|

Thread Number: 34213

GE 7 cu ft electric dryer |

[Down to Last] |

|

Post# 514116 , Reply# 1 4/27/2011 at 07:44 (4,740 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

DRYER CONSTRUCTION QUALITY I am glad you like your new dryer but the construction and durability of your old dryer was much better than the GE dryers of the last 15 years or so. There is a gap all the way around the front of your new GE that gets bigger at the bottom half and starts staining clothes that get caught there, I just fixed one last week that was 9 years old and it is much more expensive and less satisfactory a repair than replacing the rear drum seal on a WP built dryer. | ||

Post# 514118 , Reply# 2 4/27/2011 at 07:56 (4,740 days old) by logixx  (Germany) (Germany) |

||

Euro vs. US | ||

Post# 514127 , Reply# 3 4/27/2011 at 09:12 (4,740 days old) by yogitunes  (New Jersey) (New Jersey) |

||

Don't kid yourself!!!.....you may not have the GAP that was seen in the rear of the Whirlpool.....but you'll have even more fun and damaged clothes from the gap at the front of your GE, just wait......mine started doing this in the first year, always grabbed a washcloth, sock, or button on jeans, and twisted the heck out of them until they ripped, you wouldn't notice it until the load was done and you opened the door......

NOT to mention, the rear is where the heat comes in, this back panel gets scorching HOT, a full load of towels or a blanket will melt from constant contact, best to stay with medium or low heat for almost all loads, and will take a little longer to dry....at least with your Whirlpool, the clothes slid along the stationary back panel, while a small built in ramp tossed the clothes away from the heat source..... ALSO, most Whirlpool/Kenmores had a soft heat feature dropping down the temp for minimizing wrinkles...an exclusive other manufacturers don't have | ||

Post# 514130 , Reply# 4 4/27/2011 at 09:23 (4,740 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

DRYER DRUMS  Many American dryer drums are one piece, the GE that we are talking about the only thing that doesn't revolve is the front of the machine and the door. The most successful and safest dryer designs have stationary fronts and or back areas. All MTs after 1976, all WP built after 1966, all Nogre built after 1980, all Speed Queen home and commercial after 1980. Having stationary areas where the heat enters the drum, this allows better clothing protection from excessive heat of having the whole rear of the drum become super heated. It is also a less expensive way to build a dryer which is one of many reasons that 80+% of US homes have and use dryers. US dryers are by far and away the best in the world. | ||

| Post# 514213 , Reply# 5 4/27/2011 at 17:51 (4,740 days old) by the7 () | ||

|

Dear yogitunes Could you tell me the model no of your 1 year old GE dryer? Dear combo52 Could you remember the model no of the 9 year old dryer? | ||

| Post# 514217 , Reply# 6 4/27/2011 at 18:04 (4,740 days old) by the7 () | ||

|

Please note my GE is of the new style (not of old style from Frigidaire). See diagram attached.

| ||

Post# 514232 , Reply# 7 4/27/2011 at 19:13 (4,740 days old) by dadoes  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

That is not a "new" design. I have a 1999 GE/Camco-sourced F&P DE04 dryer that looks exactly the same, and a GE DS4500EB0WW manuf'd 2002 per the S/N. The GE I got for free, and refurbished it with $210 in parts -- front drum support & bearings, rear bearing sleeve, inner door panel, heating element, front air duct/filter housing, idler pulley. | ||

| Post# 514236 , Reply# 8 4/27/2011 at 19:31 (4,740 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

Just bought yesterday,

New Kenmore Dryer.

