|

Thread Number: 28183

question for the rollermatic experts please! |

[Down to Last] |

| Post# 431087 4/25/2010 at 16:11 (5,107 days old) by rollermatic (cincinnati) | ||

|

working on a 1967 non rapidry rollermatic, the red machine i call it. put tub back in today (very carefully) and took it for a spin to see if the spin clutch assembly is working properly.

this one has no capacitor on the motor like my 1965 model so i assume motor will come up to full speed at once and tub will gain rotation speed via clutch inside the spin wheel. well it's not coming up to full speed, spin wheel is at full speed and there is no slippage on the rollers i can see, the problem must be in the clutch. the 1965 tech talk manual talks of adjustment screws, i assume this 67 model has them too. is it easy to do? should i pull tub again and flip it all the way over and remove bottom snubber brace or can i simply lay it on it's side and insert a board to keep inner tub positioned to prevent possible damage to mechanism support and work on it that way? i can pull tub out easily enough if that's the best way, have not put bellows on yet. is there any other advise on this clutch assembly? i have never torn into one yet. can the clutch linings be repaired in any way? replaced? one of my other machines is a 1966 model non rapidry and i already have tub out. maybe i should flip it over and experiment on it's clutch assembly a bit to learn about it. any advice will be greatly appreciated!!

| ||

|

Post# 431096 , Reply# 1 4/25/2010 at 16:55 (5,107 days old) by joelippard  (Hickory) (Hickory) |

||

Hey Pete, | ||

| Post# 431158 , Reply# 3 4/25/2010 at 21:39 (5,107 days old) by rollermatic (cincinnati) | ||

|

thanks, that helps | ||

| Post# 431206 , Reply# 4 4/25/2010 at 23:49 (5,107 days old) by rollermatic (cincinnati) | ||

|

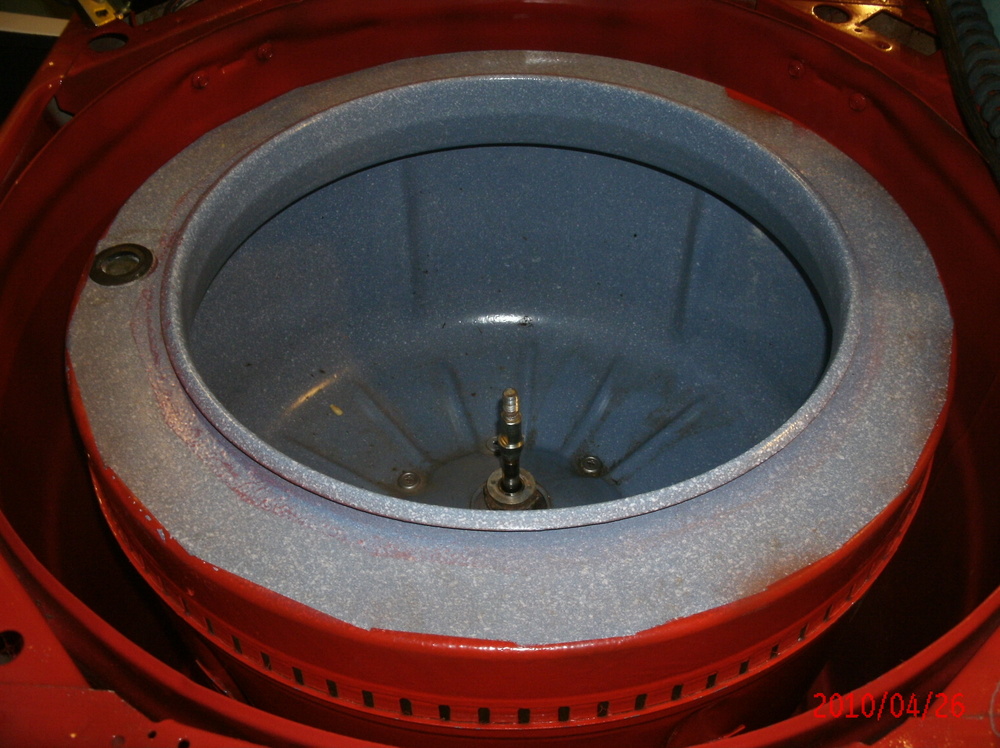

okay i pulled the tub

flipped the machine over and took off the bottom brace. i took out the 3 screws and decided to have a look inside this clutch assembly.

