|

Thread Number: 30564

Can a KitchenAid (KDI16) be saved? Anyone? |

[Down to Last] |

Post# 462258 9/8/2010 at 21:08 (4,971 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Today I received a call from my sister who has a KDI16 KitchenAid dishwasher from 1968 (we even have the manuals, if anyone is interested in them too). Even though it is still washing for 42 years the machine now has a leak. I went over and looked over all the tubing and it is intact. I was actually hoping it was just a hose but no, the leak seems to be from a pump seal? It is leaking a spray from the motor fan and water coming from inbetween the motor and the tub. I don't know how to repair this problem. So I ask the following:

1. Would anyone like this dishwasher? I might be able to keep it some time. If you do, its free! 2. Is it possible this dishwasher can still be repaired? I know if she calls Sears they will tell her to replace it. Would an independent repair person know how? How do you all find independent repairmen (besides the Yellow Pages) Are there still parts out there? 3. I might give it to a Habitat for Humanity store, but again, would they want an appliance that leaks? If anyone here wants parts, I might be able to part it out too. 4. She wants to shop for a new dishwasher this weekend. I told her only Miele is equal to her KA but she wants to get a new KitchenAid. What are the current models like? I know it is not as heavy duty as this one. 5. I talked to her about locating the KA in the basement where a leak won't matter and using it for extra dishes but she does not like the idea. If that were possible, would it be safe to run with a leak, until it finally dies? Also, she may replace a GE over and under range from 1979 because it does not self clean anymore. Anyone interested? | ||

|

| Post# 462271 , Reply# 1 9/8/2010 at 21:42 (4,971 days old) by qsd-dan (West) | ||

|

Is it possible this dishwasher can still be repaired?

Yep! I'm willing to bet the leak is from the motor shaft seal. It's common for machines that have seen hard use, or have sat unused for long periods of time (rubber seals dry out and crack). You have 2 choices for the seal and impeller kit. A genuine Hobart kit (I believe the 00-435102 seal and impeller kit works for 16 series machine....stevet will slap me if I'm wrong) or a Whirlpool kit. The Hobart kit is the better of the 2 kits, but it doesn't come with installation instructions. The Whirlpool seal kit comes with instructions, but RCD had trouble with the new WP shaft seal, sealing, when he installed it by following the WP instructions for my KDS-19. He tore back into the motor and re-installed the kit in the way that made logical sense to him (gotta love being experienced) and it has been leak free ever since. If that were possible, would it be safe to run with a leak, until it finally dies? It should be ok to run the machine with a leak, but it will QUICKLY tear up the ball bearings in the motor. I'd let it die with a little more dignity, myself (possibly part it out?). But that's just me. | ||

| Post# 462282 , Reply# 2 9/8/2010 at 22:15 (4,971 days old) by rollermatic (cincinnati) | ||

|

i know parts are still available at hobart

because i recently bought a few pump seals from the local cinti office. they will fit the 15-17 pumps because i have used them on all 3 models.

i would love to have it but i have (3) 16 models already and no more room at all!!! hopefully someone will save it! i do have the instruction sheet for installing that seal if anyone is ever interested, just e mail me. | ||

Post# 462302 , Reply# 3 9/8/2010 at 23:20 (4,971 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

| ||

Post# 462311 , Reply# 4 9/8/2010 at 23:58 (4,971 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

| ||

| Post# 462316 , Reply# 5 9/9/2010 at 00:24 (4,971 days old) by qsd-dan (West) | ||

|

| ||

Post# 462342 , Reply# 6 9/9/2010 at 07:42 (4,971 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

KDI-16 SEAL

Call Larry @ Modern Parts in Ohio 216-661-6966. Any Independent repair thats been around for more than 20 years will know how to work on this, but be sure to ask them and tell tell them you have a KD16 with a shaft seal leak and see if they are interested in working on it. On a new machine a WP OR KA is far better than a Meile but get one with a disposer rather than a filter.

| ||

Post# 462466 , Reply# 8 9/9/2010 at 18:06 (4,970 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Thanks everyone so far...

