|

Thread Number: 48434

It begins... The Inglis restoration |

[Down to Last] |

Post# 701785 9/7/2013 at 15:33 (3,876 days old) by turquoisedude  (.) (.) |

||

When I took stock of my what's in my collection and how it all started, I quickly realized that the 1966 Inglis Sterling washer and dryer set were the first laundry appliances in the collection! I fell head over heels for the Inglis washer pretty fast - so much so that I never even bothered to hook up the 2004 GE that we moved from our former home in Brownsburg-Chatham...

Well, that Inglis set served me well until summer of 2010 - one fine Sunday morning, I set the washer going and came back upstairs to pour myself another coffee when the smoke detector in the basement went off. There was a haze of evil-smelling smoke pouring out of the back of the washer. Long story short, I concluded that the motor burnt and I set about finding a new one. To really add insult to injury, the dryer motor (or possibly just the starting switch of said motor) went bad on me. In February of 2011, I got a good, used motor and installed in the washer, along with a new drive belt. Initally it seemed to work, but on the second test, the washer motor seemed to stall and I heard that tell-tale 'zapping' sound one associated with an Extend-O-Let meant for 8 plugs but into which you have plugged 10. Well, I was discouraged to say the least. At some point or another, though, I examined the pump (thinking it was what may have stalled the motor). I was partially right - a whole bunch of nasty chunks of rusty metal fell out of the pump when I opened it up.

So, my theory was that something inside the washer tub was rusting off and had fallen into the pump. But this was late summer of 2011 and I had other projects to work on, so the poor Inglis Sterling pair (I call them 'Roger' and 'Mona'...) went to the back of the garage, waiting for their chance to be revived.

Now, as I am in the mad rush to complete projects in progress (anyone else hear that whine of 'I had better be able to get the car into the garage this winter'??) I have nonetheless decided to take a run at getting the Inglis set restored!

So, after two years sitting and with no pump in, I decided to throw caution to the wind and test the washer. The motor started right up and ran fine!! I think I got real lucky and did not manage to mess up the 'new' motor after all!!

This post was last edited 09/07/2013 at 15:55 | ||

|

Post# 701786 , Reply# 1 9/7/2013 at 15:34 (3,876 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 701788 , Reply# 2 9/7/2013 at 15:37 (3,876 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 701789 , Reply# 3 9/7/2013 at 15:40 (3,876 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 701790 , Reply# 4 9/7/2013 at 15:42 (3,876 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 701792 , Reply# 5 9/7/2013 at 15:44 (3,876 days old) by turquoisedude  (.) (.) |

||

Now here's the dilemma.... | ||

Post# 701793 , Reply# 6 9/7/2013 at 15:51 (3,876 days old) by turquoisedude  (.) (.) |

||

The tub is in much better shape, but I have to ask myself, 'What's it like inside?'

To be fair, the Inglis was well-used (one can tell that from the wear on the inside of the wash tub). However, I am reluctant to tear apart a decent machine if the Inglis is salvageable.

My initial thought is to attempt to clean up the rust damage and treat it with POR15. I would also consider using the POR15 'WhiteCoat' for the inside tub to spiffy it up. Oh, and I think it might be prudent to remove the inner tub and give it a cleaning and a coat of the POR15.

An easy option would be to slap the Inglis top on the Whirlpool, but if the Whirlpool needs a recon job anyway... I could potentially have two restored machines (and because hubby is hovering over me while I write this, I will go on the record as saying - only ONE will remain)

Any thoughts or suggestions?

| ||

Post# 701843 , Reply# 7 9/7/2013 at 20:24 (3,875 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Whirlpool Washer Restore | ||

| Post# 701867 , Reply# 8 9/7/2013 at 20:58 (3,875 days old) by danemodsandy (The Bramford, Apt. 7-E) | ||

|

Paul: | ||

| Post# 702270 , Reply# 9 9/9/2013 at 11:52 (3,874 days old) by mickeyd (Hamburg NY) | ||

HI PAUL | ||

Post# 703579 , Reply# 10 9/16/2013 at 15:55 (3,867 days old) by turquoisedude  (.) (.) |

||

Let's check out the 'donor' machine | ||

Post# 703580 , Reply# 11 9/16/2013 at 16:01 (3,867 days old) by turquoisedude  (.) (.) |

||

|

This post has been removed by the member who posted it. | ||

Post# 703581 , Reply# 12 9/16/2013 at 16:02 (3,867 days old) by turquoisedude  (.) (.) |

||

The timer dial and controls are pretty close - note the WP machine doesn't have the 'suds return' option on the dial. But we know better, don't we??

Added bonus, this timer also works perfectly!

This post was last edited 09/16/2013 at 16:43 | ||

Post# 703582 , Reply# 13 9/16/2013 at 16:05 (3,867 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 703583 , Reply# 14 9/16/2013 at 16:08 (3,867 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 703584 , Reply# 15 9/16/2013 at 16:11 (3,867 days old) by turquoisedude  (.) (.) |

||

Well after nearly deafening myself pounding the tub nut loose, I got the Whirlpool tub out. I was surprised to see the accumulation of flaked off crud in this machine. I'll bet a turquoise dishwasher that if I'd filled this machine with water I'd have jammed the pump as thoroughly as I did with the Inglis!!

| ||

Post# 703585 , Reply# 16 9/16/2013 at 16:13 (3,867 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 703587 , Reply# 17 9/16/2013 at 16:16 (3,867 days old) by turquoisedude  (.) (.) |

||

Well, I'm going to have to pull the inner tubs and see which is worse.. By the end of the day yesterday, I had only managed to knock off the drive block from the Inglis (ran out of propane for the blowtorch...curses!) so I'll have to come back to this next week.

So ya think I can re-use this drive block?? LOL

| ||

Post# 703591 , Reply# 18 9/16/2013 at 17:08 (3,867 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Paul --