i found a spring that pushes down on the clutch lining. the clutch lining had some oil on it as well as dirt. i lifted all parts up and began a 1/2 hour of cleaning with rubbing alcohol. got a lot of dirt and oil off the lining and mating surface. gonna let it air dry overnite and put it back together tomorrow and flip it over and reinstall tub and give it a whirl. hopefully this will do it! i did not see how the 3 screws i took out could serve as an adjustment. they seem to simply screw in tight, holding the bottom half of the spin wheel to the top half, the clutch being inside these two halves ofcourse. hopefully cleaning it all up will do the trick.

| ||

| Post# 431208 , Reply# 5 4/25/2010 at 23:53 (5,107 days old) by rollermatic (cincinnati) | ||

|

close up shows

both clutch lining and steel mating surface in good detail.

both surfaces are clean and dry now. i even rubbed sandpaper on the clutch lining surface to help remove dirt and oil. it did help as when i rinsed it with alcohol a lot more dirt came off. i might not know what i;'m doing here but it sounds good i theory. a clean dry surface free of oil and dirt will make for a better clutch. we shall see tomorrow!

| ||

| Post# 431322 , Reply# 6 4/26/2010 at 12:27 (5,106 days old) by rollermatic (cincinnati) | ||

|

no luck

put it back and tried it out, tub will not come up to speed.

gonna e mail dave from dave's repair and mark michaels to see what kind of clutch parts are out there. hopefully i can find a new lining or something, or some good advice. gonna pull tub again and flip it over and start again. i'm not giving up here! these rollermatics can be a challenge but i am determined to get them running well again if it takes the rest of my life! | ||

| Post# 431389 , Reply# 9 4/26/2010 at 17:50 (5,106 days old) by rollermatic (cincinnati) | ||

|

thanks a lot!

that helps!

what i plan to do is remove the agitator shaft coupler so i can move the agitate arm out of the way and get to the clutch. i will "carefully" remove the clutch and spin wheel assembly. now my question for you or anyone else. what can i use to clean up and degrease the clutch linings? alcohol? should i soak them in something for awhile? i put in on hold for the rest of the day and just finished putting my tub back in my 65 rapidry custom imperial and it does come up to full speed and goes into rapidry perfectly so at least i got something done today. gonna work on the red machine that has the clutch problem a little each day, taking my time, not screwing it up. any other info will be appreciated and those pics you sent were very helpful. didn't know there were two clutch linings. i also sent e mails to dave and mark to see if they have any parts around. this machine will run again, i have faith in it! thanks | ||

| Post# 431415 , Reply# 12 4/26/2010 at 19:56 (5,106 days old) by rollermatic (cincinnati) | ||

|

thank you thank you!!!

great ideas you have!!! brake cleaner, why not!!!!! i'll try it.

speaking of brakes the 65 custom deluxe (non rapidry) i have that is fully operational and i use frequently runs great but no brake action. the 1965 custom imperial rapidry that i'm putting back together tonite and goes into rapidry spin perfectly and pulsates perfectly also has no brake action. the 1967 red machine that has the clutch problem also has no brake action. and the 1966 green machine that i haven't even begun to restore (non rapidry) spins great and pulsates great but no brake. i have yet to see a rollermatic where the brake works! is it really that important, outside of throwing rinse water when it should be filling? it doesn't hurt the spin roller to have the tub coasting to a stop does it? thanks again, will keep you posted and am going to post pics of the 1965 cistom imperial soon. just got the oil bellows on without a hitch as well as it's clamp. now working on the water bellows! thanks | ||

Post# 431418 , Reply# 13 4/26/2010 at 20:06 (5,106 days old) by joelippard  (Hickory) (Hickory) |

||

Pete, | ||

Post# 431420 , Reply# 14 4/26/2010 at 20:16 (5,106 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

| Post# 431441 , Reply# 16 4/26/2010 at 21:39 (5,106 days old) by rickr (.) | ||

| ||

| Post# 431559 , Reply# 17 4/27/2010 at 11:15 (5,106 days old) by rollermatic (cincinnati) | ||

