|

Thread Number: 21311

1960 Maytag Highlander Restoration Progress (Pix) |

[Down to Last] |

|

| Post# 336042 , Reply# 1 3/17/2009 at 21:23 (5,511 days old) by ttuee2006 () | ||

|

Tub Ring Now we have the underside of the tub ring

| ||

| Post# 336043 , Reply# 2 3/17/2009 at 21:24 (5,511 days old) by ttuee2006 () | ||

|

Tub Now for the tub itself...

| ||

| Post# 336044 , Reply# 3 3/17/2009 at 21:24 (5,511 days old) by ttuee2006 () | ||

|

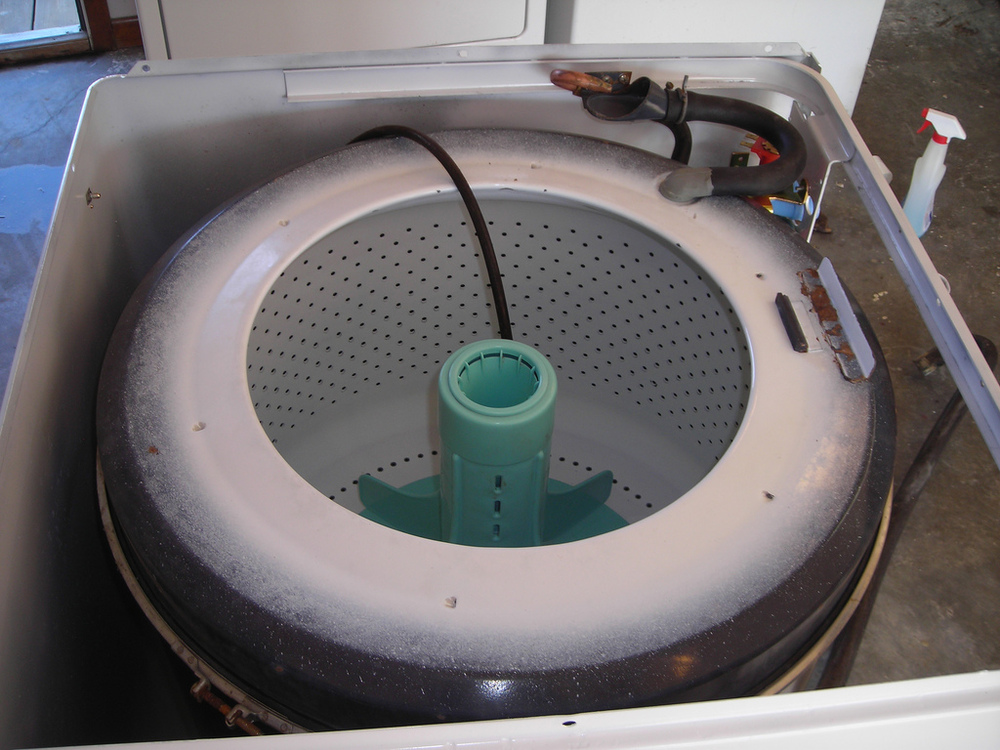

Spin Basket Inside of the Spin Basket... This part was a PAIN to de-lime

| ||

| Post# 336045 , Reply# 4 3/17/2009 at 21:25 (5,511 days old) by ttuee2006 () | ||