I've noticed in your pictures that Inglis appears to have been using older versions of parts after WP USA had revised them. Brastemp in Brazil did the same thing. The inner wash basket is a very good example, as those with four rows of bottom perfs and the upper splash holes at the rim were a 1950s production standard here. The two row and no splash holes version was in production by late 1960 in the US. A further later 1960s or very early 1970s revision reversed the tub top curl to an outward curl instead of the inward curl as your tubs have. I am quite sure that the US versions of all of these are still cross-compatible, but I have no idea if the parts are dimensionally exact to the Inglis or not. We probably should not assume that they are, but the best way to know is to try to swap them and see if they fit in each machine. Since Inglis was its own entity and not subject to all the US changes as if they were another WP plant, I wouldn't want to assume that every part is dimensionally identical, though they may well turn out to be. As to the rust, some of that is detergent and other residue build-up, that gets stained by a bit of rust as it accumulates, especially from the centerpost. I have chisled and scraped away at that for hours, and made huge piles of it, but it didn't take much metal off the centerpost of either the basket or the baseplate --- note I'm not saying it didn't take any, just not as much as it looks like. In general, I think things in this area often look worse than they are. Much of that though was probably loosened with all the banging from the hammer and spanner wrench --- and YES, I know exactly what you're talking about as to the noise. I usually wrap some of those blue paper automotive shop towels around the spanner wrench to quiet the sound. They rip fairly fast, so on really stubbon spanner nuts I have found that a heavy dead-weight rubber coated mallet works well. I had to quit working on my '65 Kenmore 800 because I'd made the notches on the spanner nut two to three times their size, and got nowhere, even with heat from a torch and a huge amount of spray penetrant. Time to cut that one off... The important part here is to re-seal the centerpost of either/both machines, whatever you decide, so that the agitator shaft is sealed by a spin-tube seal and the spin-tube is sealed by the centerpost seals. This will trap air again as when new, and won't allow water to rise so far up the post, which hastens the crud build up and deterioration you see. You can see the old build-up line in the Whirlpool where water and air met under the agitator for years until the seal began to wear. I wish you success!! Gordon This post was last edited 09/16/2013 at 17:38 | ||

Post# 704654 , Reply# 19 9/22/2013 at 15:33 (3,861 days old) by turquoisedude  (.) (.) |

||

Got the inner tub out of the Inglis.... | ||

Post# 704655 , Reply# 20 9/22/2013 at 15:34 (3,861 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 704657 , Reply# 21 9/22/2013 at 15:36 (3,861 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 704658 , Reply# 22 9/22/2013 at 15:37 (3,861 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 704660 , Reply# 23 9/22/2013 at 15:40 (3,861 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 704662 , Reply# 24 9/22/2013 at 15:41 (3,861 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 704663 , Reply# 25 9/22/2013 at 15:42 (3,861 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 704664 , Reply# 26 9/22/2013 at 15:44 (3,861 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 704666 , Reply# 27 9/22/2013 at 15:47 (3,861 days old) by turquoisedude  (.) (.) |

||

| ||

| Post# 704673 , Reply# 28 9/22/2013 at 16:17 (3,861 days old) by christfr (st louis mo) | ||

| ||

| Post# 704674 , Reply# 29 9/22/2013 at 16:20 (3,861 days old) by PhilR (Quebec Canada) | ||

| ||

Post# 704730 , Reply# 30 9/22/2013 at 19:30 (3,860 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Wow Paul... | ||

Post# 704839 , Reply# 31 9/23/2013 at 08:32 (3,860 days old) by turquoisedude  (.) (.) |

||

| ||

| Post# 704856 , Reply# 32 9/23/2013 at 10:48 (3,860 days old) by mickeyd (Hamburg NY) | ||

Replies 25 & 26

The post and the tub look like they went through the magic vortex of a black hole in outer space and came out the other end fully rejuvenated and nicely black. I love it. Hubby must be growing fearful of your galactic power and becoming ever more tolerant.

Glad you're keeping the lighted Inglis alive; it's so much more stellar, not to mention patriotic ;'D | ||

Post# 704860 , Reply# 33 9/23/2013 at 11:21 (3,860 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

The spin tube 'lip' just dropped right off as if it

Wow Paul, that's incredible!! Maybe people who dealt this these machines every day saw this, but I've never come across a machine that was wet for so long down there that it destroyed the lip on the spin tube. That is probably why the transmission below that area is so crudded up with black goop. They are seldom clean in that area, but that one is really greasy/wet looking.

This leads me to a question - is the original Inglis gearcase fouled with water or contaminated oil inside? It may well be. I'd be tempted to use the WP gearcase, OR open the Inglis trans and see what condition the oil is in. I had one a couple years ago that had chocolate milk colored "oil" in it that was the consistency of heavy molasses. Good luck on the hunt for a spin tube! Gordon | ||

Post# 704910 , Reply# 34 9/23/2013 at 15:39 (3,860 days old) by turquoisedude  (.) (.) |

||

You know, I never actually saw the washer leak, but I have an awful feeling that the washer sat for some time with water in it. The reason this washer got de-commissioned was because the hot water solenoid was shot. I guess the former owner lived with this issue for a while, too.

Waiting for a call back from a parts place in Stanstead (the guy who wanted me to buy him out...) about the spin tube, tub seal, and a new drain hose. I'm in a bit of a race against time now - I was hoping to get this all done this week because I'll not be back down here in Ogden until late October! More pictures of today's work coming soon... | ||

Post# 705027 , Reply# 35 9/23/2013 at 22:35 (3,859 days old) by 114jwh  (Vancouver) (Vancouver) |

||

|

the spin tube, tub seal, and a new drain hose If you can't get these parts from your local parts guy you might get them from Reliable Parts. Not sure if they have a branch near you but if not they'll ship. It looks like they have the spin tube 383921 and tub seal 383727 if these are the correct P/N's. | ||

Post# 705099 , Reply# 36 9/24/2013 at 10:40 (3,859 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Inglis Rebuilding WOW Paul it looks like you are doing a great job.

The transmission oil level and quality can be checked easily without taking the transmission apart by inserting a three" piece of coat hanger wire through the vent hole with the transmission sitting level. You may have to rotate the drive pulley to get the dip-stick to go all the way to the bottom of the gear case as it will hit the top of the connecting rod depending on its position. The oil should be about 1/2" deep in this area and should be a nice light color, if it is murky, brown or white it most likely has water in it. If it looks OK but is just real low you can add transmission oil to increase the level and new oil added helps rejuvenate the oil oil, do this by putting the oil to be added into an empty Zoom-Spout bottle and filling into the vent hole.

You should try to be sure that the transmission is one of the Heavy Duty ones, You can tell by looking at the bottom of the case.

On the spin tubes sometimes the bottom flange will separate and all the clutch and brake parts fall off from the bottom, if this happens it means you need a new ST, which you almost always need anyway during a rebuild.

One thing I like to do when repainting the center post is after installing the top spin tube seal is to paint any exposed metal at the top of the center post right up to the rubber seal, as this area can corrode and cause a serious failure of the whole job.

Good Luck and keep us posted on your progress, John. | ||

| Post# 705108 , Reply# 37 9/24/2013 at 12:04 (3,859 days old) by pierreandreply4 (St-Bruno de montarville (province of quebec) canada) | ||

| ||

Post# 705334 , Reply# 38 9/25/2013 at 17:49 (3,858 days old) by turquoisedude  (.) (.) |

||

Check your oil?? | ||

Post# 705335 , Reply# 39 9/25/2013 at 17:51 (3,858 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 705337 , Reply# 40 9/25/2013 at 17:53 (3,858 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 705340 , Reply# 41 9/25/2013 at 17:55 (3,858 days old) by turquoisedude  (.) (.) |

||

It's still a race against time, though... I am expecting the tub seal and hoses tomorrow. And I still want to replace the bearings, so I'm not out of the woods yet...

