|

Thread Number: 3080

Work Continues Tonight on the Turquoise 1958 GE |

[Down to Last] |

Post# 79904 8/23/2005 at 22:35 (6,817 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

While I would really like to save both GE's I'm not too sure at this point, there is a 50/50 chance. Here is the progress for this evening.

CLICK HERE TO GO TO Unimatic1140's LINK | ||

|

| Post# 79905 , Reply# 1 8/23/2005 at 22:36 (6,817 days old) by Compwhiz128 () | ||

|

#2 will have to fit ;-) | ||

| Post# 79907 , Reply# 2 8/23/2005 at 22:46 (6,817 days old) by tlee618 () | ||

|

Fingers crossed hoping #2 will work, always nice to have an extra in stock!! Enjoyed seeing your bathroom redo tonight again on HGTV. Terry | ||

| Post# 79929 , Reply# 3 8/24/2005 at 00:20 (6,817 days old) by frontaloadotmy (the cool gay realm) | ||

|

Fingers X'd , both hands! | ||

| Post# 79936 , Reply# 4 8/24/2005 at 01:28 (6,817 days old) by whirlcool (Just North Of Houston, Texas) | ||

|

I saw that too on HGTV, very nice. How long ago was that segment shot? | ||

| Post# 79947 , Reply# 5 8/24/2005 at 04:16 (6,817 days old) by Spiraclean (UK) | ||

|

Hi Robert, Thanks for the great restoration pictures; I really enjoy seeing the workings of these great vintage machines. I hope you are able to have two running machines, the right man is on the job. I am interested in the Water Level Diaphragm, I have never seen that particular design before, and I presume it is used instead of a pressure switch? All the best. Hugh | ||

| Post# 79955 , Reply# 6 8/24/2005 at 07:03 (6,817 days old) by Mayken4now (Panama City, Florida) | ||

| ||

| Post# 79956 , Reply# 7 8/24/2005 at 07:05 (6,817 days old) by westytoploader () | ||

|

I'm hoping #3 will work since it looks the best, IMHO. Good luck Robert, and Happy Activating!! | ||

| Post# 79957 , Reply# 8 8/24/2005 at 07:06 (6,817 days old) by FilterFlo (Chicago Area) | ||

|

Robert, the pics are great! Love those GE washers. Question: Do you use the same old oil that was in the tranny, or do you refill it with new oil? | ||

Post# 79970 , Reply# 9 8/24/2005 at 08:42 (6,817 days old) by Jmm63  (Denville, NJ) (Denville, NJ) |

||

| ||

Post# 79971 , Reply# 10 8/24/2005 at 08:46 (6,817 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Hugh the way the water level diaphragm works is when the spin tub is full of water, it starts to overflow, after four or five gallons of water has overflowed into the outer tub, the weight of the water presses the rubber diaphragm down which starts agitation. Jimmy, on my white 1958 machine I did completely rebuild that 1960 transmission, including changing the oil. A GE tranny takes some 65 or 70 oz of oil, about three times the amount of a Whirlpool or Unimatic tranny. So before I even consider doing that again I want to make sure one of those spare transmissions will work. Since the GE transmission only swirls the oil around and doesn't pump the oil through channels it should be fine as it is. Allen there is a thread started about the TV show in the Super Forum. | ||

| Post# 79981 , Reply# 11 8/24/2005 at 10:07 (6,817 days old) by Spiraclean (UK) | ||

|

Hi Robert, Thanks for the explanation; I was forgetting that the GE Filter Flo is a solid basket design whereas its UK cousin is a perforated basket design. Just a thought; a solid basked design must use much less water and energy than a perforated basket design, I wonder why manufacturers did not look at this design again I am sure it would be easier to engineer a solid basket top load washer to meet Energy Star guidelines. All the best. Hugh | ||

| Post# 79982 , Reply# 12 8/24/2005 at 10:13 (6,817 days old) by lesto (Atlanta) | ||

|

Are # 2 and 3 the pre-1960 design with no spin brake? I hope so. It would be nice to have one of the machines with that great GE "coast-to-a-stop" action. If neither 2 or 3 work is it possible to rebuild one like you did the 1960 tranny? Perhaps take the best parts of all 3? Good luck! | ||

Post# 79995 , Reply# 14 8/24/2005 at 11:40 (6,817 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Hi Les, yes both transmission #2 and #3 are pre-1960 no brake transmissions. To answer your question about whether I can take and combine two or three of the trannys into one good one, that's a possibility, but it depends on what is wrong with #2 and #3. If all three have a broken Anti-Indexing Pawl, then no, since I don't have that part, we're out of luck. If one of those spare trannys has a good Pawl but is inoperative for some other reason then there is a chance that I could repair the bad tranny. I just hope that #2 or #3 works without the need of having to open one of those up; itís a really big job.

