|

Thread Number: 25794

History of D&M |

[Down to Last] |

Post# 396323 11/28/2009 at 19:05 (5,255 days old) by sudsmaster  (SF Bay Area, California) (SF Bay Area, California) |

||

D&M stands for Design & Manufacturing, which at one time produced an estimated 25% to 37% of the dishwashers sold in the world. The origins of the company are rather complex, the result of a series of mergers and consolidations, and eventual purchase by one Sam Regenstrief, who formerly ran Philco's appliance division. The company's history can be traced as follows: Central Manufacturing Company, 1898-1929; Central Manufacturing Co./Cord Corp. 1929-1937; American Kitchens Division, Auburn Automobile Co. 1937-1940; Auburn Central Manufacturing Co., 1940-1942; American Central Manufacturing Co. 1942-1946; American Kitchens division, AVCO Manufacturing 1946-1959 - Design & Manufacturing Corp. 1959-1987 - Connersville, Indiana Here's a partial history that jumps in at the end of WWII, when the former company's resources were switched from producing jeeps and other war materiel back to consumer appliances: Excerpted below is a portion of an American Central Visitor’s Brochure dated 1948: “Welcome to American Central Division AVCO Manufacturing Corporation, Home of American Kitchens, Styled in Steel. “Too often people think of a manufacturing plant as a collection of bricks, steel, machinery, railroads, statistical departments, and so forth... We here at American Central are very conscious that our plant is primarily dependent on the people who make it live. “We start in building 28 with die storage—a veritable treasure house. These dies, many worth thousands of dollars, mold or shape the parts required by their various products. They are the acme of the machinist’s art. Next stop is building 2, the steel storage warehouse. Here are great piles of sheet steel, tons of it, to meet the hungry demands of the production lines. Steel is brought to the warehouse in trucks and railroad cars. A private railroad siding shunts the cars into the unloading area, where steel is removed in slings suspended from powerful overhead cranes. “In building 1 we encounter the press room. A thundering, clanking rumble echoes about this building as the big and little presses thump out a thousand different sheet metal parts used in the manufacturing process. This is a building of strong contrasts: A 500-ton capacity press that weighs 464,000 pounds and cost $169,204 sits close by a 5-ton capacity press that weighs 750 pounds and cost $450. A big hydraulic press requires ten men to operate it, while many small presses are controlled by a lone operator. “In the jeep body assembly department, we find steel banging on steel, welding arcs sputtering and sending forth dancing showers of sparks. We see hundreds of small parts joined into front and rear sections of the jeeps’ steel bodies. As the bodies gradually assume recognizable shapes, they reach the joining tables, where they are welded into a complete body. Then it’s on to the metal cleansing cabinets, the paint booths, the drying ovens, final inspection, and at last the loading docks.” In addition to Admiral Refrigerators, American Kitchens manufactured kitchen sinks, faucets, kitchen shelving, and modular kitchen base & wall cabinets. AVCO had purchased the Crosley Appliance Co. from its founded Powell Crosley Jr. in 1945. During the early 50s AVCO introduced their Crosley Kitchens line of metal kitchen cabinets and appliances in the early 50s. The Crosley kitchen cabinets were built alongside the firm’s American Kitchens products in Connersville. In the early 50s AVCO Manufacturing introduced a line of prefabricated gasoline service stations that were built in the American Kitchens plant in Connersville, and Crosley Kitchens automatic dishwasher was added to the American Kitchens assembly line at about the same time. In the mid-50s American Kitchens expanded their dishwasher business and began selling re-branded units to the Sears, Roebuck Co., Whirlpool and Westinghouse. However, competition from AVCO’s other appliance divisions hurt them in the marketplace, and they struggle to find new avenues of distribution. By the late 50s, AVCO Manufacturing’s dishwashers held a paltry 11% share of the market and Sears was being courted by Whirlpool, who had recently announced they were getting into the dishwasher business. AVCO’s appliance division had also started losing money, and the Connersville facility was underutilized. AVCO quietly let it be known that the Connersville operation was for sale. On January 1, 1959, Sam Regenstrief (1911-1988) purchased the bulk of AVCO’s Connersville operations for $2.6 million. He bought the former plants of the Central Manufacturing Co., Indiana Lamp Co. and Anstead Engineeering Co. Regenstrief down $500,0000 in cash and AVCO agreed to finance the rest. Regenstrief was a marketing genius who had amassed a small fortune while serving as president of the Rex Manufacturing Co and vice-president of Philco. The opportunities that presented themselves in the poorly marketed American Kitchens line were too much to resist and he decided to purchase the company after taking a tour of he plant in 1958. Regenstrief assumed the presidency of Connersville’s Rex Manufacturing Co. in 1939. Rex was still owned by members of the Ansted family and had progressed from manufacturing convertible tops to producing stamped steel refrigerator cabinets for Philco and Stewart Warner. He turned the floundering firm around and in 1944, it was taken over by Philco. At Philco Regenstrief became vice-president of their refrigeration division, then later on senior vice-president of the entire appliance division. After being passed over as Philco’s president, he resigned when Philco announced their pending merger with the Ford Motor Co in 1958. When he took over American Kitchens, it employed 2,500 and the plant consisted of 920,000 square feet of space spread across 93 acres. Regenstrief named his new firm the Design and Manufacturing Corporation (D&M). The Architectural Products Division of the H.H. Robertson Company purchased the last remaining property, originally the Lexington Motor Car Co., on February 8, 1960. D&M decided to concentrate on dishwashers and by the end of the decade, they were manufacturing re-branded portable and undercounter units for Sears, Philco, Admiral, Kelvinator, Hotpoint, Frigidaire, Chambers and Preway. By 1972, D&M controlled 25% of the nation’s dishwasher market. D&M purchased the former Crosley appliance plant in Richmond, Indiana from AVCO in 1975. By the time of his death Sam Regenstrief had amassed a $50 million fortune which passed to the Regenstrief Foundation when he died in January of 1988. Design & Manufacturing’s assets were sold to White Consolidated Industries in 1987 and the firm was dissolved in 1990. CLICK HERE TO GO TO sudsmaster's LINK | ||