7.0 cu ft. Capacity, around $400.00. Love it. Runs Great, on every Cycle. Great Daily Driver which I needed going into the summer. Model # 110.61202010. Just does it all without spending $800.00 +. I just can't see spending that kind of money on a dryer. It's Perfect for my needs. What's up with these $1000.00 plus dryers ? Just need dry clothes. | ||

Post# 514326 , Reply# 9 4/28/2011 at 05:45 (4,739 days old) by Tomturbomatic  (Beltsville, MD) (Beltsville, MD) |

||

|

I wonder if part of the inflated price for dryers is the cabinet changes they are making to keep the dryers matching all of the variations in the fronts of the new FL washers. American-made dryers would go decades in some cases with only minor trim changes to the front panel. | ||

Post# 514343 , Reply# 10 4/28/2011 at 07:54 (4,739 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

PRICES OF NEW DRYERS I think that there are several factors that are allowing the price of new dryers to equal that of the matching dryer. 1 People are so used to having a dryer that they are willing to pay the price. 2 People wrongly assume that a new dryer will work better and be more energy efficient. 3 the energy-star washers are being subsidized by the goverment, state, utilities which makes them cheaper than they would otherwise be. 4 The building and assembly of the new washer designs that have come out is very automated compared to the building and assembly of clothes dryers. 5 The manufactories are making more money on the sale of dryers than washers which is way they are being pushed in pairs. I am sure that they would love to sell you a new stove to go with that new washer and dryer LOl. In many cases it will be cheaper and work better to keep your old dryer or buy a more sensible rear control machine than buying one that matches the new washer. Many new dryers are actually smaller inside than the older wider machines and a larger diameter drum seems to work better than the deeper ones in the newer 27" machines.

| ||

| Post# 514381 , Reply# 11 4/28/2011 at 12:06 (4,739 days old) by the7 () | ||

|

Thanks combo52 for the valuable info. It seems there are two heating elements in the GE 7 cu ft dryer. Wonder if you know the wattage of them and why it uses two instead of one? | ||

Post# 514666 , Reply# 13 4/29/2011 at 20:12 (4,738 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

| ||

| Post# 514887 , Reply# 14 5/1/2011 at 09:26 (4,736 days old) by the7 () | ||

|

After using the new dryer for several days, my wife is quite happy with the new dryer because the clothing dried from the new dryer are softer than from the old dryer. | ||

| Post# 516898 , Reply# 17 5/10/2011 at 19:03 (4,727 days old) by the7 () | ||

|

The sensor in the lint tray.

| ||

| Post# 516900 , Reply# 18 5/10/2011 at 19:05 (4,727 days old) by the7 () | ||

|

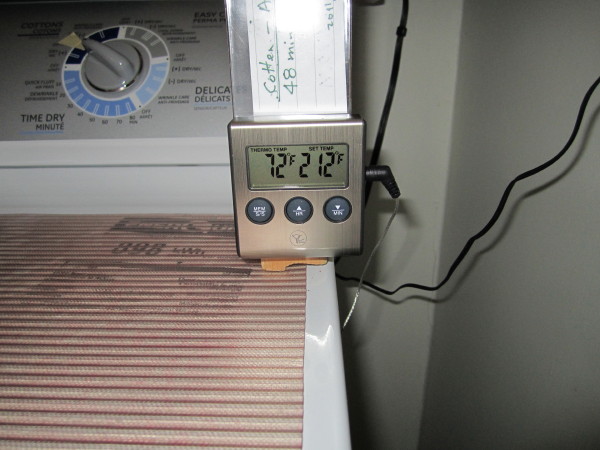

The digital thermostat.

| ||

| Post# 516904 , Reply# 19 5/10/2011 at 19:09 (4,727 days old) by the7 () | ||

|

It should be a digital thermometer. | ||

Post# 516908 , Reply# 20 5/10/2011 at 19:28 (4,727 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

NEW GE DRYER During periods A & B one heater should not be cutting on and off at such a low outlet temperature, you likely have too long an exhaust system or other problem with the exhaust system. If you want to get the best life and performance out of this dryer make sure your exhaust installation meets GEs recommendations in every way, A bad exhaust system likely contributed to the problem with rusting rear seals on the old KM dryer. | ||

| Post# 516927 , Reply# 21 5/10/2011 at 21:02 (4,727 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

New Kenmore Dryer.