| ||

| Post# 79998 , Reply# 15 8/24/2005 at 11:49 (6,817 days old) by jmirawm (Barling Arkansas) | ||

|

How will you know...... If the tranny is going to work? Will you have to install one in the machine and run it before you can tell? | ||

| Post# 80007 , Reply# 16 8/24/2005 at 12:51 (6,817 days old) by lesto (Atlanta) | ||

|

Robert, what does the anti-index pawl look like? Is it inside the tranny housing? Also, what causes it to disengage when the washer goes into the spin cycle? | ||

Post# 80023 , Reply# 17 8/24/2005 at 13:52 (6,817 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Les the Anti-Indexing Pawl is a plastic bar thatís adapted to fit into a notch on the metal Anti-Index Snubber Band. The pawl is attached to a rotating shaft and normally the pawl faces downward and points to the 6:00 position. Because of a spring on the shaft, the pawl is only allowed to move counterclockwise from 6:00 all the way up to 12:00. The pawl is restricted from moving clockwise from the 6:00 position up to 12:00. When the washer is in Activation mode, the motor turns the transmission pulley and internal components clockwise so the pawl catches on notch on the Snubber Band and prevents the tub from rotating clockwise. I'm doing this from memory, so itís hard to explain and even harder for someone to picture in their head how this works without a visual aid. Tonight I will find and post a picture of the tranny parts including the pawl and snubber band that will make it much more clear. Les do you remember your mom's solid-basket GE washer before it had tranny problems and started to spin during Activation? How much indexing (if any) did the wash tub? Eddy does your Pink '58 GE washer tub index at all? Inquiring minds need to know! :) | ||

Post# 80032 , Reply# 19 8/24/2005 at 15:59 (6,816 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

"There was a slight swaying back and forth as the activator made a stroke with slightly more movement clockwise than counterclockwise as this is the direction the motor rotates during agitation." Thanks Les, that is exactly what I had pictured in my head that is was suppose to do, it's nice to have confirmation. Tom yes the only way to find out if one of those spare transmissions has a good pawl is to install it, put the tub back in, fill the machine with water and towels and see what the tub does, it's not a quick job in any way shape or form. Tonight I'm going to try #3 and see what happens. Stay tuned. | ||

| Post# 80036 , Reply# 20 8/24/2005 at 16:10 (6,816 days old) by westytoploader () | ||

|

Best of luck Robert!!! I'll keep my fingers crossed! | ||

Post# 80134 , Reply# 23 8/24/2005 at 22:29 (6,816 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

We Might Have Success

Well with transmission number three installed with a full tub of water and clothes the washer tub still indexes, but at a much more slow and reasonable rate of about 1 360 degree turn every seven or eight back and forth strokes of the agitator. I think that is about normal, its a similar rate to my early 1951 GE washer with a heavy load. The heavier the load, the more indexing the tub will do. BUT, There is a strange ticking sound coming from near the pulley, I have a feeling the Main Transmission Drive Spring is not in good shape. Tomorrow I'm going to have to inspect. At least you can replace the drive spring without having to open the entire transmission. CLICK HERE TO GO TO Unimatic1140's LINK | ||

| Post# 80138 , Reply# 24 8/24/2005 at 22:37 (6,816 days old) by tlee618 () | ||

|

Congratulations Robert, we will hope that all goes well from here. It's great that you can replace the drive spring without having to tear down the entire transmission. Thanks for the neat pictures. Terry | ||

Post# 80145 , Reply# 25 8/24/2005 at 22:45 (6,816 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 80148 , Reply# 26 8/24/2005 at 22:53 (6,816 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

According to the 1958 GE Service Manual... "An internal snubber pawl is used on this transmission. During activation the snubber butts against the tab of the snubber band. The snubber band acts as a spring and tightens under pressure from the snubber causing a braking action between the snubber band lining and the hub of the bearing frame. During spin, the snubber pawl is held up against the gear case casting because its light weight (hence plastic) and shape permit it to "plane" on the transmission oil and ride over the tab on the snubber band." Now we see why GE made the pawl out of plastic so it would ride up and not interfere with the spinning case. | ||

| Post# 80211 , Reply# 27 8/25/2005 at 07:59 (6,816 days old) by Spiraclean (UK) | ||

|

| ||

Post# 80217 , Reply# 28 8/25/2005 at 08:11 (6,816 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

| ||

| Post# 80232 , Reply# 29 8/25/2005 at 09:39 (6,816 days old) by lesto (Atlanta) | ||

|

Thanks for the pics and diagram, Robert. I hope all continues to go well with the machine. As soon as you get it all put back together I hope you remove that ghastly black activator cap and put a pink one on! :) | ||