Oh, and opinions please: should I keep the original Inglis inner tub? The centre looks bad, but I am sure it could be fixed with enough patience and JB Weld...

| ||

Post# 706129 , Reply# 42 9/29/2013 at 15:15 (3,854 days old) by turquoisedude  (.) (.) |

||

Out of time....

Well, alas, I lost the race against the clock on the Inglis project... I really, really, really wanted it done before I take off for Brazil 'cause I won't be back to Ogden until the 21st of October. C'est la vie, I guess.

Anyway, what I did get done was to fix a chip in the Inglis tub (I simply had to keep it, what can I say!)

| ||

Post# 706130 , Reply# 43 9/29/2013 at 15:19 (3,854 days old) by turquoisedude  (.) (.) |

||

Now, that tub was in pretty bad shape. However, I took a chance and tried out a product I'd wondered about - it's called White-Coat and it's made by the same folks who make POR-15. The product is one of those two-part enamel paints intended for wet applications; sinks and tubs were mentioned in the list.

So I ordered a quart (and it got to me in two days unlike the spin bearings, tub seal and other parts from the local parts guy here in Stanstead... GRRRR!). It's a bit of a pain to work with, but holy moley, I think it worked well!

| ||

Post# 706131 , Reply# 44 9/29/2013 at 15:22 (3,854 days old) by turquoisedude  (.) (.) |

||

| ||

| Post# 706146 , Reply# 45 9/29/2013 at 17:20 (3,854 days old) by pierreandreply4 (St-Bruno de montarville (province of quebec) canada) | ||

| ||

Post# 706181 , Reply# 46 9/29/2013 at 20:30 (3,853 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Re-coating Outer Tubs and Other Washer Parts Exposed to Wate WOW it looks good Paul, I have been using two part epoxys for over 30 years for outer tubs etc and have had good results with them. I have only once used Por-15 and it seemed pretty good but I don't see any advantage to the Por-15, so I guess that I will keep using the Dura-Coat 2 part epoxy from Duron, their main plant is just two blocks from our warehouse in Beltsville. The nice thing about the 2-part epoxy is that it seems to keep forever, I have been using the same batch for almost 30 years. | ||

| Post# 706187 , Reply# 47 9/29/2013 at 21:03 (3,853 days old) by 70series ( Connecticut.) | ||

|

This is an entertaining restoration; thanks for sharing it with us. It was good luck that you had the donor washer with useable parts. I hope your results are successful. Have a good one, James | ||

| Post# 706217 , Reply# 48 9/29/2013 at 23:12 (3,853 days old) by PhilR (Quebec Canada) | ||

| ||

| Post# 710063 , Reply# 49 10/18/2013 at 20:48 (3,834 days old) by pierreandreply4 (St-Bruno de montarville (province of quebec) canada) | ||

| ||

Post# 710184 , Reply# 50 10/19/2013 at 09:10 (3,834 days old) by turquoisedude  (.) (.) |

||

Progress report:

Well, the fellow who said he could get all the parts locally in Stanstead has vanished and is not returning my phone calls. Thank the powers that be that I did not go into business with this person!!

Fortunately yesterday I was able to track down a whole bunch of NOS parts from a parts place that Phil has used in the past. It's nowhere near Ogden (or Montreal) but it was worth the drive - I got a new spin bearing kit (with seals), a new spin tube and clutch assembly, a spare belt pulley, and a new agitator shaft!! I still need the tub seals and the drain outlet hose, but with any luck, I'll get those new bearing in early next week! The weather is starting to turn cool now, so I'll probably have to continue the work inside. I am still hoping to repaint the cabinet, too. Oy, still so much to do and time still seems to fly away on me... | ||

| Post# 710325 , Reply# 52 10/19/2013 at 21:32 (3,833 days old) by PhilR (Quebec Canada) | ||

After I left Paul at home yesterday, I spotted the remains of another BD Inglis/Whirlpool washer that had been dismantled sitting on the sidewalk a few hundred feet away from Paul's home in Montreal. I called Paul and told him to look in my direction at his window and he joined me on the sidewalk in the next minute! We got a few parts (transmission, base plate and tub) from the pile in my car's trunk, then I backed-up on the one-way street to his garage and we got the parts in Paul's garage while people from the crowded neighborhood looked at us with a funny look! When I left for the second time, I noticed that the pedestrians who looked at us a minute before seemed to enter in the house where the dismantled washer was sitting. Maybe it was theirs?!?

When I arrived at home, I noticed we forgot the motor and a hose in my car's trunk... Next time I see you Paul, I'll have to bring that back!

| ||

Post# 710880 , Reply# 53 10/22/2013 at 16:29 (3,831 days old) by turquoisedude  (.) (.) |

||

Yes, that Inglis tub, tranny, and motor was a great score! I brought most of the stuff down to Ogden with me this week.

