|

Thread Number: 31297

CODE BLUE, I NEED BEARINGS STAT!!! |

[Down to Last] |

|

| Post# 472452 , Reply# 4 10/30/2010 at 21:31 (4,920 days old) by supremewhirlpol () | ||

|

My Neptune has security torx screws that hold the door and front panel on the machine. There are 2 on both sides of the door.

| ||

| Post# 472453 , Reply# 5 10/30/2010 at 21:32 (4,920 days old) by supremewhirlpol () | ||

|

Hinges need to be replaced too, That will have to come later.

| ||

| Post# 472454 , Reply# 6 10/30/2010 at 21:34 (4,920 days old) by supremewhirlpol () | ||

|

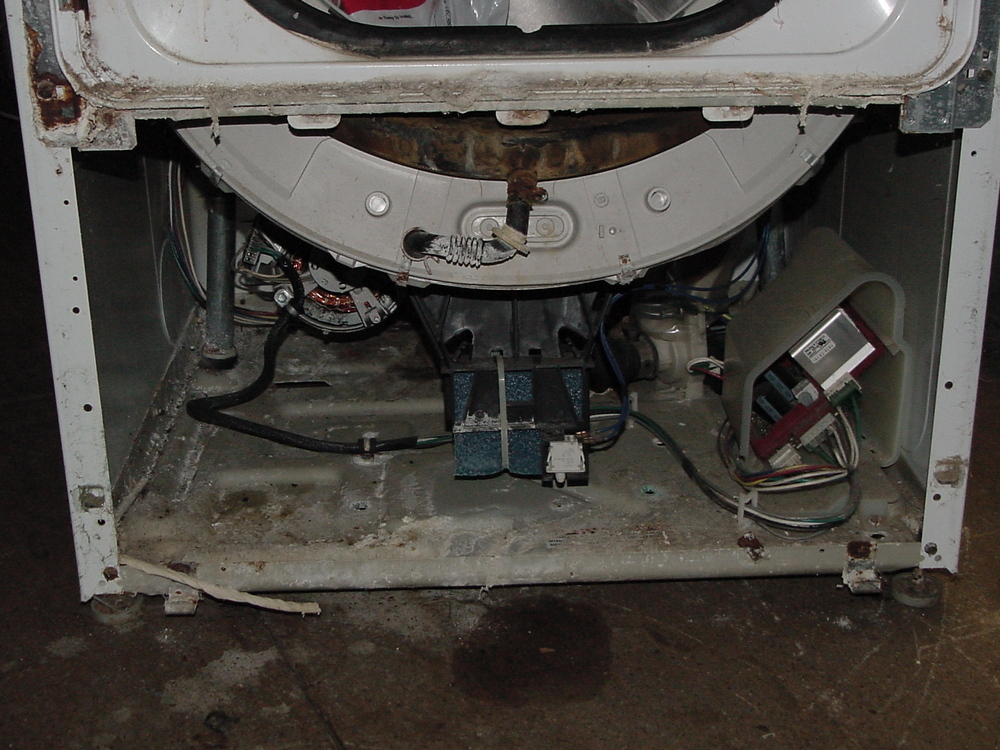

Remove the door, remove the front panel. Looks nasty!

| ||

| Post# 472455 , Reply# 7 10/30/2010 at 21:35 (4,920 days old) by supremewhirlpol () | ||

|

A lot of that crud is actually soap-> more about that later.

| ||

| Post# 472460 , Reply# 8 10/30/2010 at 21:58 (4,920 days old) by supremewhirlpol () | ||

|

The top is held down by a lock bracket on each side of the machine and the top of the of the dispenser

| ||

| Post# 472461 , Reply# 9 10/30/2010 at 21:59 (4,920 days old) by supremewhirlpol () | ||

|

lock bracket

| ||

| Post# 472463 , Reply# 10 10/30/2010 at 22:02 (4,920 days old) by supremewhirlpol () | ||

|

dispenser The top of the dispenser is held on by 4 Philips screws.