|

| Post# 396329 , Reply# 1 11/28/2009 at 19:50 (5,255 days old) by redcarpetdrew (Fairfield, CA) | ||

Thank you, Rich... | ||

Post# 396335 , Reply# 2 11/28/2009 at 20:19 (5,255 days old) by sudsmaster  (SF Bay Area, California) (SF Bay Area, California) |

||

But wait, there's more...

D&M was really the "baby" of Sam Regenstrief, and I found an entire biography of the man online. Chapters that deal primarily with D&M include "One Act Show", and "The Show Closes". CLICK HERE TO GO TO sudsmaster's LINK | ||

Post# 396336 , Reply# 3 11/28/2009 at 20:26 (5,255 days old) by appnut  (TX) (TX) |

||

|

| ||

| Post# 396339 , Reply# 4 11/28/2009 at 20:59 (5,255 days old) by favorit () | ||

|

someone is still involved in cars ...... NEXXT time you'll drive your car, think about ABS, ESP, power steering ... maybe even wipers and spark plugs CLICK HERE TO GO TO favorit's LINK | ||

Post# 396366 , Reply# 5 11/29/2009 at 02:16 (5,255 days old) by panthera  (Rocky Mountains) (Rocky Mountains) |

||

I remember the carbon seal and the soft-food

disposer ring in my last D&M dishwasher. They were built to fail after a certain number of uses and were a clever application of built-in obsolescence. The machines were otherwise pretty much bullet-proof, so they had to do something to kill them. Washed quite well. I figured out pretty early on that if I ran the wash cycle 'till the detergent dumped then ran ahead to the sanitary rinse - 165°F - the dishwasher really could clean absolutely everything without pre-rinsing. After a few glasses cracked when I turned back at the end of the rinse cycle, I got the welding shop in our local Vo-Tech center (another word sacrificed at the alter of political correctness) to run up a simple heat-exchanger for me. The water pumped out heated the water which was going to be let in sufficiently to put an end to the thermal shock. Today, I'd probably just run up an electronic circuit and a few relais.... | ||

Post# 396410 , Reply# 6 11/29/2009 at 11:20 (5,254 days old) by sudsmaster  (SF Bay Area, California) (SF Bay Area, California) |

||

D&M Invented the Macerator...

