|

Thread Number: 38155

Replacing bearings on Whirlpool WFW9600 |

[Down to Last] |

|

| Post# 566605 , Reply# 1 1/3/2012 at 03:14 (4,495 days old) by qualin (Canada) | ||

|

I found that video very informative. Thanks for posting the link. I can't believe how filthy the inside of the outer tub was on that machine in the video.. | ||

Post# 566632 , Reply# 4 1/3/2012 at 07:10 (4,495 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

DreamSpace

Whats the cost of the official spares from Whirlpool as opposed to the non genuine??

I would be wary of doing all that work just in case the sealant gave away easily later, At least on the larger machines they come apart for repairs easily, I like the cross braces at the back, and the fact that the top back brace swings out of the away with everything attached, though with everything doing it real world always offers other challenges...LOl | ||

Post# 567084 , Reply# 8 1/5/2012 at 07:35 (4,493 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

WP DUET BEARING CHANGE Hi Matt I am carefully watching your rebuild of this machine and excited to see you succeed as this is a repair that many people will try to undertake in coming years. I think that it is very CRAPPY of WP not to sell the bearings or at least the water seal for thier machine, this type of customer support is catching up with them.

Yesterday I just heard from my WP authorized parts distributor that WP DOUBLED the price of many of the replacement circuit boards used on thier washers, dryers, DWs and range products. It will now in many cases cost the customer around $400.00 just for one part for machines that are less than 10 years old.

Anyway back to your rebuild, Be very sure that the area on the shaft where the seal rides is in excellent condition with no groves or corrosion or the replacement seal may not last long and water will get into the bearings again. We are all excited to see the results Good Luck. | ||

Post# 567097 , Reply# 9 1/5/2012 at 09:12 (4,493 days old) by MattL  (Flushing, MI) (Flushing, MI) |

||

|

Thanks for the encouragement, am trying to do a little pictorial to go along with this post, just waiting for the parts to arrive. Outside of getting the parts it really seems to be a relatively easy fix. | ||

Post# 568411 , Reply# 10 1/11/2012 at 00:51 (4,487 days old) by MattL  (Flushing, MI) (Flushing, MI) |

||

|

Well the parts showed up Monday, but had out of town company so I tore into the project today. I bought sealed Japanese bearings and the seal from the You tube guy. The seal has CHO- 03283 TC 50 100 10 stamped on it. It has a solid metal underbody unlike the one it's replacing. here is a shot of the new set:

| ||

Post# 568412 , Reply# 11 1/11/2012 at 00:51 (4,487 days old) by MattL  (Flushing, MI) (Flushing, MI) |

||

|

New seal underside :

| ||

Post# 568413 , Reply# 12 1/11/2012 at 00:52 (4,487 days old) by MattL  (Flushing, MI) (Flushing, MI) |

||

|

Here are some pics of the tear down:

| ||

Post# 568414 , Reply# 13 1/11/2012 at 00:53 (4,487 days old) by MattL  (Flushing, MI) (Flushing, MI) |

||

|

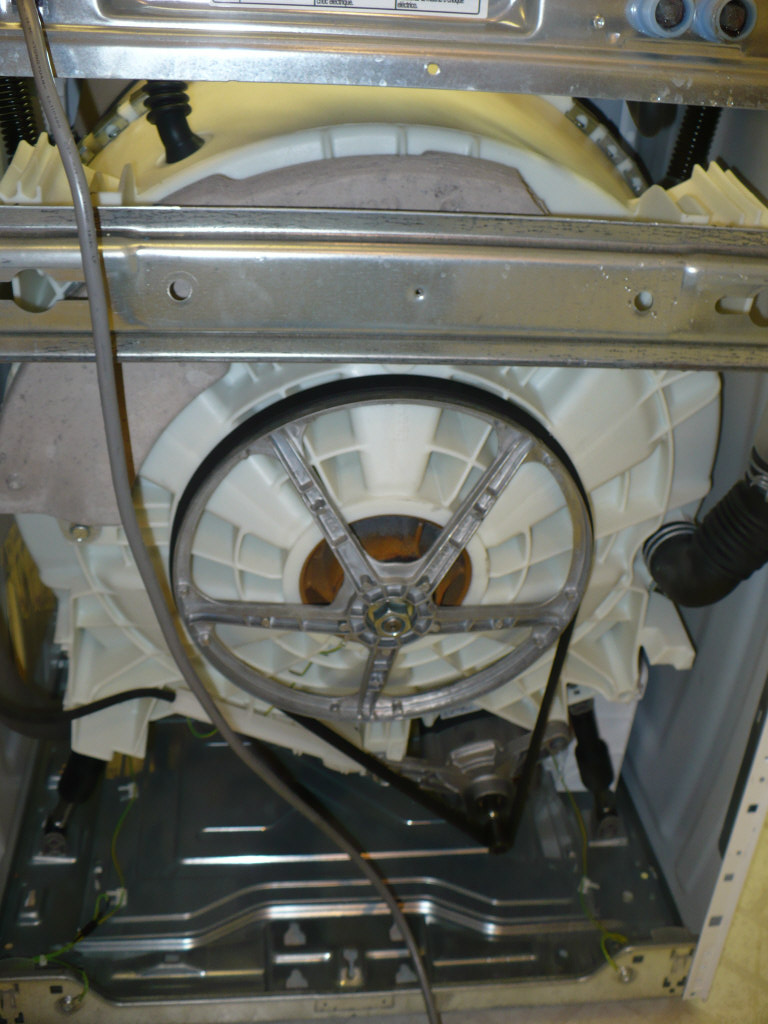

Apart:

| ||

Post# 568415 , Reply# 14 1/11/2012 at 00:54 (4,487 days old) by MattL  (Flushing, MI) (Flushing, MI) |

||

|

Drum open:

| ||

Post# 568416 , Reply# 15 1/11/2012 at 00:55 (4,487 days old) by MattL  (Flushing, MI) (Flushing, MI) |

||

|

Old seal:

| ||

Post# 568417 , Reply# 16 1/11/2012 at 00:55 (4,487 days old) by MattL  (Flushing, MI) (Flushing, MI) |

||

|

Old seal underside:

| ||

Post# 568418 , Reply# 17 1/11/2012 at 00:57 (4,487 days old) by MattL  (Flushing, MI) (Flushing, MI) |

||

|

Shaft and spider in decent condition. I used some steal-wool to clean up the shaft, it was pretty corroded.

| ||

Post# 568494 , Reply# 19 1/11/2012 at 14:09 (4,487 days old) by MattL  (Flushing, MI) (Flushing, MI) |

||

|

I've run a number of loads through the unit now and all seems well. In thinking about the rubber squeak now I wish I had put a light layer of silicon lube on the seals, odds are that would have stopped the noise. | ||

Post# 568535 , Reply# 20 1/11/2012 at 18:20 (4,486 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

LUBRACTING THE WATER SEAL You may be correct about the squeak coming from the water seal, I always grease the lip type water seals on washers FL & TL alike with a good quality grease. But in any event you have done an outstanding job saving a good washer from the crusher, your efforts will inspire many others to do the same. We are still in a learning curve with the newer Hi-Efficiency washers, but I have no dough that with the excellent quality control that is used in the production of new appliances today that many of these machines will easily be used 20-30 years. | ||

| Post# 568576 , Reply# 21 1/12/2012 at 06:40 (4,486 days old) by mrb627 (Buford, GA) | ||

20 - 30 years? | ||

Comes to the Rescue!

Comes to the Rescue!