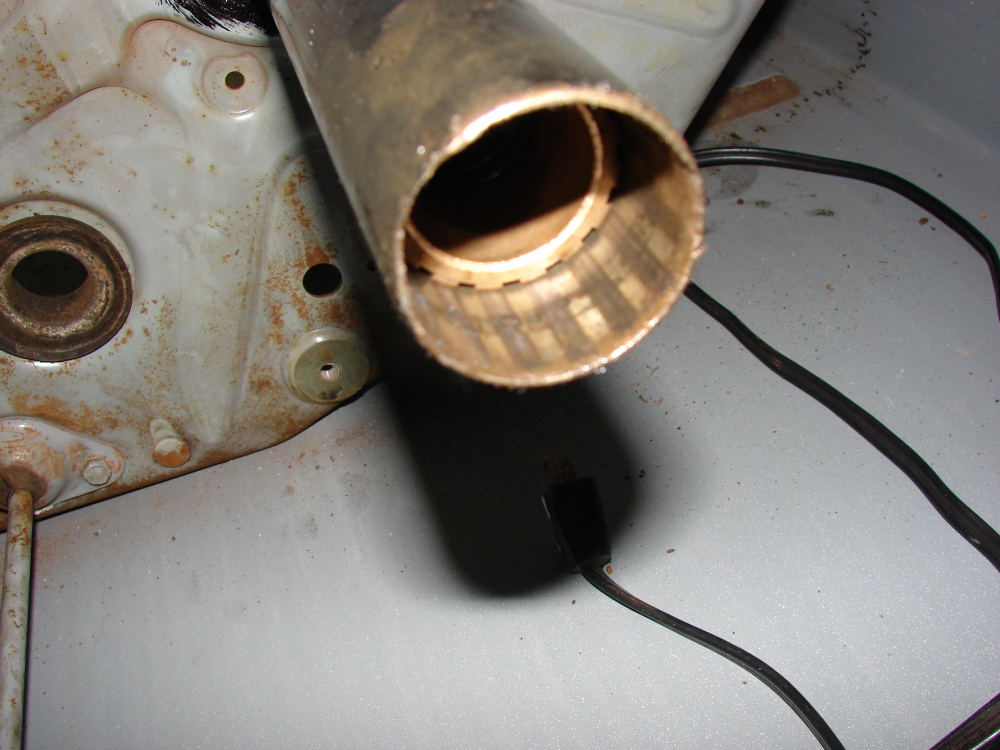

Today was a dismal day here, so I figured it would be a good chance to get my bearings... into the Inglis that is! So, I had the original Inglis baseplate hanging around and since this was my first bearing job without a safety net (ie - having someone who knows what they are doing to guide me...) I figured I'd do a practice run on this.

| ||

Post# 710881 , Reply# 54 10/22/2013 at 16:31 (3,831 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 710882 , Reply# 55 10/22/2013 at 16:32 (3,831 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 710883 , Reply# 56 10/22/2013 at 16:33 (3,831 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 710885 , Reply# 57 10/22/2013 at 16:35 (3,831 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 710886 , Reply# 58 10/22/2013 at 16:38 (3,831 days old) by turquoisedude  (.) (.) |

||

And... It worked! The new upper bearing is shown here (it still needs some lubrication and the seal) but I did it!

With any luck tomorrow, I'll have the transmission put back together and, if the phantom repair guy in Stanstead comes through with the tub seal, I'll have the machine more or less back together! Hubby misses all the fun stuff when he's away on a business trip... LOL

| ||

Post# 710894 , Reply# 59 10/22/2013 at 17:44 (3,831 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

| ||

Post# 711109 , Reply# 60 10/23/2013 at 18:44 (3,830 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 711110 , Reply# 61 10/23/2013 at 18:46 (3,830 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 711111 , Reply# 62 10/23/2013 at 18:51 (3,830 days old) by turquoisedude  (.) (.) |

||

Bad move.... I had to change the pulley on the water pump to accommodate the narrow belt. Oh, yeah, the original motor was made for the wider belt too, so I swapped it for a more recent square motor.

I got it all back together fine, but now I am wondering if I have made a huge mistake... I was trying to keep this machine as true to the original as possible but I got caught up in the "get this damn washer back together and out of the garage by the time I'm back or else" order I was under and rushed the job... Oh and I still don't have the washers to mount the outer tub on the baseplate anyway, so I lose... This washer isn't going to be finished this weekend for sure. Oh forgive me, ye gods of Whirlpool!

| ||

Post# 711114 , Reply# 63 10/23/2013 at 19:07 (3,829 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Paul -

If nothing else (and there is a lot more than nothing you efforts on this project) you are getting a great indoctrination to working on belt-drives. It sounds like you've installed the quiet-pak belt system, perhaps unintentionally. I can understand how that would happen if the basket drive assembly had the narrow pulley, as the other three have to be swapped to match. The square motor isn't going to please the gods much, but WP will sell us a square one you if you need a replacement motor for most any BD machine originally equipped with a round single or two speed motor, and they've done that for years and years. On the other hand, you may or may not be happy with the performance of the machine, even if it all works dandy, because the quiet pak system removes most belt sounds and especially the woo-woo. You will have a very interesting hybrid machine for sure. If you decide you have to have the original belt to make the "right" machine sounds, the most common basket drive assembly (which has a spin tube) you're looking for is part number 383923 in the U.S. --- they show up on eBay fairly often. This has the proper height spin tube, the fast brake, and a new spin cam bar for those machines that were not originally fast-brake. If the donor WP or the Ingliss's original basket drive pulley are able to be removed from the origial spin tubes, you could install one of those on the new spin tube and keep the old-style belt and sounds, you just get the fun of taking apart the basket drive. By the way Paul, what washers are you talking about for the tub mounting, the 76673 tub repair kit or the 21365 originals? I have lots of the 76673 and I'm happy to share. Just send me an e-mail. Gordon This post was last edited 10/23/2013 at 21:03 | ||

Post# 711164 , Reply# 64 10/24/2013 at 06:42 (3,829 days old) by turquoisedude  (.) (.) |

||

Gordon, I don't have the Whirlpool part numbers for the washers I need (I have the Inglis parts numbers, but they don't jive with current Whirlpool part numbers, even on the Canadian parts sites...)

The washers are the ones used at the bottom of the inner tub below the screws that attach the tub to the baseplate. I'm sneaking down to Boston today (gotta pick up the pink Hotpoint dishwasher!) so I know I'll not be working on it this weekend! | ||

Post# 715155 , Reply# 65 11/13/2013 at 18:38 (3,808 days old) by turquoisedude  (.) (.) |

||

Finally back at it....

EEESH! I let this slide badly... I swear that if there were a 'Ten Commandments of Washer Restoration', number two or three would be 'Thou Shalt Not find the danged parts you need BEFORE you start tearing into a machine'...

I had a positive devil of a time finding silly little parts like, oh I don't know, the agitator stud and the washers for the inner tub. I could write a whole essay on how incredibly unhelpful appliance parts dealers in Montreal are (I am sure that is the case elsewhere too...) but I'll hold my tongue... Well, thanks to the kindness of folks whose houses we pillage (Jon - that's you and thank you again) I got the agitator stud. Only just yesterday I turned up a set of the tub bolts and washers in the fair haven of Magog (the parts person said it had been years since they had been asked for them!). So I dragged the carcass of the Inglis, its tubs and top into the basement to work on it in relative warmth. Fiddling around in the garage with temperatures in the 20s did not appeal to me, what can I say...

| ||

Post# 715156 , Reply# 66 11/13/2013 at 18:40 (3,808 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 715157 , Reply# 67 11/13/2013 at 18:41 (3,808 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 715159 , Reply# 68 11/13/2013 at 18:46 (3,808 days old) by turquoisedude  (.) (.) |

||

And here it comes: But....

There seems to be a leak from the pump...

I thought better of using the original Inglis pump - it had jammed up twice on me and I did have a perfectly good one on the donor Whirlpool. I think it is just a bad gasket and I will deal with that tomorrow. Again, slight rant about Canadian parts places: I was told there is no way to obtain just the gasket for a pump like this and that I would have to buy the whole pump. Is that really true?? I'll probably just make a new seal out of some silicone or liquid gasket, but that will wait until tomorrow or Friday. So close....

| ||

Post# 715361 , Reply# 69 11/14/2013 at 16:16 (3,808 days old) by turquoisedude  (.) (.) |

||

So.....