| ||

| Post# 472465 , Reply# 11 10/30/2010 at 22:04 (4,920 days old) by supremewhirlpol () | ||

|

Top up Top comes up

| ||

| Post# 472466 , Reply# 12 10/30/2010 at 22:06 (4,920 days old) by supremewhirlpol () | ||

|

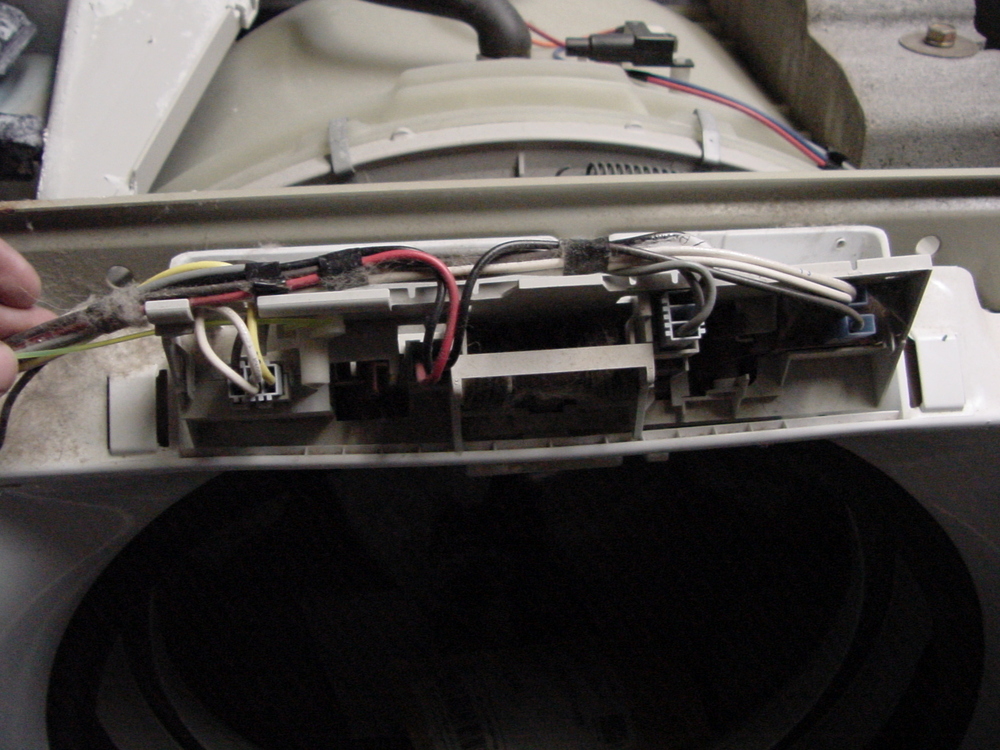

Looks Gnarly!

| ||

| Post# 472468 , Reply# 13 10/30/2010 at 22:12 (4,920 days old) by supremewhirlpol () | ||

|

removing outer drum In order to remove the outer drum, the dispenser has to be removed, along with the counter-weight, wiring for swiches/sensors, hoses, motor wire harness, lower drum out of balance switch, springs. | ||

| Post# 472471 , Reply# 14 10/30/2010 at 22:16 (4,920 days old) by supremewhirlpol () | ||