We are not going to run it anymore and try to save the motor. Steve T I may be in touch with you. My brother also says we can store the KitchenAid at his house so I will do all I can to save it. Now just have to tell my brother in law not to have sears come and take it away. Oh, but there are 3 layers of flooring making about an inch difference, making it almost impossible to get the old machine out (or a new one in). Oh, well, she wants new flooring anyway. I am doing everything I can to keep it out of the landfill.

My brother Sam says throwing this appliance away is like throwing away a Gibson Les Paul electric guitar. Agree? | ||

Post# 462473 , Reply# 9 9/9/2010 at 18:52 (4,970 days old) by rp2813  (Sannazay) (Sannazay) |

||

| ||

| Post# 462613 , Reply# 11 9/10/2010 at 16:27 (4,969 days old) by rollermatic (cincinnati) | ||

|

in see that the seal kit | ||

Post# 462625 , Reply# 12 9/10/2010 at 17:58 (4,969 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Thanks Rollermatic, I will go and take a look

Stevet: I think it is customary for the appliances like a built in dishwasher to be on the plywood or wood flooring with 1 layer of subflooring and then flooring. This way the flooring can be replaced without having to disturb the cabinets. The screw legs have enough clearance for 1 layer but not enough for the 3 layers they have. Turns out my brother in law thought it was cheaper to just have flooring laid over the existing flooring, thinking nothing would ever happen to the dishwasher (it turns out no one in that side of the family is a "plan ahead" person). The only way I can think of to get the appliance out is to lift up the countertop and since it had to custom made to their layout, it was expensive I am don't really want to take the risk of cracking it. We might get the installer to take it out, put a new one in, and then save the KD 16. Thanks for all the help I will let you know and see if I can get some pictures.

| ||

Post# 462644 , Reply# 13 9/10/2010 at 19:34 (4,969 days old) by rp2813  (Sannazay) (Sannazay) |

||

I have just the opposite issue at my house. My dad built new cabinets and counters about an inch higher than is standard. He did that in order to create a garage for a 1970-ish Wards Signature (aka Flimsidaire) BOL portable top-loading dishwasher adjacent to the sink. When that machine was replaced in the mid 70's by a built-in D&M Kenmore, and again later with a '90 Maytag JetClean, 2x4 skids were required so that there wouldn't be a big gap between the the machine and the counter top. Skids will be required until that whole section gets blown up in an eventual remodel. Currently my always entertaining 1985 Thermador THD3600 steam model is resting on them.

For the first half of the 1970's, we had a battle going between two Wards Signature machines. With the kitchen on one side of the family room and laundry area on the other, watching TV was an exercise in futility with either the clothes washer or dishwasher doing its best to drown out the TV audio. As it happened, both machines got replaced by Kenmores, which I facilitated, and even with both of them running simultaneously, TV viewing was no longer disrupted. So much more civilized than the Wards junk. | ||

Post# 463095 , Reply# 16 9/12/2010 at 18:54 (4,967 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

So far it looks like I will be getting the 16 at the house where I live. My BIL has a Honda element and he has agreed to drive the dishwasher there if I help him lift it in and out. He wants it out by this coming Wednesday. He and my sister just bought a new range (Whirlpool) and dishwasher (Maytag, is it same as WP now?) because the range and DW are next to each other and they have been told that if the range comes out the DW can too. Someone in the neighborhood wants the range and they are getting it. I took pictures and will soon post them and let you all know of this "soap opera"

Steve, Sam found the seal from an appliance web site, it is just that I am not familiar with a "Hobart office' but I will look into it. Do I just tell them the number and pay and I can get the parts? It is taking a lot of family negotiation to save the appliances we like doesn't it? | ||

| Post# 463099 , Reply# 17 9/12/2010 at 19:26 (4,967 days old) by rollermatic (cincinnati) | ||

|

good luck with that kd-16

you know the 15-17 series are my favorite kitchenaids. i have a couple 15's 3-16 models and a bunch of 17's.

that seal is pretty easy to replace. you can still get a motor too if you ever need it, i just bought one last year from a local appliance repair place here in cincinnati. put it on one of my 17's. e bay has the top of the pump housing (the wash arm support) for about 15 bucks apeice. i have bought about 4 of these from this guy. i saw them the other day still listed. might grab a couple more. with a little care and tune up you can keep that kitchenaid running for another 20 years! if you have any questions just e mail me! good luck and enjoy it! pete | ||

Post# 463115 , Reply# 19 9/12/2010 at 20:11 (4,967 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Steve thanks for the Hobart web site!

