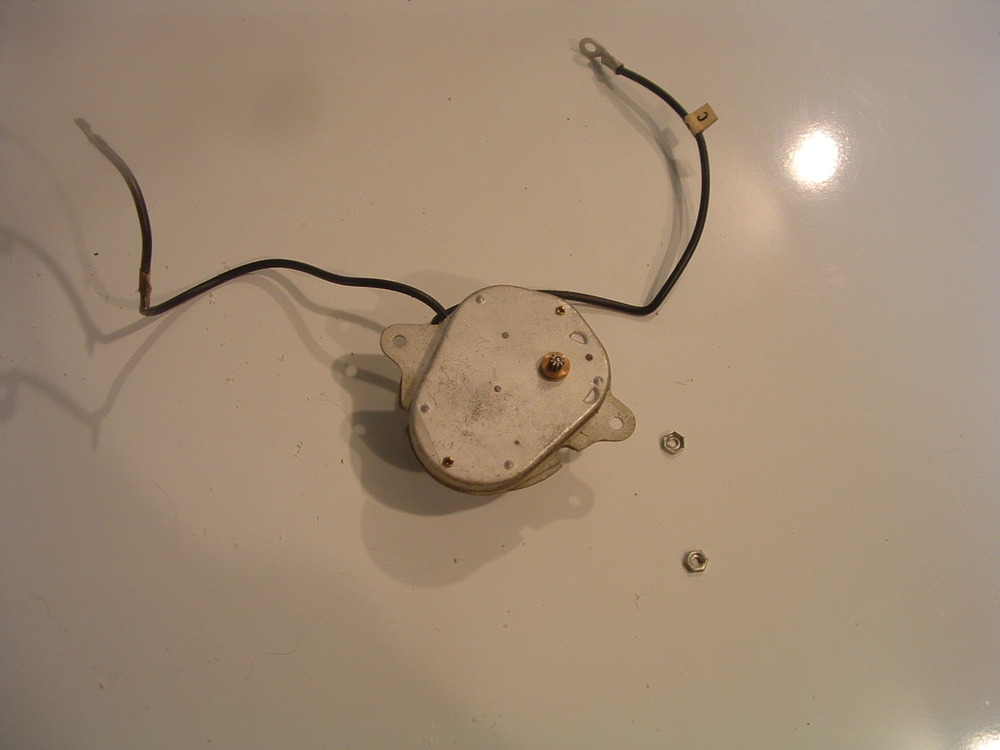

timer motor the motor

| ||

| Post# 334390 , Reply# 4 3/8/2009 at 20:59 (5,525 days old) by soberleaf () | ||

|

timer motor more

| ||

| Post# 334392 , Reply# 5 3/8/2009 at 21:00 (5,525 days old) by soberleaf () | ||

|

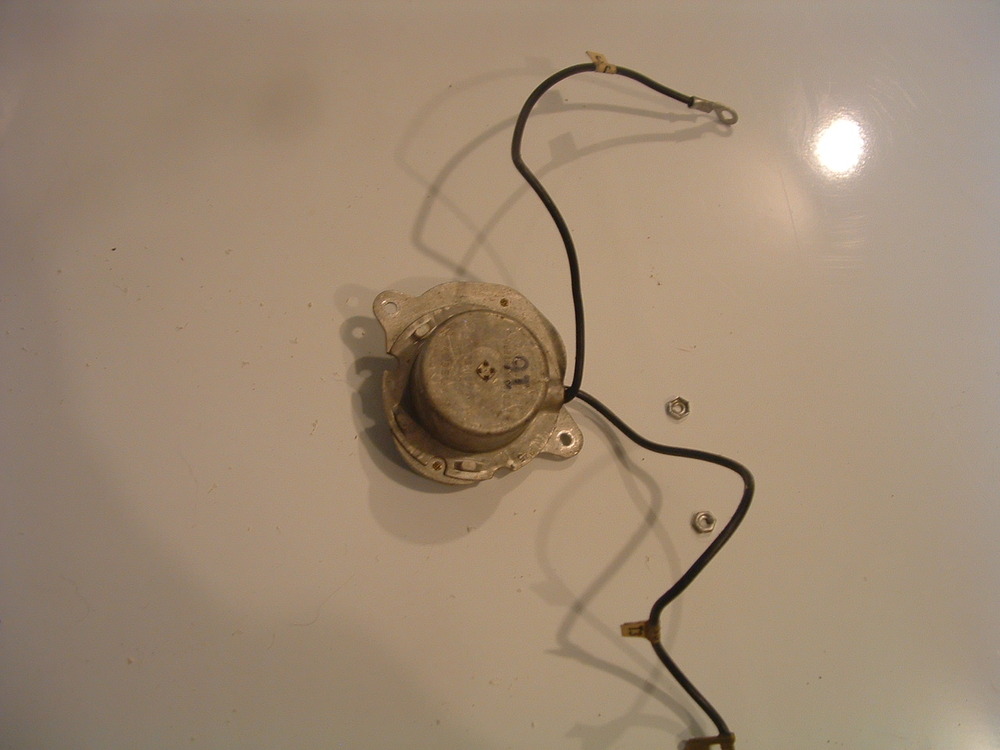

more more motor

| ||

| Post# 334393 , Reply# 6 3/8/2009 at 21:01 (5,525 days old) by soberleaf () | ||