I spent the afternoon today attacking the pump leak. I was convinced it was just a bad gasket, so I used some of my favourite liquid gasket compound as a booster to the existing gasket. This meant removing, disassembling, re-assembling, and re-installing the pump.

It didn't work the first time... Or the second time for that matter... And the third time?? Still dripping!! I was ready to tear my hair out (which would have been really easy with liquid-gasket-coated hands... LOL).

| ||

Post# 715363 , Reply# 70 11/14/2013 at 16:18 (3,808 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 715364 , Reply# 71 11/14/2013 at 16:20 (3,808 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 715481 , Reply# 72 11/15/2013 at 08:31 (3,807 days old) by turquoisedude  (.) (.) |

||

So here's today's "progress"....

The original 66 Inglis pump has been cleaned and re-gasketed; I used silicone sealant instead of liquid gasket this time. The downside is that it takes 24 hours for a full cure. So I'll have to wait until tomorrow to test it. If the chamber holds water, I'll try re-installing it and hope that the shaft seals are still OK. I think I may be asking Santa for a Whirlpool pump rebuild kit (or 4...) this Christmas. LOL

| ||

Post# 715715 , Reply# 73 11/16/2013 at 15:40 (3,806 days old) by turquoisedude  (.) (.) |

||

Well, I managed to patiently wait until the full 24 hours had passed to test the pump. Canyon woke me up at 5:40, no doubt anxious to find out if the original Inglis pump was saved or not...

I did an 'out of machine' water test and no leaks were spotted. I installed it (if they ever make changing a Whirlpool washer pump an Olympic sport, dammit, I'll be sure to qualify now... LOL) and poured in a few buckets of water... It looked good from up here....

| ||

Post# 715716 , Reply# 74 11/16/2013 at 15:42 (3,806 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 715717 , Reply# 75 11/16/2013 at 15:44 (3,806 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 715718 , Reply# 76 11/16/2013 at 15:45 (3,806 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 715719 , Reply# 77 11/16/2013 at 15:49 (3,806 days old) by turquoisedude  (.) (.) |

||

The moment of truth...

So, wiring block reconnected? Check

Tub lights reconnected? Check Hubby standing by with the fire extinguisher? Check I plugged it in and was delighted to see the control panel and tub light up again. Better still... It runs!!! I did a 'dry' test to make sure the motor was running freely and that the other components were kicking in. I had to cheat the water level control to check the agitation; it agitated and spun when it's supposed to! And I did one last check of the timer - it's advancing normally!! So, the big test will be tomorrow... I'll have to scare up some test laundry, I guess!!

| ||

| Post# 715745 , Reply# 78 11/16/2013 at 18:36 (3,805 days old) by pierreandreply4 (St-Bruno de montarville (province of quebec) canada) | ||

| ||

| Post# 715789 , Reply# 79 11/16/2013 at 23:55 (3,805 days old) by camMURRAY22 (Savannah,Georgia) | ||

|

Inglis Washer Back Together Again Do an unbalanced load with Michael Jackson's Billie Jean playing. LOL I like to see the washer moonwalking during the spin. LOL | ||

| Post# 715800 , Reply# 80 11/17/2013 at 01:54 (3,805 days old) by PhilR (Quebec Canada) | ||

| ||

Post# 715835 , Reply# 81 11/17/2013 at 10:36 (3,805 days old) by turquoisedude  (.) (.) |

||

Water test time!

I had to move the Dominion washer to make room for the Inglis (the Dominion needs some TLC so this is a good thing...).

First, got the water hooked up. Check out these 'quick disconnect' hose couplers that I installed. I hope they are solid, because if they are, it will make the swapping of machines into and out of the collection a snap (pun intended)!

| ||

Post# 715836 , Reply# 82 11/17/2013 at 10:38 (3,805 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 715837 , Reply# 83 11/17/2013 at 10:39 (3,805 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 715838 , Reply# 84 11/17/2013 at 10:43 (3,805 days old) by turquoisedude  (.) (.) |

||

And some short video evidence... A real wash test with laundry will be filmed soon, I promise!

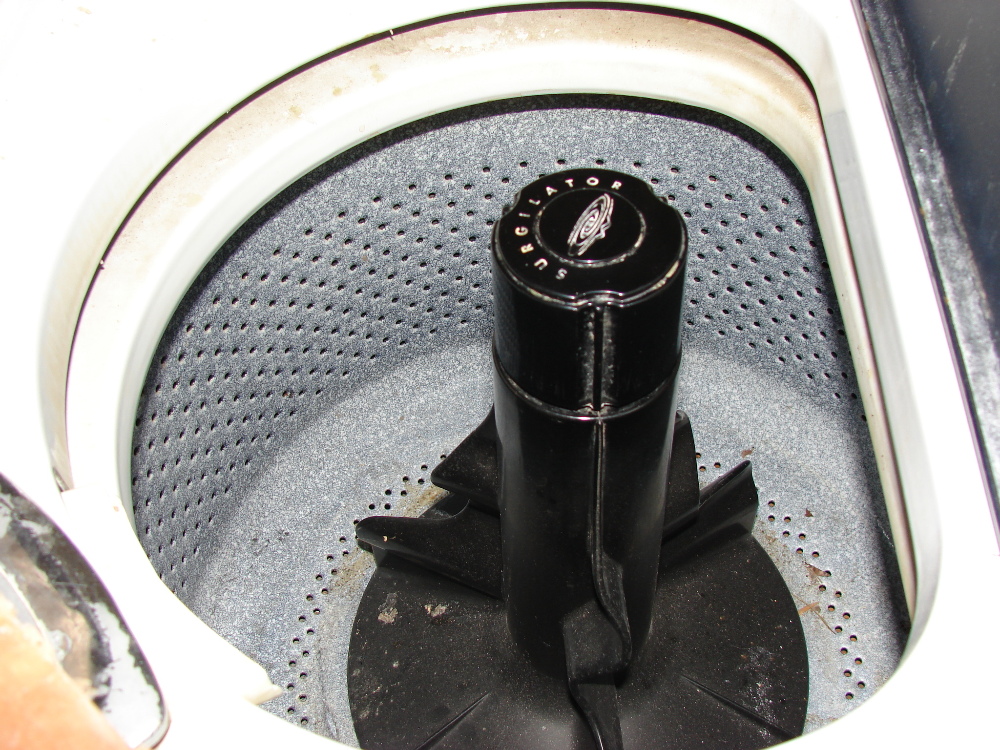

Although the machine now has a lot fewer of its original components, I think it will still be a good performer. One thing I added was the pump guard from the donor Whirlpool. I had the choice of agitators, but I kept the original black swirl-vaned one that came with the Inglis for the sake of appearances. I could swap it with a white surgilator (with fabric softener dispenser), though... I'll see how I go. | ||

| Post# 715843 , Reply# 85 11/17/2013 at 11:49 (3,805 days old) by pierreandreply4 (St-Bruno de montarville (province of quebec) canada) | ||

Its back in action  | ||

Post# 715882 , Reply# 86 11/17/2013 at 16:30 (3,805 days old) by turquoisedude  (.) (.) |

||

Not out of the woods yet, it seems...

