|

Thread Number: 48735

No wonder the motors burn out |

[Down to Last] |

| Post# 705868 9/28/2013 at 07:16 (3,856 days old) by Washman (o) | ||

|

Spec from Whirlpool/Amana site for the NTW4600YQ Wash Motor 1/4 hp PSC A whopping 1/4 HP? Are they serious? CLICK HERE TO GO TO Washman's LINK

| ||

|

Post# 706506 , Reply# 3 10/1/2013 at 02:01 (3,853 days old) by kb0nes  (Burnsville, MN) (Burnsville, MN) |

||

Properly built I'll take the Inverter and electronic multi-phase variable frequency drive over the mechanical transmission. Electronics, when run well within their design limits will basically never wear out. The only failure point (again assuming proper design) is the motor bearings failing.

The electronic control not only holds the potential of being more reliable but also more efficient and offer far more controllability then any mechanical transmission. How come every CNC machine tool has done away with transmissions, and they run day in and day out with no problems. Please do note the first two words above though. It isn't assured that in appliances the electronics are properly built, there is too much cost cutting. Note that this will apply to mechanical transmissions too, a modern transmission will suffer just as much or more from the cost cutting. | ||

Post# 706523 , Reply# 5 10/1/2013 at 07:17 (3,853 days old) by Frigilux  (The Minnesota Prairie) (The Minnesota Prairie) |

||

Wish I had the room to keep both the 2006 Frigidaire top-loader (with agitator + indexing tub) and the 2013 Immersion Care (on/off reversing tub indexing creates the agitation) to see if one outlasts the other. The agitator version was pretty reliable, in part because the "power stroke" of the agitation became shorter the more resistance it met due to load size. I suppose this helped ease the strain on the transmission and motor.

Will be interesting to see if the Immersion Care machines prove to be as reliable as their old-school siblings. Both my Frigidaire top-loaders found new homes, so I guess I'll never know. | ||

Post# 706540 , Reply# 6 10/1/2013 at 09:39 (3,853 days old) by kb0nes  (Burnsville, MN) (Burnsville, MN) |

||

Rex,

You'd be surprised at how aggressive the handling of that motor is. ALL the speed control is done by the inverter and it will ramp from 500 to 5000 RPM. The machine has constant linear speed so every diameter step comes with a speed change. Facing starts out slow and ramps up as the tool moves in towards the center to maintain a constant cutting speed (try that with gears!). The inverter/motor provides braking and reversing too. We have both front and rear mounted tools so in some cycles the spindle runs at speed clockwise and it then braked and spun the other direction for the rear operations, 3500 RPM CW to CCW in less then 2 seconds again and again. The chuck is 14" diameter and about 140 lbs. When reversing you feel it through the concrete floor ;) You are correct that comparing expensive industrial electronics to consumer stuff isn't entirely fair. But I refuse to accept that the consumer electronic controls can't be made to last, they are certainly less expensive and can add features one could never dream of in a pure mechanical world. And the point that we have to compare modern electronics to modern mechanical transmissions stands. An old Whirlpool belt drive transmission will run practically forever, but these could never be made again due to cost constraints. | ||

Post# 706567 , Reply# 8 10/1/2013 at 11:47 (3,852 days old) by kb0nes  (Burnsville, MN) (Burnsville, MN) |

||

Show me a flat screen more than 5 years old please.

I could show you 6 in my immediate family that are over 7 years old and have never blinked.... And they are all florescent back-lit models too.

Old CRT TV's were indeed amazing considering their high voltage complexities and heat related problems. Just to be fair remember CRT technology had over 50 years to work out the bugs. The new LED back-lit LCD's hold the potential to be even more reliable, while having much higher resolution and using a ton less energy too. And they are still the new kid on the block. | ||

Post# 706578 , Reply# 9 10/1/2013 at 12:57 (3,852 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

| ||

Post# 706643 , Reply# 10 10/1/2013 at 18:55 (3,852 days old) by logixx  (Germany) (Germany) |

||

*facepalm* | ||

| Post# 706660 , Reply# 11 10/1/2013 at 20:05 (3,852 days old) by mrb627 (Buford, GA) | ||

Amana | ||

Post# 706748 , Reply# 13 10/2/2013 at 10:42 (3,851 days old) by kb0nes  (Burnsville, MN) (Burnsville, MN) |

||

Rex,

The motors in all CNC machine tools today are designed to be run with a variable frequency drive inverter. Even our oldest 1997 machine has an electronic VFD drive. Manual machines are different, most of them still use gearboxes or variable sheave belt drives for speed adjustment, even today. Pretty much all motors can be reversed at full speed with no problem. As long as the safe currents in the windings aren't exceeded and nothing snaps off from the mechanical stress all is good. Its just magnetics. I remember in junior high we had a 12" radial arm saw that had a reversing brake on it. You'd push a button after you turned it off and it would stop the blade dead in less then a second, hold the button and the saw ran in reverse. That motor was never designed for that but it didn't hurt it a bit. I used to worry that the rotational inertia would loosen the blade nut but that never happened either. Our lathe is a Milltronics ML-18. Its not the most sophisticated machine out there but it is made here in MN and the owner here used to work for Milltronics so they have an "in". I may create another thread to post some photos etc since this is pretty far off topic at this point. The link is for an interesting video on Youtube provided by the manufacturer. I'm a bit appalled that they couldn't find a clean machine to use for the video. Even our 2 year old machine is still clean and shiny. Also note that they are turning on the backside of the part using the turret but they are using the wrong handed tools so they are cutting upwards. This is bad practice as the cross slide saddle isn't designed for upwards loading. If you accidentally crash the machine it could be costly! CLICK HERE TO GO TO kb0nes's LINK

| ||

Post# 706755 , Reply# 14 10/2/2013 at 11:23 (3,851 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

