|

Thread Number: 49660

Hoover 155 (A3072) Dryer Overhaul Pt 1 |

[Down to Last] |

|

| Post# 717752 , Reply# 1 11/25/2013 at 22:18 (3,801 days old) by crouzet951 () | ||

|

Dust and fluff everywhere - on everything inside the cabinet. It is quite ingenious how the same basic cabinets were used for the washers and the dryers.

| ||

| Post# 717754 , Reply# 2 11/25/2013 at 22:22 (3,801 days old) by crouzet951 () | ||

|

I mainly used to dry my maroon sheets, hence the colour of the fluff. The rust looking stuff on the lower back panel is more fish-oil based paint that I seemed to have used on everything. Hehe.

| ||

| Post# 717755 , Reply# 3 11/25/2013 at 22:23 (3,801 days old) by crouzet951 () | ||

|

More fluff.

| ||

| Post# 717765 , Reply# 7 11/25/2013 at 23:37 (3,801 days old) by crouzet951 () | ||

|

The rear of the drum. The rear support bearing is a bronze bush. You can make out the lint filter through the holes.

| ||

| Post# 717766 , Reply# 8 11/25/2013 at 23:40 (3,801 days old) by crouzet951 () | ||

|

This is the dual-temperature thermostat. It reacts to the temperature of the air exiting through the rear duct.

| ||

| Post# 717768 , Reply# 9 11/25/2013 at 23:47 (3,801 days old) by crouzet951 () | ||

|

This is the heating element assembly. Air is drawn into the front of the drum, through the elements, for the whole circumference of the element assembly. The small disaster can be seen at the 10.30 position.

| ||

| Post# 717773 , Reply# 12 11/26/2013 at 00:01 (3,801 days old) by crouzet951 () | ||

|

This is the flange at the front of the drum that rests on the bearings.

| ||

| Post# 717777 , Reply# 15 11/26/2013 at 00:21 (3,801 days old) by crouzet951 () | ||

|

The motor is an induction type of very simple construction. Being an induction motor, it has no brushes. The cooling fan for the motor can be seen, together with the small pulley that drives the drum fan.

| ||

| Post# 717778 , Reply# 16 11/26/2013 at 00:24 (3,801 days old) by crouzet951 () | ||

|

This was the sight when one of the end plates was removed. Even the holes through the rotor were blocked. The motor was well on its way to burning out the windings again.

| ||

| Post# 717779 , Reply# 17 11/26/2013 at 00:27 (3,801 days old) by crouzet951 () | ||

|

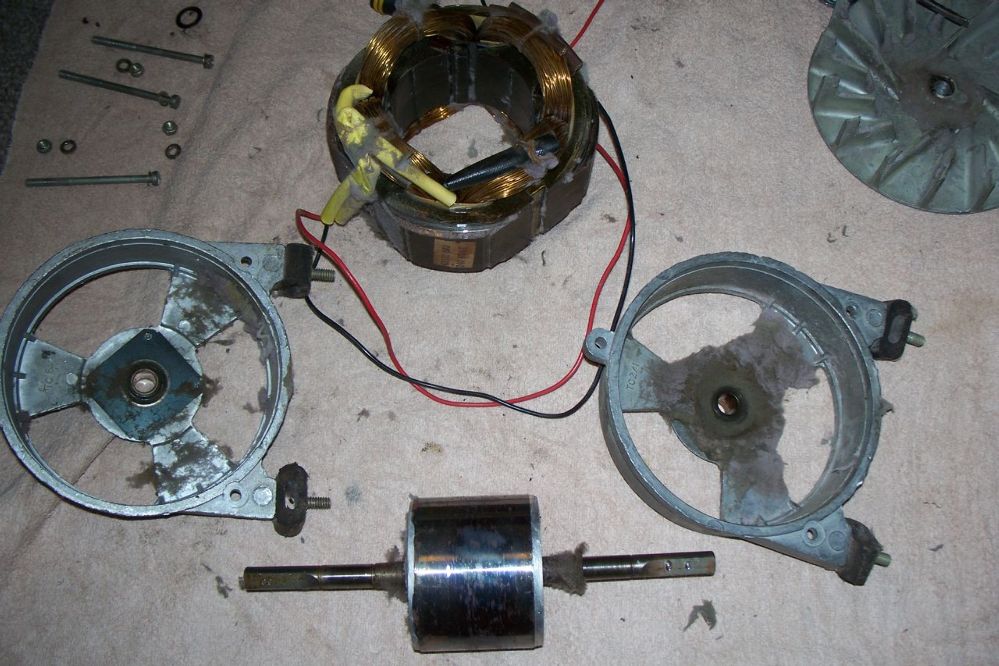

As mentioned earlier, the motor is of very simple construction. Remove the pulleys, the fan, and a few screws, and it breaks down into four major sub-assemblies. They are the two end plates with bearings, the windings, and the rotor.

