|

Thread Number: 23840

ROLLERMATIC TEAR DOWN! BALL SUPPORT OFF! SUCCESS! PICS! |

[Down to Last] |

|

| Post# 371057 , Reply# 1 8/10/2009 at 21:55 (5,370 days old) by soberleaf () | ||

|

i bought a new heavy duty pair of vice grips at work tonite and a standard hose clamp

| ||

| Post# 371058 , Reply# 2 8/10/2009 at 21:57 (5,370 days old) by soberleaf () | ||

|

it was suggested to me on a previous post that i attach a hose clamp to the rubber ball support to make it more "grippable" (is that a word?) with a channel lock pliers or pipe wrench.

| ||

| Post# 371059 , Reply# 3 8/10/2009 at 21:59 (5,370 days old) by soberleaf () | ||

|

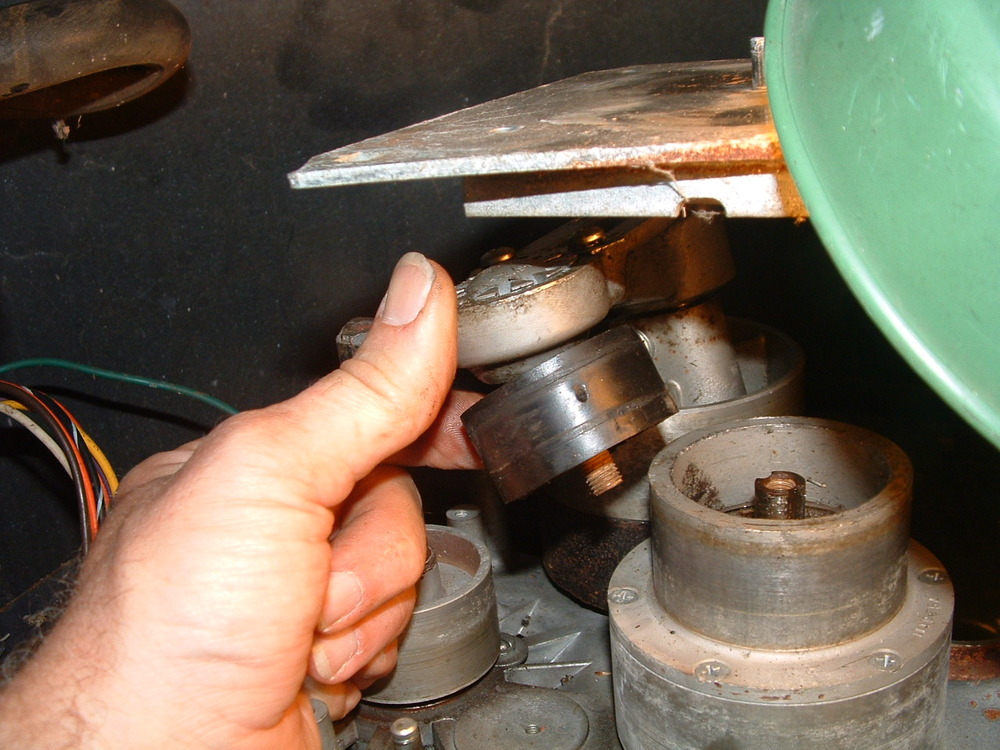

here is a pic of the ball support with it's hose clamp tightened around it and the vice grips firmly gripping the agitator shaft

| ||

| Post# 371071 , Reply# 10 8/10/2009 at 22:31 (5,370 days old) by soberleaf () | ||

