|

Thread Number: 2556

What did I do wrong? |

[Down to Last] |

| Post# 72340 7/5/2005 at 10:52 (6,862 days old) by roto204 (Tucson, AZ) | ||

Hi everyone!! Thank you for all your help to date on my '61 Kenmore. I'm really grateful for all the pointers and advice--it's gotten me through hell and back, and all the way to reassembly. Thank you so much! We have reached yet another impasse, though. It agitates fine, and does its neutral drain, but it will not spin in any cycle. The motor gets unbelievably loud, and the wig-wag pops the cam bar out, and the centershaft pops up a little, but nothing happens and nothing moves basket-wise. Not a twitch. I'm hoping there's an adjustment that will remedy the situation, and preferably one that doesn't involve pulling the tranny again, but since this machine has fought me every step of the way (and yes, I'm getting pics for later), I wouldn't be surprised. (I don't think it wanted to be rescued. I am convinced it wanted to die.) Please let me know what you think--and thank you in advance. :-D --Nate | ||

|

| Post# 72346 , Reply# 1 7/5/2005 at 11:42 (6,862 days old) by fixerman () | ||

|

Did you put the little spring and clip on top of the spin clutch actuator plate. Another member put it underneath and had problems. Does the tub turn freely by hand? Can you turn the belt in the spin direction freely? Check these things get back to us. | ||

| Post# 72629 , Reply# 2 7/6/2005 at 23:59 (6,860 days old) by roto204 (Tucson, AZ) | ||

Minor adjustment?

Hi Fixerman! Further investigation showed that, while the clip and spring were in place, things were out of whack. When, after poring over the situation for quite a while with Roger, and completely redefining our understanding of how the mechanism works, he noted that the threaded nut provides a means of adjusting the clutch plate. Figuring (after thinking a lot more) that it might be too high up the threaded shaft, we tried cranking it down--now it spins marvelously! I do have a further question, though... How do you "fine-tune" the threaded nut? Is there a place at which things are in equilibrium? I'm guessing that if it's too far down, it will try to spin the basket even when the agitator is engaged. Maybe back it off bit by bit until it stops misbehaving? Thank you again for your help! --Nate | ||

| Post# 72631 , Reply# 4 7/7/2005 at 00:22 (6,860 days old) by roto204 (Tucson, AZ) | ||

| ||

| Post# 72964 , Reply# 5 7/10/2005 at 00:44 (6,857 days old) by roto204 (Tucson, AZ) | ||

The plot thickens...

Okay, so after tweaking and adjusting the threaded nut so that the space between clutch plate and pulley is about that of a dime (and doing this after twirling the belt with the power off to reset the cam bars), Ross and I gave the '61 a go. It agitates beautifully and promptly gives up when it goes to spin. With the basket empty, the machine spins with gusto. Put some wet clothes in there (or, God forbid, let the spray rinse wet them down), and the machine starts to spin up slowly, shrugs, and gives up, letting things slow to a standstill. At first, I thought it might be the belt tension, so I tightened up things, and that improved the matter a little, but not enough to keep it going. I tried adjusting the threaded nut some more, but obviously I'm not working magic. I doubt the motor's too tired, but I wonder if all the oil and ick that leaked when the tranny was having fits may have gotten between that clutch plate and pulley, and if it's fighting some oil residue. Perhaps I should take some brake cleaner and fire away? I'm headed off to Pennsylvania for a week, and will resume work on the Kenmore then. Until then, I'm contemplating getting a nice foam-rubber grip sledgehammer at the Home Depot. It's getting frustrating to have a machine that fights you e-v-e-r-y step of the way! Thanks for your help in advance-- Embittered Nate >:-| | ||

| Post# 75358 , Reply# 7 7/27/2005 at 12:07 (6,840 days old) by roto204 (Tucson, AZ) | ||

Revenge of the spin

Okay, so further evaluation of my Kenmore indicates weirdness. On comparing it to Ross' '59 machine, I noticed some interesting things. 1.) The agitator on the '59 spins as fast as the basket does. My agitator just sits there most of the time, but twirls intermittently. 2.) If I wash a light load of materials that don't absorb a lot of water, my '61 can deal with it relatively easily, but a load of towels? You're sunk. 3.) Even the introduction of spray rinse water during the spin slows the machine down--and even when it's completely empty! I hear an intermittent "scrape, scrape, scrape" which, I think, is the little plastic tabby that fits onto a tub bolt beneath the basket. I had to swap washers for a new one (the old ones are crunchy), and I think it raised that tab. But I seriously doubt the tab has the fortitude to slow the basket down if things were working properly. It seems to me that the best solution would be a new spin tube/clutch assembly, new agitator shaft, and new bearings (like Robert recommended in his restoration, but I tried to get around :-). Problem is, I don't think my centerpost shaft will survive having its bearings pulled--there is very little intact metal left holding it together. So, for now, I do sheets in it and just kind of ignore the fact that it can't deal with the heavy stuff. Any thoughts? I'm kind of past the point of hoping that simpler solutions will provide the answer :-) --Nate | ||

