|

Thread Number: 22574

1967 G.E. MOBILE MAID PUMP IMPELLER IS OUT! PICS! |

[Down to Last] |

|

| Post# 353700 , Reply# 3 5/31/2009 at 20:30 (5,436 days old) by soberleaf () | ||

|

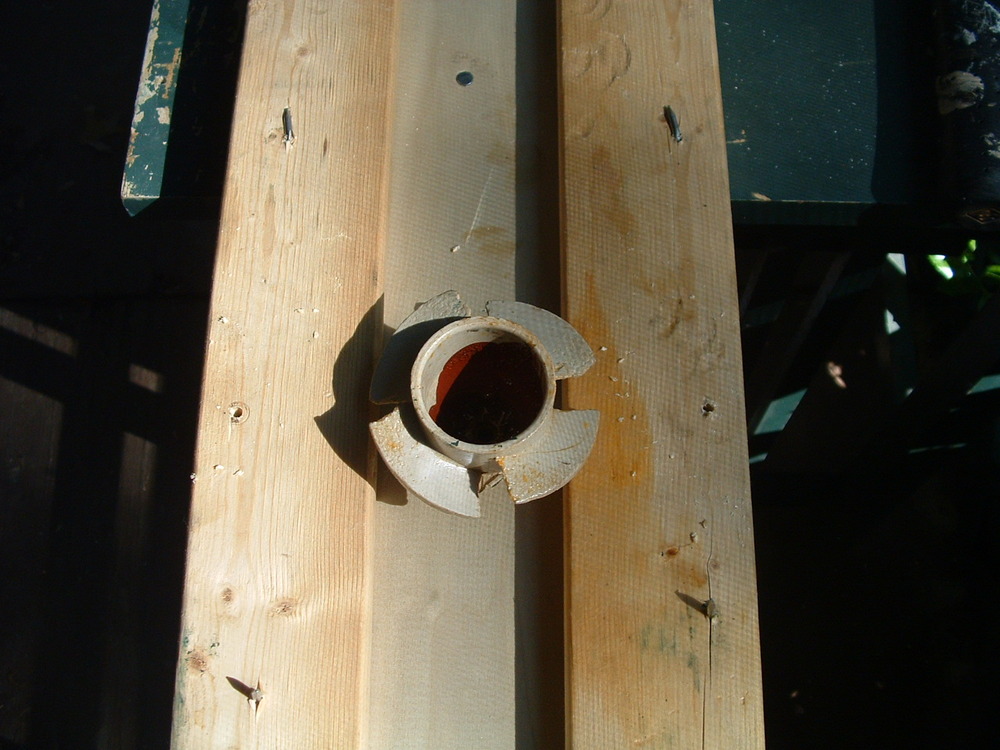

to get that impeller in that hole i cut the board in half

| ||

| Post# 353701 , Reply# 4 5/31/2009 at 20:32 (5,436 days old) by soberleaf () | ||

|

the idea was to assemble it around impeller shaft and then clamp it together using more boards, 1 by 3 lumber firing strips.

| ||

| Post# 353702 , Reply# 5 5/31/2009 at 20:33 (5,436 days old) by soberleaf () | ||

|

so here it is

| ||

| Post# 353703 , Reply# 6 5/31/2009 at 20:34 (5,436 days old) by soberleaf () | ||

|

here it is again a nice tight fit! we like that!

| ||

| Post# 353706 , Reply# 7 5/31/2009 at 20:36 (5,436 days old) by soberleaf () | ||

|

next i started building the impeller puller out of 5/16 threaded rod that i bought and cut into 12 inch sections. i used fender washers and nuts to anchor it down into it's little "impeller puller tower" this was starting to be fun!

| ||

| Post# 353707 , Reply# 8 5/31/2009 at 20:37 (5,436 days old) by soberleaf () | ||

|

another view

| ||

| Post# 353708 , Reply# 9 5/31/2009 at 20:38 (5,436 days old) by soberleaf () | ||

|

the tower rises!

| ||

| Post# 353712 , Reply# 11 5/31/2009 at 20:46 (5,436 days old) by soberleaf () | ||

|

another view after impeller was lifted off shaft about 1/2 inch. i could feel it moving and it made a creaking sound with every turn of the nut! the wood was groaning a bit too! very interesting experience i must say!