Well, I've had it for a couple of weeks now, and after 7 loads of Laundry of all types, It Ranks with me as one of the Best Dryers I've ever owned. 40-50 minutes tops per load. Heavy Bath mats... 50 minutes. Cotton anything, 40 minutes.

Just love it, and still can't see spending 900+ for a Dryer. Just Old Fasion here. (And getting Older). | ||

Post# 516931 , Reply# 22 5/10/2011 at 21:10 (4,727 days old) by coldspot66  (Plymouth, Mass) (Plymouth, Mass) |

||

|

Like I've always said, W/P Kenmore 29" dryers are the best at any $$$. Eddie, that model has a moisture sensor, do you use the moisture sensing cycle? There is a small circuit board in the console for moisture sensing. | ||

Post# 516955 , Reply# 23 5/10/2011 at 22:37 (4,727 days old) by syndets2000  (Nanjemoy, MD) (Nanjemoy, MD) |

||

|

moisture sensor... ...setting is what I use on the WP (I found behind a store some years ago), during the winter- I line dry during the summer, its only for two people- | ||

| Post# 516960 , Reply# 24 5/10/2011 at 23:32 (4,727 days old) by the7 () | ||

|

combo52 Thanks for the advice. Will check the venting against the requirement. | ||

| Post# 516984 , Reply# 26 5/11/2011 at 06:01 (4,726 days old) by aquarius1984 (Planet earth) | ||

US dryers are by far and away the best in the world.

Combo52 thats quite a statement - you must of used hundreds of dryers in your vacations out of America!

When did you visit the UK and how did your find your trip here? If it was recent you should have spoken up and you could of come to play with our collection. More than welcome anytime to though if you plan a return journey. Just curious as to how you found the British made machines that you have used and where you felt their downfall was? | ||

| Post# 516989 , Reply# 27 5/11/2011 at 06:27 (4,726 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

Moisture Sensor. | ||

Post# 517008 , Reply# 28 5/11/2011 at 08:08 (4,726 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

US VS EUROPEAN DRYERS Hi Robert I would love to visit sometime and we hope you get a chance to come here also. I am basing my claims of superiority of US built dryers from my experience of repairing and selling laundry appliances for over 35 years here in the Washington D C area. This being an international city I have had quite a few opportunities to get my hands on European and other imported dryers over the years and in almost ever case I have ended up selling them for almost nothing , giving them away or usually just scraping them.

Whats different in a nutshell 1 they are only about 1/2 half the size in drum capacity [ not a enough room for loads of 10 pair of mens jeans or king size comforters]. 2 They are seldom more than 3000 watts [ slow ] 3 Gas dryers are almost unheard of [ too large a carbon foot print from thier use ] 4 They are very difficult to work on [ not designed for longevity ] 5 They are often noisey 5 The blowers are not powerful enough to exhaust air through 15-30 feet of exhaust pipe without clogging quickly.

Almost all US dryers are also used in commercial applications, I would love to see how many of the European 24" machines are sold with a coin box on them. | ||

Post# 517014 , Reply# 30 5/11/2011 at 08:46 (4,726 days old) by ozzie908  (Lincoln UK) (Lincoln UK) |

||

US VS EUROPEAN DRYERS

Having used the majority of dryers available in the UK including commercial gas ones I have for my personal use a Whirlpool dryer made in the USA its 240 13amp 3kw and is the best dryer ever it beats all uk ones including 7kg condenser its quick and due to its size is excellant at drying anything including king size duvets its only down side is its dimensions make it hard to fit in most kitchens luckily I have an unused airing cupboard that it fits in its exhausted through the roof. I hope I can always find space for it as I would hate to lose it now... and the best bit it was only £5.00 as it had a blown internal fuse.

