|

Thread Number: 45806

Seeking advice for kd12. |

[Down to Last] |

|

Post# 670129 , Reply# 1 4/3/2013 at 00:40 (4,035 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

I had a KDC-14 dishwasher with the same problem. The cast iron drain outlet was rusted away so I just clamped a hose onto it and then onto an electric pump to drain into a garbage disposer, but you could connect the hose onto an extension that is fitted to a new p-trap as well. It may take a little reconfiguring of the existing drain parts and a trip (or two) to the hardware store, but this doesn't have to be the end of the machine.

| ||

| Post# 670190 , Reply# 2 4/3/2013 at 09:43 (4,034 days old) by aloysius (Lake Tapawingo, Missouri) | ||

|

Thank you for your advice. As soon as I get the time I will try what you have suggested. If I run into any more problems with the drain repair or anything else that comes up in the process I may have to call on you again for help. | ||

Post# 670205 , Reply# 4 4/3/2013 at 11:50 (4,034 days old) by kb0nes  (Burnsville, MN) (Burnsville, MN) |

||

Drain valve repair | ||

Post# 670269 , Reply# 5 4/3/2013 at 15:08 (4,034 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Here's what a really | ||

Post# 670321 , Reply# 6 4/3/2013 at 19:52 (4,034 days old) by kb0nes  (Burnsville, MN) (Burnsville, MN) |

||

Jon,

Could you describe what I'm seeing in your photo? Its a bit too much of a close-up to discern ;) What is the black canister at the bottom (the one with the crusty seam), is that the drain valve itself? The hose in the right foreground that runs up to? The tub?? The rusty fitting on this particular machine is close to beyond repair. There needs to be a bit of something there to attach anything new to. What exactly causes them to rust this badly? Last I checked they don't salt the roads under a dishwasher! | ||

Post# 670328 , Reply# 7 4/3/2013 at 20:11 (4,034 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

| ||

Post# 670336 , Reply# 8 4/3/2013 at 20:30 (4,034 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

The black canister is actually the sump, only found on "P" or pump models - a "trap" of sorts to protect the pump that mounts directly to the bottom of the motor.

When I had the KDC-14 (gravity drain) in my kitchen, I wired in an electric pump that ran continuously with the motor and attached the 1 1/2" hose to the drain valve on the machine and the other to the electric pump. | ||

Post# 670345 , Reply# 9 4/3/2013 at 20:47 (4,034 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

| ||

| Post# 670399 , Reply# 10 4/4/2013 at 06:48 (4,033 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

Hi Greg. | ||

Post# 670442 , Reply# 12 4/4/2013 at 11:52 (4,033 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

| ||

Post# 670448 , Reply# 13 4/4/2013 at 12:33 (4,033 days old) by kb0nes  (Burnsville, MN) (Burnsville, MN) |

||

| ||

Post# 670745 , Reply# 14 4/5/2013 at 19:53 (4,032 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Early KA DWs The drain valve that Jon pictured usally do not get that rusty, the style he pictured was used on the KD-11 through 14 DWs.

Last night I parted out two gravity drain KD-10 KA DWs that I have had for years. I have wanted a good example of a KD-10 for years and Robin [ crestwood52 ]gave me a great deal on one that she had that was in excellent condition. So I parted out the other two saving parts for ours and to help anyone else out that needs parts.

For anyone that never got to see a Kitchenaid KD-10 Dishwasher up close you have truly missed seeing the most overbuilt major appliance built for the home. And it is easy to see that this is a commercial quality Dishwasher that could do at least 25,000 loads and still keep going. Even though Hobart always built a sturdy DW for home use the KD-10 is just amazing, they really should have just quit building DWs after this one. | ||

Post# 670942 , Reply# 16 4/6/2013 at 20:04 (4,031 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Drain valve on A KD -12 DW | ||

| Post# 674202 , Reply# 18 4/20/2013 at 16:41 (4,017 days old) by aloysius (Lake Tapawingo, Missouri) | ||

|

I thought I would let you know how I resolved the problem. I would have let you know sooner but I have had a number of emergencies over the past ten days. The first photo shows the drain pipe with the nut removed.