| ||

| Post# 353713 , Reply# 12 5/31/2009 at 20:47 (5,436 days old) by soberleaf () | ||

|

and another view. it's comin off!

| ||

| Post# 353717 , Reply# 15 5/31/2009 at 20:54 (5,436 days old) by soberleaf () | ||

|

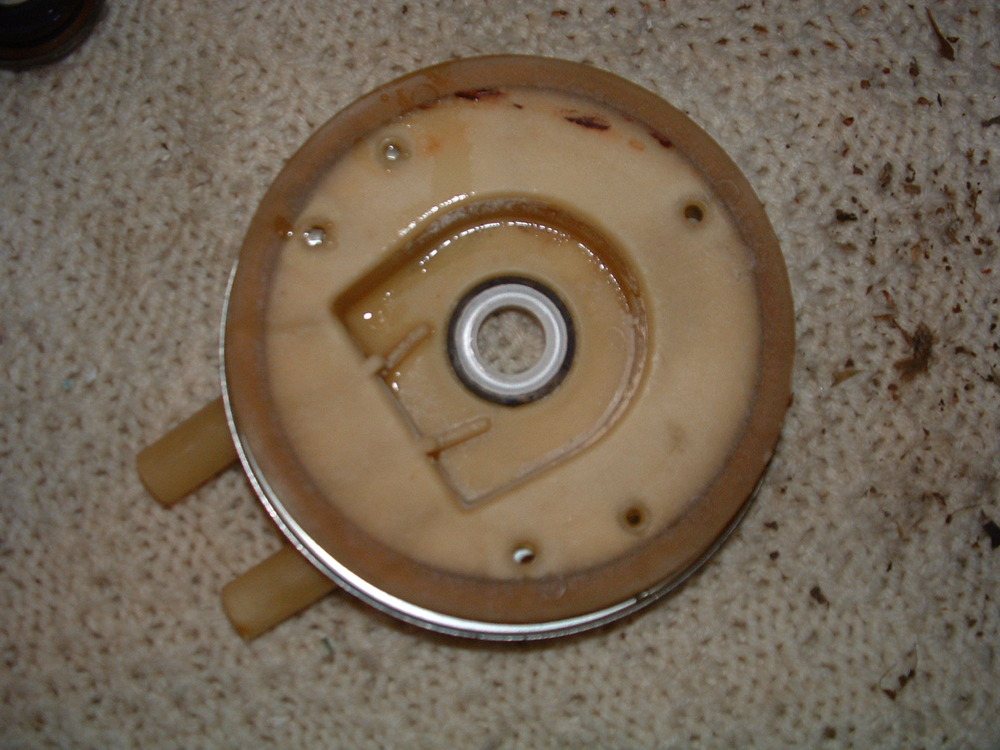

here is the lower drain pump housing. seal is pressed into it. the drain impeller is in the background and is the other half of the seal. both look good actually, i wonder if that was where the leak was coming from?

| ||

| Post# 353719 , Reply# 16 5/31/2009 at 20:54 (5,436 days old) by soberleaf () | ||

|

another view

| ||

| Post# 353721 , Reply# 17 5/31/2009 at 20:56 (5,436 days old) by soberleaf () | ||

|

here is the drain impeller a bit beat up looking but actually it's just discolored. it's metal. it will shine right up with a wire brush on the drill

| ||

| Post# 353722 , Reply# 18 5/31/2009 at 20:57 (5,436 days old) by soberleaf () | ||

|

the other side showing water seal. obviously i won't be taking a drill to this side!

