|

Thread Number: 3112

My Maytag 104 AMP |

[Down to Last] |

| Post# 80445 8/26/2005 at 14:01 (6,810 days old) by gmpayne (INDIANAPOLIS, IN) | ||

|

My Maytag 104 AMP had delveoped a leak. Seem 2 be comeing from around the center post where it gose up through the outer tub. Would like all the info on how 2 repair this leak. Only leaks when it throws water. Hope some of u guys have pic of how this works. Thanks, Gary

| ||

|

Post# 80471 , Reply# 1 8/26/2005 at 18:28 (6,810 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

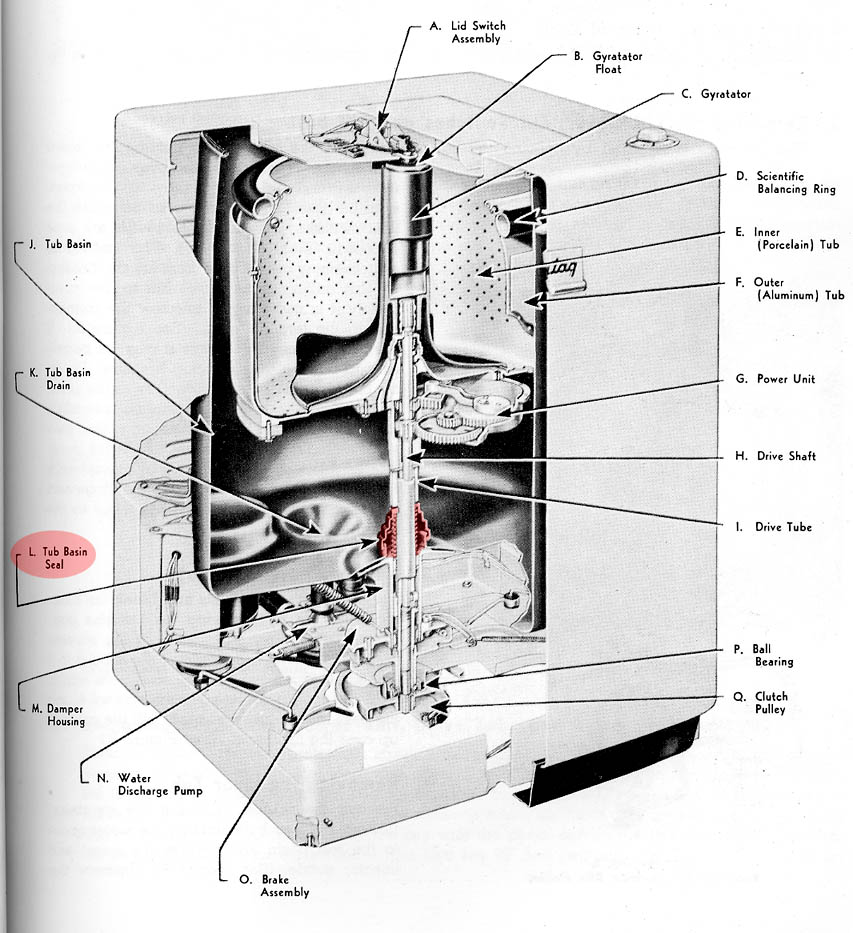

Hi Gary, you have a 140 Maytag AMP. The following diagram shows an ealier 1949 Maytag, but the internal workings are almost exactly the same as your 1957 AMP. The problem is either a hole in your Tub Basin Boot Seal or some grit between the carbon ring molded into the top of the Basin Boot Seal where it presses against the drive tube. Of course you could get lucky and the clamp holding the Basin Boot Seal down to the bottom of the outer tub basin could have rusted and come loose. A relatively easy fix. I colorized the Boot in red...

| ||

Post# 80473 , Reply# 2 8/26/2005 at 18:31 (6,810 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