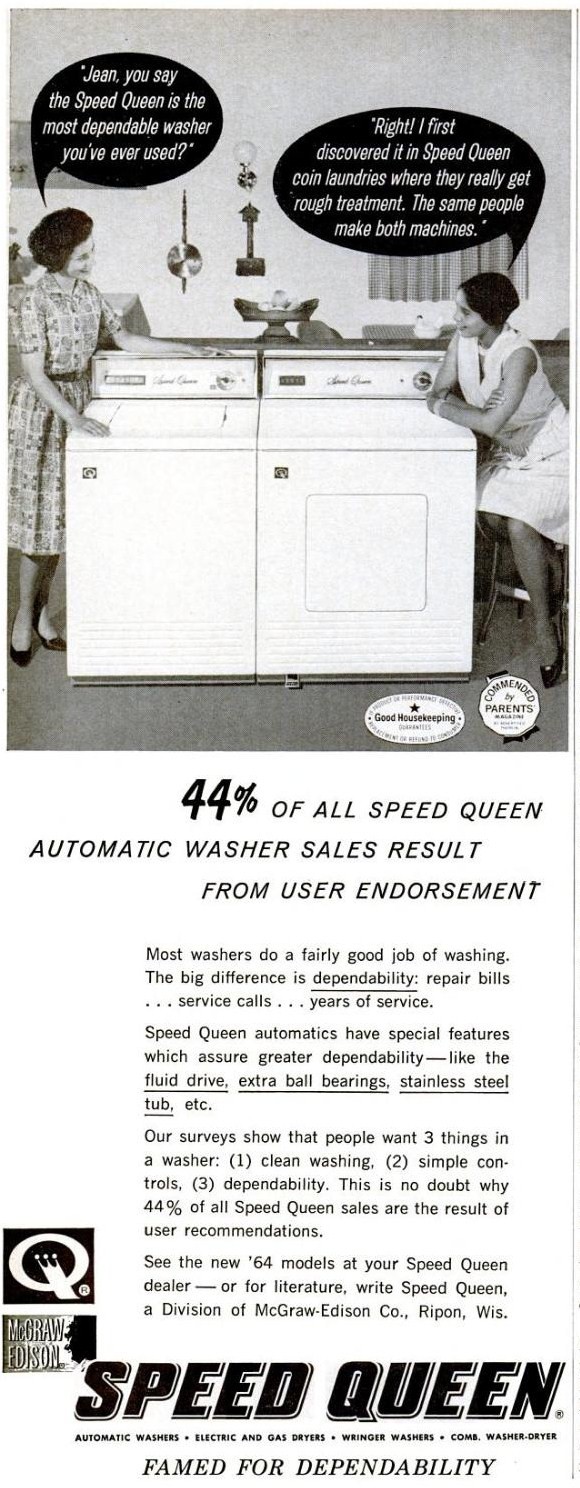

1/4 HP Motor Too Small for A Washer ? Hi Ben , where do you come up with this stuff? as a servicer I have never seen a problem with these 1/4 HP motors and WP has been using this system in their compact TL machines for over 20 years. I can guarantee you that the 1/2 HP motor in your new SQ TLer will not last 1/2 as long as these new more efficient motors do. Just the running temperature alone is amazing, the motor in your SQ you can hardly touch after running a load and these newer design machines barely get warm.

Ben I love all the old SQ ads that you have posted and I am very happy that you love your new SQ TL washer, I sold two more this morning, but when you make this other crap up it makes people think you are clueless about appliances. | ||

| Post# 706762 , Reply# 16 10/2/2013 at 12:16 (3,851 days old) by Washman (o) | ||

|

forgot to add on SQ site with regard to vended laundry, they too use the same 1/2 HP motor as the residential unit. I find it hard to imagine those motors, in a high use environment, would not last very long.

| ||

Post# 706771 , Reply# 17 10/2/2013 at 13:31 (3,851 days old) by kb0nes  (Burnsville, MN) (Burnsville, MN) |

||

Ben,

I don't think that John's point was that your beloved 1/2 horsepower SQ motors were failure prone. It was that he didn't agree your assumption that the 1/4 hp motors were more likely to fail. How many of either of these motors have YOU SEEN in person fail? 'nuff said. Looking at web reviews like epinions gives very little statistical evidence because you have zero idea how many motors _didn't_ fail. Typically the only reviews you see are when something fails. You also have no idea of the total numbers of machines out there, they are zillions more of those 1/4 hp motors out there then the SQ 1/2 models due to total sales. You should see many more reports of 1/4 hp motor failures due to the sample size. It has nothing to do with the size of the motor of the engineering behind it's choice. You know what they say about assuming. The results may be about the same as having to invoke Al Gore's name in most all of your posts... | ||

| Post# 706884 , Reply# 19 10/2/2013 at 20:04 (3,851 days old) by thefixer () | ||

|

The Whirlpool VMW belt drive's use a 1/4hp motor in the smaller (3.4-3.5 cu ft) capacity models and a 1/3hp in the larger (3.6-4.2 cu ft) models. | ||

Comes to the Rescue!

Comes to the Rescue!