|

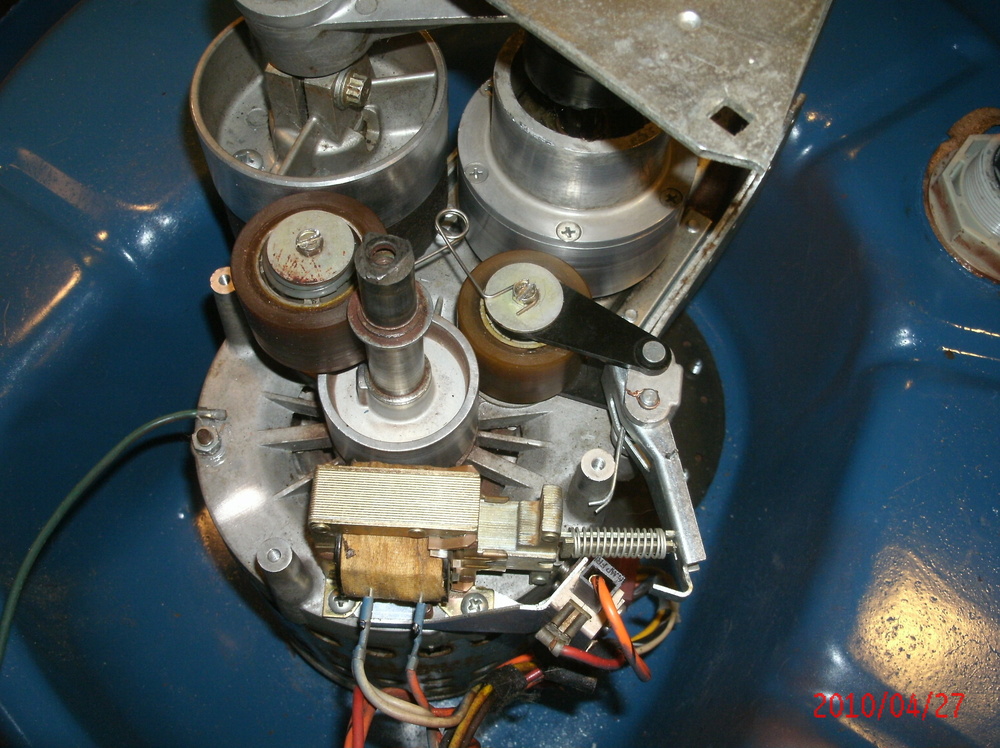

thanks

joel, i never thought rollermatics even had a brake on them till recently since i've never seen one work. i kinda like mine beter without the brake. when it starts to fill for rinse the tub is spinning so faast it throws a lot of water up and over, fun to watch at least!

swestoyz, thanks for the info. i assume that's why my 65 custom deluxe has a capacitor start due that the motor takes a good 20 seconds or more to get out of start winding mode as the motor and tub seem to be directly coupled with no clutch action. my red machine and my custom imperial are different in that motor starts up at full speed right away and tub picks up speed gradually. in the case of the red machine too gradually. i notice that the only machines that have the capacitor on the motor are my 1965 machines. saltysam, you must have the only rollermatic with a working brake! rickr, thanks so much, i will gladly pay you for it and shipping ofcourse if you do have one that you don't mind parting with. the red machine is on hold for now, been working on the 65 rapidry a bit. oil bellows and water bellows are in but can't get the water bellows clamp on. gonna try a screw worm clamp like has been suggested here. or i can always break down and buy a pair of mark michaels bellows pliers for 35 bucks. this machine seems to work great, rapidry spin is really fun to watch. i have not seen a frigidaire in rapidry spin up close since i was a teen with my aunt's! here's the motor/transmission all cleaned up and back in place. took me forever to figure out how those 2 springs on the high speed roller clutch assembly go in! the tech manual had a good pic and i finally got it right yesterday.

| ||

| Post# 431561 , Reply# 18 4/27/2010 at 11:19 (5,106 days old) by rollermatic (cincinnati) | ||

|

here it is | ||

| Post# 431562 , Reply# 19 4/27/2010 at 11:22 (5,106 days old) by rollermatic (cincinnati) | ||

|

slightly better pic | ||

| Post# 431564 , Reply# 20 4/27/2010 at 11:31 (5,106 days old) by rollermatic (cincinnati) | ||

|

the stubborn water bellows!

i've heard you guys talk of what a nightmare it is to get these on. i immersed mine in really hot water and it seemed to slide right on with a bit of gentle help with my fingers. but that clamp is a different story!