|

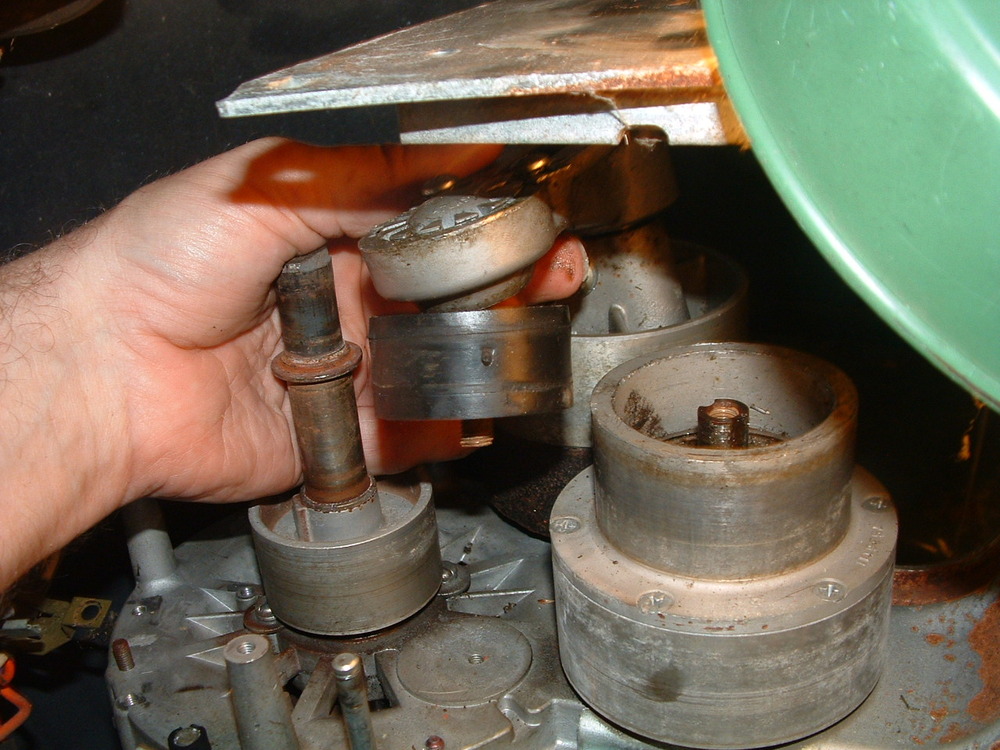

here's the ball support with the hose clamp removed

| ||

| Post# 371072 , Reply# 11 8/10/2009 at 22:33 (5,370 days old) by soberleaf () | ||

|

here's a good pic of the little nipple that screws into the agitaor shaft. i was expecting to find a lock washer like on my 1-18 but no washer! pretty rusty, no wonder it was so hard to loosen!

| ||

| Post# 371073 , Reply# 12 8/10/2009 at 22:34 (5,370 days old) by soberleaf () | ||

|

another pic

| ||

| Post# 371074 , Reply# 13 8/10/2009 at 22:36 (5,370 days old) by soberleaf () | ||

|

can't get enough i'm excited, i got this part loose! doesn't take much these days to excite me! sad indeed but oh well!

| ||

Post# 371162 , Reply# 21 8/11/2009 at 07:51 (5,369 days old) by joelippard  (Hickory) (Hickory) |

||

Keyway's?

Oh that was me, when I was in rollermatic hell a few weeks ago. I found them in the loose parts area at ACE Hardware. If you all look back on my post the size is listed there. Coincidentally I just did a pump job on my '65 rollermatic and it went very well, had to change some old hoses out too. Apparently when I was reworking the pump I disturbed the holy rollers and they insisted on being cleaned before it would agitate properly again. | ||

Post# 371226 , Reply# 23 8/11/2009 at 12:48 (5,369 days old) by joelippard  (Hickory) (Hickory) |

||

Post | ||

Post# 371316 , Reply# 24 8/11/2009 at 18:24 (5,369 days old) by gyrafoam  (Wytheville, VA) (Wytheville, VA) |

||

|

Putting the cross-brace back on is always a good move. An empty 1 gal. paint can does a great job of chocking a mechanism when the machine is on its side. You just want to avoid the tub support mechanism taking all the stress when the machine is lying on its side. | ||

Post# 371367 , Reply# 26 8/11/2009 at 21:13 (5,369 days old) by joelippard  (Hickory) (Hickory) |

||

You mean you can't get the tub nut to loosen right? Don't even try those screws, they always win. You may need PB Blaster for that nut. Try impacting the nut with a rubber mallet, or line the tub with rags and do it carefully with a standard hammer. I learned from Gyrafoam, and my dad that these machine cooperate best with impact, rather than brute force. | ||

| Post# 371371 , Reply# 27 8/11/2009 at 21:23 (5,369 days old) by soberleaf () | ||

|

oh no! the nut is off, it came off quite easily, the only thing preventing me from pulling that inner tub out is the fact that the hub is stuck on the spin shaft even with no nut holding it! any ideas, i know you have been here before! thanks! | ||

Post# 371382 , Reply# 28 8/11/2009 at 21:41 (5,369 days old) by joelippard  (Hickory) (Hickory) |

||

Wow | ||

Post# 371464 , Reply# 30 8/12/2009 at 07:22 (5,368 days old) by gyrafoam  (Wytheville, VA) (Wytheville, VA) |

||

|

Yoy might try an application of some heat. Sometimes after the PBlaster has had some time to work, taking a torch to it finnishes the job. Just be careful not to get it too hot----don't want to damage the porcelain tub or melt any of that famous Frigidaire "pot metal". | ||

Comes to the Rescue!

Comes to the Rescue!