|

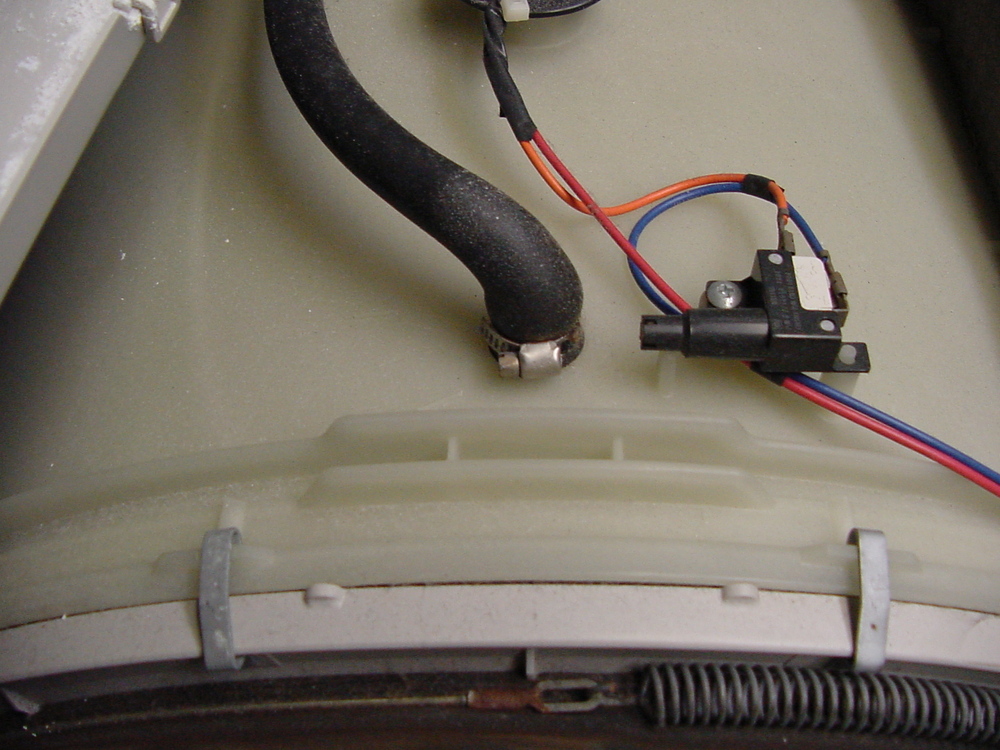

Hose in the middle of the top of the drum, has to go-> it's goes from the dispenser to the outer drum. Also remove sensor next to the hose.

| ||

| Post# 472473 , Reply# 16 10/30/2010 at 22:24 (4,920 days old) by supremewhirlpol () | ||

|

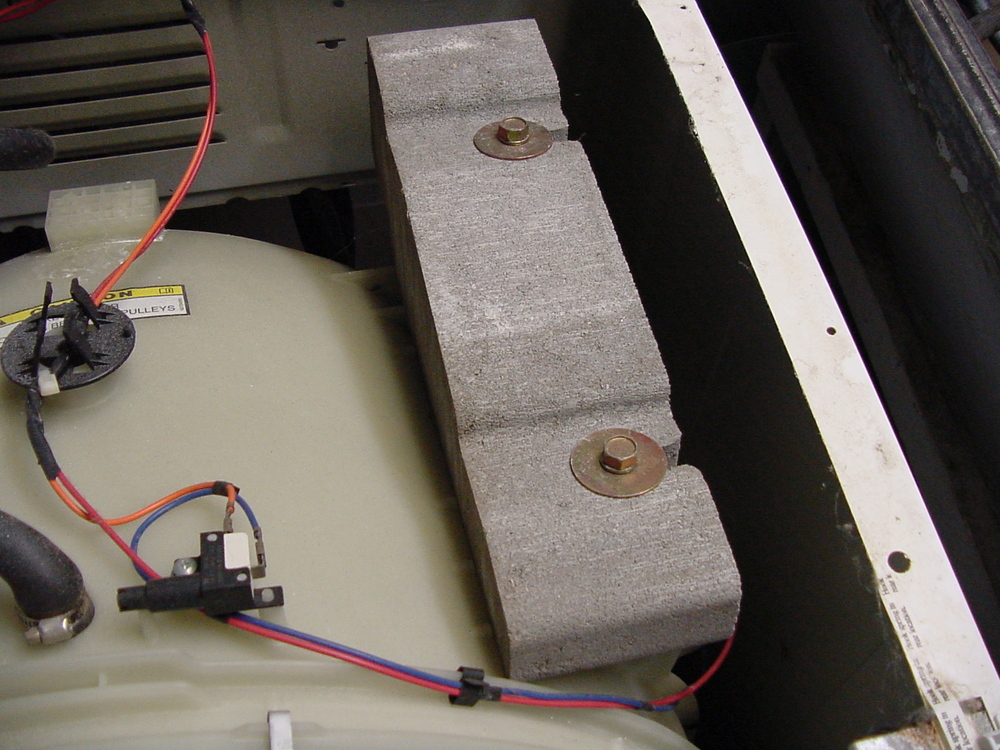

Counter-weight Remove counter-weight->save/separate which bolts, screws go where

| ||

| Post# 472474 , Reply# 17 10/30/2010 at 22:26 (4,920 days old) by supremewhirlpol () | ||