| ||

| Post# 353723 , Reply# 19 5/31/2009 at 20:58 (5,436 days old) by soberleaf () | ||

|

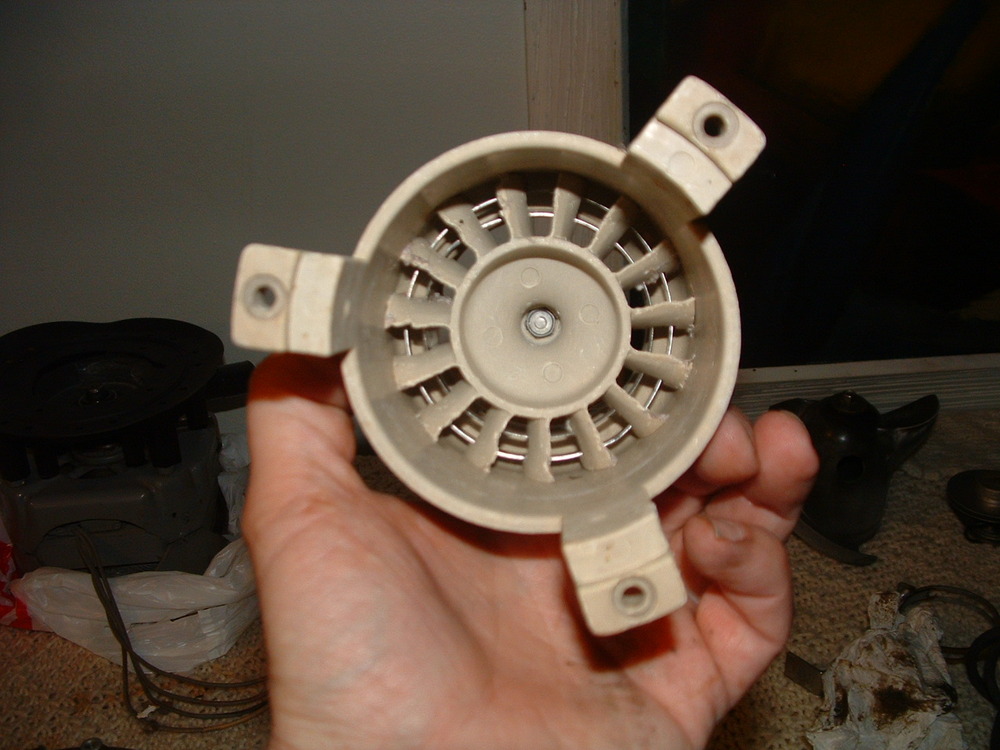

here is the wash pump housing that spray arms mounts to. it's in great shape.

| ||

| Post# 353724 , Reply# 20 5/31/2009 at 20:59 (5,436 days old) by soberleaf () | ||

|

another view very good condition for being 42 years old!

| ||

| Post# 353727 , Reply# 22 5/31/2009 at 21:04 (5,436 days old) by soberleaf () | ||

|

love that spray arm though this used to intrigue me to no end when i was a kid! God only knows why?!

| ||

| Post# 353730 , Reply# 23 5/31/2009 at 21:04 (5,436 days old) by soberleaf () | ||

|

and another

| ||

| Post# 353731 , Reply# 24 5/31/2009 at 21:05 (5,436 days old) by soberleaf () | ||

|

look at those jets! can't get enough!

| ||

| Post# 353732 , Reply# 25 5/31/2009 at 21:07 (5,436 days old) by soberleaf () | ||

|

back to the impeller it's in great shape

| ||

| Post# 353733 , Reply# 26 5/31/2009 at 21:08 (5,436 days old) by soberleaf () | ||

|

well pretty good shape, maybe not great but usable!

| ||

| Post# 353734 , Reply# 27 5/31/2009 at 21:08 (5,436 days old) by soberleaf () | ||

|

another view

| ||

| Post# 353735 , Reply# 28 5/31/2009 at 21:09 (5,436 days old) by soberleaf () | ||

|

another view again

| ||

| Post# 353736 , Reply# 29 5/31/2009 at 21:09 (5,436 days old) by soberleaf () | ||

|

another pic

| ||

| Post# 353738 , Reply# 30 5/31/2009 at 21:10 (5,436 days old) by soberleaf () | ||

|

one more to bore you!