D'OH! That's the most G-rated phrase I can come up with at the moment...

So, the first load of clothes (some doggie towels and rags) are going through the wash part of the cycle; towards the end of the cycle, I swear I thought the agitation slowed down... Had a wee drainage issue due to a kinked discharge hose but when the rinse cycle started, the Inglis was making a squeaking noise... The video link below is a no-load test I did after draining out the washer. I did not hear any other abnormal noises during the spin or neutral drain - I have a horrible feeling that there is something that I should have lubricated but didn't... Help!! | ||

| Post# 715930 , Reply# 87 11/17/2013 at 20:02 (3,804 days old) by PhilR (Quebec Canada) | ||

| ||

Post# 716008 , Reply# 88 11/18/2013 at 05:42 (3,804 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 716017 , Reply# 89 11/18/2013 at 07:19 (3,804 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Squeaking Inglis | ||

| Post# 716092 , Reply# 90 11/18/2013 at 16:48 (3,804 days old) by pierreandreply4 (St-Bruno de montarville (province of quebec) canada) | ||

a song to dedicate the newly reborn inglis sterling washer | ||

| Post# 716095 , Reply# 91 11/18/2013 at 16:53 (3,804 days old) by camMURRAY22 (Savannah,Georgia) | ||

|

Inglis Washer Back Together Again Play Michael Jackson's Billie Jean the minute it goes of balance. For the agitation, play Beat It. | ||

| Post# 716140 , Reply# 92 11/18/2013 at 20:43 (3,803 days old) by rustyspaatz () | ||

|

sounds like something is either slipping, or binding. Pump getting ready to seize? | ||

Post# 716167 , Reply# 93 11/19/2013 at 01:01 (3,803 days old) by 114jwh  (Vancouver) (Vancouver) |

||

|

Could it be too much tension on the belt? When I changed the belt on my Inglis the directions indicated that there should be about 1/2 inch deflection. | ||

| Post# 716596 , Reply# 94 11/20/2013 at 18:07 (3,802 days old) by camMURRAY22 (Savannah,Georgia) | ||

|

This post has been removed by the webmaster. | ||

Post# 716796 , Reply# 95 11/21/2013 at 12:35 (3,801 days old) by turquoisedude  (.) (.) |

||

Not ready for a spin quite yet...

Just got back down to Ogden and after letting Canyon have a romp around the woods, I decided to try the Inglis again.

I set the timer to 'Spin' and pulled the timer. The machine started but I must admit I heard some groaning... The breaker popped very quickly thereafter. I pulled out the timer dial and clicked the breaker back on. Surprise! The motor kept running! I tried to push the timer dial - it still kept running. I tried turning the dial to 'off'... It still kept running... I pulled the plug and cursed for a spell... Now I am a mixture of pissed off, stumped, and curious. My gut feeling is saying there's a BIG ol' short circuit somewhere and I can't help but wonder if it's in the motor. I'll be pulling the Inglis out and doing more testing this weekend and cursing myself that I should have perhaps put the 57 Hotpoint in the slot where the Inglis now sits... Stay tuned... | ||

| Post# 716804 , Reply# 96 11/21/2013 at 12:43 (3,801 days old) by mickeyd (Hamburg NY) | ||

Take heart, dear friend.

The paint job on the tub is so good, I had to blink and draw my jaw back up. How is it that a refurb can look better than the original factory job. The shine and the brilliance of the white have me nuts. This is like when Chris painted the Westy pink. You're motivating me to paint the Visimatic Blue or Sunset, but I'd probably have to hide the results. LOL

Also drooling over the pic of her all lit up inside and out, the water flowing fast through the looking glass. This post was last edited 11/21/2013 at 13:45 | ||

| Post# 716811 , Reply# 97 11/21/2013 at 12:51 (3,801 days old) by mickeyd (Hamburg NY) | ||

"Through the looking glass" | ||

Post# 716812 , Reply# 98 11/21/2013 at 12:59 (3,801 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Wow Paul, what a bummer! I wouldn't count the timer out either when you start to diagnose the machine. I'm wondering (and hoping it isn't the case) if a contact in the timer welded itself closed during the short? If you trip the breaker and put it to fill and turn the breaker on does the motor still run?

Also - I think maybe a new water pump would be a lovely Christmas present for you! Is it a 2 port or 4 port? Ben | ||

Post# 716936 , Reply# 99 11/21/2013 at 19:57 (3,800 days old) by turquoisedude  (.) (.) |

||

Ben, I've been agonizing over the possibility of a fried timer all afternoon... The light at the end of the tunnel for that scenario is the 67 Whirlpool donor timer, though. The motor runs wherever the timer dial is, even 'Off'! I can get the machine to spin simply by advancing the timer to the 'Spin'. Tub and panel lights seem to be the only thing still being controlled by the push/pull of the timer knob. Just wondering now that since the 67 WP did not have a lighted tub or panel if this is going be an issue...

Dumb question - should I try swapping motors anyway, since the one currently installed may be a problem?? Dumber question - could a motor short have caused a timer contact weld?? I think I may just give the machine a rest for a spell. I pulled the Dominion to make room for the Inglis and the Dominion pump needs some TLC and I'd like to do some more tinkering with the original water valve... Hopefully I won't fry THAT timer... OY! Oh, and the pump is a four-port version. Tell Santa I've been mostly good this year... LOL And I shouldn't forget that I picked up a very interesting Frigidaire laundry appliance addition to the collection in Ottawa yesterday. It had to go right to the storage locker alas, but come spring, my 'Canadian Corner' in the Ogden laundry will have a new member (hint: it's a close match to a certain time-capsule washer...) | ||

Post# 717276 , Reply# 101 11/23/2013 at 13:07 (3,799 days old) by turquoisedude  (.) (.) |

||

Well, colour me "embarrassed"

Yes, as we all know, there are two ways to do things: the right way or the 'turquoisedude' way...