I might even apply for a job with them! Becky, my sister, found out where the office in Greensburg is so we will probably go there.

Rollermatic, what do you do with all your KitchenAids? Do people say you have too many dishwashers? BTW, my BIL worries that Becky is getting more handy and is starting to get a "Tool belt". | ||

Post# 463142 , Reply# 20 9/12/2010 at 23:31 (4,967 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

What's a "BIL"? | ||

Post# 463147 , Reply# 21 9/12/2010 at 23:45 (4,967 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Brother In Law. He is an athletic Italian who I am not supposed to mention on the internet, especially on a forum like this one but he wants the 16 out of the house as soon as possible. Oh, and he doesn't see why anyone wants a 42 year old dishwasher. BTW, they paid 800 for a Maytag dishwasher - think it will last?

| ||

| Post# 463273 , Reply# 23 9/13/2010 at 20:35 (4,966 days old) by rollermatic (cincinnati) | ||

|

do people say i have too many kitchenaids?

i don't tell everyone that i collect appliances, most people would not "get it" so i just skip it.

my friends who i do tell think i am nuts ofcourse! but that's ok. i'm not one to be easily swayed by anyone elses opinion, especially when it comes to any of my hobbies!. the main question they ask is where i keep them all. i tell them i have a room in my house i keep them all in which is a partial truth. i also have 7 of the kitchenaids in the kitchen area and 8 washers in my living room area. i enjoy being around them! plus i am still working on the rollermatics, 3 are done, 3 more to restore. i probably do have too many dishwashers but when i started here 2 years ago my goal was to collect at least one of every model kitchenaid made up thru the 23 series. at this point i still need a 10, 11, 20, and 22. plus i really love the old d&m machines, g.e. mobile maids, and just about any other brand made in the 50's or 60's. so i spent most of 2008 and all of 2009 scouring e bay and craigs list and grabbing them all up like a hungry kid! but if i never get those remaining kitchenaids it's ok, i've had my fun! i'm not actively looking for them anymore. once i discovered how much i love the frigidaire rollermatics, and love working on them my dishwasher cravings really tapered off! if they come my way fine, if not, oh well! it's a great hobby but it doesn't matter if we have 2 or 42, it's the enjoyment that these old vintage classic machines bring to us that is important i think! at first i thought the more i got the better collector i was, now looking at it i realize it's not a race! i'm not in competition with anyone! and i'm going to thin out my stash a bit here in the next year. thanks for asking! good luck with your kitchenaid! | ||

Post# 463279 , Reply# 24 9/13/2010 at 21:21 (4,966 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Rollermatic,

Have any of your machines been heavily used? I was having second thoughts because I notice Robert gets his dishwashers from little old ladies at estate sales. Aunt Mac had this dishwasher for 20 years and she was only one person but my sister had it the next 22 and they used it hard, sometimes twice a day. I'm worried that the other parts are all worn out. The tub and racks, however, do not look worn at all. They look a lot better than the Maytag we have that only 6 years old. Wouldn't it be something if the new Maytag they spent 800 dollars on had an early demise and they wanted the KA 16 back? You think that could happen? By the way, what number are they up to now? Would a current KitchenAid be like KD127? | ||

Post# 463349 , Reply# 25 9/14/2010 at 09:39 (4,966 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Sorry, the news may not be good...

It turns out there may be no way to get this machine to my house in time and I also found out that there is a burning smell from the blower and the detergent dispenser never worked. My sister really used the dishwasher heavily and they want it out tomorrow. My BIL and my brother are both coming down with something and they cannot help me haul it.

