|

Thread Number: 23104

QUESTIONS FOR THE 1-18 FRIGIDAIRE EXPERTS |

[Down to Last] |

|

| Post# 360653 , Reply# 1 6/30/2009 at 14:50 (5,405 days old) by soberleaf () | ||

|

i removed this bolt also, the one right above the left side end of the arm.

| ||

| Post# 360654 , Reply# 2 6/30/2009 at 14:54 (5,405 days old) by soberleaf () | ||

|

looking at the agitator arm on the right side end i removed that phiilip screw that holds the nut ring tight. i have no idea what this ring nut does, it removed easily after the screw ws out. if anyone knows it's purpose please inform me.

| ||

Post# 360710 , Reply# 7 6/30/2009 at 19:56 (5,405 days old) by jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

No no No. Put the bolts back in | ||

| Post# 360736 , Reply# 9 6/30/2009 at 21:45 (5,405 days old) by soberleaf () | ||

|

well, success! i got the agitate arm to drop as i said, i sued my 1 1/2 deep socket on the hub nut and it came right off! i decided to completely strip it all down and took transmission, motor, everything off! here are some pics!

| ||

| Post# 360739 , Reply# 10 6/30/2009 at 21:47 (5,405 days old) by soberleaf () | ||

|

the hub is out and so is the old seal

| ||

| Post# 360741 , Reply# 11 6/30/2009 at 21:48 (5,405 days old) by soberleaf () | ||

|

here is that nut that took so long to get off

| ||

| Post# 360742 , Reply# 12 6/30/2009 at 21:49 (5,405 days old) by soberleaf () | ||

|

here is the old water seal

| ||

| Post# 360743 , Reply# 13 6/30/2009 at 21:50 (5,405 days old) by soberleaf () | ||

|

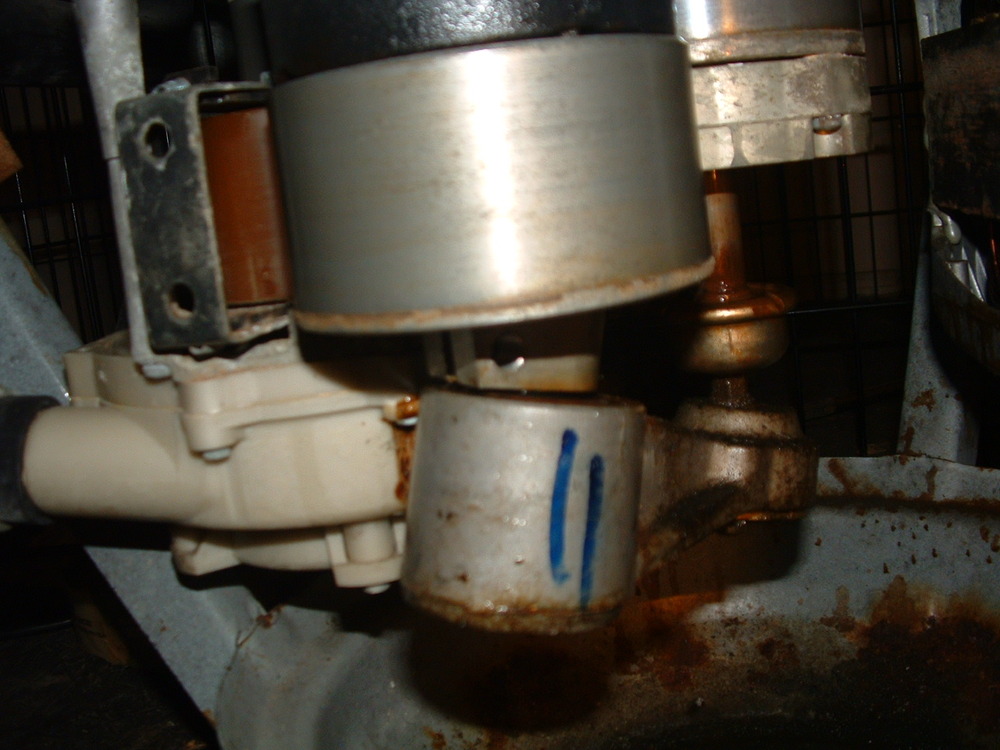

transmission is out and motor comes next

| ||

| Post# 360744 , Reply# 14 6/30/2009 at 21:51 (5,405 days old) by soberleaf () | ||