|

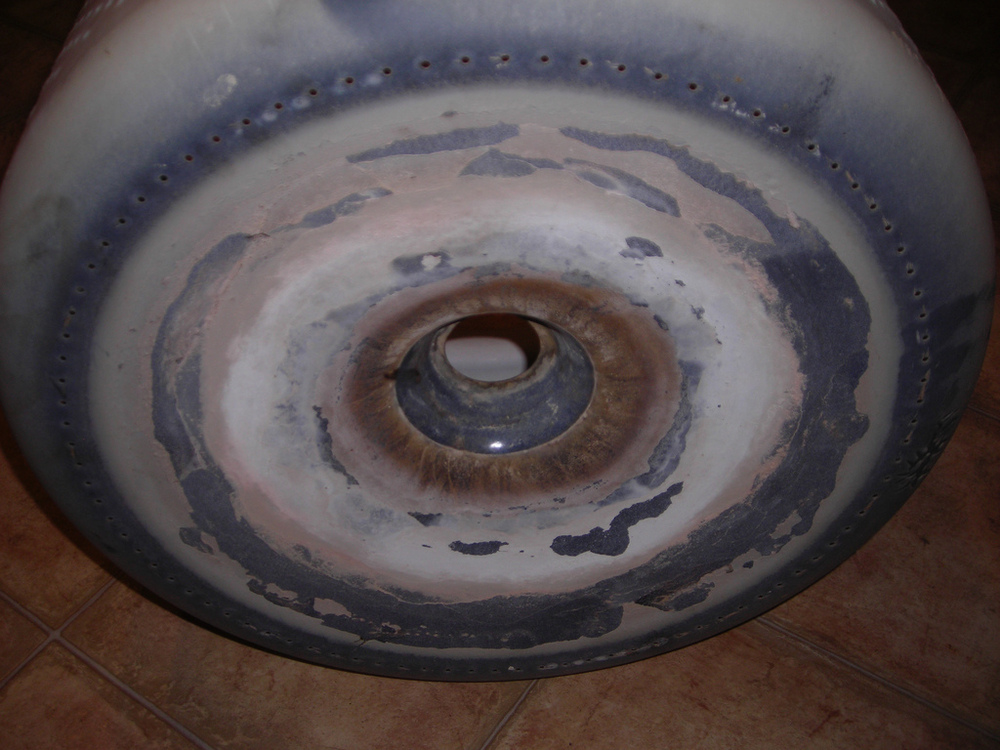

Underside of the spin basket Underneath the Spin Basket...

| ||

| Post# 336046 , Reply# 5 3/17/2009 at 21:26 (5,511 days old) by ttuee2006 () | ||

|

Clean Spin Basket Spin Basket post-cleanup...

| ||

| Post# 336047 , Reply# 6 3/17/2009 at 21:27 (5,511 days old) by ttuee2006 () | ||

|

Underside of Spin Basket post-cleanup Under the spin basket after cleanup...

| ||

| Post# 336048 , Reply# 7 3/17/2009 at 21:28 (5,511 days old) by ttuee2006 () | ||

|

Clean Tub Ring Tub Ring post-cleanup...

| ||

| Post# 336049 , Reply# 8 3/17/2009 at 21:29 (5,511 days old) by ttuee2006 () | ||

|

Underside of Tub Ring post-cleanup Clean tub ring, post-cleanup...

| ||

| Post# 336050 , Reply# 9 3/17/2009 at 21:29 (5,511 days old) by ttuee2006 () | ||

|

Tub Post-Cleanup Tub inside post-cleanup...

| ||

| Post# 336051 , Reply# 10 3/17/2009 at 21:30 (5,511 days old) by ttuee2006 () | ||

|

Tub Post-Cleanup Outside of the tub post-cleanup...

| ||

| Post# 336068 , Reply# 11 3/17/2009 at 23:15 (5,511 days old) by redcarpetdrew (Fairfield, CA) | ||

