|

Thread Number: 28069

Maytag A606 drive pulley install and stop lug adjustment |

[Down to Last] |

|

Post# 429668 , Reply# 1 4/18/2010 at 15:59 (5,120 days old) by goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

| ||

| Post# 429677 , Reply# 2 4/18/2010 at 17:14 (5,120 days old) by qsd-dan (West) | ||

|

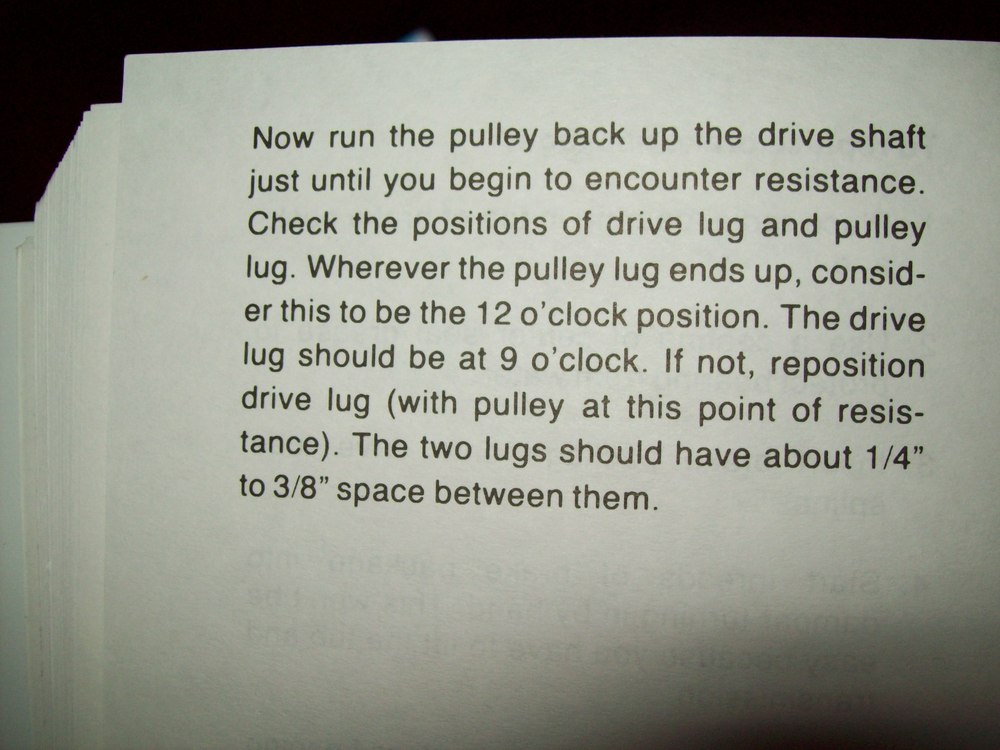

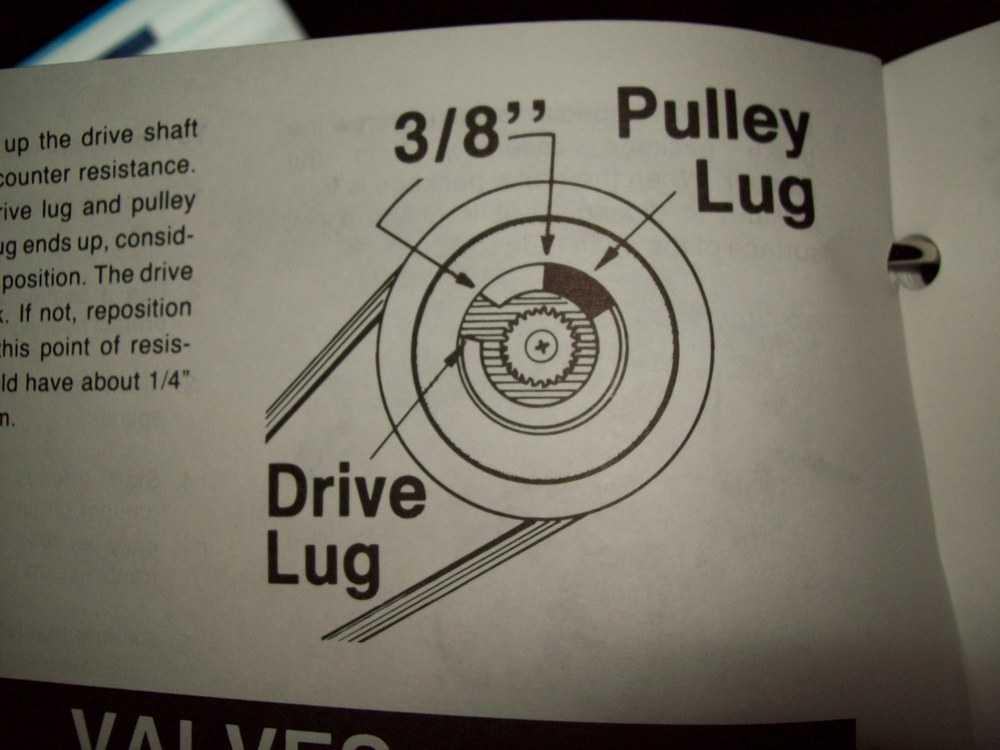

There's actually a long and short version, so I'll just stick with the short version.

Run the pulley up the shaft until it stops. Take the stop lug, with the flat side pointing down (towards the pulley), and install it to the left of the pulley stop (stop lug should be in the 9 o'clock position in reference to 12 o'clock position of the pulley lug). The goal is to position the stop lug until you get 1/4-3/8 play between the stop lug and pulley. I shoot for 1/4 (.25) of an inch, otherwise you may get a knocking sound during agitation. Don't go any tighter then .25, or it'll be engaging the brake and the motor has to overcome that during agitation. | ||

| Post# 429704 , Reply# 3 4/18/2010 at 19:01 (5,120 days old) by oldschool (SE PA. USA) | ||

|

Dan, would running the drive pulley up until it contacted the bottom of the brake assembly be acceptable? That's where mine goes to and stops. In my case the drive pulley isn't stopped by running out of threads on the drive shaft. | ||

Post# 429706 , Reply# 4 4/18/2010 at 19:24 (5,120 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

| Post# 429710 , Reply# 6 4/18/2010 at 19:34 (5,120 days old) by qsd-dan (West) | ||

|

Dan, would running the drive pulley up until it contacted the bottom of the brake assembly be acceptable?