Post# 80239 , Reply# 30 8/25/2005 at 10:26 (6,816 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Pink--Turquoise--Black Activator Caps

I'm not sure if I have another pink cap Les, I might, but I know I have at least five black caps. The most important thing is that the machine works exactly the way it is suppose to. Of course a pink cap could certainly be found at some point in the future. GE produced a lot of replacement caps, but only in black, because they did have a tendency to get stuck and break during removal. | ||

Post# 80265 , Reply# 31 8/25/2005 at 14:54 (6,816 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

Pink Caps In Stock... | ||

| Post# 80274 , Reply# 33 8/25/2005 at 15:43 (6,815 days old) by lesto (Atlanta) | ||

|

Bruce, do you have any pics of your 59 you can post? That's the machine I grew up with and I'd love to see yours. Does it have the turquoise cap? | ||

Post# 80407 , Reply# 34 8/26/2005 at 08:58 (6,815 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Hi Bruce, just move the drive block up a 10th or an inch or so, you probably will need to torch it before it will more. As for the paint around the dial bezel, I painted mine. Just mask off the sides and top with blue painters masking tape. Use a good high gloss spray paint, three light coats. The after its dry for 24-48 hours, take some paint thinner on a old bedsheet or pillowcase and slowly rub the words that are raised up in the metal that say "water saver" until the chrome shows through. Put the paint thinner on the sheet first, then gently rub each letter one at a time. | ||

| Post# 80414 , Reply# 35 8/26/2005 at 09:12 (6,815 days old) by lesto (Atlanta) | ||

|

GE Timer question I noticed on Robert's 58s and Greg's 60 that the wash times on the normal cycle are 14,12,10,6,4,2, but on the 59 it was 15, 12,9,6,3. Both the 59 and the 60 have a 3 min "short cycle" in red letters. Any idea why they flip-flopped those 3 years? | ||

Post# 80544 , Reply# 36 8/26/2005 at 23:15 (6,814 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Bad News

Hi Les, I have no idea what GE engineers were thinking, I'm sure they had some good reason for switching, then switching back. Well it seems transmission #3 is indexing the wash tub an awful lot, much more than what its suppose to. I looked at Tranny #2 and it appears its binding when you turn the pulley counterclockwise or in the spin direction. It looks like I've got to put on my boots and get ready to dive into a couple of GE transmission and see if I can get enough good parts to make one good tranny. This is a messy, stinky GE oil job. Pictures to come of the inside of a GE transmission later on in the weekend. | ||

| Post# 80553 , Reply# 37 8/27/2005 at 01:37 (6,814 days old) by Spiraclean (UK) | ||

|

| ||

Post# 80562 , Reply# 38 8/27/2005 at 04:17 (6,814 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Best Of ...

Hi Robert Another restoration in the process, lookin good, I would have needed therapy after the pinky breaking, thank goodness for those spares amongt us.. Did GE always use the tall agi tube?? The hotpoint here used a 3 way spider a few inches up from the tub base, often wondered which has the better torque, noticed the Maytags have short tubes etc...all the other UK machines had the long tubes.The pump coupler is the same over here.. Happy oil lapping!!! Cheers, Mike CLICK HERE TO GO TO chestermikeuk's LINK | ||

Post# 80568 , Reply# 40 8/27/2005 at 06:30 (6,814 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Robert

Here's hoping the nylon pawl is just stuck up. I remeber seeing alot of women used to back spin the tub to unload it by grabbing the rubber balance ring and pulling the tub backwards. Schenectady is a GE town so everybody had these when I was a kid. The Hohenstein's and Cusano's were odd because they had Kenmore's! Pulling backwards on the rubber ring like that would either snap the nylon pawl in two if they pulled hard enough or knock it into an upright position where it would stay and not engage anything. Hopefully you'll find the pawl sitting upright and can just knock it back down. jon | ||

| Post# 80571 , Reply# 41 8/27/2005 at 07:18 (6,814 days old) by mayken4now (Panama City, Florida) | ||

| ||

| Post# 80609 , Reply# 42 8/27/2005 at 17:32 (6,813 days old) by Helicaldrive (St. Louis) | ||

|

Suspense about the tranny is mounting. Hopefully you aren't running out of options! -S | ||

| Post# 80625 , Reply# 43 8/28/2005 at 01:03 (6,813 days old) by eddy1210 (Burnaby BC Canada) | ||

indexing

Yes, Robert my pink '58 does index but not at a fast rate. Just a few inches per activation. I'd say it takes 10 to 12 back and forth strokes for it to make the 360 degree turn. I lucked out with my tranny being in such good shape. Well, it sat 18 years in that shop in Edmonton and when we moved it out, there were only a few drops of tranny oil on the floor under her after all that time. | ||

