|

Thread Number: 15284

Maytag Electronic Dry DG906 Question |

[Down to Last] |

|

| Post# 257551 , Reply# 1 1/3/2008 at 20:56 (5,949 days old) by danemodsandy (The Bramford, Apt. 7-E) | ||

|

Phil:

Grounding seems to be essential on electronic sensor 'Tags- my own DE606 doesn't work correctly if it's not grounded. And it's a much simpler machine than yours. Since you do have a ground wire attached to the cabinet (are you using the factory ground screw, or some other screw?), your outlet may be somehow at fault, but I'll leave that to mightier minds than my own. | ||

Post# 257553 , Reply# 2 1/3/2008 at 21:22 (5,949 days old) by toggleswitch  (New York City, NY) (New York City, NY) |

||

|

~ Have a ground wire from the very bottom of the cabinet in back attached to a cold water pipe. Assuming all works as it should (and that paint is not insulating the ground wire from the cabinet) this effectively grounds the outlet, even if it is improperly (or is no longer) grounded through its own wiring. | ||

| Post# 257576 , Reply# 3 1/4/2008 at 00:01 (5,948 days old) by pturo (Syracuse, New York) | ||

|

I assume it is the factory ground screw,but I am wondering if that is overrided by the 3 prong to the outlet. Toggles has a point, I painted the back of the cabinet, but to my original question, could I ground the cabinet anywhere? | ||

| Post# 257578 , Reply# 4 1/4/2008 at 00:07 (5,948 days old) by pturo (Syracuse, New York) | ||

|

Another Thought How about connecting a ground where the cabinet first is grounded from the ground wire first coming in that attaches to the cabinet? That seems to me where the discharge or non discharge of the electronic control would happen based on the wiring, but correct me if I am wrong. | ||

Post# 257582 , Reply# 5 1/4/2008 at 00:53 (5,948 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

With the dryer empty, press the damp-dri button to start the machine. It should shut off within 20-30 seconds if the electronic control is working properly. If it does shut off within that timeframe, we'll go on to step two... You can ground the cabinet anywhere - and it should be fine the way you have it. I've used quite a few of these HOH dryers w/electronic control with the cabinet not grounded and they worked just fine. | ||

Post# 257622 , Reply# 6 1/4/2008 at 08:36 (5,948 days old) by cuffs054  (MONTICELLO, GA) (MONTICELLO, GA) |

||

|

Have you cleaned the sensors in the drum? | ||

Post# 257682 , Reply# 8 1/4/2008 at 14:43 (5,948 days old) by volvoguy87  (Cincinnati, OH) (Cincinnati, OH) |

||

Grounded outlet.

Go to the hardware store and in the home electrical section you can buy an inexpensive outlet tester. It plugs into your outlet and has 3 lights on it. The lights will come on in a sequence according to how your outlet is wired. By checking the displayed lights against the key on top of the tester, you can determine if your outlet is properly grounded, and properly wired otherwise. Also, make sure that the water pipe is actually grounded. If there's a plastic connection between sections of pipe somewhere, it may not be grounded. Good luck, Dave | ||

| Post# 257684 , Reply# 9 1/4/2008 at 14:48 (5,948 days old) by bobbyderegis (Boston) | ||

|

Phil, the loose connections on the electronic control could be your problem. I had to solder the connections on my 606. Did you consider replacing the electronic control as well? Bobby in Boston | ||

| Post# 257691 , Reply# 10 1/4/2008 at 15:50 (5,948 days old) by pturo (Syracuse, New York) | ||

|

Bobby, This is a new electronic control(1 year) But the wires seem to fit very loosely. Dave, Thanks for the tip. Never hurts to have an outlet tester. Phil | ||

Post# 257814 , Reply# 14 1/5/2008 at 06:38 (5,947 days old) by toggleswitch  (New York City, NY) (New York City, NY) |

||

|

Can't recommend this on 230v................