|

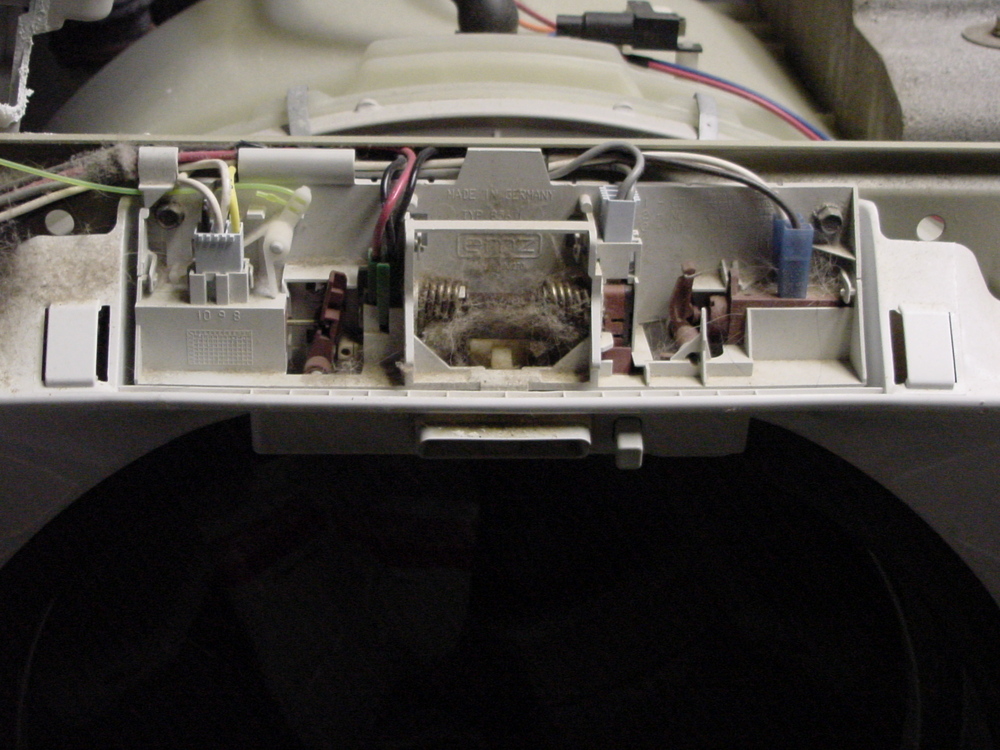

Door-lock module Remove the door lock module->2 screws on each side hold it in place.

| ||

| Post# 472475 , Reply# 18 10/30/2010 at 22:28 (4,920 days old) by supremewhirlpol () | ||

|

Tilt forward and remove.

| ||

| Post# 472491 , Reply# 19 10/30/2010 at 23:13 (4,920 days old) by supremewhirlpol () | ||

|

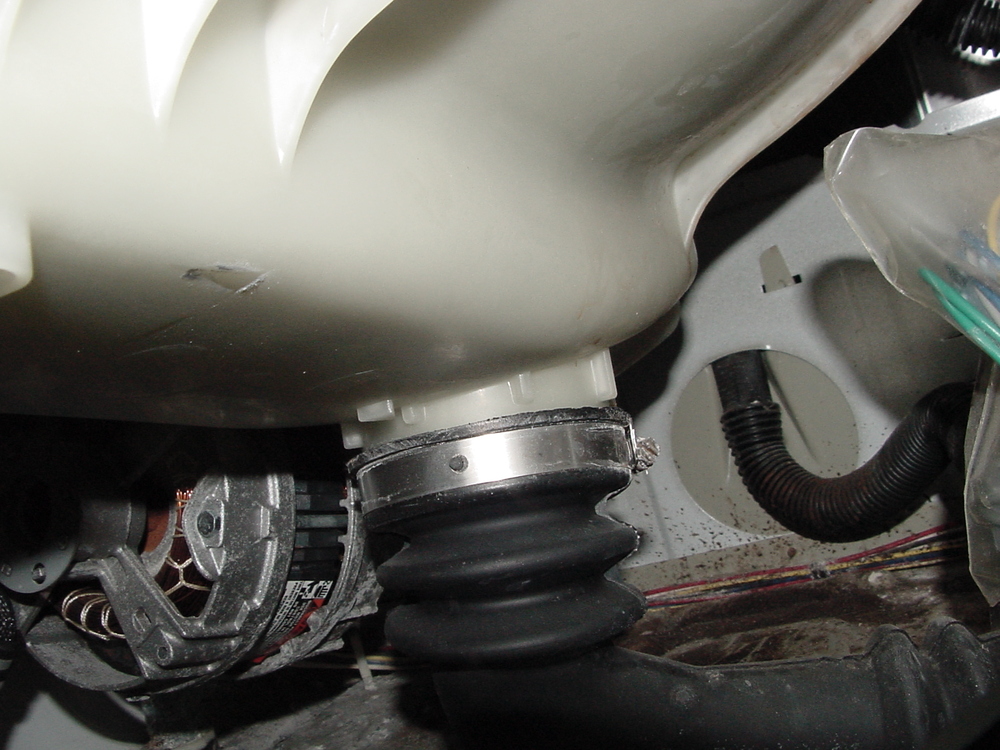

The front bottom of the outer tub can be removed by two bolts on each side->move it out of the way

| ||

| Post# 472493 , Reply# 20 10/30/2010 at 23:14 (4,920 days old) by supremewhirlpol () | ||

|

Remove the drain hose.

