|

Thread Number: 31201

Add 2 speeds to helical A882? |

[Down to Last] |

|

Post# 471045 , Reply# 2 10/23/2010 at 21:34 (4,932 days old) by appnut  (TX) (TX) |

||

|

May I ask a stupid question | ||

| Post# 471054 , Reply# 3 10/23/2010 at 21:57 (4,932 days old) by kenmore700bill (Lodi NJ) | ||

I have to agree with Bob i have the smaller tub Fabticmatic one speed and we have no issue at all with the delicate cycle even the Permanant Press which i use alot because of dress shirts for work no wrinkles. The machine is a work horse. I dont know the year of the machine but i do know the console is brown not black and we wash everyting in it from heavy towels to sheer curtains and sweaters.

| ||

| Post# 471061 , Reply# 4 10/23/2010 at 22:18 (4,932 days old) by qsd-dan (West) | ||

|

TG = April 1987. It has the newer lower lip seal, instead of the older o-ring style.

You can swap the whole "tree" into the 606 and retain your 2 speed wash action. It's a direct swap and shouldn't take more than 30-45 minutes to accomplish. There was a member here who swapped the newer style console onto an older center dial machine, so I'd say it's very possible. | ||

| Post# 471067 , Reply# 6 10/23/2010 at 22:54 (4,932 days old) by fltcoils (South Bend, Indiana) | ||

|

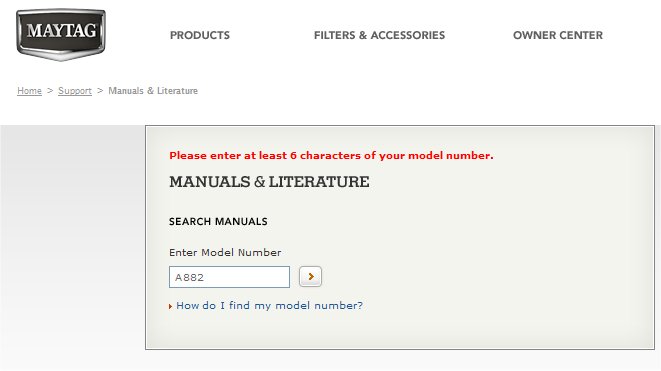

manual where might I find a manual for this machine? The maytag site doesn't recongnize the model no A882, says there are too few digits? 88204 and 882 04 and 882-04 don't work either. :(

| ||

Post# 471072 , Reply# 7 10/23/2010 at 23:34 (4,932 days old) by appnut  (TX) (TX) |

||

|

| ||

| Post# 471079 , Reply# 8 10/24/2010 at 01:09 (4,932 days old) by alr2903 (TN) | ||

|

The gentle on the A206 (fabrimatic), works quite well and the spin is quick and short. I never use the gentle on my more modern Tag with the load sensor. alr2903 | ||

Post# 471083 , Reply# 9 10/24/2010 at 02:23 (4,932 days old) by appnut  (TX) (TX) |

||

|

| ||

| Post# 471134 , Reply# 10 10/24/2010 at 09:33 (4,932 days old) by fltcoils (South Bend, Indiana) | ||

|

I may have to drop in on Whirlpool I may end up driving up to Benton Harbor and see if I can get a manual. I'm surprised they don't have pdfs of them all. | ||

Post# 471135 , Reply# 11 10/24/2010 at 09:43 (4,932 days old) by appnut  (TX) (TX) |

||

|

| ||

Post# 471139 , Reply# 12 10/24/2010 at 11:07 (4,931 days old) by Toggleswitch  (New York City, NY) (New York City, NY) |

||

|

| ||

Post# 471163 , Reply# 14 10/24/2010 at 12:34 (4,931 days old) by appnut  (TX) (TX) |

||

|

If your A606 has both a regular and perm press cycle, they are identical to what is on this machine. the only thing that's different is the delciate (fabric-matic) cycle. Set the timer for 8 minutes and always use a full water level. Fill the wash tub no more than 1/2 full. Once agitation begins it will agitate for one minute and pause for 4 or 5 minutes. then it agitates again for another minute and then pauses/soaks. then an abbreviated spin & spray rinse. A very short rinse (1 minute) then final spin which is 3 minutes at the most.

| ||

| Post# 471244 , Reply# 16 10/24/2010 at 22:35 (4,931 days old) by alr2903 (TN) | ||

|

Bob, you are right, I have an A108, serial number 126572 AX, thanks for the question. The plate is under the lid and most of the paint is worn off. I wonder how old she really is? arthur | ||

| Post# 471447 , Reply# 18 10/25/2010 at 22:25 (4,930 days old) by qsd-dan (West) | ||

|

Maytag certainly went a little berserk with motor start switches. I don't understand why they didn't just use 2 start switches (1 speed motors, 2 speed motors). By '66, Maytag narrowed their multiple motor usage down to 2 motors for each speed. 201805/201664 for 1 speed and 201807/201666 for the 2 speeders. I don't know what differences occur in them internally, but the 201664/201666 motors are beefier, leading me to believe they're more of "heavy duty" style motor.

Before '66, Maytag used all sorts of motors, motor makes, start switches, ect. God forbid you get an older, uncommon pre '66 motor that has had the color dabs worn or wiped off. I smoked a couple of those while attempting to use the process of elimination. | ||

| Post# 471565 , Reply# 20 10/26/2010 at 18:56 (4,929 days old) by fltcoils (South Bend, Indiana) | ||

|

Finished modification pic 1 Here is the A882 with a gentle/regular speed switch added.

| ||

| Post# 471567 , Reply# 21 10/26/2010 at 18:58 (4,929 days old) by fltcoils (South Bend, Indiana) | ||

|

Pic 2 Closeup of panel with switch on top. I thought that if I eventually found a "real" speed switch from a panel I could grommit cap the hole here on top better. Then I'd put the real sw where it belongs on the front, there's a cutout for it inside already. For now the machine has a toggle on the top.

| ||

| Post# 471568 , Reply# 22 10/26/2010 at 18:59 (4,929 days old) by fltcoils (South Bend, Indiana) | ||

|

Washing a load in my newly modified 2 speed A882. Here it is washing whites

| ||

| Post# 471571 , Reply# 23 10/26/2010 at 19:30 (4,929 days old) by fltcoils (South Bend, Indiana) | ||

|

Needed switch 206217 I'll be looking for a speed sw pn 206217. I may also play around with the ratcheting agitator some more. ---- Next job is replacing the input shaft on my A606 transmission. | ||

| Post# 471579 , Reply# 24 10/26/2010 at 20:07 (4,929 days old) by fltcoils (South Bend, Indiana) | ||

|

Found switch 206217 I found and bought a 206217 switch, when it arrives I will modify the panel and insert it. | ||

Post# 471829 , Reply# 25 10/27/2010 at 21:13 (4,928 days old) by appliguy  (Oakton Va.) (Oakton Va.) |

||

If I am not mistaken... | ||

Post# 472254 , Reply# 26 10/29/2010 at 21:15 (4,926 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

LOAD SENSOR AGITATOR | ||

Post# 472259 , Reply# 27 10/29/2010 at 21:20 (4,926 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

LOAD SENSOR AGITATOR | ||

| Post# 472294 , Reply# 28 10/29/2010 at 23:42 (4,926 days old) by macboy91si (Frankfort, KY) | ||

The Party Hat | ||

Comes to the Rescue!

Comes to the Rescue!