Using a standard neon tester to check for earth/ground. I'm sure most of us understand sticking one lead into the hot opening of an outlet /power-point, and the other in the ground opening should cause the tester to light. Here is what you may not know (although it may be safe and possible........I CAN NOT recommend this on 230v....) WITH THIS TYPE OF TESTER ONLY..... one lead may be stuck in the hot side of an outlet and the other lead may be allowed to make contact WITH YOUR VERY OWN FINGER. You will get the thing to partialy light up. This is useful to ensure that you have actually made contact witht the "hot/live" lead should the outlet not have a neutral or a good ground enabling you to light it up otherwise. REMEBER: THIS PROCEDURE IS FOR A "NEON" NOT A REGULAR LAMP / LIGHT BULB TESTER!

| ||

Post# 257815 , Reply# 15 1/5/2008 at 06:45 (5,947 days old) by toggleswitch  (New York City, NY) (New York City, NY) |

||

|

Make your work interesting, but NOT shocking/ heart-stopping | ||

Post# 257915 , Reply# 17 1/5/2008 at 16:12 (5,947 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

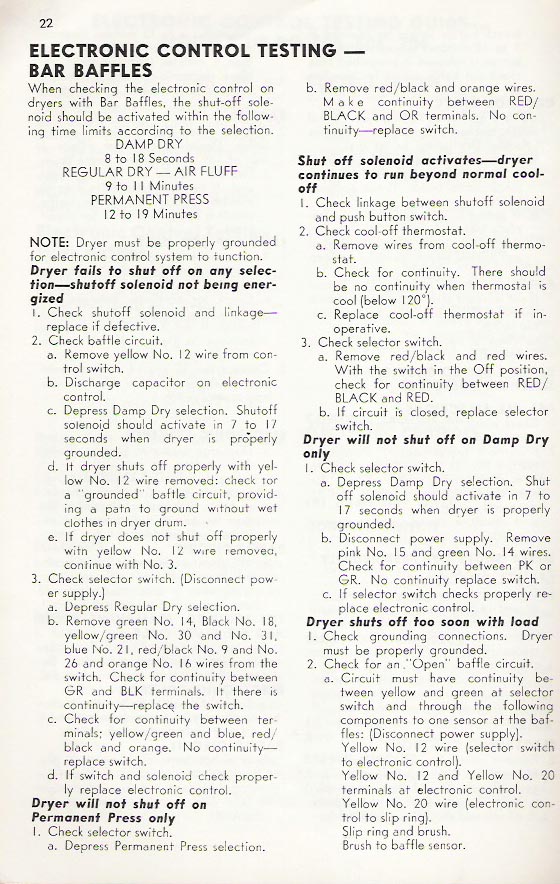

Further Testing | ||

Post# 257917 , Reply# 18 1/5/2008 at 16:13 (5,947 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

| ||

Post# 257918 , Reply# 19 1/5/2008 at 16:13 (5,947 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

| ||

| Post# 258023 , Reply# 20 1/6/2008 at 00:28 (5,946 days old) by pturo (Syracuse, New York) | ||

|

Thanks Gansky, What a great and thoughfully accurate contribution.

| ||

| Post# 258024 , Reply# 21 1/6/2008 at 00:33 (5,946 days old) by pturo (Syracuse, New York) | ||

|

Thanks Gansky, What a great and thoughfully accurate contribution. | ||

| Post# 258570 , Reply# 23 1/8/2008 at 07:00 (5,944 days old) by bobbyderegis (Boston) | ||

|

Phil: one loose connection to the electronic control and it's a freak show. Try the new harness. Bobby in Boston | ||

| Post# 258901 , Reply# 24 1/9/2008 at 18:58 (5,943 days old) by pturo (Syracuse, New York) | ||

|

New harness on order, and thanks Bobby. | ||

| Post# 258991 , Reply# 25 1/10/2008 at 06:54 (5,942 days old) by bobbyderegis (Boston) | ||

|

Phil, I'm surprized you can still get them. Is it new? Bobby in Boston | ||

Comes to the Rescue!

Comes to the Rescue!