|

Thread Number: 32165

big Problems with Candy/Hoover in Germany |

[Down to Last] |

|

| Post# 485147 , Reply# 1 12/30/2010 at 03:14 (4,857 days old) by mielemondia757 () | ||

|

here an other candy this one was explode when a women was near the washer

| ||

| Post# 485148 , Reply# 2 12/30/2010 at 03:17 (4,857 days old) by mielemondia757 () | ||

|

This one is a Hoover Im sorry, I would pst it at deluxe, but i don´t know why I posting here...

| ||

| Post# 485149 , Reply# 3 12/30/2010 at 03:18 (4,857 days old) by mielemondia757 () | ||

|

OHBOY look at this... you see the motor there... realy small :D

| ||

| Post# 485162 , Reply# 4 12/30/2010 at 05:10 (4,857 days old) by SuperElectronic (London, UK) | ||

|

We've seen these pictures before - someone else posted them earlier in the year. Still a shocking state of affairs. Something about a faulty drum weld as I recall. What is the latest news as of now? Interesting to see inside the machines, albeit in their mangled state! | ||

| Post# 485163 , Reply# 5 12/30/2010 at 05:37 (4,857 days old) by solsburian (SE Northumberland) | ||

|

This is also starting to happen with some Indesit/Hotpoint machines as well. CLICK HERE TO GO TO solsburian's LINK | ||

| Post# 485187 , Reply# 7 12/30/2010 at 08:53 (4,857 days old) by nrones () | ||

|

@SuperElectronic Ofcourse there are no recent news about this.. Maybe nobody would know about it if it didn"t happend at Stiftung warenttest laboratory.. And don"t worry about your paren"ts OPH616 --- it"s not affected aswell as 100000"s Candy/Hoover washers. | ||

| Post# 485189 , Reply# 8 12/30/2010 at 09:19 (4,857 days old) by solsburian (SE Northumberland) | ||

|

Indesit/Hotpoint are apparently fitting securing braces to thier models that are at risk, this is supposed to fix the issue (that remains to be seen). What are Candy doing with their models that are at risk? | ||

| Post# 485191 , Reply# 9 12/30/2010 at 09:25 (4,857 days old) by nrones () | ||

|

Candy made a warning on their website, and anyone with Candy machine can call to check (even they know it"s only few affected machines). Checkup is compleatly free. But I think they stopped doing that, since probobly no case was reported, and months passed... | ||

| Post# 485194 , Reply# 10 12/30/2010 at 09:32 (4,857 days old) by solsburian (SE Northumberland) | ||

|

That's good, as far as I know Indesit only released information on their affected models via a tech bulletin that was then leaked. CLICK HERE TO GO TO solsburian's LINK | ||

| Post# 485239 , Reply# 12 12/30/2010 at 13:27 (4,857 days old) by 3beltwesty () | ||

|

another 201 stainless pdf another 201 stainless pdf CLICK HERE TO GO TO 3beltwesty's LINK | ||

| Post# 485270 , Reply# 13 12/30/2010 at 15:34 (4,857 days old) by solsburian (SE Northumberland) | ||

|

Coincidentally, Hotpoint have recently transitioned from using a screwed drum to the standard Indesit welded drum. | ||

| Post# 485271 , Reply# 14 12/30/2010 at 15:38 (4,857 days old) by nrones () | ||

|

Lol I know all about washing machines, except their built (well, I am rating it by experience). So I think this is a very basic question, but what is screwed, and what is welded drum? :P | ||

| Post# 485280 , Reply# 15 12/30/2010 at 16:15 (4,857 days old) by aegokocarat (United Kingdom) | ||

|

I used to own a candy nova dishwasher it was junk!!!. it never washed the dishes well and left particals on the plates and bowls it died in 2008 due to circut failiur and lo and behold i now have a zanussi zdf 131 essentials dishwasher. | ||

| Post# 485302 , Reply# 16 12/30/2010 at 17:05 (4,857 days old) by solsburian (SE Northumberland) | ||

|

@nrones: My mistake, I'm getting my terms mixed up, I believe the terms screw and welded refer to how the outer tub is assembled. The older Hotpoint drums have a different drum seam to the Candy and Indesit drums. I’m assuming that the seams could be a weak part in the drum and that could be what’s causing these problems. | ||

| Post# 485515 , Reply# 20 12/31/2010 at 16:00 (4,856 days old) by solsburian (SE Northumberland) | ||

|

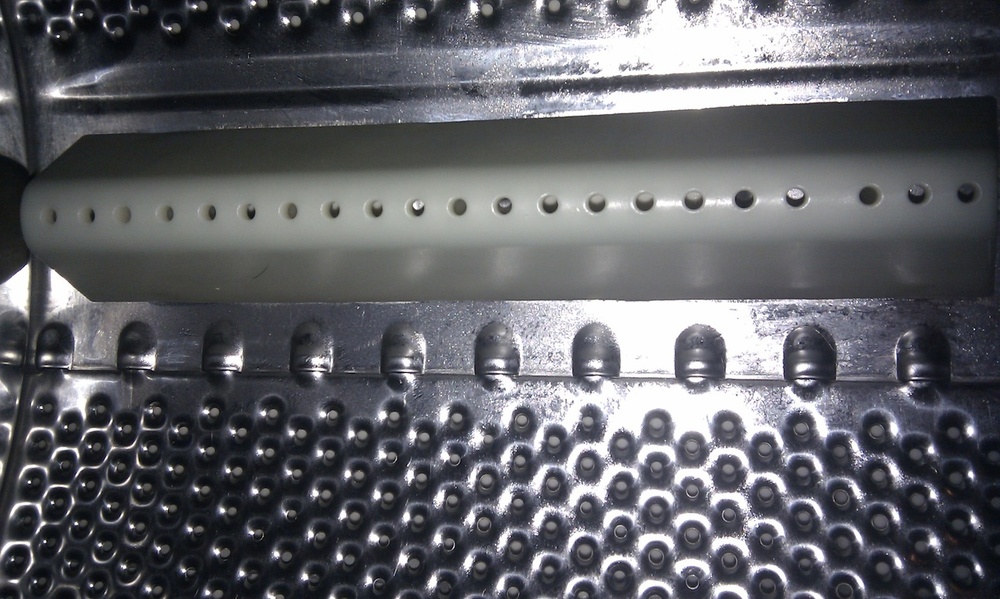

Just for a comparison, here is the drum seam from my parents Hotpoint WF541 that has the recently phased out Hotpoint drum:

| ||

| Post# 485516 , Reply# 21 12/31/2010 at 16:04 (4,856 days old) by solsburian (SE Northumberland) | ||

|

... and here is a pic of our Hoover's drum seam that will have the same kind of seam on the Hoover/Candy machines that exploded. I checked today and the Indesit drum now fitted to Hotpoints also has this kind of seam:

| ||

Comes to the Rescue!

Comes to the Rescue!