| ||

| Post# 472498 , Reply# 21 10/30/2010 at 23:21 (4,920 days old) by supremewhirlpol () | ||

|

Remove the harness to the motor from the control board.

| ||

| Post# 472499 , Reply# 22 10/30/2010 at 23:24 (4,920 days old) by supremewhirlpol () | ||

|

Remove the front of the outer drum->the front of the outer drum is held on by a series of small clips. Just remove the clips, do not remove the boot!!

| ||

| Post# 472500 , Reply# 23 10/30/2010 at 23:25 (4,920 days old) by supremewhirlpol () | ||

|

Here is what the clips look like.

| ||

| Post# 472503 , Reply# 24 10/30/2010 at 23:28 (4,920 days old) by supremewhirlpol () | ||

|

The front is also held to the frame of the machine by 4 bolts->remove those, carefully remove the outer tub front and boot.

| ||

| Post# 472504 , Reply# 25 10/30/2010 at 23:34 (4,920 days old) by supremewhirlpol () | ||

|

Remove the cylinder! To remove the cylinder, locate the three big baffles, each baffle if held to the cylinder by 2 torx screws. Remove the screws, and baffles.

| ||

| Post# 472505 , Reply# 26 10/30/2010 at 23:36 (4,920 days old) by supremewhirlpol () | ||

|

Removing the baffles exposes three bolts that hold the cylinder to the spider assembly.

| ||

| Post# 472508 , Reply# 27 10/30/2010 at 23:41 (4,920 days old) by supremewhirlpol () | ||

|

Remove the cylinder, remove the springs that hold the outer tub in place. CAREFULLY remove the outer tub-> lift up and forward. Remember that you have a motor that may or may not be open-framed, attached to the outer tub.

| ||

| Post# 472649 , Reply# 28 10/31/2010 at 19:24 (4,919 days old) by supremewhirlpol () | ||

|

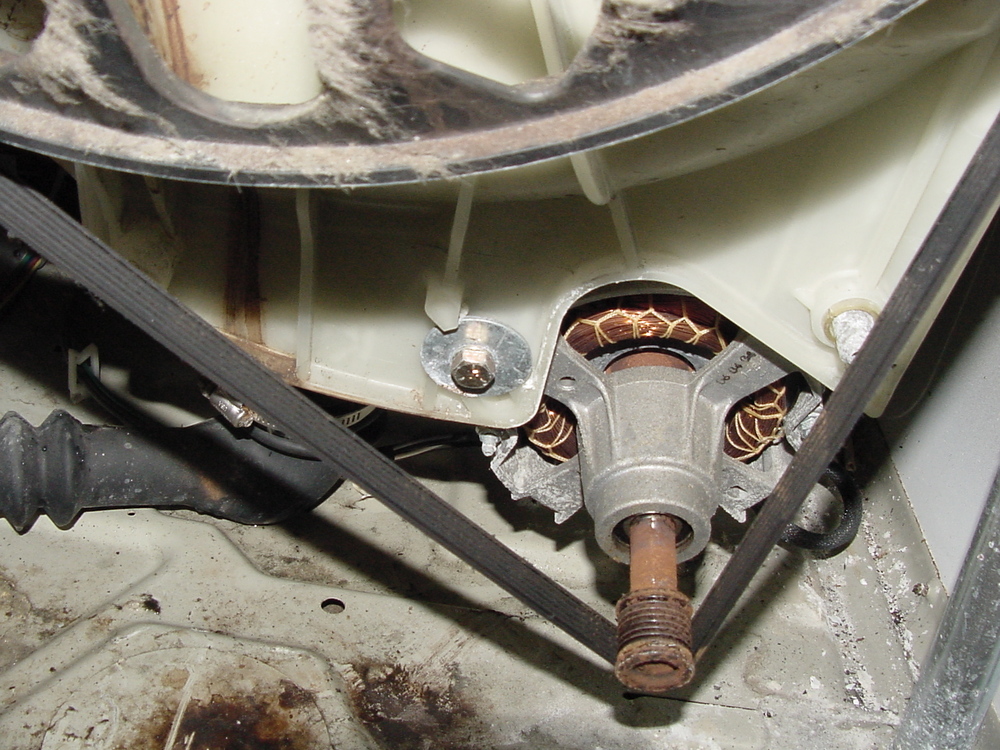

Remove the belt. It has multiple grooves, carefully slide the belt off the shaft of the motor. The motor is mounted by one bolt and a pivot arm. Remove the bolt, use a hammer to tap the top of the pivot arm->motor will slide out, be ready to catch it.