|

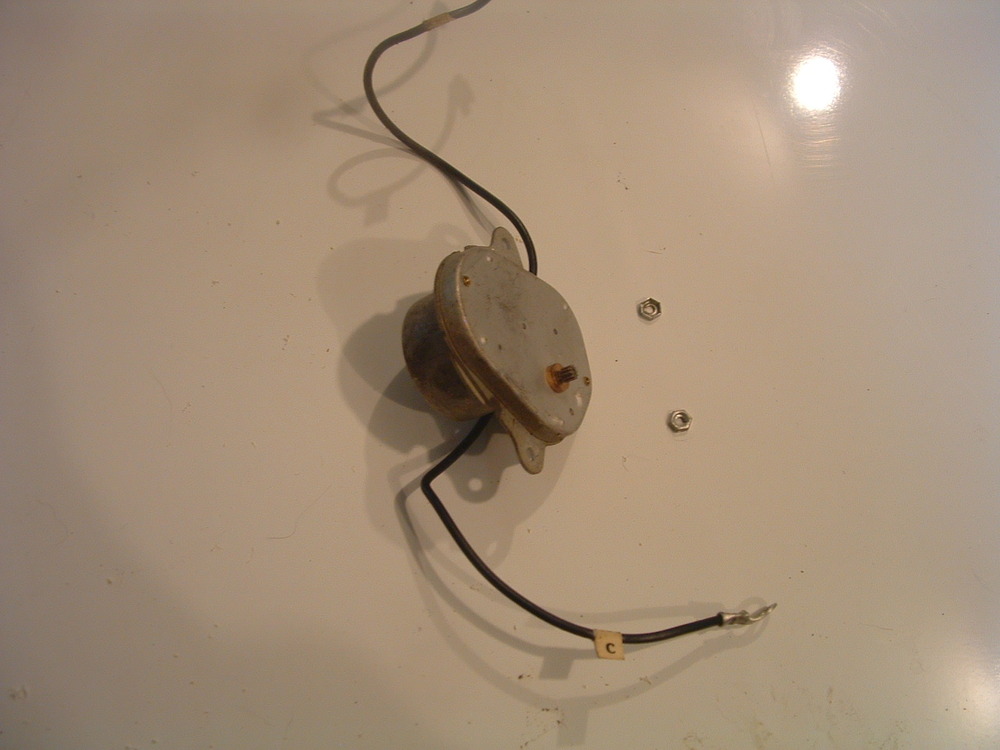

last pic one more

| ||

| Post# 334404 , Reply# 7 3/8/2009 at 21:40 (5,525 days old) by 58limited (Port Arthur, Texas) | ||

| ||

Post# 334452 , Reply# 8 3/9/2009 at 09:01 (5,525 days old) by jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Try this guy | ||

| Post# 334466 , Reply# 9 3/9/2009 at 10:09 (5,525 days old) by soberleaf () | ||

|

thanks i contacted skycraft, they said they might have one. does anyone know what rpm this motor turns at? | ||

| Post# 334614 , Reply# 14 3/9/2009 at 23:17 (5,524 days old) by oldappliancenut () | ||

|

no no you have one waiting here lol

| ||

| Post# 334645 , Reply# 15 3/10/2009 at 03:21 (5,524 days old) by soberleaf () | ||

|

hey look another kds-17 oh yes, can't forget my kds-17a that is waiting for me in pennsylvania! beautiful looking! i'll make room for it somewhere!!!!! | ||

| Post# 334766 , Reply# 17 3/10/2009 at 19:12 (5,524 days old) by soberleaf () | ||

|

it died of old age it's dead, tested it with 120 volts, nothing! | ||

| Post# 334890 , Reply# 20 3/11/2009 at 12:03 (5,523 days old) by fltcoils (South Bend, Indiana) | ||

|

oil here Gear axles easy to see Oil with a tiny bit of oil

| ||

| Post# 334891 , Reply# 21 3/11/2009 at 12:10 (5,523 days old) by fltcoils (South Bend, Indiana) | ||

|

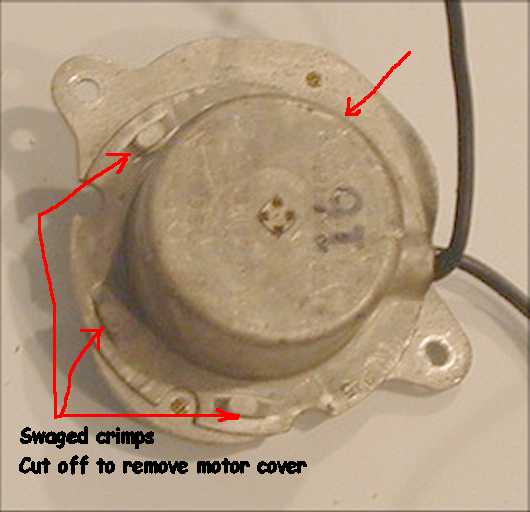

You can also try to get to the armature, The cover appears to be held in place by crimping. One might drimel grind thru a bit of those crimps. Then one could pry them out of the way and get to the motor. It really is easier to disassemble than modern welded plastic covers (i.e. a laptop battery case)

| ||

| Post# 335569 , Reply# 27 3/15/2009 at 09:24 (5,519 days old) by fltcoils (South Bend, Indiana) | ||

|

Probably not rewire But you could fix a broken magwire/leadwire termination. That is not too hard. Rewiring motors is a good skill. I bet there are a few here who would love to learn how to rewire a failed stator for one of these appliance motors. | ||

Comes to the Rescue!

Comes to the Rescue!