So I think I am going to raid it for parts. I know I can get the racks, strainer, upper pump, buttons, light, timer, knob, and maybe the latch assembly? Anybody want these? Is there anything else I should try to get? Since you have all been of help, I'm willing to give the parts away for shipping. Thank you all. Bob. P.S. Pictures are coming as soon as a get a cable for my camera. | ||

| Post# 463409 , Reply# 26 9/14/2010 at 14:42 (4,965 days old) by rollermatic (cincinnati) | ||

|

gee that's too bad

but maybe another kitchenaid will come along you can get as a whole machine. i personally don't need any parts, i have tons now, but i'm sure someone here will want something. that timer, motor, and pump assembly would be the choice selection in my book!

you ask about my machines, most are in very good shape, the little old lady type as you say. but a couple of the 17 models are rough, racks not that great and some sump rust. but all are in operating condition. if the sump is rusty i give it about 3 coats of rusty metal primer and then 3 coats of rustoleum before i put the pump and motor back in. as far as model numbers go, i stopped collecting at the 23 series and even that one is not interesting to me in the least. i think the 23 was the last model before whirlpool completely took over, i may be wrong here. the kitchenaid historians on the site will probably know that one! i don't have much interest in them after they changed the pump and went with a reversing motor on the 21 series. and even the 18-20 are not one's i really care for. i like the old one's i remember as a kid, one spray arm at the bottom! 15-17 are my favs! | ||

Post# 463468 , Reply# 27 9/14/2010 at 19:50 (4,965 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

News Flash!

Just as I was raiding the 16 for parts, somehow I figured out how to get it out of there and my BIL came with the Element and he said we might as well get it to your house. So now I have it after all!

I find it actually is quite dirty and it may be pretty bad off but I think if I fix the leak it mostly is just a lot of cleaning. I could not get the timer off, so good thing he came. But now that I started taking it apart, now I have to screw it all together again! Fortunately, I have the screws and it seems that Hobart used actual screws instead of clips and I really didn't notice much corrosion. Actually its better that he came today. I had a chance to clean the dishwasher space. It was disgusting, and I think the installers would have just installed the new one without cleaning it up. | ||

Post# 463490 , Reply# 29 9/14/2010 at 21:44 (4,965 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Well, I am going to work on putting the parts back tomorrow before I forget.

To be truthful, KA was never as loud, even toward the end, as the dying Maytag we have now and the cheap Hotpoint that roars I had in my apartment. You know when its running, but it you could have a conversation. There is some dense fiber insulation on there already. I also wonder if before I use something like CLR on the tub inside I should probably order the kit and repair the leak first, shouldn't I? Have you come across many Hobart KitchenAids that were "too far gone"? It's possible this could be one of them. Then again, just about any other machine (Kenmore, GE) would probably be shot a long time ago. | ||

| Post# 463543 , Reply# 30 9/15/2010 at 08:35 (4,965 days old) by rollermatic (cincinnati) | ||

|

too far gone??

i doubt it. i have 23 kitchenaids at this present time and out of all of them only 2 have even needed a new pump seal when i got them. one was an 18 model, one a 19. all the early ones, the 12, 14, 15-17 series didn't even leak and still don't.

sump rust can be a problem and i have had a couple that were starting to get to be a problem but again i cleaned it all out and coated them with rustoleum rusty metal primer followed by several coats of rustoleum paint and they are now as good as new. without looking at it i cannot say for sure but i would guess your 16 model is in fine shape overall. like steve said don't use it till you replace that seal or you will ruin the motor most probably. but even then motors are out there, used and new. pump gaskets are still available too, i bought 6 from larry in parma last year. he's at modern parts house. he has those seals as well. | ||

Post# 463577 , Reply# 31 9/15/2010 at 13:07 (4,964 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

I promise, pictures are coming!

The motor seems to be fine. Should it be oiled somewhere?

I felt better when I started to clean some of the parts up. There seems to not be any sump rust but a lot of mineral build up. Sam recommended CLR to remove it. There was also a LOT of crap in there, and that might have been why she was complaining of burning odors. The strainer at the bottom and the door handle were particularly cruddy. What I ended up doing was filling a pot up with a solution of new Cascade and water and heating it up on the stove. The chrome is so bright it almost blinded me! Be careful when using new Cascade to clean things like that, it dried and caused almost chemical burns to my hands. It must have more lye than the phosphated detergents. Right now I am cleaning up the outside and when I get the seal from Hobart I thought I would work on the crud inside but I don't want to do that until sealed. The wheels on the racks are shot but I think I can steal wheels when our Maytag dies. Even though I pulled some wires I was able to put them back. It turns out Hobart neatly labels all the wires and terminals, I guess to make it easier to assemble? With some other brands, it was easy to get lost. | ||