I pulled the Inglis out of its 'slot' and took off the motor access hatch and the timer box back panel, looking for anything unusual that might hit me smack in the face... SMACK! Check the arced sections on this spade connector. Mr-Know-It-All here decided to not hook up the suds return valve just yet. This wire is mated to a sleeved connector for the suds return valve solenoid, but I simply left it in the timer box. Dumb, very dumb of me... This wire obviously shifted and hit a contact or three on the timer. That explains the popped breaker on Thursday. Since the machine had been spinning, I am guessing that when the machine stopped, the wire shifted again and seemed to land across the drive motor 'hot' feed into the timer. Hence why the motor ran all the time... With the offending wire removed, normal operation resumed. Water valves started to buzz in the 'fill' part of the cycle with no motor. The motor engaged normally in 'spin'. So, big sigh of relief on this end... I had taken the precaution of bringing in the console from the WP donor and the 'new' motor I had installed back in 2011 from the garage to warm up; I'll see if I still need that motor and frankly my gut feeling is saying 'Swap It'... Now, back to work!

| ||

| Post# 717304 , Reply# 102 11/23/2013 at 18:28 (3,798 days old) by camMURRAY22 (Savannah,Georgia) | ||

|

This post has been removed by the webmaster. | ||

Post# 717365 , Reply# 103 11/24/2013 at 06:41 (3,798 days old) by turquoisedude  (.) (.) |

||

Right, so last night after a day in the kitchen (Christmas goodies time) and before heading to a neighbour's for dinner, I figured I had time to play with the Inglis. I rechecked the belt tension and it seemed fine; I did a test of wash, drain and spin functions - the 'squeal' seemed to get worse. I popped the belt from the motor and just ran it. To me, it seemed to make a hell of a racket... Then I tried the motor that came out of this washer - in comparison, it purred like a kitten.

So I swapped the motors. I adjusted the belt tension and tried a dry test - the squeal was back already... I still tried an agitation test and I will swear that the squeal was now far worse than before. Now here's the fun part: the tub was no longer emptying in neutral drain and the ever-present squeal was still heard (people in Stanstead started to complain, it was that bad...LOL). Oddly enough, water was being recirculated into the tub, no problem. So, as we've eliminated the motor, it looks like the pump is the problem after all. I am not all that surprised - it was the very pump that did the machine in back in 2010... So, I'll be heading to the mall to see Santa next week.... LOL | ||

Post# 717442 , Reply# 104 11/24/2013 at 13:44 (3,798 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Squeaking Inglis

Wow Paul this one is really testing your patience, But hopefully a new pump will help things.

The water pump was one of the weakest parts of WP built drive washers and even though many ran for years without failure it probably is not a good idea to try to rebuild or otherwise fix them. The only ones I ever fool with are the ones that have no problems, but if they leak, make noise or have other problems just replace them. Hopefully Andy and the other Maytag guys are taking note that I criticized a WP product, LOL. John L. | ||

| Post# 717448 , Reply# 105 11/24/2013 at 13:59 (3,798 days old) by mickeyd (Hamburg NY) | ||

Don't be fooled, Paul! | ||

Post# 717539 , Reply# 106 11/24/2013 at 22:52 (3,797 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

| Post# 717943 , Reply# 107 11/26/2013 at 22:07 (3,795 days old) by kitty () | ||

|

WOW....... AMAZING restore!!!! Our 74 Kenmore bit the dust. EVERYTHING in that was metal was rusted COMPLETELY together. We could get the top off, but after that , you're in the hole. | ||

Post# 720076 , Reply# 108 12/9/2013 at 10:35 (3,783 days old) by turquoisedude  (.) (.) |

||

The elves have been working very hard...

And have found not one, but two brand-new aftermarket replacement pumps for the Inglis (in Canada to boot!). Since the elves have switched to Canada Post for most deliveries, they say that they might get to me by the end of the week. That would be perfect timing - this coming weekend will be the last one I spend in Ogden before New Year's!

| ||

Post# 720646 , Reply# 109 12/11/2013 at 16:37 (3,781 days old) by turquoisedude  (.) (.) |

||

This just in... | ||

| Post# 720736 , Reply# 110 12/12/2013 at 04:35 (3,780 days old) by NYCWriter () | ||

|

Wow. Such talent!! | ||

Post# 720775 , Reply# 111 12/12/2013 at 08:40 (3,780 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 720779 , Reply# 112 12/12/2013 at 08:43 (3,780 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 721149 , Reply# 113 12/14/2013 at 11:47 (3,778 days old) by turquoisedude  (.) (.) |

||

Yeah, well...

So in keeping with the Holiday Season, I did my best to re-enact a scene from a beloved Holiday movie this morning while working on the Inglis...

You know the scene in "A Christmas Story" where the father of the family (played by Darren McGavin) is down in the basement cursing to the point where everyone around the table is gape-jawed in disbelief at the foul oaths and incantations echoing through the furnace ductwork? That would have been me about 20 minutes ago... I started by swapping the pumps - the new aftermarket one went in nicely enough. I filled the Inglis up and there were no leaks from the pump or its various hoses (one bit of good news I suppose). It gets gradually worse from here on in... As the machine completed filling, nothing happened. The timer was running but the machine did not start to agitate. What the ???? I was not amused. Just for the heck of it, I tried the Wash'N'Wear section of the dial. Nada. However on the Gentle section, the machine began to agitate! Turns out I had yanked the Blue lead for the high speed winding on the motor out by accident. My relief was short-lived, however... The washer ran through a brief wash, neutral drain, and a spin; and it was still squeaking every now and then!! That was when the oaths and incantations began to flow... I tried to isolate the noise (I practically had my head IN the motor compartment but I will be damned if I could determine where exactly it was coming from... Now it gets better... I tried to fill the machine up again for a short test wash - this time around, I got no agitation at any speed. The pump was still recirculating water through the Magic-Mix filter though. I tried to drain the machine by setting it to just before the end of wash spin. Nope. Just recirculating water again. Now I am stumped... This is exactly what the original-Inglis-pump-I-thought-was-shot did last week. I monkeyed around in the back and manually pulled back the agitate cam bar - I got the darn thing agitating again but still no draining! I am thinking I have a wig-wag solenoid issue now. Not surprising since I have practically replaced every other blessed component on this washer! But the squeak is still bothering me... It sounds like something rubbing metal to metal. To my unscientific ear, it sounded like it was coming from or around the main pulley for the tranny. This makes me wonder if I did a bad thing mixing and matching narrow-belt components with regular wide-belt ones. Part of me is saying, 'Just slap the '67 Whirlpool transmission in!' However, I should at least put a new spin tube on it (and lord knows, getting one here was a pain in the a...anyway.... So I won't be ringing in the New Year with clean laundry from the Inglis!! Think I'll go hook up the Maytag that's been out of service for nearly a year now... OY! | ||

| Post# 721164 , Reply# 114 12/14/2013 at 12:32 (3,778 days old) by mickeyd (Hamburg NY) | ||

Hi Paul ~ | ||

Post# 721357 , Reply# 115 12/15/2013 at 20:33 (3,776 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Oh boy Paul, you're really being thrown through the wringer on this one (no pun intended).

