|

Thread Number: 1383

Help! Maytag Repairman recommends euthanasia! |

[Down to Last] |

|

| Post# 58237 , Reply# 3 2/25/2005 at 06:58 (6,999 days old) by Mayken4now (Panama City, Florida) | ||

Maytag Repair

Pat, welcome to this site. Go and get yourself a reapir manual for that machine. Has the machine been in your home? (and I mean inside your home, not in a barn, not on the porch not in the shanty etc....) If so, you are in good shape! You will not have much rust to contend with especially if you have kept the Maytag looking new and not sloping bleach all over it. I have a 1973 pair, and have worked (minimal) on mine, oh so easy, and I have rust! Yea you have to replace a few additional items, but sooooooooooo. Buy the parts in question, which I could not tell you what they are, but find out, then get those obvious ones first. You will probably need a new drain pump located in the right front of the machine on the bottom, so get that while you are at too. The felt under the pedistal that the outer tub rest on will need to be changed as well. Other than that, your in good shape. Do not trash the Machine(s), if you get over it and want new ones, go ahead, but please, let us know on here, someone would want your coppertone. Steve In Pensacola | ||

| Post# 58243 , Reply# 4 2/25/2005 at 09:53 (6,999 days old) by PeterH770 (Marietta, GA) | ||

The breaking mechanism (which is part of the helical drive) should be basically the same one that is used in the current line of orbital drive transmission machines. That the tub has now siezed up is further indication that there is something wrong in the helical drive. The parts are readily available. Any "Ol' Lonely" who is worth his muster can take care of it. You have a lazy repairman. Call someone else or give it a shot yourself! Welcome to the club!

| ||

Post# 58265 , Reply# 5 2/25/2005 at 19:46 (6,998 days old) by appnut  (TX) (TX) |

||

|

| ||

| Post# 58288 , Reply# 8 2/26/2005 at 05:31 (6,998 days old) by laundromat (Hilo, Hawaii) | ||

Maytag washer

Hi Pat and welcome aboard!I would recomend that you call an AUTHORISED Maytag repairman.One who is actualy a technician and knows the product inside and out.Usualy,someone who says it isn't worth fixing either wants to sell you one of their rebuilt,used ones or a new one they'll make profit on.The cost of repair may be a little steap but believe me,it's well worth the investment.Call 1-888-4-maytag ant see if they can set up a service call for you.

| ||

| Post# 58300 , Reply# 9 2/26/2005 at 07:30 (6,998 days old) by Mayken4now (Panama City, Florida) | ||

Poor old MAY

Hi Pat: Be real kind to her, as I mentioned, if you do it your self, Newton Iowa will have the repair manual. Yes Yes, laundromat says call 1-888-4-maytag, he is so right! Then you have a "no-strings" ............... to fix the 1977. You can buy all of the parts yourself, if money is an issue. The repair personell will will have them or order them, but at a greater expense to you. Lay it out on the line, to exactly what you want, require a written estimate of labor, time, and add'l parts needed. If the tub wrench is $80+'s, then thats a little steep for a one time fix. You would need to buy a large nice clean or have one built on your property,(a building) to start re-doing Maytag's LOL!!!!!!!!!!!!!! Let us know how you fair. I will email you and share my maytag pic with you! Steve in Pensacola Steve In pensacola | ||

Post# 58329 , Reply# 10 2/26/2005 at 14:51 (6,998 days old) by Goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

| ||

Post# 58356 , Reply# 15 2/26/2005 at 18:43 (6,997 days old) by Goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

Yep,the belts can be fried,without actually being broken. Is it possible that the washer might have had a heavy load in it,like a lot of jeans or similar? That would cause marginal belts to slip badly,and get the burning smell you had.The black residue is from the belt slipping,time to replace the set. It's easy enough to check the pump.With the belts off,make sure the pump pulley is turning freely,no binding or noise.I don't think a bad pump will cause the washer to stop spinning,but it would cause the belt slippage if it were locked up.Maytag belts are very easy to replace,about a 10 minute job at most.Feel free to ask any more questions. kennyGF | ||

