|

Thread Number: 34338

RCA Whirlpool Spin, 1959-60 |

[Down to Last] |

Post# 515395 5/3/2011 at 08:31 (4,740 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

My machine is all back together, agitation is fine, basket turns with slight drag by hand, spin is only OK with no load, entirely stops with clothes in basket. Spintube looked like it ran perfectly before I installed the basket. I can help push it a bit, but slows back to an almost complete stop. The repair manual said to back off on the gearcase 3 bolts by 2 turns, it barely made a difference. Should i check for oil on the brake pads? Isn't there a toothed bushing that rises up to meet the spin tube? I thought spin was relatively an engaged action due to the teeth, more than a disk-friction action. Where do I look next?

Other than that, no moer leaks anywhere after the new seals and bearings and tub gasket and new tub bolts, transmission leak seems sealed up and 90 weight oil inside. I was liberal with oil in the center post, did I overdo and get some on friction pads? This post was last edited 05/03/2011 at 08:49 | ||

|

Post# 515472 , Reply# 1 5/3/2011 at 16:06 (4,740 days old) by dadoes  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

| ||

Post# 515474 , Reply# 2 5/3/2011 at 16:14 (4,740 days old) by KenmoreGuy64  (Charlotte, NC) (Charlotte, NC) |

||

Mark -

While I am certain that Combo-John will have something to add to this, here are my thoughts: First, you have 90-weight oil in the transmission? Whirlpool standard oil was 60-weight. In the automotive world, engines experience something called "pumping losses" when heavy oil is used, which robs horsepower, efficiency, and performance. I would not have put something so heavy in there as it could be dragging the entire system, but to what degree I can only speculate. Use only 15 ounces. Too much may be a hindrance as well. This is probably only contributing to your problem; I would be surprised if it explains all of it. If not using spec. Whirlpool FSP gearcase oil, I would use 50 or 60 weight automotive racing oil (light on the detergent). Last I checked, Valvoline had these available at Auto Zone. The only thing I can think of when you say "toothed bushing that rises up to meet the spin tube" is the set-screw that marries the clutch and pads to the spin tube. This set-screw can cause a major decline in spin performance if it is not engaged properly with the spin tube. In fact, it was almost the death of our 1974 Kenmore when the set screw backed out, causing the clutch to slip on the spin tube. Spin performance did exactly what you describe. First the machine would not spin at full speed. When it wore further, it would not accelerate unless given a hand assist, then not at all. Check to be sure the set-screw is flush with the outer rim of the brake drum. If it is not, it is not fully engaged. The best way to tell is to look down into the spin tube and see the set-screw peeking out of the hole from the inside. I have found the best way to ensure proper installation of the set-screw is to compress the brake with C-clamps or a vice attached between the brake drum and the lower rim of the spin tube. Another possibility is a mis-aligned spin-tube in the bearings. This can be installed in a bind, and spin performance will suffer. In these cases, obvious drag on the belt can be seen, which slows the belt sometimes to a crawl. To relieve a bearing bind, take the tension off the belt and lower the three trans bolts at least a half-inch or so. Remove the basket and agitator so nothing is putting weight on the agitator shaft or spin tube, and giggle the transmission and/or baseplate side to side and push up and down on the transmission. I try to do this with the machine sitting upright. It's a bit awkward, but I think it works best vs. the machine being on it's side. When re-tightening the bolts, do so using a gradual star pattern like you're tightening a car rim. Do not tighten any of them all at once, as this will also create a bind. Also, examine the basket drive. It shouldn't have oil on the drive surface of the pulley, or on the clutch pads. If they are dry, you don't have a slipping problem due to oil. If they are not dry, you should try to ascertain why. As I said, there may be more to comment on here, but this is where I would start if given your situation. Out of curiosity, what does the belt-speed do when the machine is supposed to be / or is trying to spin? Gordon | ||

| Post# 515483 , Reply# 3 5/3/2011 at 17:08 (4,740 days old) by supremewhirlpol () | ||

|

Well that's interesting, my blue machine is doing this too. I thought it was the spin tube that was bad, but maybe not. | ||

Post# 515720 , Reply# 4 5/4/2011 at 22:23 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

Fixed

Gordon-----Thank you! Originally, I had tightened the 3 gearcase bolts while it was on its side, stupid thing to do. I left her upright now, loosened all 3 by 1/2 inch, loosened belt, shoook like hell and spun the agitator shaft, shook like hell, spun the tub, etc, tightened everything back up in proper rotation and slowly, and now she gets up to spin speed in under 30 seconds with a medium load of clothes, cool and thanks. I got a close-up look at all the brake disks/spin tube items, no oil or grease, fortunately. And now I know what you mean by the set screw in the brake cylinder, but I never touched it during dis-assembly, since spin and brake had never before been a problem. It seems to have just been a poorly aligned installation(by me, first timer) of the entire gearcase, and your trick solved it 100%.