Post# 75374 , Reply# 8 7/27/2005 at 13:43 (6,840 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Nate if you manually put the washer into spin, what I mean by manually is turn the belt and hold the spin solenoid plunger up as you do this so the spin cam bar is engaged into spin. Then can you turn the spin basket rather easily (back and forth) or is it still tight like the brake hasn't released? Do you hear anything scraping then. Also when you turn the spin basket with the brake engaged do you still hear the scraping sound? Take care not to pinch your fingers when you manually engage spin and be sure the washer is unplugged. | ||

| Post# 75419 , Reply# 9 7/27/2005 at 19:05 (6,840 days old) by roto204 (Tucson, AZ) | ||

Sunny and 72

Thanks very much, Robert. I'll test things when I get home (next, Nate bounces to San Diego for training--oy! I just wanna stay home and do laundry!!) :-D One thing I did notice last time I spun the belt to adjust the clutch plate was that the belt is quite difficult to turn as-is. I wonder if this is a symptom of the brake, or if I just overtensioned it? I'll do the cam-shift test when I return. Thank you again! --Nate | ||

| Post# 75450 , Reply# 10 7/27/2005 at 23:34 (6,840 days old) by kenmore1978 () | ||

|

spinning You never mentioned if you checked for the little steel ball that goes into the agitator shft. If it's not there, it won't spin properly. | ||

| Post# 75495 , Reply# 11 7/28/2005 at 12:01 (6,839 days old) by roto204 (Tucson, AZ) | ||

| ||

| Post# 75507 , Reply# 12 7/28/2005 at 13:19 (6,839 days old) by rickr (.) | ||

Missing parts Nate?? | ||

| Post# 75527 , Reply# 14 7/28/2005 at 15:06 (6,839 days old) by rickr (.) | ||

Don't get our balls caught in the  | ||

| Post# 76731 , Reply# 15 8/5/2005 at 11:04 (6,831 days old) by roto204 (Tucson, AZ) | ||

LOL

This discussion seems to be deteriorating rapidly :-D...but in a delightful way. I decided to go balls to the...ah, er, well I decided to spin the belt, and it is still tough to turn. The fact that the agitator doesn't rotate freely with the tub when spinning, and tends to sit in place (though obviously disengaged from agitating) is just too weird, especially since Ross' '59 exhibits no such symptoms. I'm thinking that, in a proper scenario, the machine would drop the spin assembly down to contact the clutch plate, and would have (via wig-wag) popped the agitator shaft out of the "engaged" position. So, assuming no oddities, the agitator shaft should be free to spin at the same rate as the spin tube, and everything's hunky-dory. Mine doesn't...and I'm thinking that whatever is causing the agitator shaft to now stay mostly still while the spin tube is spinning (or trying to) must lie somewhere along the spin tube assembly. I can't see how that could be a symptom of a transmission problem, since it agitates, neutral drains, and disengages the agitator appropriately. Would the brake being stuck possibly mess with the agitator shaft, as well as slowing down the spin? I'm thinking about waiting for a good weekend to analyze Ross' machine and compare it with my own; properly adjusting the spin tube/yoke/clutch assembly is just not my forte, especially without a service manual. I can play around all I want, but I don't know what I'm doing, really *sheepish grin*. BTW, what determines if the brake is "stuck on" or not? If it were, how would you resolve that (or is that all contingent upon proper adjustment of the threaded nut that is on the side of the yoke with the spring)? Thank you as always for your guidance (and moral support) :-) --Nate | ||

Post# 76736 , Reply# 16 8/5/2005 at 11:24 (6,831 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

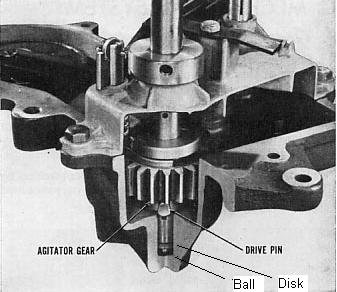

Nate I think there are many things you might need to check. I don't remember if you opened the tranny on this or not. But the discussion of balls is important because two areas that contain them would cause the agitator not to spin with the tub if they are missing. The first one is what Rick mentioned, if the ball and disk (or one or the other) is missing from the pit in the bottom of the transmission where the agitator shaft goes, it will cause problems, like the agitator not spinning with the basket. This happened to me with my Lady Kenmore rebuild when I forgot to put the disk back in.

| ||

Post# 76737 , Reply# 17 8/5/2005 at 11:29 (6,831 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