Yeah, that works. You just don't want to run the pulley up beyond that point, or you'll be disengaging the brake and turning the transmission/basket assembly. All you're trying to do is take up the play between the pulley and brake so you can position the stop lug in order to accomplish 1/4-3/8 inch play between the stop lug and pulley lug when gently rotated in the clockwise/counter-clockwise fashion. Taking up too much play will keep the brake engaged. Too much play, and you'll get a knocking sound during agitation. | ||

| Post# 429711 , Reply# 7 4/18/2010 at 19:39 (5,120 days old) by qsd-dan (West) | ||

|

| ||

| Post# 429718 , Reply# 10 4/18/2010 at 20:13 (5,120 days old) by dnastrau (Lords Valley, PA) | ||

|

Page 2 Page 2

| ||

| Post# 429719 , Reply# 11 4/18/2010 at 20:14 (5,120 days old) by dnastrau (Lords Valley, PA) | ||

|

Page 2 cont'd ...more

| ||

Post# 429763 , Reply# 12 4/18/2010 at 23:16 (5,120 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

or it's time to buy another. | ||

| Post# 429859 , Reply# 13 4/19/2010 at 09:45 (5,120 days old) by dnastrau (Lords Valley, PA) | ||

|

Crosses to 200835... ...and looks like this example. CLICK HERE TO GO TO dnastrau's LINK | ||

| Post# 430003 , Reply# 15 4/19/2010 at 19:04 (5,119 days old) by dnastrau (Lords Valley, PA) | ||

|

The bearing on my '61... ...was open on one side so I was able to jamb some more new grease in there and work it in. Mine was in great shape too. | ||

| Post# 430004 , Reply# 16 4/19/2010 at 19:08 (5,119 days old) by qsd-dan (West) | ||

|

| ||

| Post# 433262 , Reply# 18 5/5/2010 at 09:03 (5,104 days old) by oldschool (SE PA. USA) | ||