From "The Dishwasher King"... (previously linked) ... As head of product engineering, Tom Duncan lived in constant fear of being scooped by someone else’s engineering department. But on more than one occasion, his innovations set the competition on its ear. In particular, Tom came up with the macerator. Housed in the pump system, this device had twelve blades that spun around at 3,450 revolutions per minute (rpm). Anything that got into the upper pump had to go through the macerator, and the macerator chopped up food like it had never been chopped before. The macerator was impressive, but the real innovation was the self-contained pump system that held it. In the earlier dishwashers, water emanated from an impeller at the bottom of the unit. The impeller looked like a boat propeller, and it spun around spraying water on the dishes, which had to be loaded in a circular pattern at just the proper angle to catch the sudsy liquid. Besides offering no flexibility in how a consumer could load the dishes, this impeller had to be protected because the Bakelite plastic of which it was made could easily chip. If a leading edge of the impeller got chipped, it wouldn’t pump worth a hoot. Everyone in the business had been working on this problem, and Kitchenaid and Hobart had developed a new spray arm system that overcame the loading inconveniences and made possible the rack system that people are familiar with today. Tom’s coup was the self-contained pump that would not only drive a spray arm but also house the redoubtable macerator. D&M’s field sales manager had a favorite demonstration. He would put a D&M model side by side with a Kitchenaid and fill both of them with twelve sets of plates, cups, glasses, and silverware. Then, before the astonished crowd, he would pour cans of Dinty Moore beef stew over everything in the two machines and start them running. Et voila, his model would remove all traces of the Dinty Moore, and the Kitchenaid wouldn’t. As the final coup de grace, he would insert the stew-flecked lower rack of the Kitchenaid into the D&M machine and let it clean up the mess. His audiences were impressed. D&M’s feature designers worked out of the Connersville plant, but to be sure his product had the right washability and convenience, Sam would make a trip up to Lafayette, Indiana, every so often and talk to the home economics people at Purdue University. He wanted to know what they considered a good wash job and how they would measure that. | ||

Post# 396412 , Reply# 7 11/29/2009 at 11:29 (5,254 days old) by appnut  (TX) (TX) |

||

|

Thanks Rich, I loved that. Now I know why I love Dint More beef stew, it's because a KitchenAid couldn't stand up to it and a D&M got rid of it. I'm vindicated on why I had such unpleasant results in real-life suberbia with rice and other starchy foods in Superbas vs. our RotoRack and even the Waste King from 1968.

| ||

| Post# 396426 , Reply# 8 11/29/2009 at 13:27 (5,254 days old) by travlincub321 () | ||

|

Thats cool | ||

Post# 396430 , Reply# 9 11/29/2009 at 14:08 (5,254 days old) by sudsmaster  (SF Bay Area, California) (SF Bay Area, California) |