Post# 80626 , Reply# 44 8/28/2005 at 01:52 (6,813 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 80628 , Reply# 45 8/28/2005 at 02:24 (6,813 days old) by foraloysius  (Leeuwarden, Friesland, the Netherlands) (Leeuwarden, Friesland, the Netherlands) |

||

| ||

Post# 80718 , Reply# 46 8/28/2005 at 21:20 (6,812 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Hey Mike, GE never used a low post drive here in the USA, what does the transmission look like in your filter-flo Hotpoint? I wonder if there are any similarities between the UK and US versions??? Anyway, I started by taking Transmission #2 apart today. The Snubber Pawl is fine, but there are other problems inside this tranny as it is binding during spin. But I think I can use the Snubber Pawl, Band and Lining from this unit as those parts look great and transplant them into Transmission #3. Tomorrow I will open up Tranny #3 (the one that is currently installed in the machine and indexing too much) and see whatís going on in there. Later on I want to have a discussion with everyone about the Drive Spring. Many washers such as GE, Kelvinator, Frigidaire Unimatic, Pulsamatic and Multimatic, Franklin, Norge, etc used Drive Springs to determine whether to spin the tub or agitate so its important to see how this simple but very strong spring works. Here is everyone's first peek into a GE Transmission... CLICK HERE TO GO TO Unimatic1140's LINK | ||

| Post# 80728 , Reply# 48 8/28/2005 at 22:10 (6,812 days old) by Spiraclean (UK) | ||

|

| ||

Post# 80734 , Reply# 49 8/28/2005 at 23:03 (6,812 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

