|

Thread Number: 71246

/ Tag: Vintage Automatic Washers

Maytag Wringer Washer |

[Down to Last] |

|

| Post# 942978 , Reply# 2 6/11/2017 at 03:11 (2,504 days old) by Stan (Napa CA) | ||

Maytag Service manual

Says to use Center seal grease 5616 (whatever that is) for most everthing with regards to wringer, and it's moving parts...Except it says to fill wringer head with 1lb of grease.. Says to use 56078 ?

Larry will probably stop by here and give you details on your questions for the power unit (transmission) and what kind of oil he used, can't remember off hand. 3 1/2 oz of power unit oil are supposed to be used in the cavity of the wringer post where the bevel gears mate. Hang on help is on the way | ||

| Post# 943026 , Reply# 4 6/11/2017 at 14:27 (2,504 days old) by tarantulae (Colorado) | ||

|

As promised, here's some pictures. | ||

| Post# 943116 , Reply# 5 6/11/2017 at 22:41 (2,504 days old) by Stan (Napa CA) | ||

Duncan

You may be able to get most of what you need at the auto store or the auto section of WalMart, with maybe one exception

(the power unit) not sure if you can use 85 90 gear oil or not. The 3 1/2 oz mentioned in the service manual, may be the equivalent to the 1/4 lb soft grease mentioned below. Hope this helps Keep us posted | ||

| Post# 943186 , Reply# 7 6/12/2017 at 13:48 (2,503 days old) by Stan (Napa CA) | ||

I'm glad

You found Larry and that thread! He will be a great source of info for you. (Good move with the bolts)

If you've read his entire thread.. It's long but worth the read, youl find that he ordered gaskets, I think you should too. If I remember correctly there was some adjustment he made to get everything to fit right and not leak during reassembly. I believe your right about the 3 1/2 oz of grease, and packing grease for the wringer head.. But double check with Larry or Geoff or recheck Larry's thread (info is in there) Yes yours will accommodate a pump. Youl most like find one one on eBay, and mostl likely it will be Phil from Ovid NY that has them, and offers them through eBay, as well as the correct gaskets, Think Larry added a pump as well when he restored his. Maytag pumps will make short work out of draining the water out. If you get one youl see what I mean. And if you have a sink or stand pipe for it to drain to, much easier. I'd say 55 would be the year of manufacture for yours.. If you post your serial number, We'l decode it and find the month and year. Take pics for us if you can, during your restore, we love pics.. Cuz we all want to be there to have our hands in it! Pics are the next best thing! I'm particularly interested in how you clean those gunked up parts. | ||

| Post# 943248 , Reply# 9 6/13/2017 at 02:42 (2,502 days old) by Stan (Napa CA) | ||

Not sure

Where the serial # is located on a model N. On a model E, it stamped just below the crown on th back of the machine. So with your N I'd stand behind the wringer post and look to the left near the top of the body.

Someone who has a N may come by? By looking at pic 3, I think I can see the pre drilled holes in the crossbar that will accommodate the pump assembly. | ||

| Post# 943250 , Reply# 10 6/13/2017 at 03:07 (2,502 days old) by Stan (Napa CA) | ||

Forgot to mention  | ||

| Post# 943281 , Reply# 11 6/13/2017 at 11:30 (2,502 days old) by tarantulae (Colorado) | ||

|

It has a lint screen (a little rusty, but what isn't on this one!) Its what made me think it had a pump originally. I found the serial number. Stamped in the back at the top of the skirt. 3562390 | ||

| Post# 943283 , Reply# 12 6/13/2017 at 11:56 (2,502 days old) by ken (NYS) | ||

Duncan

Check out the info listed in this thread for serial number date info.

www.automaticwasher.org/cgi-bin/T... Sorry...Looks like yours wouldn't be covered because its later than 1952. Didn't realize until after I posted. | ||

| Post# 943291 , Reply# 13 6/13/2017 at 13:08 (2,502 days old) by tarantulae (Colorado) | ||

|

Bad news I think I'm out of luck now. In trying to remove the broken brass bolts, the centerplate has broken. No chance of making a seal now is there? Is the centerplate replaceable or am I going to need a whole new power unit now anyway?