Just about factory new! | ||

| Post# 336090 , Reply# 12 3/18/2009 at 06:26 (5,510 days old) by christfr (st louis mo) | ||

| ||

| Post# 336094 , Reply# 13 3/18/2009 at 07:45 (5,510 days old) by geoffdelp (SAUK RAPIDS) | ||

|

Looks great, Eric! It's a rewarding process, isn't it? Can't wait to see it when you get done. | ||

| Post# 336180 , Reply# 15 3/18/2009 at 23:32 (5,510 days old) by whirlaway (Hampton Virginia) | ||

|

Amazing!!!!!!!!!!!!!!!!!!!!!!!! Just beautiful!!!!!!!!!!!!!!!!!!!!!!!!!! What did you get that scale off with? | ||

| Post# 336200 , Reply# 17 3/19/2009 at 05:49 (5,509 days old) by kenmore81 () | ||

|

Cant wait to see more Im hoping there will be a vid on you tube as well ;), Im subscribed. for how long I dont know lol. My you tube acct erases everthing for some reason | ||

| Post# 336383 , Reply# 19 3/20/2009 at 03:13 (5,508 days old) by kenmore81 () | ||

|

All I have to say is... WOW.What a project, and a terrific job.Just The thought of painting the timer makes my hands shake lol, i cant do that unless its a stencil. | ||

Post# 336394 , Reply# 20 3/20/2009 at 04:21 (5,508 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Restore | ||

| Post# 336528 , Reply# 22 3/20/2009 at 22:09 (5,508 days old) by ttuee2006 () | ||

|

The rusty agitator shaft and the top of the tranny...

| ||

| Post# 336529 , Reply# 23 3/20/2009 at 22:10 (5,508 days old) by ttuee2006 () | ||

|

And of course the timer dial......which I'm currently working on

| ||

| Post# 336552 , Reply# 24 3/21/2009 at 00:06 (5,508 days old) by ttuee2006 () | ||

|

Finished Timer Knob Got the knob finished! And yes.....that IS the same knob!

| ||

| Post# 336553 , Reply# 25 3/21/2009 at 00:07 (5,508 days old) by ttuee2006 () | ||

|

Uh......Picture? Let's try that again.....

| ||

| Post# 336568 , Reply# 26 3/21/2009 at 01:51 (5,508 days old) by qsd-dan (West) | ||

|

Whoa!! | ||

| Post# 336856 , Reply# 28 3/22/2009 at 14:21 (5,506 days old) by ttuee2006 () | ||

|

At least I can show how she came out.. Here's how she turned out:

| ||

| Post# 336857 , Reply# 29 3/22/2009 at 14:22 (5,506 days old) by ttuee2006 () | ||

|

Closer view of the Control Panel... The control panel didn't turn out as nice as I would have desired, but it's a FAR CRY from what it was!

| ||

| Post# 336860 , Reply# 30 3/22/2009 at 14:31 (5,506 days old) by ttuee2006 () | ||

|

Of course for comparison, you've gotta understand what it looked like when it came home! The link below posts to the original thread in the archives section... CLICK HERE TO GO TO ttuee2006's LINK | ||

| Post# 336878 , Reply# 31 3/22/2009 at 15:31 (5,506 days old) by qsd-dan (West) | ||

|

Center shaft

Well, the shaft and collar are still available but at the steep price of $91-110, depending where you purchase it :( CLICK HERE TO GO TO qsd-dan's LINK | ||

| Post# 336932 , Reply# 33 3/22/2009 at 19:26 (5,506 days old) by qsd-dan (West) | ||

|

I'm thinking of possibly using a very hard epoxy | ||

| Post# 336934 , Reply# 34 3/22/2009 at 19:32 (5,506 days old) by autowasherfreak () | ||

|

Wow, it looks great! What did you use to clean the dial with? | ||

Post# 336936 , Reply# 35 3/22/2009 at 19:42 (5,506 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

| Post# 336939 , Reply# 37 3/22/2009 at 19:59 (5,506 days old) by ttuee2006 () | ||

|

More Pix Here's some more pix from the restoration process... This one is of the right side before it was repainted.....what a wreck!

| ||

| Post# 336940 , Reply# 38 3/22/2009 at 20:00 (5,506 days old) by ttuee2006 () | ||

|

Left Side before Repainting... The left side before being repainted...

| ||

| Post# 336941 , Reply# 39 3/22/2009 at 20:01 (5,506 days old) by ttuee2006 () | ||

|

Front Before Repainting The Front before repainting...