| ||

| Post# 717780 , Reply# 18 11/26/2013 at 00:31 (3,801 days old) by crouzet951 () | ||

|

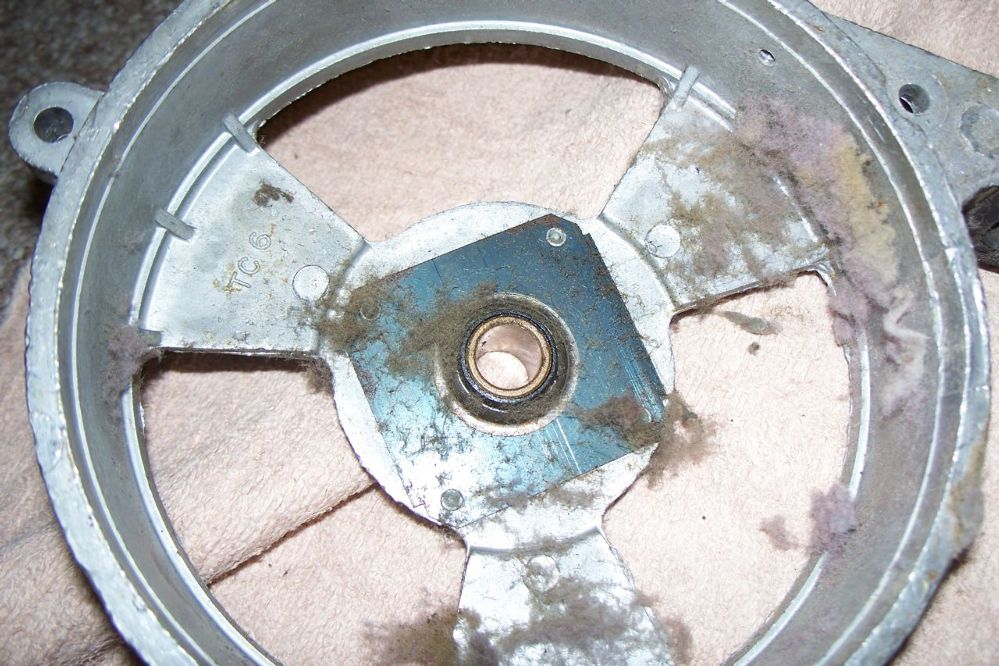

The rotor bearings are self-aligning sintered bronze bushes. There is virtually no wear to either the bushes, or the rotor shaft surfaces. These motors are very lightly loaded compared to washer motors.

| ||

| Post# 717781 , Reply# 19 11/26/2013 at 00:34 (3,801 days old) by crouzet951 () | ||

|

The bracket supporting the rear drum bearing post is retained by pop rivets. These were easily drilled out. This bracket traps the fan in the housing, so it must be removed to get the fan out.

| ||

| Post# 717783 , Reply# 20 11/26/2013 at 00:41 (3,801 days old) by crouzet951 () | ||

|

When the fan is removed, its bearing housing is visible. The bearing housing is made from alloy, and it's retained by three aluminium rivets. More fluff everywhere of course.

| ||

| Post# 717785 , Reply# 22 11/26/2013 at 00:48 (3,801 days old) by CREEDY () | ||

|

good work on the refurb! I have one of these i'm looking to sell its working and tidy does anyone want to make an offer on it? i'm on the gold coast :)

| ||

| Post# 717788 , Reply# 24 11/26/2013 at 00:54 (3,801 days old) by crouzet951 () | ||

|

A close up of the rear drum bearing post. The drum turns quite slowly, so this bearing is lightly stressed. There's virtually no wear on the shaft.

| ||

| Post# 717789 , Reply# 25 11/26/2013 at 01:01 (3,801 days old) by crouzet951 () | ||

|

These later dryers have the cabinet closed up at the bottom by a pressing which is pop riveted in place.

| ||

| Post# 717790 , Reply# 26 11/26/2013 at 01:02 (3,801 days old) by crouzet951 () | ||

|

This is the rear of the heating elements assembly.

| ||

| Post# 717791 , Reply# 27 11/26/2013 at 01:04 (3,801 days old) by crouzet951 () | ||

|

This is the back of the thermal cutout that protects the elements.

| ||

| Post# 717793 , Reply# 28 11/26/2013 at 01:06 (3,801 days old) by crouzet951 () | ||

|

An image of the rear of the door catch.

| ||

| Post# 717794 , Reply# 29 11/26/2013 at 01:08 (3,801 days old) by crouzet951 () | ||

|

This is the door switch at open position (power cut off to machine).

| ||

| Post# 717795 , Reply# 30 11/26/2013 at 01:09 (3,801 days old) by crouzet951 () | ||

|

This is the door switch at closed position (power supplied to machine).

| ||

| Post# 717796 , Reply# 31 11/26/2013 at 01:10 (3,801 days old) by crouzet951 () | ||

|

The small door buffers have perished, as is usual. I have new ones but they're black.

| ||

Comes to the Rescue!

Comes to the Rescue!