Post# 463672 , Reply# 33 9/16/2010 at 01:35 (4,964 days old) by rp2813  (Sannazay) (Sannazay) |

||

| ||

Post# 463734 , Reply# 35 9/16/2010 at 12:45 (4,964 days old) by rp2813  (Sannazay) (Sannazay) |

||

| ||

Post# 464517 , Reply# 37 9/21/2010 at 00:12 (4,959 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Now the first pictures! | ||

Post# 464518 , Reply# 38 9/21/2010 at 00:15 (4,959 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Here's another, with their boxer dog. | ||

Post# 464519 , Reply# 39 9/21/2010 at 00:16 (4,959 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

The before "money shot" | ||

Post# 464521 , Reply# 40 9/21/2010 at 00:28 (4,959 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Will I took all the chrome parts off,...

And soaked them in a solution of Cascade and cooked it on the range; there was LOTS of crud. Used a lot of Windex and Pledge on the console. It is actually chrome underneath the brown paint! Now everything is so shiny that, even though this photo was taken in the evening it's almost blinding!

I noticed very little rust on the internal this machine and most of it was at the bottom toward the floor. The custom panel kit was a different matter - the frame fell apart and it is rusty and the wood is starting to rot so looks like I will paint the panels. More about them later. But it turns out there was crud everywhere. Maybe all it needed was a good clean up?

| ||

Post# 464522 , Reply# 41 9/21/2010 at 00:36 (4,959 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

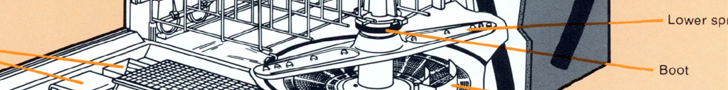

Now for the parts layout.....

I unscrewed all I could to access the shaft seal and, uh, oh, oh, the motor fell out. Steve, now I know what you mean about the metal fan on top, but I think the fan kind of saved the motor from the leak. The shaft turns freely but there is a little rust on it.

Now there appears to be a pump housing, a rubber impeller, and the a lower housing. The shaft seal which I ordered from the Pittsburgh Hobart office I believe is the smaller round piece right below here. Sam is soaking all this in like a CLR solution he used at his work.

| ||

Post# 464524 , Reply# 42 9/21/2010 at 00:52 (4,959 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Parts are on order.

Reason I say parts is that "Barbara" the nice Hobart lady asked me how many I needed so I ordered 2, maybe to sell to one of us or on ebay. I guess some businesses have multiple machines? Anyway, not wanting to confuse anyone there about a KA machine I made up a story that I was a manager at a Cinnabon I used to work at that had a Hobart machine and I wsa trying to impress my boss because I didn't know if they would sell to a "regular consumer". I guess that when you are preservationist like we are, it helps to have a vivid imagination. Barbara asked me where this store was because I guess Hobart is fussy about which office services which area. Anyway, I can pick them up at the counter when they come in and if anyone here needs one, you can have it for my cost + postage.

Oh, and I am going to give them my resume too. | ||

Post# 464731 , Reply# 44 9/21/2010 at 22:44 (4,958 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

| ||

| Post# 464889 , Reply# 46 9/22/2010 at 18:15 (4,957 days old) by rollermatic (cincinnati) | ||

|

since the whole pump assembly

is out, how does the tub sump area look? any rust around the holes that the lower pump bolts thru?

some of mine have been fine, others have needed work. a couple of mine were badly rusted around these holes. on the one's that needed it i cleaned it up getting rid of the rust and painted the outer surafce of the tub sump area with rustoleum rusty metal primer, followed by rustoleum spray paint, about 3 coats each. hopefully yours is fine. if you need a new gasket for the lower pump larry in parma had them last year, i bought about half dozen and he had more. i think you can get them at parts select or repair clinic .com on the web too. hobart has them too i think, not sure. i seem to remember them there last year when i bought some stuff from hobart cinti. keep at it! you will feel so good when it is all restored and running! | ||

| Post# 464890 , Reply# 47 9/22/2010 at 18:22 (4,957 days old) by stevet (West Melbourne, FL) | ||

|

For the record... The gaskets for the 15's would be available in limited numbers but they never carried the 16/17 gaskets as they were different from the commercial line. The commercial WM series did not have the constant rinse and therefore only had the circular gaskets not the one with the cut out for the upper spray supply. | ||

Post# 464894 , Reply# 48 9/22/2010 at 18:49 (4,957 days old) by rp2813  (Sannazay) (Sannazay) |

||

Steve, thanks for the advice above about my KDS-20.