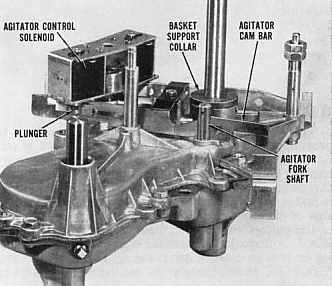

Next on the list is what Fixerman was talking about the Basket Drive Support Collar/Bearing. If this is installed improperly it would definitely cause problems with the agitator not spinning with the basket and possibly with spinning the basket itself. They redesigned this bearing later on to be plastic with a ball to inset into the agitator shaft. They did this because of problems with the agitator not spinning properly with the basket; normally this wouldn't be a problem except it was causing problems with the agitator mounted fabric softener dispensers not working properly.

| ||

| Post# 76738 , Reply# 18 8/5/2005 at 11:29 (6,831 days old) by roto204 (Tucson, AZ) | ||

Check one

The ball and disk in the sump of the transmission are definitely in place. I was forewarned about those :-D (and sure enough, they went "plink!" and fell out when I tore it apart). You said two areas...are there more lurking out there? I would swear my machine did not have a ball and T bearing--just the brass fitting that went over the agitator shaft and inserted in the spin tube... | ||

| Post# 76739 , Reply# 19 8/5/2005 at 11:31 (6,831 days old) by roto204 (Tucson, AZ) | ||

I take it... | ||

Post# 76740 , Reply# 20 8/5/2005 at 11:31 (6,831 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Nate another thing you can do is temporarily adjust the brake adjustment nut all the way down as a test. With the brake out of the picture you will be able to test spin with a full load of wet clothes and see if it still has trouble. You should also check to make sure there is no grease on the clutch pads. | ||

| Post# 76741 , Reply# 21 8/5/2005 at 11:33 (6,831 days old) by roto204 (Tucson, AZ) | ||

Adjust nut down...

Good to know! I'll do that. I would bet there could be grease on the clutch pads, because of the unique way the tranny leaked before I replaced the spring and seal around the agitator shaft. Is there a good way to degrease those? I have various things--brake cleaner and the like. Anything you would recommend? Thank you VERY much for all your help--your advice and the pictures are really helping. --Nate | ||

Post# 76742 , Reply# 22 8/5/2005 at 11:39 (6,831 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Well if I'm remembering correctly the T shaped bearing should be installed upside down so the column of the T is sticking up into center hole of the spin pulley itself. I will see if I have a picture of this over the weekend. My favorite degreaser is "Goof-Off", but any good degreaser will work that you can get at the hardware store. | ||

| Post# 76744 , Reply# 23 8/5/2005 at 11:43 (6,831 days old) by roto204 (Tucson, AZ) | ||

Thanks for the degreaser info. I'll look into that. Darn! I was hoping my eyes didn't deceive me and that I had found a simple fix...but I think you're right; the T part goes flat-part-down and the collar support slides down over it...and that's how it is on mine now. How did the collar supports cause problems that were later rectified with the plastic sleeve/little metal ball design? Is it a wear-out thing? Maybe I need to look for a replacement... Thank you again! --Nate | ||

Post# 76747 , Reply# 24 8/5/2005 at 11:55 (6,831 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

I'm not sure exactly what the difference between the metal and plastic bearing is, but the ball provides a more solid contact between the bearing and the agitator shaft. The tight belt is also troubling, when the basket slows down to a crawl does the belt slow down or is it turning at full speed and just slipping? Is the basket drive pulley turning at a different speed than the clutch plate above it? Can you get a bright light in there and see exactly what is happening between the clutch and drive pulley? Another thing I thought of is there is a chance that the spin shaft is misaligned in the center post bearing. To fix this you need to loosen the three tranny mounting bolts a bit so the tranny can drop down about 1/2". Then stand the machine up and hold the agitator shaft and give it a good shake and rock. Then with the machine still standing tighten the bolts back up. | ||

| Post# 76750 , Reply# 25 8/5/2005 at 12:17 (6,831 days old) by roto204 (Tucson, AZ) | ||

| ||

| Post# 78183 , Reply# 27 8/14/2005 at 00:56 (6,822 days old) by roto204 (Tucson, AZ) | ||

Resolving debates

Thanks Jaune, I'll be sure to exercise caution when retightening--that would be great to do all the work and put it right back to crooked. Robert, I notice that the picture you posted in #76737 shows the basket support collar...does that go underneath the T bearing on the agitator shaft, or does the T bearing go first, and then the collar slide down on top of it? Roger and I have researched this in his manuals, but no one seems to have a good picture. This is one of the things I want to check when I take it apart to see if I didn't make a reassembly error. Thanks very much! :-) --Nate | ||

| Post# 78191 , Reply# 29 8/14/2005 at 02:55 (6,822 days old) by fixerman () | ||

|

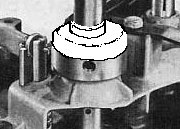

Here is a rather poor illustration of how the bearing goes on. Hope it is understandable.

| ||

Post# 78199 , Reply# 30 8/14/2005 at 09:25 (6,822 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Comes to the Rescue!

Comes to the Rescue!