that blue enamel paint will not be seen once pulsator is back in. this is the bellows that came with the machine, it looks to be in great shape with no tears or holes so i'm reusing it! oil bellows was fine too! another idea i have is to wedge small wooden dowel sticks in between clamp and tub wall spacing them about 6" apart to 'hold" clamp as i work my way around it. then pushing it closed with one of the dowel rods. just an idea but i may try it tonite when i get home from work. i should just buy the bellows pliers and be done with it!

| ||

| Post# 431645 , Reply# 21 4/27/2010 at 22:24 (5,105 days old) by rollermatic (cincinnati) | ||

|

found a cheap way to get the water bellows

clamp on. bought a dowel stick for $1.29 and cut it into 9 1/8 inch lengths. i wedged them between the bellows clamp and the tub and after putting 3 of them in i was easily able to push the open end of the clamp closed and locked using a 4th smaller length stick!

it also works to take it off! i used a 1/2 inch dowel stick. whatever works!

| ||

| Post# 431646 , Reply# 22 4/27/2010 at 22:25 (5,105 days old) by rollermatic (cincinnati) | ||

|

another view | ||

| Post# 431690 , Reply# 23 4/28/2010 at 08:13 (5,105 days old) by rickr (.) | ||

| ||

Post# 431693 , Reply# 24 4/28/2010 at 09:11 (5,105 days old) by joelippard  (Hickory) (Hickory) |

||

Hey Rick | ||

| Post# 431696 , Reply# 25 4/28/2010 at 09:41 (5,105 days old) by rollermatic (cincinnati) | ||

|

what exactly is the sure spin

vs the impact style?

and rickr, thanks anyway for looking! joel, i have a 1-18 all torn down and the clutch itself is bigger than the clutches on my rollermatics. the whole rollermatic transmission is bigger it seems, and heavier. i'm gonna take this clutch off my red machine completely apart and clean the linings with brake cleaner as suggested above and see if that does it. | ||

| Post# 431708 , Reply# 26 4/28/2010 at 11:23 (5,105 days old) by mickeyd (Hamburg NY) | ||

Good luck with big red, Pete

and thanks for the close up and stunning shot of the roller mechanism. Wish I could help but I'm still in first grade with this stuff and not afraid to admit it. Your pictures advance the learning curve immensely. Neat trick with the bellows. Call Mark for the pliers. He's got a bunch of them.

It'll be a great day when you get this TOL Roller back in business. | ||

| Post# 431921 , Reply# 27 4/29/2010 at 14:22 (5,103 days old) by rollermatic (cincinnati) | ||

|

today the clutch came out! | ||

| Post# 431922 , Reply# 28 4/29/2010 at 14:23 (5,103 days old) by rollermatic (cincinnati) | ||

|

here is the spin | ||

| Post# 431923 , Reply# 29 4/29/2010 at 14:26 (5,103 days old) by rollermatic (cincinnati) | ||

|

next the center nut | ||

| Post# 431925 , Reply# 30 4/29/2010 at 14:28 (5,103 days old) by rollermatic (cincinnati) | ||

|

the entire spin wheel clutch assembly | ||

| Post# 431927 , Reply# 31 4/29/2010 at 14:33 (5,103 days old) by rollermatic (cincinnati) | ||

|

i removed the plate by | ||

| Post# 431942 , Reply# 32 4/29/2010 at 14:50 (5,103 days old) by rollermatic (cincinnati) | ||

|

taking the assembly out in the | ||

| Post# 431944 , Reply# 33 4/29/2010 at 14:56 (5,103 days old) by rollermatic (cincinnati) | ||

|

here is the | ||

| Post# 431945 , Reply# 34 4/29/2010 at 14:59 (5,103 days old) by rollermatic (cincinnati) | ||

|

here is a pic | ||

| Post# 431976 , Reply# 35 4/29/2010 at 17:30 (5,103 days old) by rollermatic (cincinnati) | ||

|

here is the

brake lining, also oil soaked and dirty.

i am going to the auto parts store now to get some cleaner for the linigs and oter parts as well as more alcohol and paper towels from the drug store. i shopuld have this assembly cleaned up, dry and re-assembled by tonite! i was surprised at how simple this design is and easy to get out and work on. these rollermatics are fascinating, at least to me! they really engineered them well. i guess that's why they still are in such great shape after 45 years! hobart and frigidaire are definately my 2 favorite vintage appliance makers!

| ||

Post# 432010 , Reply# 37 4/29/2010 at 21:34 (5,103 days old) by joelippard  (Hickory) (Hickory) |

||

I can't believe

How much oil is in that clutch, no wonder it wouldn't spin up!