| ||

| Post# 353740 , Reply# 31 5/31/2009 at 21:12 (5,436 days old) by soberleaf () | ||

|

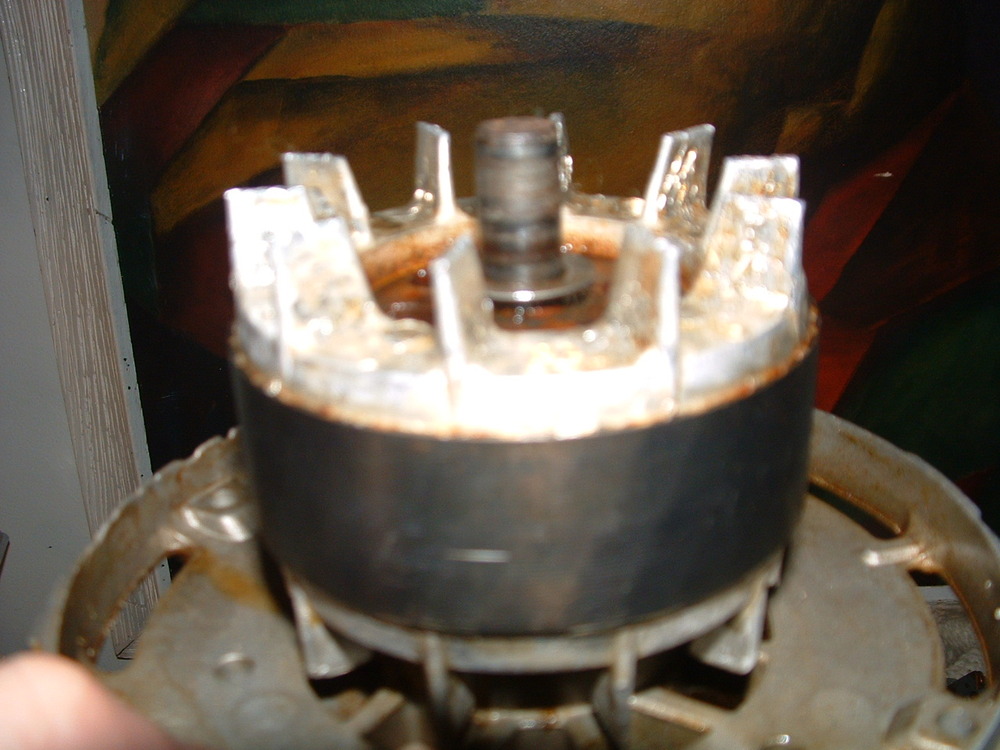

on to the motor all in all not in as bad a shape as i thought. top bearing seems great, very smooth silent rotation. shaft is rusted, that's why impeller was stuck, gonna use my wire brush and drill on it and clean it up good.

| ||

| Post# 353742 , Reply# 32 5/31/2009 at 21:14 (5,436 days old) by soberleaf () | ||

|

the bottom bearing that looked like nightmare before

| ||

| Post# 353744 , Reply# 34 5/31/2009 at 21:19 (5,436 days old) by soberleaf () | ||

|

the bottom of the motor shaft is kinda roughed up but i can smooth it down using steel wool, wire brush on drill and sand paper. i think if i pack bearing good it will actually run pretty smoothly. but i could be wrong here.

| ||

| Post# 353746 , Reply# 35 5/31/2009 at 21:19 (5,436 days old) by soberleaf () | ||

|

another view of this shaft

| ||

| Post# 353751 , Reply# 38 5/31/2009 at 21:27 (5,436 days old) by soberleaf () | ||

|

p.s. i just love this little dishwasher! it's so classic 60's! 1967 i was told!

| ||

| Post# 353821 , Reply# 42 6/1/2009 at 08:17 (5,435 days old) by soberleaf () | ||

|

thanks so the best thing for a sleeve bearing is to simnply give it a good dose of 3 in one motor oil? that's what i did i this one. | ||

| Post# 353836 , Reply# 43 6/1/2009 at 09:37 (5,435 days old) by tristarcxl () | ||

|

Bingo. | ||

| Post# 353838 , Reply# 44 6/1/2009 at 10:03 (5,435 days old) by dnastrau (Lords Valley, PA) | ||

|

Lesson on sleeve bearings - thanks! Thanks for the lesson on sleeve bearings tristarcxl - I appreciate it! I have, in the past, used both grease and car motor oil on sleeve bearings on a couple of motors that were on their last legs. I won't be doing that again! Andrew S. | ||

Comes to the Rescue!

Comes to the Rescue!