| ||

| Post# 472666 , Reply# 29 10/31/2010 at 20:23 (4,919 days old) by supremewhirlpol () | ||

|

One bolt holds the pulley into place->usually this bolt is on VERY tight.

| ||

| Post# 472670 , Reply# 30 10/31/2010 at 20:30 (4,919 days old) by supremewhirlpol () | ||

|

Remove the spider assembly->Screw the bolt back on to the shaft, use a hammer to release the spider assembly from the bearings. Hit ONLY the bolt, otherwise if you divert from the bolt, you WILL damage the shaft.

| ||

| Post# 472672 , Reply# 31 10/31/2010 at 20:35 (4,919 days old) by supremewhirlpol () | ||

|

Before hitting the shaft, place the outer tub on a blanket to protect the edges of the tub from being damaged from the force applied by the hammer. Spider-> After spider is removed, set it aside, along with the three plastic spacers.

| ||

| Post# 472673 , Reply# 32 10/31/2010 at 20:36 (4,919 days old) by supremewhirlpol () | ||

|

Top view of the spider and one of the spacers.

| ||

| Post# 472676 , Reply# 34 10/31/2010 at 20:49 (4,919 days old) by supremewhirlpol () | ||

|

The front bearing requires a bigger diameter pipe. In my case this bearing was the hardest to remove. It took ~30 minutes of solid pound to get it out. Here is the pipe afterward

| ||

| Post# 472677 , Reply# 35 10/31/2010 at 20:50 (4,919 days old) by supremewhirlpol () | ||

|

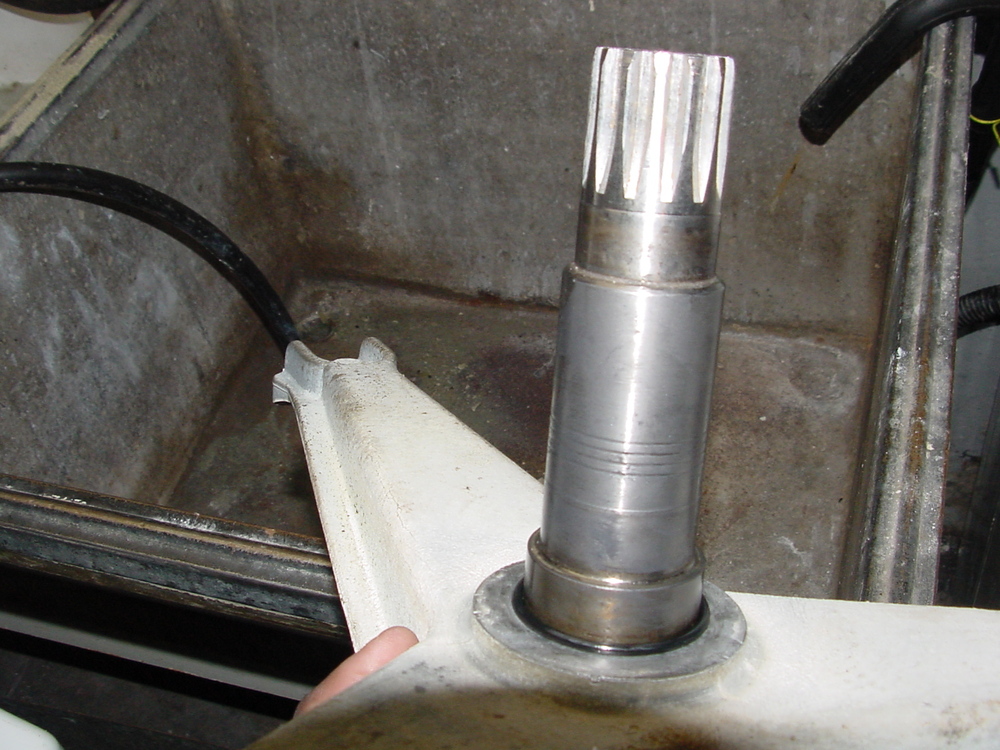

rear bearing and collar

| ||

| Post# 472678 , Reply# 36 10/31/2010 at 20:55 (4,919 days old) by supremewhirlpol () | ||

|

As you can see it is impossible to confuse which bearing goes where, or how far they have to go in. Also there is a weep hole for water run off

| ||

| Post# 472679 , Reply# 37 10/31/2010 at 20:57 (4,919 days old) by supremewhirlpol () | ||

|

Where rear bearing goes.

