|

Thread Number: 47008

How to lubricate washing machine motor carbon brushes |

[Down to Last] |

|

| Post# 683951 , Reply# 2 6/15/2013 at 01:18 (3,965 days old) by norgechef (Saint George New Brunswick ) | ||

|

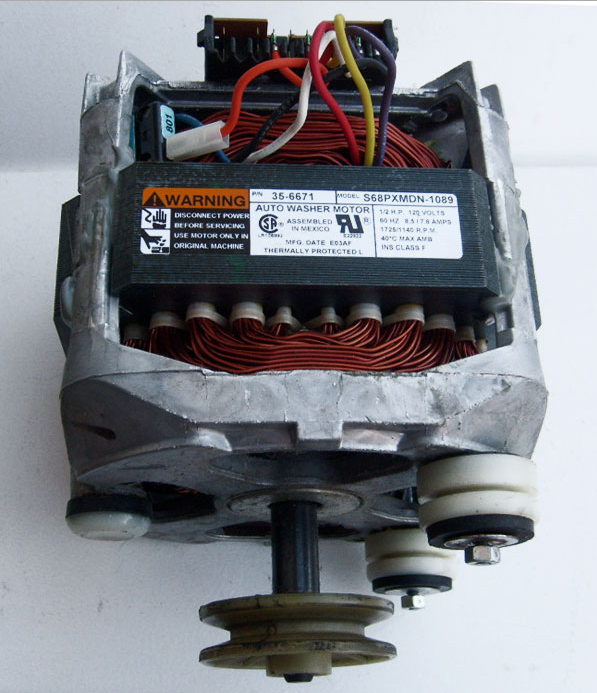

I got the motor out of the washer...now what? Not sure that i know how to open the motor up to do this, don't want to break it! this is a picture of the motor- Maytag model 21001950.

| ||

| Post# 683966 , Reply# 4 6/15/2013 at 07:28 (3,965 days old) by thefixer () | ||

|

These are AC induction motors, there are no brushes as there is no direct electrical connection to the rotor. | ||

| Post# 683979 , Reply# 5 6/15/2013 at 12:01 (3,965 days old) by thefixer () | ||

|

By the way, there are induction motors that utilize brushes and slip rings but these are "wound rotor" type. The ones in washing machines are the "squirrel cage" type that have no physical outside electrical connection to the rotor. | ||

Post# 683992 , Reply# 6 6/15/2013 at 13:24 (3,965 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Black Dust Around the Motor Pully of Norge-Tag Is from the belt, The belt is not used as a clutch on Norge-Tag style washers, first of all the pump is driven by the same belt and if the belt was running slowly like on a real MT the machine would not pump out the water. Secondly the cheap plastic motor pulley that Maytag introduced as an improvement on NT models would be lucky to last for two loads before it would melt and destroy itself and the belt, LOL. | ||

Post# 683993 , Reply# 7 6/15/2013 at 13:25 (3,965 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Black Dust Around the Motor Pully of Norge-Tag Is from the belt, The belt is not used as a clutch on Norge-Tag style washers, first of all the pump is driven by the same belt and if the belt was running slowly like on a real MT the machine would not pump out the water. Secondly the cheap plastic motor pulley that Maytag introduced as an improvement on NT models would be lucky to last for two loads before it would melt and destroy itself and the belt, LOL. | ||

| Post# 683998 , Reply# 8 6/15/2013 at 14:37 (3,965 days old) by norgechef (Saint George New Brunswick ) | ||

|

The black dust Is coming out around the bottom of the motor like black lint and it was very hard to wash off my hands, like soot from a wood stove. | ||

| Post# 684043 , Reply# 9 6/16/2013 at 02:12 (3,964 days old) by arbilab (Ft Worth TX (Ridglea)) | ||

| ||

Post# 684058 , Reply# 10 6/16/2013 at 08:05 (3,964 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Black Dust Around the Motor Pully of Norge-Tag | ||

Post# 684408 , Reply# 12 6/18/2013 at 11:03 (3,962 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

PLASTIC MOTOR PULLEY MT actually does make you buy a whole new motor if the plastic pulley fails [ which happens often when the crappy water pump bearing fails and starts to seize ], good news is our parts distributor found a pt# for just the pulley and we get the replacement pumps for these washers from Exact rather than WP at about 1/4 the cost.

There are only about four or five repairs that make any sense on Norge-Tag washers at this point in time, replacing a bad inlet valve, a bad water pump, belt and motor pulley and maybe a bad lid switch, other than these items the washers usually get replaced and crushed. CLICK HERE TO GO TO combo52's LINK | ||

Post# 684542 , Reply# 13 6/19/2013 at 00:40 (3,961 days old) by tolivac  (greenville nc) (greenville nc) |

||

|

Link didn't work-guess for the infamous NorgeTag washers-they are crusher bait unless you can do simple fixes to them.Glad the pulleys can be a separate part.Kinda of a stupid idea-plastic pulleys.The belt could last longer than the pulleys!Sounds like the pumps in these washers frequently fail. | ||

| Post# 685768 , Reply# 19 6/26/2013 at 12:30 (3,954 days old) by DaveTranter (Central England) | ||

|

'Money Shot' I have no idea where the term 'money shot' originates, but this is probably the nearest thing for this post.. ;) Sorry about the shadowing..... Photographed in natural (and rare!!) sunlight :) All best Dave T

| ||

Post# 685860 , Reply# 20 6/26/2013 at 18:07 (3,953 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Old Motor | ||

Post# 686101 , Reply# 23 6/27/2013 at 23:52 (3,952 days old) by tolivac  (greenville nc) (greenville nc) |

||

|

Curtain drenchers would only be used in an emergency-an actual fire.For routine use--would be rather messy.Might feel good on a hot summer day!Repulsion motors weren't as common as others.Nowadays I don't see them being made anymore. | ||

| Post# 688258 , Reply# 24 7/9/2013 at 15:49 (3,940 days old) by bertrum () | ||

|

lubricating carbon brushes! Quite honestly if you are asking questions about how to lubricate carbon brushes its time to call in professional help. | ||

Comes to the Rescue!

Comes to the Rescue!