I think the machine will end up in the hands of Nate or Dan, so they can opt to do the bearing work if they choose. I'm going to wait for a KDS-21 to come along, but will remain custodian of the KDS-20 until either party decides to take it off my hands. Ralph | ||

Post# 466913 , Reply# 50 10/2/2010 at 13:34 (4,947 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Well I have kept at it, I have questions, and pictures are c

I did pick up the seal assembly from Hobart and started to install it. Pictures are coming, but try to use your imagination for now as I have a question:

There are 2 seals in the kit, a drain impeller, and an O ring that goes on top of the rubber impeller. The thinner of the two seals appears to go in the bottom of the pump housing and the larger appears to fit at the bottom of the impeller. The 2 metal surfaces face and rub each other, creating the seal. Is this correct? Reason I ask is that I notice the rubber impeller, it will be very difficult to get it onto the shaft of the motor, it only just goes on the top. Is it supposed to be this stubborn? I am afraid if I pounded it on there, if I did not do the seals right, I will never get this off. Also, the old impeller simply lifted off but I think it was just so worn I don't know how it ever turned. I did use the dishwashing liquid as a lube (Dawn with Olay beauty!). After this it is just a matter of screwing everything back together. Oh and a tip: If you want the black plastic parts to look new, spray them with a lot of Pledge. My brother told me about Pledge because they used it for everything when he was in the Air Force. I did not know Pledge was used so much in the military. Anyone here in the service and use Pledge? | ||

| Post# 466925 , Reply# 51 10/2/2010 at 15:27 (4,947 days old) by stevet (West Melbourne, FL) | ||

|

Check your email Bob, I just sent you some instructions and pictures which should help you install the seal kit. Let me know if you need anything else. | ||

Post# 466940 , Reply# 52 10/2/2010 at 17:02 (4,947 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Thanks, steve

It looks like I may have it in right with the 2 metal surfaces rubbing. Should the impeller be so stubborn and tight against the shaft? I am reluctant to pound on it, knowing I may never get it off again. But I'll try the soap again.

Once I finish this critical part I can get the motor back in the tub - As you probably know, the motor is Very Heavy. And get the machine - Who I call Kenni - into the game room where I plan to set up a counter and sink for when we have functions. I can assemble the rest then. | ||

Post# 467037 , Reply# 54 10/3/2010 at 09:35 (4,947 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Stevet | ||

| Post# 467070 , Reply# 55 10/3/2010 at 11:49 (4,947 days old) by stevet (West Melbourne, FL) | ||

|

On the way! Jon, I am sending you what I sent to Bob yesterday. If you need anything else, let me know Steve | ||

Post# 468353 , Reply# 56 10/10/2010 at 13:37 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

But there's more! | ||

Post# 468354 , Reply# 57 10/10/2010 at 13:41 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Here's the parts as I understand them. I used dishwashing soap to lubricate - Actually Dawn with Olay Beauty, if anything would lubricate well, that would.

Actually, there is a little confusion here. The metal ring on the left actually goes into the "turbine" toward the right. The fact they put it in rubber confused me for a while but that must have been only to protect it. The O ring later goes on top of the turbine.

| ||

Post# 468355 , Reply# 58 10/10/2010 at 13:43 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

It lets you know it is made in the USA! | ||

Post# 468356 , Reply# 59 10/10/2010 at 13:44 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

|

This post has been removed by the member who posted it. | ||

Post# 468359 , Reply# 60 10/10/2010 at 13:47 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

| ||

Post# 468363 , Reply# 61 10/10/2010 at 13:50 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

I figured it out! | ||

Post# 468364 , Reply# 62 10/10/2010 at 13:51 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

| ||

Post# 468365 , Reply# 63 10/10/2010 at 13:53 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

| ||

Post# 468366 , Reply# 64 10/10/2010 at 13:57 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

| ||

Post# 468367 , Reply# 65 10/10/2010 at 14:00 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Its a bit hard to see with all the black.... | ||

Post# 468436 , Reply# 67 10/10/2010 at 22:09 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Sorry, steve, but its a bit late...

