|

Thread Number: 36756

Whirlpool la9800T |

[Down to Last] |

| Post# 546888 10/2/2011 at 09:10 (4,588 days old) by mulligan () | ||

|

There is a problem with our washing machine the water fils in the tub but it never start to wash the clothes, or spin | ||

|

Post# 546892 , Reply# 1 10/2/2011 at 09:46 (4,588 days old) by Tomturbomatic  (Beltsville, MD) (Beltsville, MD) |

||

|

Is the motor running? If so, you might have a broken drive coupler between the motor and the transmission. | ||

Post# 546962 , Reply# 3 10/2/2011 at 19:23 (4,587 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

WP BUILT WASHER DRIVE CUPPLINGS The drive cupeling is there to stop transmission of the motor vibration to the rest of the machine and make for any slight misalignment between the motor and transmission shafts. It does not in any protect the motor or the transmission from any damage from overloading. These are very strong commercial style washers and you can wash anything that can be easily put in this machine as long as it can circulate when washing without any harm. These drive couplings do ware out eventually and will need replacement. | ||

Post# 547294 , Reply# 5 10/3/2011 at 19:32 (4,586 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

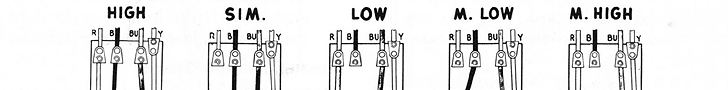

WP BUILT WASHER DRIVE CUPPLINGS | ||

| Post# 547421 , Reply# 7 10/4/2011 at 11:47 (4,586 days old) by whirlcool (Just North Of Houston, Texas) | ||

|

The rubber coupler breaks or shears to prevent any more damage. Thank you..that's pretty much what I've been told and thought too. If it wasn't there to prevent further damage why did they put it there in the first place? Why didn't they just bolt the motor directly to the transmission with a metal gear or shaft? | ||

Post# 547590 , Reply# 9 10/5/2011 at 11:17 (4,585 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

WP BUILT WASHER DRIVE CUPPLINGS Hi Allen go back and read post #3, that is why they did not just bolt the motor to the transmission.

Hi Rex I have never seen any washer or dryer that has any parts in it that are designed to break if the machine is overloaded. We are not talking about movie projectors.

WP DD washers are even used in commercial installations and they use the same transmission and motors and an even stronger drive cupping and yet transmissions and motors usually last more than 10 years in these installations where they are constantly overloaded.

Imagine if the DC was actually designed to break if the washer was overloaded. When people bought thier new WP super capacity washers they would want to try them out with a big load while they are still under warranty. And WP would end up with the warranty repair bill, yet I have never seen a DC break under first year warranty. If it was actually designed to break they would add a disclaimer in the warranty and not cover this type of repair, It might also say something in the repair manuals that this part is designed to break. [ it doesn't ]

DCs like belts and other parts of machines do ware and weaken over time and yes a severe overload can break a weak DC or belt. But it would have soon broken anyway. I always love how our customers like to blame themselves for any thing that ever breaks. Often when I replace a bake element in an electric oven I here oh I must have left something boil over or I must have gotten oven cleaner on it, just nonsense LOL.. | ||

Comes to the Rescue!

Comes to the Rescue!