| ||

| Post# 472680 , Reply# 38 10/31/2010 at 20:59 (4,919 days old) by supremewhirlpol () | ||

|

Both bearings-> they do differ in size.

| ||

| Post# 473074 , Reply# 41 11/2/2010 at 19:38 (4,917 days old) by supremewhirlpol () | ||

|

Here is a picture of the new vs old bearings.

| ||

| Post# 473077 , Reply# 42 11/2/2010 at 19:42 (4,917 days old) by supremewhirlpol () | ||

|

Here is the collar, I cleaned it up a little, BUT again I don't want to change the bore sizes.

| ||

| Post# 473083 , Reply# 45 11/2/2010 at 20:02 (4,917 days old) by supremewhirlpol () | ||

|

New bearing inserted into rear of outer tub.

| ||

| Post# 473085 , Reply# 46 11/2/2010 at 20:07 (4,917 days old) by supremewhirlpol () | ||

|

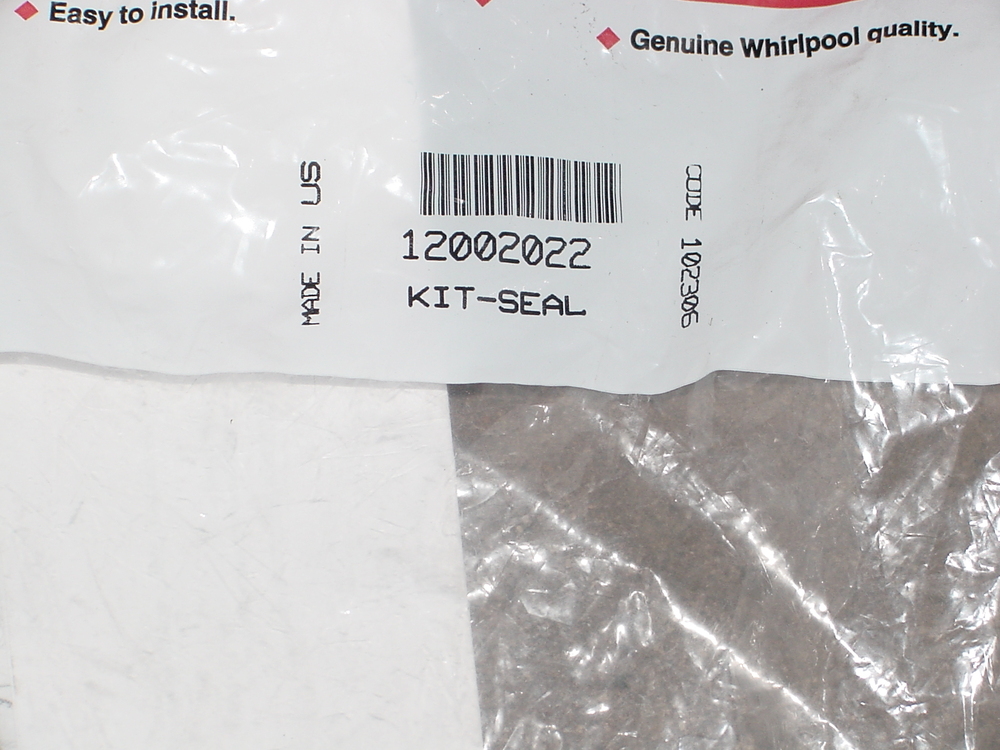

You want the 12002022 Seal kit from FSP. This kit has seals for both the new and old tub styles. The kit also has instructions.

| ||

| Post# 473087 , Reply# 48 11/2/2010 at 20:26 (4,917 days old) by supremewhirlpol () | ||

|

bearing spacer installed

| ||

| Post# 473088 , Reply# 49 11/2/2010 at 20:27 (4,917 days old) by supremewhirlpol () | ||

|

Old metal spacer coming off shaft.

| ||

| Post# 473089 , Reply# 50 11/2/2010 at 20:29 (4,917 days old) by supremewhirlpol () | ||

|

New seal being installed with provided tool.

| ||

| Post# 473090 , Reply# 51 11/2/2010 at 20:30 (4,917 days old) by supremewhirlpol () | ||

|

Seal installed

| ||

| Post# 473091 , Reply# 52 11/2/2010 at 20:32 (4,917 days old) by supremewhirlpol () | ||

|

Spider assembly shaft cleaned with new plastic ring seal.