But there is good news: The seal works and there is nary a leak!

Now that I have the impeller on, there is no way I can get it off (what do you repair people do?). I used a tip I think I saw on Deadliest Catch: On on of their ships, they needed a part for a generator that they did not have and it was a long way to shore to get a new one. So the engineer machined a metal part on his lathe but it had to fit tightly to another machine. So he put this part in the kitchen oven and heated it up, expanding the part to fit on the shaft. What I did here was place the shaft of the motor upside down on a glass of ice water (I kept the motor itself dry). Then I placed the impeller in a cup of tea. It slipped on with some resistance just right. In fact, I don't see a leak at all, yay! But now bad news: I can't get the motor to go at all. It is not getting any electricity at all. This problem started when my brother Sam insisted that he unscrew the heating element and soak it in his solution from work. Now the element looks narrower and I wonder if that has something to do with no power. When you plug it in and turn it on the timer works but the light and nothing else does. We tried bypassing the element (turning it into an energy saver) and still no luck so we put the connection back on. Sam says he is determined to find this loose connection. After all, he has a Bachelor of Science in Electrical Engineering BSEE! Also, we may be getting another KA. Sam has a girlfriend who wants a whole new kitchen and wants her 90s KA gone because "it is not sleek". Their relationship is on and off though, so we may or may not get it, because he makes him do a lot of work at her house, making him her slave. I know, this thread is turning into a soap opera, isn't it? Oh, and if all is lost (I don't think it is)I will give away parts. Steve, I wanted to thank you for all your help, its been quite a learning experience. Bob. | ||

Post# 468442 , Reply# 68 10/10/2010 at 22:26 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Some of you asked about rust and I am glad to tell you - even after 42 years there hardly is any! Mostly just a lot of crud.

Where the door and the tub meet, in an area not visible in the photo is a slime monster I have to clean up. I think it is caused by a lot of lasagna and my BIL likes to use only half an Electrsol tab because he thinks it saves money. This is the one who spends 700 dollars on weights. Please, do us repairmen all a favor, use enough detergent!

| ||

Post# 468443 , Reply# 69 10/10/2010 at 22:27 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

| ||

Post# 468444 , Reply# 70 10/10/2010 at 22:34 (4,939 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Here's a color I never seen before.

Really the grossest part of this was the custom panel kit: The frame was rusting, actually smelled, its a good thing my tetanus was updated. The wood was actually rotting at the bottom. Underneath was this kind of beige matte finish. I might leave it this way as I kind of like it. I didn't know they had "toast' back then.

What I plan to do is set up a cabinet and counter in our game room with a sink on the left and Kaddi on the right and that way we have a place to prepare food and entertain and we can have the KA mixer and coffe maker set up on top. Bajahuma can you visualize this and make a CADD picture of it? I like them. The counter will be about 6 feet long.

| ||

Post# 468504 , Reply# 71 10/11/2010 at 10:42 (4,939 days old) by CircleW  (NE Cincinnati OH area) (NE Cincinnati OH area) |

||

|

I imagine the matte beige finish is the "primed panel" they sold to be painted by the customer for those who wanted something other than the standard colors. | ||

Post# 469755 , Reply# 72 10/16/2010 at 19:36 (4,933 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Update, and it is not good... Give me some time to sulk....

First the good news, we found the loose connection, turns out one of the connections to the program switch was dislodged. But now the motor has issues. It buzzes and will not go. Oh, it will go if you turn the impeller before starting it but then you have a water swirler and not a dishwasher. When the motor is running, the sounds it makes make my skin crawl. I must have been in denial about the condition of the motor, it is more far gone than I thought. By the way, the shaft turns freely, so I don't think it is binding. It just will not go "on its own initiative".