| ||

| Post# 336942 , Reply# 40 3/22/2009 at 20:02 (5,506 days old) by ttuee2006 () | ||

|

Front after painting Shot of the front after it was painted...

| ||

| Post# 336944 , Reply# 41 3/22/2009 at 20:03 (5,506 days old) by ttuee2006 () | ||

|

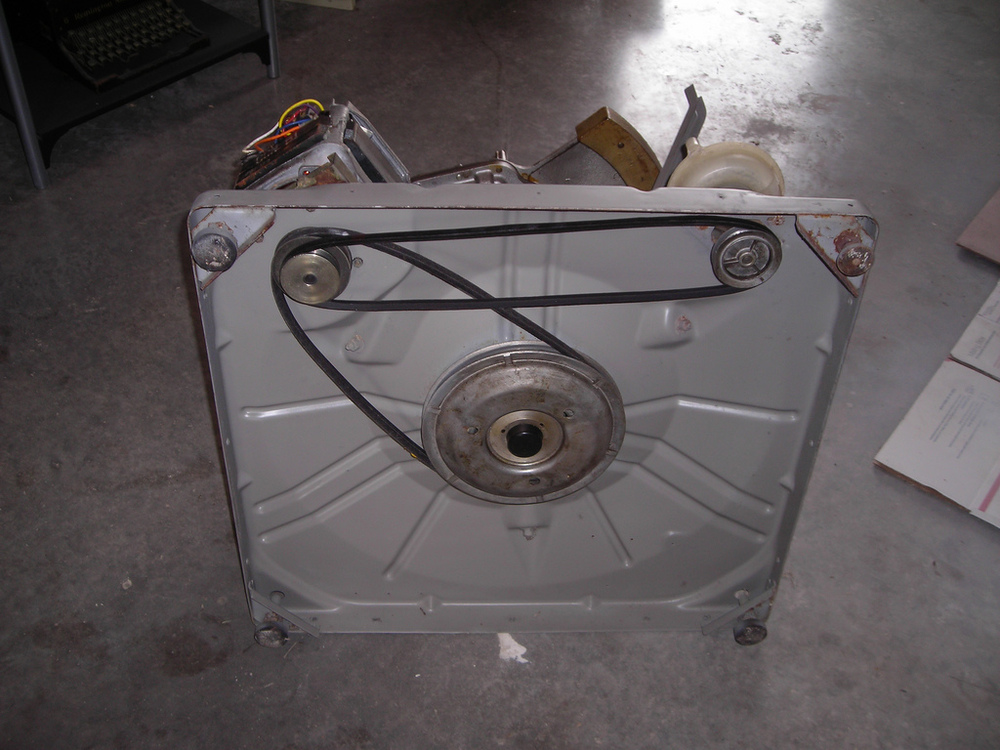

Basepan Painted Stripped the base pan down to bare metal and repainted with 2 coats of "rusty metal" Rustoleum...

| ||

| Post# 336945 , Reply# 42 3/22/2009 at 20:04 (5,506 days old) by ttuee2006 () | ||

|

Base Pan #2

| ||

| Post# 336946 , Reply# 43 3/22/2009 at 20:05 (5,506 days old) by ttuee2006 () | ||

|

Tub remounted Tub remounted on the base pan. New seals, spin bearing, and tub to pump hose.

| ||

| Post# 336947 , Reply# 44 3/22/2009 at 20:06 (5,506 days old) by ttuee2006 () | ||

|

Back in the Cabinet Cabinet remounted on base. New fill valve installed.

| ||

| Post# 336948 , Reply# 45 3/22/2009 at 20:07 (5,506 days old) by ttuee2006 () | ||

|

Plumbing remounted... Plumbing all cleaned up and remounted...