|

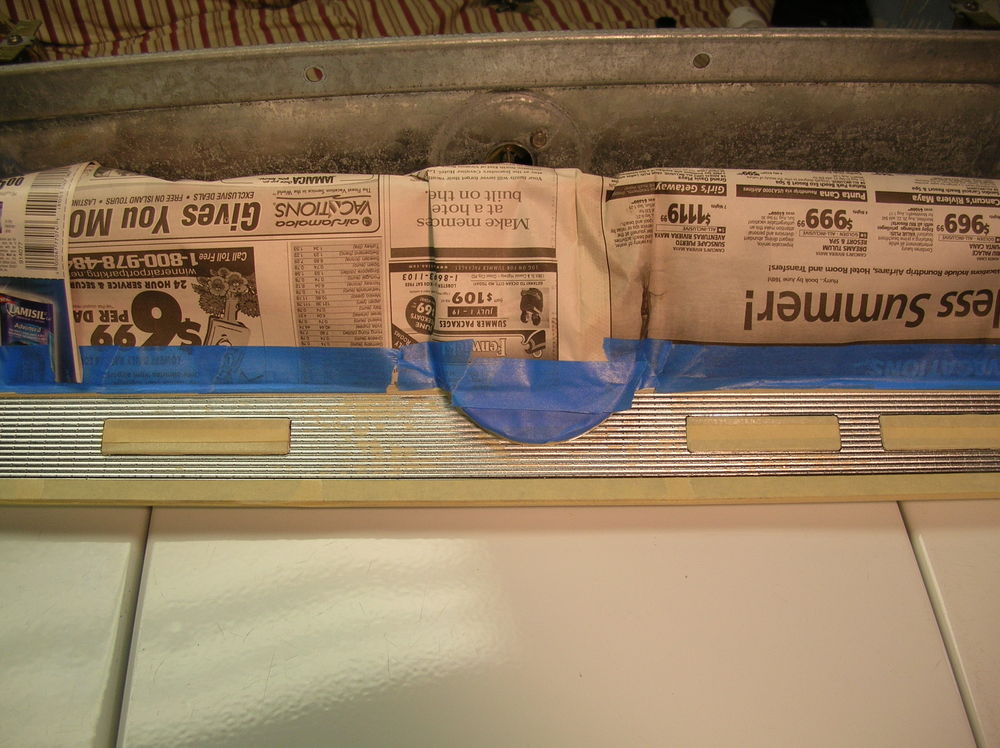

Masked off and ready for a facelift Found some paint on the shelf that would do the trick.

| ||

| Post# 433264 , Reply# 19 5/5/2010 at 09:11 (5,104 days old) by oldschool (SE PA. USA) | ||

|

Moving along with paint Step one..............the white

| ||

| Post# 433266 , Reply# 20 5/5/2010 at 09:13 (5,104 days old) by oldschool (SE PA. USA) | ||

|

Paint Now for the gold

| ||

Post# 433280 , Reply# 22 5/5/2010 at 10:13 (5,104 days old) by mistereric  (New Jersey (Taylor Ham)) (New Jersey (Taylor Ham)) |

||

|

| ||

| Post# 433318 , Reply# 23 5/5/2010 at 12:40 (5,104 days old) by dnastrau (Lords Valley, PA) | ||

|

WOW! Nice Job! That console looks NEW! | ||

| Post# 433319 , Reply# 24 5/5/2010 at 12:45 (5,104 days old) by qsd-dan (West) | ||

|

Damn! She looks GREAT! | ||

| Post# 433351 , Reply# 25 5/5/2010 at 15:29 (5,103 days old) by dnastrau (Lords Valley, PA) | ||

|

Off topic: brake tool Hi Oldschool: Were you the member who had posted that they found a Maytag brake tool for $20? If so, did they have more? Thanks, Andrew S. | ||

| Post# 433391 , Reply# 28 5/5/2010 at 21:26 (5,103 days old) by dnastrau (Lords Valley, PA) | ||

|

Thanks Oldschool... ...as I think Scrubflex wanted to buy a brake tool. That is cheap! Your brake removal method looks very good! Your restoration work looks great too! | ||

| Post# 433415 , Reply# 29 5/5/2010 at 23:21 (5,103 days old) by dnastrau (Lords Valley, PA) | ||

|

One more question That base and springs look great - did you sand/media blast the rust first or did you use something else? | ||

| Post# 433507 , Reply# 30 5/6/2010 at 13:19 (5,103 days old) by surgilator_68 (Maryland) | ||

WOW | ||

Post# 433616 , Reply# 31 5/7/2010 at 02:32 (5,102 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Restoration | ||

Comes to the Rescue!

Comes to the Rescue!