| Post# 58370 , Reply# 17 2/26/2005 at 21:11 (6,997 days old) by laundromat (Hilo, Hawaii) | ||

maytag helical drive

Pat, Newton,Iowa is where Maytag's headquarters are, not Ohio.I think the first thing I would do is replace the old belts with a brand new set.As you replace the old ones,be sure you clean off the pullies and check underneath for any oil leaks.Some of the rubber on the belts may have left a resedue on the pullies. | ||

| Post# 58376 , Reply# 20 2/26/2005 at 23:27 (6,997 days old) by rickr (.) | ||

Maytag belts

Hi Pat, Don't try to use any other type "v" belts on your machine.They cannot come from an auto parts store. They have to be the special genuine Maytag washer "v" belts.As someone stated before they are designed to act as a clutch and have a special coating on the belts to allow them to slip without undo wear or damage. Good luck,you can do it! Rick | ||

Post# 58383 , Reply# 23 2/27/2005 at 05:33 (6,997 days old) by Goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

$23.10 is probably the price for the belt set.It takes 2 belts,and lately Maytag has been packaging them together.Check locally,you might find them cheaper. You're right,you have to be able to tip the machine back,to change them.Be sure to unplug the machine first,tip it back,you can use wood blocks or similar to hold it tipped.The motor is on a sliding type bracket,so no belt adjustment should be necessary.Remove the old,replace with the new,pretty simple. kennyGF | ||

| Post# 58621 , Reply# 26 3/1/2005 at 14:55 (6,995 days old) by PeterH770 (Marietta, GA) | ||

| ||

| Post# 58640 , Reply# 28 3/1/2005 at 17:20 (6,994 days old) by PeterH770 (Marietta, GA) | ||

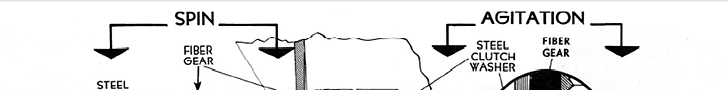

No. The belt only goes one way around the motor and drive pulley, and the way a Maytag works is turn in one direction you get spin, turn in the other direction you get agitation. In Maytag's case, the term "helical drive" actually does describe the method of transferring the rotary power of the motor to "drive" the transmission and the tub. When the drive turns in one direction, the drive shafts rides down the helix, tightening down a large spring onto the tub brake and driving the transmission. When the motor reverses, the drive shaft rides up the helix, releasing spring and the brake, causing the tub (and the transmission) to spin. When the motor stops running, there is no longer the drive force holding the drive up the helix, so the spring causes the drive to tighten down very quickly to stop all action. Like I said, it sounds like your brakes and/or helical drive needs some work. Maytag is THE favorite machine for coin laundry owners as they are relatively simple to work on (but you do need some muscles). You can do this repair if you put your mind to it. You need the book in the link below: CLICK HERE TO GO TO PeterH770's LINK on eBay | ||

| Post# 58667 , Reply# 30 3/1/2005 at 19:55 (6,994 days old) by patpackrat () | ||

|

A forgotten detail Peter -- A quick question: Should the agitator lift off fairly easily? If so and it doesn't, is that indicative of anything you just mentioned? PAT | ||

| Post# 58681 , Reply# 31 3/1/2005 at 22:06 (6,994 days old) by Mayken4now (Panama City, Florida) | ||

The Maytag!

MS. Pat, thanks for the email. My machines were totaly restored by me. It is not that hard. At this point, I will tell you to sell these to one of myself or these passoinate gentlemen on here. Go buy a new one. The washer story for one problem does not last a whole 2 weeks. You have an old machine that needs total refurbish or just replace it. Love from the know how. Steve | ||

| Post# 58725 , Reply# 33 3/2/2005 at 09:13 (6,994 days old) by PeterH770 (Marietta, GA) | ||