Pete, the difference in the clutches to the best of my knowledge is that an impact style places full motor torque through the rollers to the tub, similar to what a Unimatic would do, you'll notice on that style that the motor ramps up slowly. The sure-spin, carries the full weight of getting the tub up to speed, the motor instantly comes to full speed along with the rollers, transmitting the power to the clutch, this type of setup is easier on the rollers as it places all the stress on the clutch. | ||

| Post# 432027 , Reply# 38 4/30/2010 at 00:54 (5,103 days old) by rollermatic (cincinnati) | ||

|

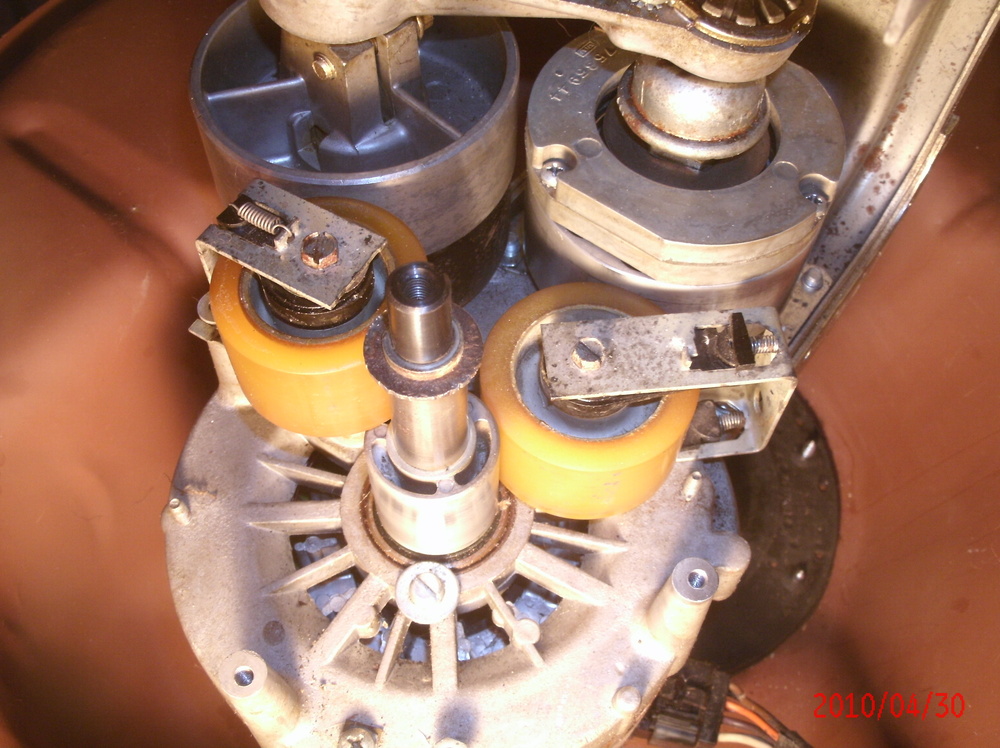

this washer will be

the death of me yet!

cleaned clutch and put it all together again, put tub back in after carefully making sure tub seal was spotless. hooked it up and it is better than it was but not good! if i disconnect timer motor wire and let it spin for about 5 minutes on high speed motor it will come up to speed i think! but it still starts out slow and takes forever and there is no brake! here are some pics at least. cleaned everything in brake cleaner and rubbing alcohol. it all came out clean as whistle!

| ||

| Post# 432028 , Reply# 39 4/30/2010 at 00:56 (5,103 days old) by rollermatic (cincinnati) | ||

|

here is the transmission | ||

| Post# 432029 , Reply# 40 4/30/2010 at 00:58 (5,103 days old) by rollermatic (cincinnati) | ||

|

as you can see | ||

| Post# 432030 , Reply# 41 4/30/2010 at 01:00 (5,103 days old) by rollermatic (cincinnati) | ||

|

another | ||

| Post# 432031 , Reply# 42 4/30/2010 at 01:01 (5,103 days old) by rollermatic (cincinnati) | ||

|

the clutch | ||

| Post# 432032 , Reply# 43 4/30/2010 at 01:04 (5,103 days old) by rollermatic (cincinnati) | ||

|

i even gave it a new drain hose | ||

| Post# 432033 , Reply# 44 4/30/2010 at 01:20 (5,103 days old) by rollermatic (cincinnati) | ||

|

here's my game plan

gonna run it everyday for a week or so and hope any and all oil left in the spin shaft will work it's way out. i agree i think someone did oil it because it is noisy and i think they were trying to quiet it as saltysam said above. i know i didn't oil it when i got it.