||

How GE and Whirlpool beat D&M

From same link... and we can thank GE for the damn flimsy plastic interiors on so many modern dishwashers... The dishwasher industry was changing in ways that nobody at D&M had foreseen. Product lines were consolidating. Where there had been ten manufacturers, pretty soon there were six, then five, then four, and as of this writing there are probably three. D&M might have been one of those three, says Len Betley, if it hadn’t been for the second big change in the industry—the move toward full lines. It now became important for a manufacturer to be able to go to a large developer, distributor, or discount chain and say, “I have a full line. I’ve got dishwashers, I’ve got stoves, I’ve got refrigerators, I’ve got washers and dryers.” What had once been a fragmented industry was consolidating both within and across lines. That was bad for D&M because, aside from a few refrigerators, it basically offered dishwashers. The one act show had nothing else to offer. Even if Sam had wanted to expand into other lines, enormous resources would have been needed to tool up for new products, and, although he had a very nice company, its coffers weren’t of the same magnitude as a GE, Whirlpool, or Westinghouse. GE had been breathing down Sam’s neck for years, and now they played a clever trick to beat Sam at his own game. Dick Goodemote recalls: GE had always competed with D&M but never achieved the volume to meet or beat Sam’s unit cost. They figured out that the only way they could produce sufficient volume to get the unit cost down was to create a totally automated production line. They spent an enormous amount of money to automate their plant in Louisville, Kentucky. In fact, GE spent much more than the product could afford. But they convinced the U.S. government that they were engaged in research on automation and robotics, research to help them beat the Japanese manufacturers. So they were allowed to write off the cost of the plant while taking a great deal of cost out of their product. And that’s how GE became a major competitor in the dishwasher business. At the time, D&M was not really a leader in the bells and whistles that housewives wanted in their dishwashers. Technology was beginning to proceed around D&M. But at its Louisville plant, GE made one particular innovation that really threw down the gauntlet: plastic door caps. These were the interior linings of dishwasher doors. D&M was tooled up for metal doors and tubs, not plastic. To compete with GE on this front, a huge infusion of capital was needed to retool the production line for plastic door liners and plastic tubs. What should D&M do? Hundreds of Harvard business school students were probably assigned to read about D&M in their 1984 case study books and to come up with an answer. Back at D&M, meanwhile, Sam’s strong leadership was never more needed. .... Sam’s emotional attachment to his company only reinforced this effect. He would have a stroke and be out for a while. When he returned, he would discover that someone had done something new, something Sam had not been involved in, so Sam would redo it. About the second or third time that happened, Sam’s managers just stopped doing things, and the company went on cruise control. At a time when the industry was changing, D&M was without leadership. This left the door wide open to the competition, who had always lurked in the background to try to steal away Sam’s huge volume. Having completely modernized their plant in Louisville, GE had all kinds of new capacity, and they started entertaining thoughts of private-label manufacturing, which Sam had had a corner on for so many years. D&M had a lot of the same modern technology under development, but it was on a back burner. It wasn’t brought into the product line simply because at that time Sam’s leadership was missing. .... Meanwhile, trouble was brewing at the Sears Tower in Chicago. The giant retailer had all its dishwasher eggs in the D&M basket, but nobody seemed to be taking over the reins from Sam Regenstrief. The powers that be at Sears headquarters were getting increasingly nervous. D&M’s 1984 strategic plan tried to convince Sears that there would be an orderly assumption of new leadership, citing recent “major steps toward strengthening the corporation management and executive staff” and noting that “Mr. Regenstrief takes much more pride in teaching than just in leading his team.” Moreover, the plan said, D&M was registered with Purdue University to receive its catalog of graduates each year from the School of Engineering, the School of Business and Industrial Management, and the School of Technology. .... If Sears lacked confidence in the leadership and innovativeness of their one-and-only dishwasher supplier, Sam himself didn’t help the situation. Because Sears had a much better reporting system for field service problems than did Sam’s other customers, their reports often looked inflated by comparison, and Sam was reluctant to believe that D&M machines had as many service calls as Sears said they did. He discounted the field service reports to the extent that he antagonized some of the people at Sears. Not long afterward, Sears moved a portion of its business to Whirlpool. You could tell which Kenmores were Whirlpool-made because they had speckles on the enamel tub interior, whereas D&M’s tubs were a pure white. .... “Dishwasher Firm Hopes To Make Comeback” was headlined in the Indianapolis Star on April 28, 1987. The competition was beginning to catch up with the Dishwasher King. First, the article said, D&M watched its Canadian sales slip away largely due to unfavorable currency valuations between the U.S. and Canadian dollars. Then GE stole most of D&M’s Tappan and Magic Chef contracts, which amounted to 9 percent of D&M’s business. “If that wasn’t bad enough, Whirlpool horned in on the king’s exclusive contract to supply dishwashers to its biggest customer, Sears, Roebuck and Co. Those were the dark days at D&M, the corporate pride of this eastern Indiana city of Connersville.” D&M’s market share had slipped from nearly 40 percent to 20 percent. | ||

Post# 396451 , Reply# 10 11/29/2009 at 16:30 (5,254 days old) by rp2813  (Sannazay) (Sannazay) |

||

Thanks Rich, | ||

Post# 396499 , Reply# 11 11/29/2009 at 23:09 (5,254 days old) by sudsmaster  (SF Bay Area, California) (SF Bay Area, California) |

||

Thanks, Ralph. Sam Regenstrief sounds like he was quite a character, and quite a businessman. He managed to corner 40% of the US dishwasher market by a combination of foresight, personal involvement, and cost control. I don't know if his machines were better or worse than the domestic competition, as I don't think I've ever run one (other than an Electrolux/Frigidaire potential descendant that was a disaster). But it sounds like GE pulled a fast one with the tax writeoff - with the US government basically financing GE's attempt to drive D&M out of business. As usual, money talks. | ||