I've run about a dozen loads, always great spin speed. As to the gearcase oil----I very much appreciate everyone's advice, believe me, and I think I got 2 folks telling me 60 weight, 3 folks saying that an ancient tranny should probably be re-filled with 75 to 90 weight. So for now it's an 80-90 blend, no leaks, no knocking, excellent agitation and spin. If I did something just horribly wrong, please advise, but I also have a line on 2 replacement 70's transmissions if I need one, Combo John says they're more robust than the 1960. | ||

Post# 515723 , Reply# 5 5/4/2011 at 22:27 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

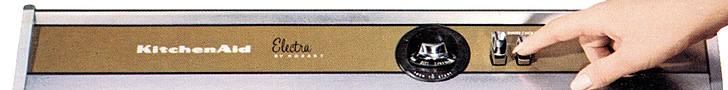

various pics as I went along | ||

Post# 515725 , Reply# 6 5/4/2011 at 22:28 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

various pics as I went along | ||

Post# 515726 , Reply# 7 5/4/2011 at 22:30 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

various pics as I went along | ||

Post# 515727 , Reply# 8 5/4/2011 at 22:31 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

4 | ||

Post# 515728 , Reply# 9 5/4/2011 at 22:32 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

5 | ||

Post# 515729 , Reply# 10 5/4/2011 at 22:33 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

6 | ||

Post# 515730 , Reply# 11 5/4/2011 at 22:36 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

more again | ||

Post# 515731 , Reply# 12 5/4/2011 at 22:38 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

more | ||

Post# 515732 , Reply# 13 5/4/2011 at 22:39 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

more again | ||

Post# 515733 , Reply# 14 5/4/2011 at 22:41 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

more again | ||

Post# 515734 , Reply# 15 5/4/2011 at 22:42 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

more paint | ||

Post# 515735 , Reply# 16 5/4/2011 at 22:43 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

more paint | ||

Post# 515736 , Reply# 17 5/4/2011 at 22:45 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

more again | ||

Post# 515737 , Reply# 18 5/4/2011 at 22:48 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

more

Finally! Thanks to Combo52, BendixMark, Yogitunes, Kenmore guy, Volvoguy, and Larry at Modern Parts in Parma OH.

I left various appliance store/repair stickers on for the hell of it, and didn't wipe that finger smudge before the photo shoot, sorry. If I forgot anyone, thank you too, plenty of helpers on this website. This Whirlpool Imperial Mark XII is from the Year of my birth, has my name in it, and so it automatically becomes my favorite!

| ||

Post# 515742 , Reply# 19 5/4/2011 at 23:34 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

video

here's 3 Youtubes of my machine.

Anyone give me advice on how to dirctly embed stuff into these threads? CLICK HERE TO GO TO akronman's LINK | ||

Post# 515743 , Reply# 20 5/4/2011 at 23:36 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

more video

neutral drain and then spin, to prove that everyone's advice on how to install/align the gearcase/agitator shaft was correct.

CLICK HERE TO GO TO akronman's LINK | ||

Post# 515744 , Reply# 21 5/4/2011 at 23:38 (4,739 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

final video

before restoration. Washed well, leaked well, both water and tranny oil

CLICK HERE TO GO TO akronman's LINK | ||

Post# 515781 , Reply# 22 5/5/2011 at 07:35 (4,738 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Whirlpool MARK 12 washer WOW Mark you got it running and it looks great anytime you want to come out we have a couple dozen BD WPs that you can further hone your rebuilding skills on. As you found out the 90 weight oil will work just fine and is really a better choice in an older gear case that had the extra wear from having been run with water in it. Now we just have to find you the matching MARK 12 gas dryer. | ||

| Post# 515825 , Reply# 23 5/5/2011 at 12:33 (4,738 days old) by cornutt (Huntsville, AL USA) | ||

|

Are you going to do the suds conversion? | ||

Post# 515831 , Reply# 24 5/5/2011 at 13:08 (4,738 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

suds

I'm not yet sure I'll do a full suds conversion. This machine has a SUDS button spaceholder in the pushbuttons, while I was cleaning the timer I saw how to easily activate it, and on this machine with no real suds components, it simply gives me a dry agitation, about 2 minutes. But that's all I need to suck the suds back, as long as I remember during the cycles to swap the drain hose from a stopped-up tub to a drain pipe at the right time. I may decide that's good enough for me, since the valve is $80 and I don't know I ever want to get into the timer to install additioanl wiring, etc.

I had to install water-level kill switches in my Maytag and filter-Flo to get a dry agitate, and then they also suck back water, so all my machines are cheap and easy versions of suds savers, not the fully automatic real thing. On this one, being the oldest and rarest of my collection, I may just decide that getting the SUDS button to give me a 2 minute dry agitate is good enough, I can swap around the drain hose from here to there easily enough. | ||

Post# 515835 , Reply# 25 5/5/2011 at 13:27 (4,738 days old) by yogitunes  (New Jersey) (New Jersey) |

||

Mark....one good turn deserves another........I figured out the GE with the water flume, but was having trouble getting my Whirlpool to spray the water into the tub and not behind it...and was trying everything I could think of.....and then I saw your trick....I am gonna try it....many thanks!

Your machine looks great.....as close to custom made for you as possible...congrats!...... | ||

Comes to the Rescue!

Comes to the Rescue!