then i will pull clutch out again and repeat the cleaning process. i see now i can pull it from the bottom so i won't have to pull tub out again and flip machine. all i have to do is disconect agitate shaft from the arm coupler which will be easy. the clutch will then drop right out when i remove center hub nut. i also possibly know of a source for a clutch, i am going to call about it tomorrow. but i don't want to put another good clutch in and have it ruined by falling oil! that's why i want to run it everyday for awhile. i also started looking on the web for a place to buy a sheet of clutch lining material that i could cut with a dremel and make new clutch linings. and if worse comes to worse i can always freeze it up somehow turning it into an impact syle like joel described above and add a capacitor to the motor start winding like my 2 1965 machines have. then when it starts spinning the motor will come up to speed as the tub does like my other two. i prefer not to go this route as i agree it's gotta be hard on the motor and rollers. hopefully cleaning it again will do the trick. as far as the brake working i don't care anymore about that! that's thre least of my worries right now concerning this machine. it can just coast to a stop like my other 2 do. i could pull transmission again and remove spin shaft but that's a big overhaul that i hope to avoid also! i'm just hoping any oil left will drip down into clutch now and be done with it! we will see and i will post pics as i continue. i'm not giving up, it may take me all summer but it will run properly! i did get the 65 turquoise custom imperial water tested tonite and it is going great! but i do have a concern about it too. it has the impact syle clutch but sometimes when i start it on spin it acts like an impact clutch should, motor slowly coming up to speed as tub does, other times motor starts instantly and tub gradually works itself up to full speed including repidry 1000? have no idea what this is all about?

| ||

| Post# 432077 , Reply# 45 4/30/2010 at 10:51 (5,103 days old) by mickeyd (Hamburg NY) | ||

And so it is.

As a kid, I kept pestering the delivery man when he installed our new Custom Deluxe Bronze Rollermatic. And he kept saying, "It's all rollers, all rollers, no belts or pulleys, just rollers, all rollers." May have been his first experience with a washer kid ;-D

A picture book encyclopedia, Pete. Amazing! Curious as to why you're gravity draining, and how you're going to manage it. | ||

Post# 432304 , Reply# 46 5/1/2010 at 15:44 (5,101 days old) by joelippard  (Hickory) (Hickory) |

||

Pete | ||

| Post# 432317 , Reply# 47 5/1/2010 at 18:06 (5,101 days old) by rollermatic (cincinnati) | ||

|

thanks

i post a lot of pics when i do a thread because i figure at some point someone will have questions about rollermatics or whatever dishwasher i am working on. that way they can archive it and maybe find my thread and perhaps it will help them understand the machine better or help in the repair.

i know when i first started here almost 2 years ago i knew absolutely nothing about frigidaire rollermatics and 1-18 machines. i used the archives and every picture i found, every commentary was very helpful to me! i learned thru all the pics i found. plus the 1965 rollermatic tech talk that i downloaded from this site was invaluable to me also! and the "history of the rollermatic" manual i got from this site as well! plus pics are fun to look at! i feel i'm doing a mini documentary of the appliance in question when i do a post. glad you enjoy them! mickeyd, enjoyed your story of the rollermatic when you were a kid! i had a similiar experience with my aunt's machine. went to the appliance store and they had a demonstration of a rollermatic transmission! i was in awe! who kinew 40 years later they would be a hobby and passion! no belts, no pins, must be an adhesive strip! i am still in awe of their simple yet effective design today as i work on them! i gravity drain as i have a small country cottage that sets on a crawlspace and i can easily drill a 1 1/2 inch hole in the floor and push the drain hose thru it. plus by pulling the pumps off i don't have to worry about leaking pump seals etc. it just seems simpler this way. but i save all pumps just in case i would want to put them back on. and i do have 2 extra pump seals. joel, i will keep pics coming as i get them! i will say that the red machine with the clutch problem is getting better. tub still takes a good 5 minutes but it comes up to full spin speed now. i keep running it everyday to try and work any leftover oil out of it. i will pull clutch in a week or so and do another cleaning. the blue machine which is the 1965 rapidry custom imperial is basically back together now. i have water tested it but not with a full tub of water. but transmission works great, motor is quiet and bearings very smooth sounding, tub spins very quietly at it's 1010 rpm rapidry spin. putting top of water container back on now!will post some pics later tonite! | ||