| ||

| Post# 517109 , Reply# 33 5/11/2011 at 20:13 (4,726 days old) by the7 () | ||

|

US VS EUROPEAN DRYERS I would say that US dryers are optimally designed for NA market in terms of simplicity and easy of maintenance and low cost and relatively large capacity. | ||

| Post# 517218 , Reply# 34 5/12/2011 at 12:10 (4,725 days old) by the7 () | ||

|

New 4" hood on the left. Old 2.5" hood on the right. New hood was installed to replace the old hood yesterday. There is less restriction of air-flow using the new hood. I will try to find out if there is any improvement in drying time.

| ||

| Post# 517259 , Reply# 36 5/12/2011 at 17:13 (4,725 days old) by the7 () | ||

|

XXX 4)The temperature variation at the outlet is about 20F (say 133F to 154F) with the Control Inlet Thermostat in active mode. XXX should read 4)The temperature variation at the outlet is about 20F (say 133F to 154F) with the Drum Outlet Thermostat in active mode. | ||

Post# 517273 , Reply# 37 5/12/2011 at 18:50 (4,725 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

NEW GE ELECTRIC DRYER How long is your vent system and how many elbows are in it? The cycling of one heater so early in the drying cycle does not seem correct. This is one of the major reasons that I have never liked dryers that have the heater elements right behind or right in front of the dryers drum. GE is cycling one heater with the inlet thermostat to keep the rear drum temperature lower to prevent scorching clothing and dryer fires. It would be interesting to try drying a load with the vent disconnected and see if the one heater cycles so early in the drying cycle.

Only GE and Frigidare still put the heaters so close to the clothes load and as a result they have to use very sensitive thromostats to prevent the above mentioned problems with clothing damage and fires. Too make matters worse both GE and Frigidare dryers have small lint filters and if you are drying a very linty load it can get quite restricted during one load.

MT discontinued this poor placement of the heater element in 1976 when they finely discontinued the HOH dryer and Frigidare got rid of this problem when they introduced the 1-18 dryers in 1970. Even European dryers separate the heater element from the clothes by placing it in a metal box away from the drum. The heater element in an electric dryer easily hits 1600 degrees or more hotter than the flame in a gas dryer.

On a full sized WP built electric dryer the heater will not cycle even once until the exhaust or blower housing thermostat is satisfied. This is one of the many problems with Consumer Reports as they rate these GE dryers highly but they are tested under perfect conditions, they even rated the worst dryer on the market in north America the Frigidare as a best buy a few years ago. Thier engineers should come on service calls with me for one week and see all the burned up heaters and rear drum bearings in GE and Frigidare dryers that we see. | ||

| Post# 517277 , Reply# 38 5/12/2011 at 19:19 (4,725 days old) by the7 () | ||

|

How long is your vent system and how many elbows are in it? The length of the flexible aluminum is about 3ft. I estimated the length of the rigid metal is about 8 ft. The effective no of elbows could be 4. This seems to be within the recommendation for the GE dryer. | ||

Post# 517534 , Reply# 42 5/13/2011 at 18:24 (4,724 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

WP 29" & 27" ELECTRIC DRYERS Most WP 29" and all 27" dryers do not tapper the inlet heat entering the drum, however some electronically controlled 29" dryers have dual heaters and some also have a thermistor on the heater box that controls the inlet temperature for low temperature loads and to save a small amount of energy on certain control settings.

The inlet temperature can be far higher on a WP or other stationary bulk head dryers because the clothing is never in constant contact with the inlet area. The clothing is always quickly passing the inlet. On revolving back dryer drums, including the European models with a separate box the entire rear of the drum can get very hot. This is more likely to happen when the load is very large, the exhaust is too long or otherwise restricted or when very linty items are being dried and the filter clogs during the cycle. | ||

| Post# 517600 , Reply# 43 5/14/2011 at 01:04 (4,724 days old) by the7 () | ||

|

Thanks combo52 for the valuable info from your experience. | ||

Comes to the Rescue!

Comes to the Rescue!