|

Thread Number: 54406

Help! My Maytag 806 made the most horrible noise |

[Down to Last] |

|

| Post# 767857 , Reply# 1 7/4/2014 at 08:29 (3,577 days old) by floyde (Los Angeles, CA) | ||

|

I took the front panel off and can't really notice anyth But when I try to turn the tub manually it will not move. Is that indicative to any certain issue. It will fill, Drain, but not agitate, spin, or the tub will not turn manually. Thanks again. | ||

| Post# 767859 , Reply# 2 7/4/2014 at 08:41 (3,577 days old) by mrb627 (Buford, GA) | ||

Broken Belt? | ||

| Post# 767870 , Reply# 3 7/4/2014 at 09:40 (3,577 days old) by Volvoguy87 (Cincinnati, OH) | ||

Damper?

Was it making a grinding / scraping noise during spin? One of mine did that right before it came into my possession. It was because the damper pads had worn out, come off, and allowed the aluminum damper to rest and scrape on the steel base of the washer. The damper is the aluminum hub at the bottom of the washer that the 3 tub support arms attach to. Check and see if yours is in more than 1 piece, mine had shattered.

If you need to replace the damper, it's not the end of the world. I did it and it wasn't too horrifying :) If your transmission is toast (not likely) they can be swapped out too. Dave | ||

Post# 767876 , Reply# 4 7/4/2014 at 10:08 (3,577 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 767878 , Reply# 5 7/4/2014 at 10:18 (3,577 days old) by RevvinKevin  (Tinseltown - Shakey Town - La-La Land) (Tinseltown - Shakey Town - La-La Land) |

||

|

No it's not the damper

Great suggestion Dave, but worn / missing damper pads would only make noise during spin as the tub moved around, plus it would not effect the machines ability to agitate or spin.

Floyd texted me this video and a couple photos. As you can hear and (barely) see in the video, the motor is running and making noise, but there is no action in the tub.

In the photos: 1. the main driven pulley came off the brake package. Floyd sent a text a few minutes ago saying the motor was making the noise as the motor pulley was hitting the baseplate / cabinet, (photo 2) probably because the belt (and pulley) was off. He put the pulley and belt back on, but it came right back off when he started the washer.

Question: Isn't there some sort of locking clip that holds the pulley nut / assembly in place? I've only been in there once and it was 4 years ago.

Thanks! Kevin | ||

Post# 767888 , Reply# 6 7/4/2014 at 10:53 (3,577 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

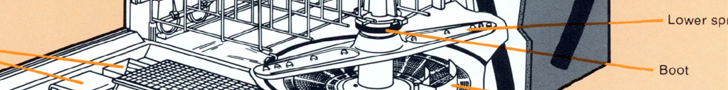

Take a look at this and see if this is helpful.

View Full Size

| ||

Post# 767890 , Reply# 7 7/4/2014 at 11:00 (3,577 days old) by Yogitunes  (New Jersey) (New Jersey) |

||

| ||

Post# 767898 , Reply# 8 7/4/2014 at 11:25 (3,577 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Martin is spot on, and that's certainly what it sounds like.

Getting the water out of the tub won't be too bad, it the washer doesn't have a siphon break. Just drop the hose near a drain to release the water, then tilt the machine and take a look. Odd that a new belt would suddenly come off. This is where you spin the drive pulley by hand. Clockwise to spin the tub, counter to agitate. To spin the pulley will first need to travel up the helix in order to release the brake. | ||

| Post# 767904 , Reply# 9 7/4/2014 at 11:53 (3,577 days old) by floyde (Los Angeles, CA) | ||

|

This is the part that came off The pully. I put it back on and it seems secure, but every time I run it it falls off. Kevin said there's a black cap to remove and adjust the nut. I will post a picture of the screws, but it seems part is broken off.

| ||

Post# 767908 , Reply# 10 7/4/2014 at 12:22 (3,577 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

I see the problem right away. The washer is broken in half and half of it is missing. Is the phillips-head screw still in the bottom of the drive shaft?

Maytag part #2011090, subs to FSP part #2200355

CLICK HERE TO GO TO Kenmore71's LINK | ||

| Post# 767914 , Reply# 11 7/4/2014 at 13:00 (3,577 days old) by floyde (Los Angeles, CA) | ||

|

I put the part back on and attached the belts but Now! The washer will not agitate . During the wash cycle it spins with the water in it asides the rinse cycle. It will spin and fill and drain. Did I do something wrong that it won't agitate? This is crazy! Thanks | ||

| Post# 767918 , Reply# 12 7/4/2014 at 13:07 (3,577 days old) by floyde (Los Angeles, CA) | ||

|

Kenmore71 No, when I pulled the little black cap off that I'm showing that's what was under half of the washer and the other part. It must have been that way for a while. So strange that would be like that. | ||

Post# 767942 , Reply# 14 7/4/2014 at 14:18 (3,577 days old) by goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

| ||

| Post# 767967 , Reply# 15 7/4/2014 at 15:38 (3,577 days old) by hippiedoll ( arizona ) | ||

awww man!!!

i'm sorry to read about you having problems with your 806 washer. i hope you can get it working and that it is an easy fix for you floyde!!

if you don't work on washers, can you still get that one appliance repair guy to come over & help you with it??? i'll keep my fingers crossed for you that it is a simple solution to getting your 806 up & running real soon for you!!! keep us posted on your progress... | ||

| Post# 767992 , Reply# 16 7/4/2014 at 16:52 (3,577 days old) by Volvoguy87 (Cincinnati, OH) | ||

Stop Lug!