| ||

| Post# 674203 , Reply# 19 4/20/2013 at 16:43 (4,017 days old) by aloysius (Lake Tapawingo, Missouri) | ||

|

The second photo shows how high I could get the extension pipe on the drain pipe.

| ||

| Post# 674204 , Reply# 20 4/20/2013 at 16:45 (4,017 days old) by aloysius (Lake Tapawingo, Missouri) | ||

|

The third photo shows where the p trap came without the extension pipe.

| ||

| Post# 674206 , Reply# 21 4/20/2013 at 16:49 (4,017 days old) by aloysius (Lake Tapawingo, Missouri) | ||

|

The fourth and fifth photos show the repair with the Fernco coupling. I only had approximately an inch under the p trap as the next photo shows - so I could not configure the repair as suggested in the last post by stevet. I could not go into the basement without more work than I wanted to do because the basement is finished with a finished ceiling.

| ||

| Post# 674207 , Reply# 22 4/20/2013 at 16:52 (4,017 days old) by aloysius (Lake Tapawingo, Missouri) | ||

|

Fifth photo.

| ||

Post# 674217 , Reply# 25 4/20/2013 at 17:13 (4,017 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

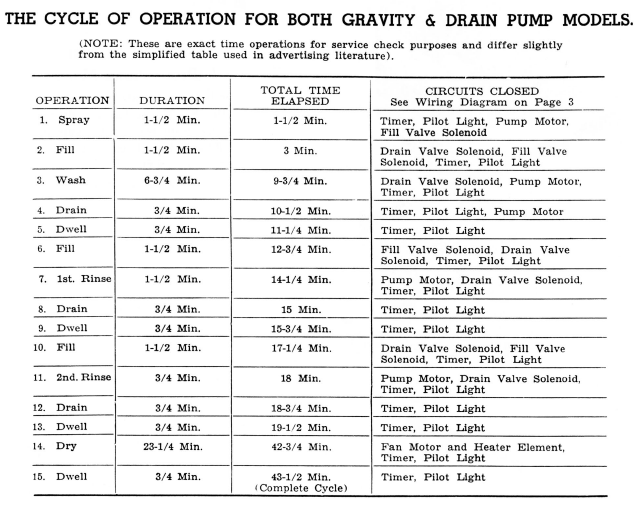

The KD12 has a 1-1/2 minute purge at the beginning of the cycle where the pump runs, the water valve is open and the drain valve remains open. This is to help warm up the interior of machine since it immediately goes into the detergent wash after this purge. If you wait for that purge to end, the pump will shut off, the drain valve will close and the machine will start to fill up with water for main wash (approx 2-1/3 gallons). The leaking will also likely slow down or stop since the drain valve will close.

Here's the cycle chart:

| ||

Post# 674233 , Reply# 27 4/20/2013 at 18:19 (4,017 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

| ||

| Post# 674235 , Reply# 28 4/20/2013 at 18:32 (4,017 days old) by aloysius (Lake Tapawingo, Missouri) | ||

|

I advanced the timer dial to off. I am not even sure I know where to disconnect the power. Unless you mean the on/off switch in the upper right corner of the machine. Do I need to move the on/off switch to the off position as well or does it automatically go to the off position? I do not recall. | ||

Post# 674244 , Reply# 29 4/20/2013 at 19:27 (4,017 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

The gravity drain Kitchenaids were wired such that if you opened the door during one of the "washing" periods it cut the power to everything EXCEPT the signal light and the drain solenoid. Because, if you think about it, since the drain solenoid was energized to keep water IN, if you opened the door while it was washing and it cut power to the whole machine the water would drain OUT. If, however you advanced the timer dial past a washing period, the drain solenoid would not be energized through the timer anyways if you opened the door.

| ||

Post# 674717 , Reply# 31 4/22/2013 at 17:23 (4,015 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

| ||

| Post# 674729 , Reply# 32 4/22/2013 at 18:22 (4,015 days old) by aloysius (Lake Tapawingo, Missouri) | ||

|

Where would I find the door switch? Does it just need some lubricant? WD40? Thanks again for your help. | ||

Post# 674741 , Reply# 33 4/22/2013 at 18:57 (4,015 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

| ||

Comes to the Rescue!

Comes to the Rescue!