| ||

| Post# 473092 , Reply# 53 11/2/2010 at 20:34 (4,917 days old) by supremewhirlpol () | ||

|

Shaft coming out the rear of the outer tub(shaft just inserted)

| ||

| Post# 473093 , Reply# 54 11/2/2010 at 20:37 (4,917 days old) by supremewhirlpol () | ||

|

Starting to put things back together-> it's best to install the motor while the tub is still out of the machine.

| ||

| Post# 473096 , Reply# 56 11/2/2010 at 20:47 (4,917 days old) by supremewhirlpol () | ||

|

plastic spacers

| ||

| Post# 473097 , Reply# 57 11/2/2010 at 20:50 (4,917 days old) by supremewhirlpol () | ||

|

Testing shows that the boot needs to be replaced.

| ||

| Post# 473098 , Reply# 58 11/2/2010 at 20:52 (4,917 days old) by supremewhirlpol () | ||

|

Test wash with items that got very dirty with repair

| ||

| Post# 473099 , Reply# 59 11/2/2010 at 20:55 (4,917 days old) by supremewhirlpol () | ||

|

Cycle complete-> no leaks from bearing area. Machine is very quiet. The only thing I hate about this machine is no window. There are still repairs that need to be made-> boot, paint, refinish area around dispenser.

| ||

| Post# 473101 , Reply# 60 11/2/2010 at 20:57 (4,917 days old) by supremewhirlpol () | ||

|

Commercial Neptune IN-> Calypso OUT!!!

| ||

| Post# 473115 , Reply# 61 11/2/2010 at 22:57 (4,917 days old) by cfz2882 (Belle Fourche,SD) | ||

|

thanks for all that!-i now know what i am in for if the bearings go in my neptune... I did do a bearing job on my '98 frigilux,was actually pretty easy job on the frigilux. | ||

| Post# 473227 , Reply# 62 11/3/2010 at 13:39 (4,916 days old) by Volvoguy87 (Cincinnati, OH) | ||

Thanks. | ||

| Post# 473243 , Reply# 63 11/3/2010 at 14:46 (4,916 days old) by vivalalavatrice () | ||

|

CLAPS CLAPS! to you! It's really a challange each times you have to replace bearings, but I see a very great job! BYE Diomede | ||

| Post# 473286 , Reply# 65 11/3/2010 at 20:09 (4,916 days old) by A440 () | ||

|

Awesome Job! You make it look so easy! | ||

Post# 473581 , Reply# 66 11/5/2010 at 19:50 (4,914 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Great walk through Supreme | ||

Post# 473693 , Reply# 67 11/6/2010 at 14:43 (4,913 days old) by yogitunes  (New Jersey) (New Jersey) |

||

Excellent job!

I have 2 neptunes, changed bearrings on both, first time, really took me a while, wasn't sure what I was geting into, so it took longer, second one went faster............ you really stripped off a lot more from your machine than I did I didn't take off the counter weights, or remove the inner tub from the spider, but yeah, getting those bearrings out was murder.....it went back together faster than I took it apart... I had to place the outter tub over 2 chairs, slide the inner tub with spider into place, and step inside with my full weight just to get it to seat onto the seal, even with a little vaseline, it fits tight..... so are you ready to do this again?

| ||

| Post# 477543 , Reply# 69 11/25/2010 at 20:38 (4,894 days old) by fordtech () | ||

|

Great job and thanks very much for taking the time to walk us through it. I plan to run my Neptunes 15 more years with lots of parts procured from Ebay in storage.

| ||

| Post# 477586 , Reply# 70 11/26/2010 at 01:18 (4,894 days old) by qsd-dan (West) | ||

|

| ||

| Post# 477602 , Reply# 71 11/26/2010 at 05:23 (4,893 days old) by fordtech () | ||

|

Thanks! I wouldn't trade them for anything on the market today. | ||

| Post# 478120 , Reply# 75 11/28/2010 at 15:21 (4,891 days old) by PeterH770 (Marietta, GA) | ||

| ||

| Post# 478315 , Reply# 78 11/29/2010 at 12:36 (4,890 days old) by fordtech () | ||

|

supremewhirlpol I found this pic of an old switched reluctance motor from the early Neptunes on Ebay... this is the one that Whirs when it runs. The new models are virtually silent.

| ||

| Post# 478484 , Reply# 80 11/30/2010 at 11:04 (4,889 days old) by PeterH770 (Marietta, GA) | ||

| ||

Comes to the Rescue!

Comes to the Rescue!