| Post# 396517 , Reply# 12 11/30/2009 at 00:14 (5,254 days old) by alr2903 (TN) | ||

|

D&M always made "beefy" looking machines, by my eye. alr2903 | ||

Post# 396972 , Reply# 13 12/2/2009 at 01:03 (5,252 days old) by sudsmaster  (SF Bay Area, California) (SF Bay Area, California) |

||

I don't know that I've ever seen (or at least realized I've seen) a D&M dishwasher. That is, the ones made before the company was bought out by WCI back in the late 80's. I'm guessing that some of the technology was incorporated into WCI/Frigidaire/etc dishwashers for a bit, but who knows? I know my late 90's MOL Frigidaire was pretty shoddy. The upper rack wouldn't stay in place - it would fall if you looked at it wrong. The fine debris filter was just a flimsy warped disk about 14" diameter, and it would lift on one side or the other and let all sorts of food stuff through, to clog the spray arms and leave nastiness on the dishes. When it worked, it worked well enough, but I got tired of having to clean crap out of the spray arms. I wound up repairing it a few times - new temperature sensors, new drain pump. But when the main pump finally gave out I got rid of the thing and replaced it with a scratch/dent Bosch which hasn't failed me yet. The one cool thing about the Frigidaire was the interesting mechanism they used to alternate powerful sprays between the upper and lower racks. It was a plastic ball that rode in a channel, and it would alternately seal off one pipe and open another. Ingenious, really. But wasted on the rest of the machine, which was too flimsy from the get go. | ||

Post# 396983 , Reply# 14 12/2/2009 at 06:37 (5,251 days old) by panthera  (Rocky Mountains) (Rocky Mountains) |

||

Rich, | ||

Post# 397234 , Reply# 15 12/3/2009 at 03:38 (5,250 days old) by sudsmaster  (SF Bay Area, California) (SF Bay Area, California) |

||

| ||

| Post# 397260 , Reply# 16 12/3/2009 at 09:39 (5,250 days old) by programcomputer (Ann Arbor Michigan, USA) | ||

From the automobile side of things. And what I know.