The drive pulley screws up onto the transmission shaft near the brake package. The pulley should be free to rotate a little bit on the shaft in either direction. One way will snug it up so it locks and turns the drum, the other way will cause it to drive the agitator shaft. How is this accomplished? The Stop Lug! (I hope I remembered the correct name.

The stop lug is the piece that looks like a washer with an extra lump on one side and a serrated interior hole. First the drive pulley screws on, then the stop lug is put on so its extra bit of material will contact a corresponding piece on the drive pulley. There is a washer that goes under the stop lug, and finally a Phillips head screw through the center of the washer to hold the washer and stop lug onto the bottom of the washer. A rubber cap is then placed on the bottom of the drive pulley as shown in your picture WITH some LUBRICANT inside to keep the slightly moving parts happy. Correct positioning of the stop lug is important to ensure that spin and agitate happen correctly. Clear as mud? Dave | ||

| Post# 768006 , Reply# 17 7/4/2014 at 17:40 (3,577 days old) by floyde (Los Angeles, CA) | ||

Dave is this the stop luge?

| ||

| Post# 768010 , Reply# 18 7/4/2014 at 17:51 (3,577 days old) by Volvoguy87 (Cincinnati, OH) | ||

Yes. | ||

| Post# 768011 , Reply# 19 7/4/2014 at 17:51 (3,577 days old) by beekeyknee (Columbia, MO) | ||

| ||

| Post# 768017 , Reply# 20 7/4/2014 at 18:04 (3,577 days old) by beekeyknee (Columbia, MO) | ||

This may help. It's old and you probably only need to read the part about the stop lug.

The stop lug is rounded on one side and flat on the other. When you're installing it put the rounded side to the floor. And the new washer on the screw, of course. CLICK HERE TO GO TO beekeyknee's LINK | ||

Post# 768279 , Reply# 24 7/5/2014 at 22:18 (3,576 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

A806 Noise Problems

Hi Floyde, I am afraid that the service guy did more harm than good, I would seek a refund, there is absolutely no reason to ever lucubrate any part of the main pulley helix and if one knows anything about MT helical drive washers there is reason why the pulley should have ever come off after working on the machine.

John L. | ||

| Post# 768609 , Reply# 28 7/6/2014 at 22:50 (3,575 days old) by beekeyknee (Columbia, MO) | ||

I doubt the motor was damaged. When the drive belt came off the motor carriage could have slid back and the motor shaft could have rubbed against the washer frame making a terrible sound but not damaging it.

You're washer could have some other issues and if you're able and can use the resources of the site, you'd probably be better off doing it yourself. Either that or getting an older fella that knows something about vintage machines. A lot of kids these days neither have the knowledge or initiative to do anything but change a circuit board. When it comes to mechanics they're totally lost. They'd be better off in a computer store. I've gone into some local stores here and asked about certain parts and the kids stand and look at me with this dumbfounded look on their face. I get mad and and ask if there's anyone older around that understands how things work. Funny, I can work on a vintage washer or computer. We're really making progress in the education of our young people, aren't we? p.s. The whining sound at beginning of spin could be dirty pulleys and cheap belts that are glazing the pulleys. You need good Maytag belts with a generous covering of cloth and pulleys that have been cleaned well with a solvent and some steal wool tell they shine. I used FSP belts during my first rebuild and in a few months the squealing started and the glazing was back. It still works, but starts to squeal at the beginning of spin. It can squeal for now. It's going to get a substitute this fall. This post was last edited 07/06/2014 at 23:10 | ||

Post# 768612 , Reply# 29 7/6/2014 at 23:06 (3,575 days old) by d-jones  (Western Pennsylvania (Pittsburgh Area)) (Western Pennsylvania (Pittsburgh Area)) |

||

Floyde Since you're here in L.A. I can recommend two places that are competent to work on the older Maytag's like this one. The first is Bob at Ralph's Maytag Repair here in Burbank. He's been working on Maytag's since the 1940's when he was a kid. Ralph was his dad and he grew up helping out in the shop, then took over the business. He's semi retired now but likes to work on the older machines, though he may ask that the machine be brought to him. The other place is Thrifty Appliance here in Burbank. They've been around a long time and have technicians in their shop that are familiar with this model, at least they did the last time I checked.

I have to agree with Brian here. A lot of the younger techs don't know these machines and don't really care to learn. | ||

| Post# 769754 , Reply# 30 7/10/2014 at 13:54 (3,571 days old) by floyde (Los Angeles, CA) | ||

|

She's back in service !

View Full Size

| ||

| Post# 769767 , Reply# 31 7/10/2014 at 14:32 (3,571 days old) by hippiedoll ( arizona ) | ||

WOOOOOO HOOOOOOOO!!!!

ALRIIIIIIIIIGHT!!!!!

i am so happy that you got your 806 back up & running. she looks beautiful in all her green & glowing glory!!! YYYYYAAAAAAYYYYYY!!!! :o) so, how did you get your baby back up & running again?? did the guy come out to do the repairs or send someone else out in his place? or did you get someone else to help you?? enquiring minds want to know..... | ||

Comes to the Rescue!

Comes to the Rescue!