View Full Size

| ||

| Post# 943296 , Reply# 14 6/13/2017 at 14:02 (2,502 days old) by stan (Napa CA) | ||

Think it's replaceable  | ||

| Post# 943303 , Reply# 16 6/13/2017 at 14:53 (2,502 days old) by stan (Napa CA) | ||

You | ||

| Post# 943311 , Reply# 17 6/13/2017 at 15:30 (2,502 days old) by tarantulae (Colorado) | ||

|

It won't come off. The bolts broke below the surface of the center plate but is still holding onto the PU. One of them has a bolt extractor broken in it too. I can't take the center plate off the PU. | ||

| Post# 943383 , Reply# 18 6/13/2017 at 21:47 (2,502 days old) by Stan (Napa CA) | ||

At least

The price was right for it! And it may come in handy for parts.

What model is the one your going to see (square tub, round tub) When you look at the one tomorrow.. There's a check list.. Make sure the agitator comes off and isn't stuck. Look for holes in the tub Look for think grease coming out of the breather hole in top of the right angle drive Look for oil running down one leg Make sure wringer turns and locks into position If possible plug in and check operation of agitator (that it starts and stops when knob is pulled in and out) If possible fill with water and check for leaks. If equipt with a pump, engage it to see. While running check to see if wringer rolls move in both directions I'm I forgetting anything, HTH and let us know | ||

| Post# 943448 , Reply# 22 6/14/2017 at 14:46 (2,501 days old) by tarantulae (Colorado) | ||

|

It works. Looks like the pump wheel has flat spots from it rubbing on the drive wheel. Any idea where I can get replacements? Takes forever to gravity drain.

View Full Size

| ||

| Post# 943518 , Reply# 25 6/14/2017 at 21:58 (2,501 days old) by Stan (Napa CA) | ||

If the manual

Is for your washer, I'd grab it, as info, parts, ect may be a little harder to get than the Maytag.

I'm not fimiler with Thor Wringers but I would think it would handle the jeans, diapers ect as good as the Maytag would? My Maytag handles a thick terry bathrobe without hesitation. It might be that Maytags had the best wringers for that time? Someone will come by that knows Thors Keep us up to date. | ||

| Post# 943519 , Reply# 26 6/14/2017 at 22:00 (2,501 days old) by Stan (Napa CA) | ||

Try  | ||

| Post# 943578 , Reply# 28 6/15/2017 at 10:39 (2,500 days old) by stan (Napa CA) | ||

You might try  | ||

| Post# 943584 , Reply# 29 6/15/2017 at 11:32 (2,500 days old) by tarantulae (Colorado) | ||

|

I paid 125. Less than what I was looking at for fixing up the maytag. | ||

| Post# 943607 , Reply# 30 6/15/2017 at 14:45 (2,500 days old) by stan (Napa CA) | ||

That's not bad | ||

| Post# 943768 , Reply# 31 6/16/2017 at 11:08 (2,499 days old) by bradross (New Westminster, BC., Canada) | ||

Shame about the Maytag - but nice you found a Thor...

Duncan, if you lived closer, I'd sell you one of my wringer washers! I'm "overflowing" with 5 currently in my collection! And that's in an apartment! Can you imagine if I had a house - I'd start a wringer washer restoration business!

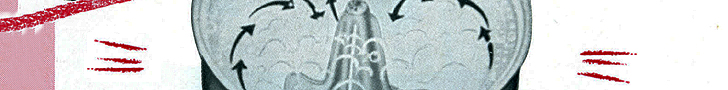

Best of success in rejuvenating the Thor. My mother and grandmother both had Thor machines from the late '30s. I've attached a couple of pics in case you'd like to see some older models. From what I know, they were very reliable machines. As you can see in the photos, the wringer assembly had two options for tension control - a screw or an automatic tension set/on-off lever (the type my mom had). | ||

Comes to the Rescue!

Comes to the Rescue!