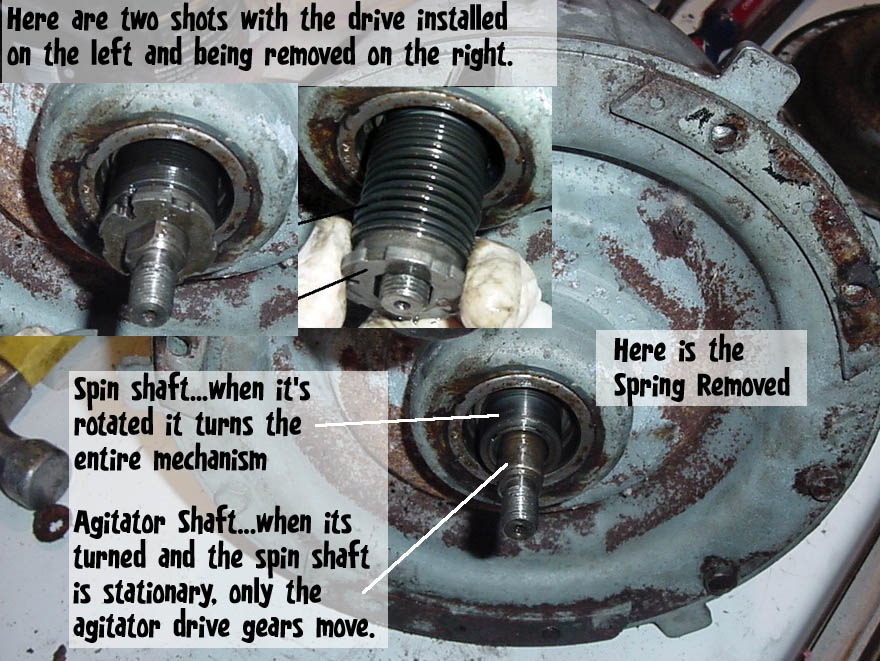

Yes Austin you are correct the Drive Spring in the Unimatic is called the Clutch Torque Spring. But first let's discuss the GE Drive Spring. GE calls simply calls their version a "Clutch Spring". Kelvinator and Franklin and Westinghouse all use a similar Drive spring to the GE's where the pulley of the transmission is turned in one direction for wash, then reversed for spin. Here is how it works, as your read this look at the picture below so you can visually see what IĎm talking about. Lets talk about spin first. During spin the transmission pulley is driven counterclockwise. The Pulley is mated directly to the Agitator shaft and Drive Spring, via the Springís hub. Since this spring is wound left hand, when it is turned counterclockwise it compresses and tightens down really hard on the spin shaft. Since the pulley and spring are mated together, this causes the entire inside of the transmission to spin, which in turn drives the spin shaft, hub and wash tub. Now for agitation the spring is driven clockwise. Driving the spring clockwise will cause it to expand and loosen as is shown in the picture in the upper right. Since it expands on the spin shaft and its not grabbing it tightly anymore and because its covered in oil it simply glides along the spin shaft only producing a small amount of friction, but not enough to turn the spin shaft. BUT I do want to point out that the small amount of friction is enough to cause the tub to index on every clockwise stroke of the agitator and thatís why they designed the anti-indexing pawl and snubber. Needless to say Drive Springs take a lot of force and have a tendency to break or become deformed, so they were a common to part to need replacement.

| ||

Post# 80739 , Reply# 50 8/29/2005 at 00:09 (6,812 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

| ||

Post# 80864 , Reply# 51 8/29/2005 at 21:45 (6,811 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

The First Peek Inside the Tranmission

Here what the inside of a GE Tranmission looks like. I'm going to try switching the snubber parts between Tranny #2 and #3 and see if this helps. I'll keep everyone posted.

CLICK HERE TO GO TO Unimatic1140's LINK | ||

| Post# 80897 , Reply# 52 8/30/2005 at 08:51 (6,811 days old) by lesto (Atlanta) | ||

|

This is most likey a dumb question but what do you mean by the transmission is "binding"? | ||

Post# 80908 , Reply# 53 8/30/2005 at 10:05 (6,811 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 80911 , Reply# 54 8/30/2005 at 10:12 (6,811 days old) by lesto (Atlanta) | ||

|

Thanks, Robert. Is this binding caused by a bad gear in the transmission? Once you're done with this restoration what's your next project, back to the 56 Hotpoint? Just curious. | ||

Post# 80916 , Reply# 55 8/30/2005 at 10:57 (6,811 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Actually the gears are not involved in the spinning process, I believe it might have to do with the compression spring (not the drive spring) at the very top of the gear case, but I'm not going to bother spending the time working on that tranny when I have a couple of others. I will save it for parts. As for what's next I really would like to go back to working on my '53 Sparton Television that has been on my work bench for months. But since Neal is flying overseas today for work and he will be gone for the next two weeks, I'm going to go vintage washer and parts hunting for five days. I'm leaving on Friday morning. I'm heading up through eastern North Dakota and into Canada up to Winnipeg. While I never get my hopes up of finding anything great, you never know, I'm keeping my fingers crossed. Maybe I'll come home from Winnipeg with a vintage Beatty automatic! I'm staying in Fargo on Friday night and will head up to Winnipeg on Saturday. I'm bringing my wireless internet laptop and camera so I will still be able to post. | ||

| Post# 80923 , Reply# 56 8/30/2005 at 11:29 (6,811 days old) by lesto (Atlanta) | ||

|

Have a safe and pleasant trip. I hope you find some great stuff. Take pics if you do. | ||

Post# 80948 , Reply# 57 8/30/2005 at 16:03 (6,810 days old) by foraloysius  (Leeuwarden, Friesland, the Netherlands) (Leeuwarden, Friesland, the Netherlands) |

||

| ||

| Post# 80982 , Reply# 58 8/30/2005 at 19:43 (6,810 days old) by Spiraclean (UK) | ||

|

| ||

| Post# 80994 , Reply# 59 8/30/2005 at 20:40 (6,810 days old) by Timonator () | ||

|

Old Oil? I was just wondering..maybe the oil has something to do with it slipping? doesnt the oil..make the pawl engage at a higher rpm? if the level is low..or the viscosity is wrong...this could be a problem? I dunno..just a suggestion | ||

| Post# 81011 , Reply# 60 8/30/2005 at 22:38 (6,810 days old) by tlee618 () | ||

|

Have a fun safe trip Robert!! I will keep my fingers crossed that you find some wonderful treasures. Terry | ||

Post# 81032 , Reply# 61 8/31/2005 at 08:34 (6,810 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Hi Tim, no the oil is at the level and viscosity that it is suppose to be, the pawl simply catches on the tab of the snubber band. I'm pretty sure the problem with these older GE tranmissions is that the snubber band's brake-style lining gets worn and allows for more movement of the tub than when the machine was brand new.

| ||

Comes to the Rescue!

Comes to the Rescue!