|

Thread Number: 32433

Hotpoint ultima WT761 - mainbearing replacement advice, please? |

[Down to Last] |

|

| Post# 489306 , Reply# 1 1/16/2011 at 10:37 (4,842 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622

Well first question is, is this a model with a removable tub front plate or is it a sealed 50/50 split tub, if itís a 50/50 you can not replace the bearings as it is impossible to part the halves.

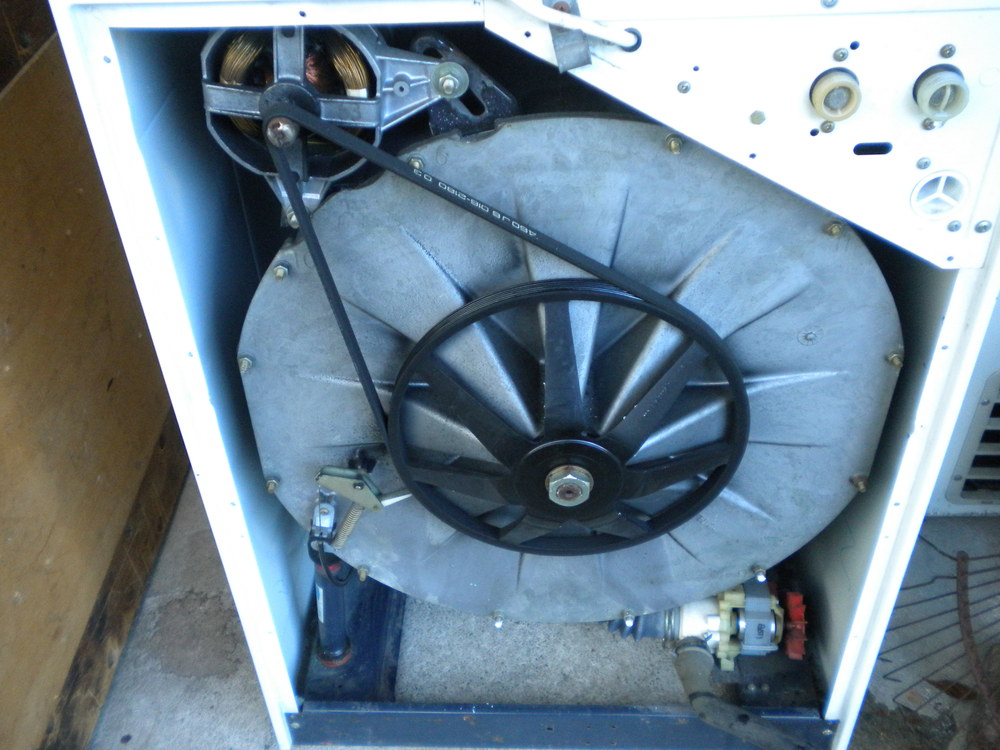

Photo of a WM63 with the tub front plate removed. Also a Link to a web site that may be of use and will make clear how the front of the tub can be removed if it has one. Lee CLICK HERE TO GO TO hotpoint95622's LINK

| ||

| Post# 489860 , Reply# 4 1/18/2011 at 13:35 (4,840 days old) by 3beltwesty () | ||

|

Here it do not come out in the first bull session The proper way is to have the washer vertical. I just do it via pushing down some; so the basket clears the washers frame CLICK HERE TO GO TO 3beltwesty's LINK | ||

| Post# 489898 , Reply# 6 1/18/2011 at 17:20 (4,840 days old) by 3beltwesty () | ||

|

2 bearings and seal 2 bearings and seal CLICK HERE TO GO TO 3beltwesty's LINK

| ||

| Post# 489905 , Reply# 8 1/18/2011 at 17:33 (4,840 days old) by 3beltwesty () | ||

|

nice kit of parts, but job still is massive Spider shaft bearings and seal kit CLICK HERE TO GO TO 3beltwesty's LINK | ||

| Post# 489906 , Reply# 9 1/18/2011 at 17:34 (4,840 days old) by 3beltwesty () | ||

|

Agreed, sometimes a tub half with bearings is required | ||

| Post# 490295 , Reply# 12 1/20/2011 at 03:20 (4,838 days old) by azimuth () | ||

|

Remains of the rear bearing - Few balls missing & a lot of corrosion... You can see the shaft has been sunk by about 1/4"

| ||

| Post# 490297 , Reply# 13 1/20/2011 at 03:23 (4,838 days old) by azimuth () | ||

|

Front view WT761, to compare to Lee's initial image - Hotpont WT761 - front view of reartub & basket, removed form machine.

| ||

| Post# 490372 , Reply# 14 1/20/2011 at 13:23 (4,838 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622

Massive job, me thinks thatís a bit of an underestimate, wow.

So much for new modern design, the very old Hotpointís like my Liberator 1851/03 from 1975 are easy, just remove twelve bolts from the back plate, pull from the tub and bobs your uncle, like wise with the later 18 series from late 70ís to early 80ís then to the 95 series from early 80ís to the 90ís with plastic tubs which have the front plate, just remove twelve spring clips, more tricky but still a lot easer than your WT761. It's all to make you buy a new machine!! Photo of the 1851/03

| ||

| Post# 490419 , Reply# 16 1/20/2011 at 17:18 (4,838 days old) by 3beltwesty () | ||

|

This design is sort of like Lees link were there is a tub fr With my machine the white "tub front" has a giant gasket, and the red clamp holds the yellow tub front to the black tub. The yellow piece's function is to hold several of the concrete weights

| ||

| Post# 490430 , Reply# 18 1/20/2011 at 17:47 (4,838 days old) by 3beltwesty () | ||

|

check the shaft If you reuse an old shaft on a basket or spider check it with a bearing. Any nick on the shaft can cause it to get hung and thus one is beating on the bearings to to a rebuild, not the greatest thing for a bearing

| ||

| Post# 496136 , Reply# 26 2/13/2011 at 08:39 (4,814 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

Comes to the Rescue!

Comes to the Rescue!