Pat, Don't sell. Fix. Maytag had this design in their domestic line from the mid 50's until today. Parts are readily available. Maytag wouldn't have kept this design around so long if it wasn't "dependable". Note that this design is the only design Maytag offers for coin-op use. That says plenty right there. The 1974 book will work just fine for any Maytag that uses the helical drive. | ||

| Post# 58760 , Reply# 34 3/2/2005 at 16:04 (6,993 days old) by kenmore1978 () | ||

|

Transmission Speaking of drives, could someone explain the difference in operation between the Helical and Orbital drives? Was one better than the other? Did both types spin with the tub? When was the changeover? etc., etc. | ||

| Post# 58765 , Reply# 35 3/2/2005 at 16:57 (6,993 days old) by PeterH770 (Marietta, GA) | ||

They are 2 completely different beasts. The problem is how the word "drive" is used in each case. Here is the deal: The Helical Drive drives the Orbital transmission. All Orbital Transmission Maytags utilize the same Helical Drive that Maytag had since the early days. Maytag changed from their tried-and-true transmission that we all love to the Orbital Transmission in the early 1990's. Orbital Transmission Maytags came to be known as "Dependable Care" shortly after they were introduced, so that consumers would not loose faith in Maytag for changing their design. The control panels say Dependable Care right on them. So today, when someone says they have a Dependable Care Maytag, you can be fairly sure that it has the orbital transmission. If someone says they have a Helical Drive Maytag, you can be fairly certain that 1) they are a bit smarter about their machine than the average bear, and 2) it has the old tried-and-true transmission. | ||

| Post# 58766 , Reply# 36 3/2/2005 at 17:02 (6,993 days old) by PeterH770 (Marietta, GA) | ||

One more thing: The helical drive is in the bottom of the washer, just above the pulley and the washer base. The transmission is just below the outer tub. If you take the front panel off a Maytag, you can't see how it works, but you can see the difference between agitate and spin. Just keep your hands out of the cabinet when spin time comes! | ||

| Post# 58774 , Reply# 37 3/2/2005 at 17:39 (6,993 days old) by kenmore1978 () | ||

|

clarification So, the "Helical Drive" exists in both types of washers. In that case what was the transmission called before Orbital transmissions came out? | ||

Post# 58785 , Reply# 38 3/2/2005 at 17:59 (6,993 days old) by goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

| ||

| Post# 58793 , Reply# 39 3/2/2005 at 18:35 (6,993 days old) by westytoploader () | ||

|

Isn't there a set screw on these as well that you might have to loosen? My Power-Fin has one. | ||

| Post# 58820 , Reply# 41 3/2/2005 at 20:35 (6,993 days old) by Mayken4now (Panama City, Florida) | ||

Pat!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Can we help, yes! However, adhere to what we have told you! I tried to help you, but you change your story? Are you an attorney? Get the manual, or get a repair man. I/we want you to repair your 77 CA408!!!!!! These machines or the MOST simple to work on. Yes the muscle has to come into play, however, it is not impossible. I have just finished restoring the two (2) that I bought only 4 days ago, no big deal, they are a breeze. Love Steve | ||

| Post# 58821 , Reply# 42 3/2/2005 at 20:39 (6,993 days old) by Mayken4now (Panama City, Florida) | ||

Pat!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

Can we help, yes! However, adhere to what we have told you! I tried to help you, but you change your story? Are you an attorney? Get the manual, or get a repair man. I/we want you to repair your 77 CA408!!!!!! These machines or the MOST simple to work on. Yes the muscle has to come into play, however, it is not impossible. I have just finished restoring the two (2) that I bought only 4 days ago, no big deal, they are a breeze. Love Steve | ||

| Post# 58840 , Reply# 44 3/2/2005 at 21:37 (6,993 days old) by Mayken4now (Panama City, Florida) | ||

Debit and Credit | ||

| Post# 58898 , Reply# 48 3/3/2005 at 09:28 (6,993 days old) by PeterH770 (Marietta, GA) | ||

| ||

| Post# 58905 , Reply# 49 3/3/2005 at 10:27 (6,993 days old) by PeterH770 (Marietta, GA) | ||

| ||

Post# 58941 , Reply# 50 3/3/2005 at 17:42 (6,992 days old) by goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

| ||

| Post# 59387 , Reply# 54 3/7/2005 at 21:34 (6,988 days old) by Mayken4now (Panama City, Florida) | ||

Is it fixed? | ||

Comes to the Rescue!

Comes to the Rescue!