| Post# 433124 , Reply# 48 5/4/2010 at 19:57 (5,098 days old) by rollermatic (cincinnati) | ||

|

I GOT IT, I GOT IT, I GOT IT!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

IT RUNS AND SPINS AT FULL SPEED! I GOT IT FIXED TODAY!!!!!!!!!!!

anyway i did 2 things. i was talkin to mark michaels last nite and he has no clutch parts but he told me the clutch linings were the same as those on the 1-18's. i did not know this! i have a 1-18 all torn down. i checked it ans they are the same lining. the ones on my 1-18 look a bit fresher so i pulled them off. i also took a peice of 2" pvc pipe and cut a small peice about 1/2 inch wide. i then filed it down using my grinder to a width of about 1/4 inch. this fit perfectly in the clutch spin wheel assembly and acted as a big thick washer to increase the pressure on the spring! so when i put it together the clutch has a better lining and also has more spring pressure! put it back on and 2 minutes later it was spinning at full speed! yeaaaaaaaaa!!!!!!!!!!!!!!!!!!!!!!!!!!!!! but i did find clutch linings available and ordered 4 of them just in case. they are cheap, about 10 bucks each. that is affordable! i also found a complete clutch available but they wanted 400 bucks!!!!!!! are you kidding??????????? oh well it runs now. gonna put it all back together this week and should be using it by the weekend. here are pics!

| ||

| Post# 433125 , Reply# 49 5/4/2010 at 20:00 (5,098 days old) by rollermatic (cincinnati) | ||

|

good old pvc | ||

| Post# 433126 , Reply# 50 5/4/2010 at 20:04 (5,098 days old) by rollermatic (cincinnati) | ||

|

clutch back together

and spring in place with pvc washer on top. now i put the other end of the spin wheel back on (wheel on the left side) and tighten the 3 screws. on this clutch assembly there is no way to adjust spring tension by adjusting the tightness of the 3 screws that hold the 2 halves of the wheel together. that's why i added a washer.

| ||

| Post# 433128 , Reply# 51 5/4/2010 at 20:15 (5,098 days old) by rollermatic (cincinnati) | ||

|

the washer i am discussing

is the one on the extreme left side here. the "red' machine as i call it due that i painted the outer tub red. i am going to spray the cabinet pink later on, keeping the top it's original white. it is a bottom line "deluxe" model, but does have a two speed motor. it is from 1967.

washer in middle is my 65 turquoise custom imperial rapidry i am also finishing up this week. washer on right is the 65 custom deluxe i got from matt in mich last summer that runs fine and i use occasionally. the little grey box on the post under the g.e. mobile maid spray arm is something i did yesterday. it has 6 lites in 3 rows. top row is for hot and cold water 'on". middle row is for low and high speed being "on". bottom row is for spin solonoid and timer speed control solonoid (i got from turquoisedude) being "on". it is wired into the custom imperial and shows me what is happening with the machine as i test it thru all it's cycles! so far all work perfactly!

| ||

| Post# 433130 , Reply# 52 5/4/2010 at 20:18 (5,098 days old) by rollermatic (cincinnati) | ||

|

this way i can tell | ||

| Post# 433131 , Reply# 53 5/4/2010 at 20:23 (5,098 days old) by rollermatic (cincinnati) | ||

|

here is the top of the

red machine, the bottom line 67 deluxe model that had the slipping clutch.

it has a 4 choice temp selector switch and a timer dial and that's it! timer has 2 cycles, one at reg wash and spin speed, one at low was/spin speed! i think it will look great with the lower cabinet painted pink. especially next to the turquoise machine! that's it for my rollermatic documentary tonite. thanks for viewing, these mnachines are so special to me! my whole living room is rollermatic!!! and i love it this way!

| ||

Comes to the Rescue!

Comes to the Rescue!