|

motor off now i am going to clean and paint this outer tub

| ||

| Post# 360748 , Reply# 15 6/30/2009 at 21:57 (5,405 days old) by soberleaf () | ||

|

i have to repair some rust where the opening is for the drain pump collection cup (back center of pic). it's not that bad yet but there was evidence of leakage in this area.

| ||

| Post# 360749 , Reply# 16 6/30/2009 at 21:59 (5,405 days old) by soberleaf () | ||

|

you can see the rust problem better in this picture, in the back right corner. i've had worse problems with my dishwashers so i'm not worried about fixing it, it will be easy!

| ||

| Post# 360752 , Reply# 17 6/30/2009 at 22:06 (5,405 days old) by soberleaf () | ||

|

if i could find a bearing set i would go ahead and replace the spin bearings while i am at it. so far no luck. if anyone knows of any please let me know. or are they a standard size i could get from a bearing company?

| ||

| Post# 360753 , Reply# 18 6/30/2009 at 22:08 (5,405 days old) by soberleaf () | ||

|

transmission is out, next thing to take off is the pump

| ||

| Post# 360754 , Reply# 19 6/30/2009 at 22:10 (5,405 days old) by soberleaf () | ||

|

pump is out and all pump parts and hoses are in the tub for safe keeping

| ||

| Post# 360756 , Reply# 20 6/30/2009 at 22:13 (5,405 days old) by soberleaf () | ||

|

here is the pump drain collection chamber the top port where the pressure switch hose connects to is broken off but that will be an easy fix too. i will drill it out and put a tube in and cement it in good.

| ||

| Post# 360757 , Reply# 21 6/30/2009 at 22:14 (5,405 days old) by soberleaf () | ||

|

another view of this chamber

| ||

| Post# 360758 , Reply# 22 6/30/2009 at 22:17 (5,405 days old) by soberleaf () | ||

|

another view of transmission with the pump impeller still on. i assume it screws off the shaft but as yet have not tried it. will do that tomorrow. i have a new pump seal on order from a friend who is selling me some frigidaire parts.

| ||

| Post# 360759 , Reply# 23 6/30/2009 at 22:19 (5,405 days old) by soberleaf () | ||