If I were in your shoes, I'll pull the trans and basket drive out. Since you've gone through everything, pulling it out will be a cinch.

First off, swap the wig wag from the '67 Whirlpool. Secondly, take an afternoon to tear the basket drive apart. It really isn't too difficult - the worst part is getting the set screw back into the hole in the spin tube. I used Robert's '57 Kenmore rebuild as a reference while rebuilding a basket drive recently. I'll post photos hopefully in the next few days as I had to go the extra step of pressing a new bearing into the pulley.

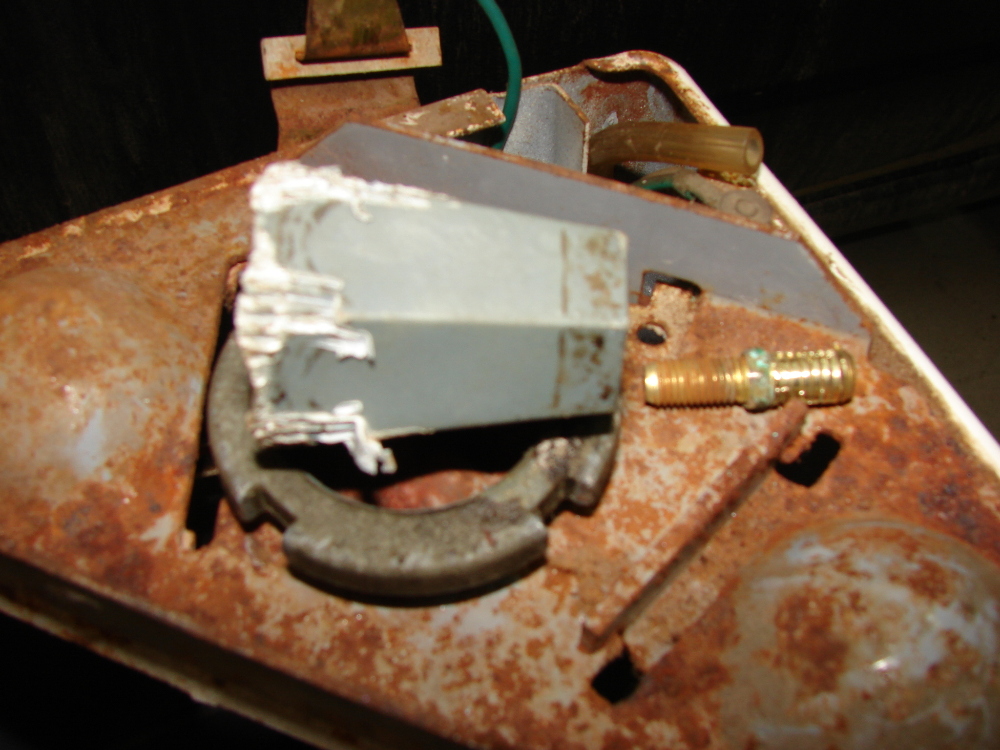

Inspect the bearing on the spin pulley. If it looks anything like this.... then, yeah. That's bad. If it is, hopefully the spin tube isn't scored too badly. If the bearing looks good (when they are new they would look like the spin tube bearings), then reuse it.

Depending on which pulley you use (original one or a donor one), clean all the parts, lubricate the bearing and the trust washers with some 3 in 1 Motor oil, put the basket drive back together, and throw the trans back in the washer. You can do a try test with no water to see if you still have a squeak.

The only catch to all of this is that you've already swapped to the smaller pulley size. You may need to swap back depending on the condition of the spin pulley bearing (eek!).

Good luck my friend!

Ben

| ||

Post# 721508 , Reply# 116 12/16/2013 at 18:49 (3,775 days old) by jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Cast iron | ||

Post# 721583 , Reply# 117 12/17/2013 at 06:47 (3,775 days old) by turquoisedude  (.) (.) |

||

Plan 'C'....

Right, so I've calmed down considerably since Saturday (a few glasses of Hi-Octane Eggnog helped...) and with good advice from Ben, I've decided I'm going to swap transmissions.

This will be after New Years unfortunately, but I'll inspect that 67 WP donor transmission and swap it after any necessary parts changes. And in the meantime, I'll be keeping an eye out for the service manual for this style and vintage of machine... The Repair Master is OK, but I think I need more details... | ||

Post# 721593 , Reply# 118 12/17/2013 at 07:57 (3,775 days old) by turquoisedude  (.) (.) |

||

Manuals found... | ||

| Post# 724759 , Reply# 119 1/3/2014 at 15:21 (3,758 days old) by pierreandreply4 (St-Bruno de montarville (province of quebec) canada) | ||

| ||

Post# 725173 , Reply# 120 1/5/2014 at 08:02 (3,756 days old) by turquoisedude  (.) (.) |

||

AAAAARGH!!

Well, after the success with the Maytag and despite hitting another wall with the Dominion, I thought I had nothing to lose by attacking the Inglis again.

I had prepared a diagnosis chart and checklist of possible causes while I was in the UK (Most folks take books to read on planes - I take Whirlpool service documentation... LOL). Anyway, I figured that the agitate solenoid was the number one cause for the Inglis' lack of agitation. I got home, tested the solenoid and glory be - it was indeed 'open'. I slapped on a new solenoid assembly (I had a sparebelieve it or not!) and when I fired up the washer, it agitated, drained, and spun! I was elated, but I thought I should try it again. I got the washer to agitate so I thought I'd try it with some clothes. With just one bathrobe in the machine, the agitation slowed to a crawl. I took the robe out and the washer no longer wanted to agitate. GRRRRRR! I tried adjusting the belt tension, but no luck. I now think that the original Inglis transmission is shot and that I probably made things a lot worse by swapping narrow-belt components. I think the only logical thing to do now is going to be to salvage the 67 WP Donor tranny and slap it into the Inglis. It would make sense, since the outer tub and baseplate came from that machine anyway! So I am on the hunt for another spin tube and I will make good use of the photos Ben posted for the restoration of his '59 Kenmore... And that whine you hear is Hubby complaining about the machines strewn all over the basement... LOL | ||

Post# 725181 , Reply# 121 1/5/2014 at 09:05 (3,756 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Inglis Restoration | ||

Comes to the Rescue!

Comes to the Rescue!