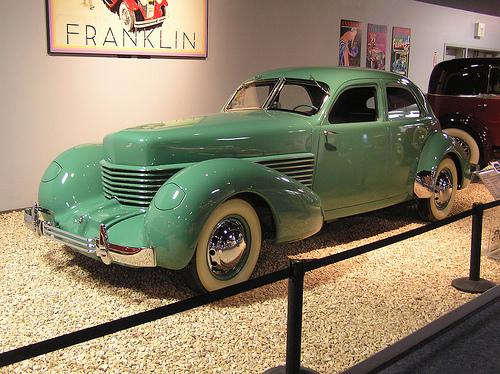

In one of my Auburn, Cord, Dusenberg historical books it states very clearly, that the original physical plants that ended up becoming D&M were originally part of the McFarland Motor Company of Connersville Indiana, that E.L. Cord purchased sometime in the early 1920's for his own use in the Auburn Cord Dusenberg empire he was attempting to build. In fact the land that the factory complex sits on was the old McFarland farm, which became the basis for the plants that still sit there today. I am at work so I cannot cite my sources, but lets say that the book is a authorized history and gives quite a good "afterward" this time frame including quite a bit of information on D&M. Everything I've seen so far that has been posted, has been spot on to what is mentioned in the history I have as well; but this one above mine here "seems" to be more "precise and informative". However.... I have a few interesting notes, and thoughts to ponder from the histories that I have, and a few questions arise about it (the history above).... I visited the Connersville area to see where the beloved Cord 810-12's were made(by me and countless others)during an Auburn Cord Dusenberg festival in 2001. (Sidebar)- THE ACD Festival is held EVERY Labor Day weekend without fail every year since 1956. So if your a car guy, make a pilgrimage one year. You'll never forget it. The factory now was really nothing to see (visually in the beauty department) except you can feel the history there. LOTS of history there. Most of 70% or better, of the original factories are still intact; and are still being used for various things, and are off limits in many areas. And the Town Barney Fife, will come a sniffin up your fanny if you violate this. As were were part of a group they (The Town and Barney too) let us look around the place (or er. DRIVE around the place). What a guide told us, was where the cars were manufactured, and what plants were used etc. How they were shipped by the rail spurs into the factory etcetera. As is well known, the main Connersville Ind. plant when it was used for car production was used to make Auburn, Cord and some basic Dusenberg bodies, and was erroneously named Auburn Central. The whole production of the 1936 and 1937 runs of Cord automobiles were built there; with motors shipped in from Lycoming, and transmissions from Auburn Gear. IT's also well known that the 1935 and short run 1936 Auburns were manufactured there as well, as E.L. Cord found the (future D&M) plants to be more acceptable in demands from workers, and was actually better laid out, and had room to expand, than the much older Auburn works in Auburn Indiana. The point is, after Cord production wound down in August 1937, the whole facility did not just grind to a halt. Cabinet manufacturing continued, some bodies were still being produced for other makes of cars, such as Checker Company in Kalamazoo Michigan. IN the histories I have read, when it was finally settled down by 1938-39 at "Central" it is mentioned that a main engineer on the Cord Front Drive Project one Slim Davidson, was the man who designed all the basic components of the dishwasher that was to be Design and Manufacturings backbone for the next 50 years. Apparently a few things from the history that has been found either aren't completely correct, or there was more than one person involved in the dishwashers creation, which seems to be the more logical explanation. It is also said that he designed the dishwasher while still on the Cord project (originally the Cord 812 from 1937, when automobiles were still being contemplated was being redesigned, and re engineered for 1938 (813), 39 (814) and 40 (815) etc., and beyond. There were also plans for future Auburns and Dusenberg's as well. I also goes onto say that the dishwasher wasn't introduced until after WWII, as Central was busy making lots of Jeep bodies, and other munitions for the War effort. IT is then possible, that Slim maybe retired, and the project was re-examined by the other fellow...uhh...Tom Duncan, inventor of at least the Macerator, as this history above had born out.. What I find interesting is that Sam Regenstrief,(sp); bought a company that at one time in all honesty made a full line of appliances. The Crosley acquisition, netted them a refridgerator line, the Philco-Bendix merger/acquisition, netted them a laundry lineup. Clearly when Philco was sold of to Ford, that put Sam in the bind, but they certainly must have had enough experience to make some sort of crack at it themselves. So in all honesty, AVCO, as it was known later in the 50's as the history reads had a quite complete line of appliances during 1955-and 1957 when cars, and such had long since been forgotten. It's quite interesting BTW, how different histories actually end up weaving together quite well, to form a pretty tight version of what really happened. None of us were there, so we only have to go by what's found left over from then, faded memories from people who WERE there, and a dollop of luck and supposition of WHAT happened. I think it all blends together quite well don't you?? Chad Ann Arbor Michigan The pic below is what was happening at Central, right about the time that Slim Davidson was working up the "dishwasher of the future"

| ||

Post# 397298 , Reply# 17 12/3/2009 at 12:54 (5,250 days old) by rp2813  (Sannazay) (Sannazay) |

||

| ||

Post# 1167708 , Reply# 18 12/27/2022 at 21:11 (478 days old) by SudsMaster  (SF Bay Area, California) (SF Bay Area, California) |

||

| ||

Post# 1167710 , Reply# 19 12/27/2022 at 21:14 (478 days old) by SudsMaster  (SF Bay Area, California) (SF Bay Area, California) |

||

Aha! Looks like this thread has moved out of the cellar in to the light of day, simply by adding another post. Yay!

I guess I'm gonna be cleaning all the clutter off my old Kitchenaid/Hobart top loading dishwasher to give it a whirl. It's been quite a while since I last ran it.

And yes, I'll be posting some before/after photos. LOL.

| ||

Post# 1167719 , Reply# 20 12/28/2022 at 01:53 (478 days old) by SudsMaster  (SF Bay Area, California) (SF Bay Area, California) |

||

OK found the photos of the KA/Hobart KD-2P Dishwasher The photos are from 2006. I replaced the lid hinges with ones I machined out of stainless steel.

| ||

Post# 1167724 , Reply# 21 12/28/2022 at 04:35 (477 days old) by SudsMaster  (SF Bay Area, California) (SF Bay Area, California) |

||

| ||

Comes to the Rescue!

Comes to the Rescue!