|

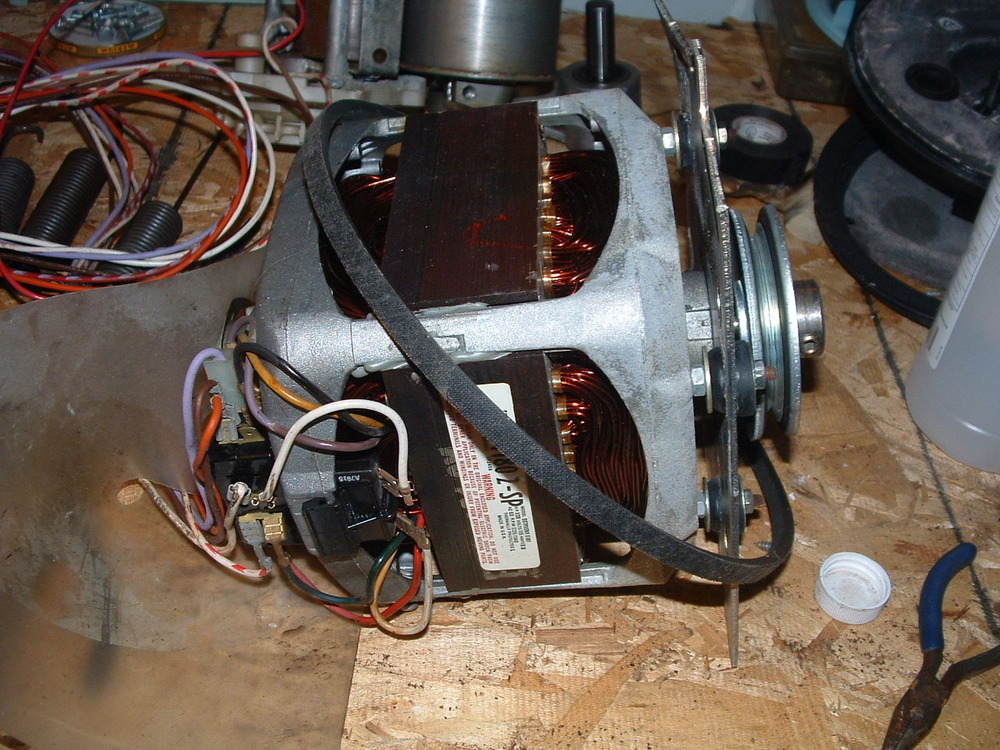

motor is in great shape and runs fine. i am going to oil bearings while it's off. anyone know where to get a belt should i ever need one?

| ||

| Post# 360785 , Reply# 27 12/31/2069 at 18:00 (19,831 days old) by norfolksouthern () | ||

|

There are some chunks broken off the bottom of the blue cone from the machine I got from goatfarmer, the one I'm hoping to rebuild. I think someone ran a belt with a heavy metal buckle through it, or maybe something else. NorfolkSouthern | ||

| Post# 360800 , Reply# 28 12/31/2069 at 18:00 (19,831 days old) by soberleaf () | ||

|

i will keep my eye out for a 1-18 pulsator cone for you! i'm going to take my time with this rebuild, spend the next few days cleaning parts and getting everything in order so when i go to put it all back together i will already have it in my mind how to do it. | ||

Post# 360808 , Reply# 30 7/1/2009 at 04:28 (5,405 days old) by goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

| ||

| Post# 360838 , Reply# 31 7/1/2009 at 09:16 (5,404 days old) by everythingold (Grand Rapids, Michigan) | ||

PITA PITA PITA | ||

Post# 360894 , Reply# 33 7/1/2009 at 12:33 (5,404 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

I personally haven't pulled a 1-18 bearing, but they look 'standard' and, more than likely, could be crossed over to an alternate. Post the number that is stamped off the upper bearing and I'll see if I can find an alternate through Grainger, etc. There are two bearnings - and upper and a lower. I'd hazzard a guess that they would need to be pressed out/pressed in from the looks of it. | ||

Post# 360898 , Reply# 34 7/1/2009 at 12:40 (5,404 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

If it ain't broke...

There was a special tool from Robinair sold to help remove the agitate shaft coupler from the shaft and the agitate arm. If you don't need to remove it for replacement, leave it alone. You really don't want to dig up another problem with an NLA part that doesn't need to be disturbed. The tool was used to hold the body of the coupler and then a wrench to un-thread it from the end of the shaft. If you remove the bearings, you should be able to get them at your local bearing/machine parts supply house - see your yellow pages. The one you pictured looks like a New Departure or similar brand bearing and there are numbers along the sides that will indicate the sizes for replacement. Even if the numbers are not fully legible, take the bearing to the shop with you (as you should in any case) and the salesperson can measure it inside and out and get the replacements for you. It would be shocking if this weren't a standard-sized bearing as custom bearings are very expensive and when profit is the motive in building appliances (all evidence having been to the contrary at GM Frigidaire) standard parts were utilized whenever possible. Best of luck! | ||

Comes to the Rescue!

Comes to the Rescue!