| ||

| Post# 336949 , Reply# 46 3/22/2009 at 20:08 (5,506 days old) by ttuee2006 () | ||

|

A better view of that air gap Siphon break!

| ||

Post# 336951 , Reply# 48 3/22/2009 at 20:18 (5,506 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Agi shaft -

If your attempts with epoxy fall short, you could always opt for a parts machine. More than likely you can find a 70's or 80's BOL 'Tag near by for cheep or nearly free. I can't say I've seen them by the thousands, but I haven't seen these get this bad on later machines (probably due to the non-splined Power Fins.) The machine came out stunning! Ben | ||

| Post# 336953 , Reply# 49 3/22/2009 at 20:27 (5,506 days old) by qsd-dan (West) | ||

|

Scratch removal | ||

Post# 337005 , Reply# 50 3/23/2009 at 07:20 (5,505 days old) by countryguy  (Astorville, ON, Canada) (Astorville, ON, Canada) |

||

Wow, that is the same washer we had when I was growing up. I remember the day (around 1967 I think) we got it, actually it was in the evening and my mom, dad and I were down in the basement watching it work for the first time! Prior to that my mom had a wringer washer (don't know what brand it was). I do remember it had a black agitator and the lint catcher was chrome with the black cup on the top and the black rubber band on the bottom. My mom used that washer up until the day she died in 2001. I don't remember it ever needing a repair other than a new belt. Gary | ||

| Post# 337971 , Reply# 51 3/26/2009 at 21:01 (5,502 days old) by ttuee2006 () | ||

|

HOLY CRAP!!!!! I FIXED THE SHAFT!!!!!! IT WORKS! IT WORKS!!!!! I'M STILL PINCHING MYSELF!!!!! Videos and an explanation to follow shortly! | ||

| Post# 338022 , Reply# 52 3/26/2009 at 23:19 (5,502 days old) by ttuee2006 () | ||

|

The Video Very first video showing it running with NO LEAKS! CLICK HERE TO GO TO ttuee2006's LINK | ||

| Post# 338025 , Reply# 55 3/26/2009 at 23:29 (5,502 days old) by ttuee2006 () | ||

|

In the Laundry Room Taking it's place in the laundry room! (Temporarily of course...)

| ||

| Post# 338026 , Reply# 56 3/26/2009 at 23:31 (5,502 days old) by qsd-dan (West) | ||

|

Indexing tub | ||

Post# 338028 , Reply# 57 3/26/2009 at 23:36 (5,502 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

| Post# 338034 , Reply# 58 3/26/2009 at 23:41 (5,502 days old) by autowasherfreak () | ||

|

Another Fantastic Restoration! Wow, you did a great job on the old girl. She looks good, and sounds great! | ||

| Post# 338041 , Reply# 60 3/26/2009 at 23:58 (5,502 days old) by ttuee2006 () | ||

|

And of course...... The Compulsory video! Wash.......WITH CLOTHES! CLICK HERE TO GO TO ttuee2006's LINK | ||

| Post# 338045 , Reply# 61 3/27/2009 at 00:13 (5,502 days old) by qsd-dan (West) | ||

|

Transmission Fluid | ||

| Post# 338277 , Reply# 63 3/28/2009 at 00:36 (5,501 days old) by redcarpetdrew (Fairfield, CA) | ||

I may be of assistance...

Can you post the model/serial? I didn't see it in the above posts. I just may have access to the orig service manual or at least I should be able to find some instructions on tear down and rebuilding of the trans and the brake package repair and adjustment. I can fax them to you or whatever... QSD can attest to the large amount of older books and manuals I have access to... The brake tool is still very much available and is a small price to pay for if you and your Maytags are to stay together for a while. That is if you don't already have it... RCD | ||

| Post# 339153 , Reply# 65 3/31/2009 at 20:29 (5,497 days old) by redcarpetdrew (Fairfield, CA) | ||

I'm working on it... | ||

Comes to the Rescue!

Comes to the Rescue!