I just need some time to think about what to do next. If anyone wants parts the offer still stands. I probably can keep him in the garage until it is really cold then I will be pressured to get it out. I can get the door off, I know the timer is rare but I cannot unscrew it from the door. I will probably save the pump parts as well. Steve, I will also take the blower too. If I go ahead with a new (emerson?) motor would it have the same screw holes for the pump as the original? I don't know how I am going to get the new seal/impeller off - maybe a "pulley puller"? Spending 200 for a motor is getting into new dishwasher territory. I am trying not to feel too bad. Doctors don't save every life, I guess I don't have to either. Give me a week I will let you know if I part him out. | ||

Post# 469769 , Reply# 74 10/16/2010 at 21:03 (4,933 days old) by neptunebob  (Pittsburgh, PA) (Pittsburgh, PA) |

||

Thanks, Steve, I'll look into it, I appreciate it. I just need a week to sulk and figure out what to do. I wonder if I want to put that much of my money into it. Looks like someone else in the area is looking for a classic KA too. Do you think I should save Kaddi or should I part him out? Anyone want the parts?

This all has been a great learning experience but one thing I think I have learned is that some appliances may be just too far gone if people really used them heavily. We collectors should stick to estate sales where the owners were little old ladies that did not use them much. | ||

Post# 721736 , Reply# 77 12/17/2013 at 23:35 (3,775 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

| ||

Post# 721779 , Reply# 78 12/18/2013 at 08:00 (3,775 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

| ||

Post# 721782 , Reply# 79 12/18/2013 at 08:09 (3,775 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

There's no float to control the fill level. Fills are timed (probably two timer increments), with a flow-washer in the water valve to limit the flow rate against various potential household water pressures. If the 16 series is same as the 17 series, overfill is detected via a pressure switch connected to the pump sump area. If overfilling is happening, the water level can possibly contact the spray arm which would slosh some out of the door vent. The normal fill level is to near top of the filter mesh, below the spray arm. | ||

| Post# 721795 , Reply# 82 12/18/2013 at 09:43 (3,775 days old) by danemodsandy (The Bramford, Apt. 7-E) | ||

|

Mark:

"Why on God's green earth are we resurrecting a 3+ year old thread instead of starting a new one?"

So we can all ask Neptunebob how his resurrection of the KDI16 turned out! One of the things that I sometimes wish was different around here is that we have a lot of threads just - you should pardon the expression - peter out. We hear of a problem, there are responses offering advice and resources, often the appliance's owner begins work and posts photos of progress, and then - nothing. This thread is a classic example. After more than 70 posts, we didn't get the end of the story. So, Bob, how's it shakin'? | ||

| Post# 721804 , Reply# 85 12/18/2013 at 10:35 (3,775 days old) by warren () | ||

|

living dangerously stevet, q-tip in the ear? so I am supposed to restrict the use of the q-tip to the exterior surface of the sump? | ||

Post# 721805 , Reply# 86 12/18/2013 at 10:39 (3,775 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

| ||

| Post# 721806 , Reply# 87 12/18/2013 at 10:40 (3,775 days old) by warren () | ||

|

grammar sorry. I didn't mean to say 'Does this machine have some things that sit in the bottom front corners by the door, I think I have seen them called 'diverters'. It doesn't. I meant to say, 'does it 'spose to have them'. | ||

Post# 721856 , Reply# 90 12/18/2013 at 16:41 (3,774 days old) by Yogitunes  (New Jersey) (New Jersey) |

||

archived threads reactivated.....what can throw you off at first is its comes up as a new un-read thread....and also not paying close attention and catching that this thread is actually 3 years old...one of those things where you start reading before you realize when it was first posted....we all do it, it happens...not to mention these archived threads don't pop up all that often, so your not really looking out for them.....

I haven't tried it yet, but wonder, can we start a new thread for our question, and link the older archive as a reference to an issue we are having?... and yes, curious, how did Bob make out, and whats the outcome from Warren's investigation.....keep us posted! | ||

| Post# 721860 , Reply# 91 12/18/2013 at 16:59 (3,774 days old) by bogo (montreal) | ||

|

Unless it's related to a resolved issue I don't see problem in resurrecting old thread. | ||

Comes to the Rescue!

Comes to the Rescue!