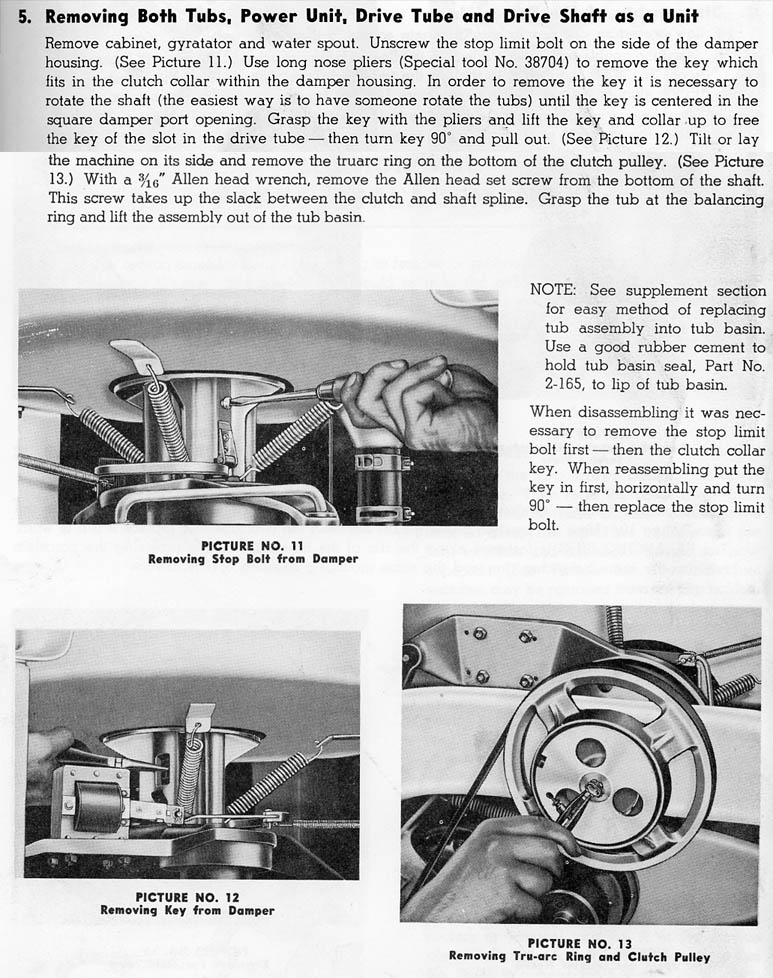

In order to make this inspection and repair you are going to have to pull out the tub/tranmission/drive tube and drive shaft all together as one unit. Here are the instructions, the only difference is that for your machine, you don't have to remove the entire cabinet, you just need to remove the front panel and top.

| ||

Post# 80475 , Reply# 3 8/26/2005 at 18:34 (6,810 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Actually after reading what I just posted, I see that Maytag uses rubber cement to hold the boot in place at the bottom of the outer tub basin. If that is the case in your '57 that cement might have worn away and you need to recement it down. I think a clamp would have been smarter in this application. Lets just hope you don't have a rip or hole in that boot. Please keep us posted! | ||

Post# 80482 , Reply# 4 8/26/2005 at 20:04 (6,810 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

More Pictures | ||

Post# 80483 , Reply# 5 8/26/2005 at 20:05 (6,810 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 80484 , Reply# 6 8/26/2005 at 20:06 (6,810 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 80485 , Reply# 7 8/26/2005 at 20:08 (6,810 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Outer Tub Turned Upside Down | ||

Post# 80486 , Reply# 8 8/26/2005 at 20:11 (6,810 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

And Finally here is the machine base | ||

| Post# 80488 , Reply# 9 8/26/2005 at 20:24 (6,810 days old) by westytoploader () | ||

|

Great AMP pictures...is that a solenoid band brake on your machine Robert? Interesting departure from the large Helical Drive pulley/clutch on the bottom of the tub... | ||

Post# 80543 , Reply# 10 8/26/2005 at 23:10 (6,810 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 80701 , Reply# 11 8/28/2005 at 18:08 (6,808 days old) by Compwhiz128 () | ||

|

Nice pics, I have a question, Robert, do you have photoshop? | ||

| Post# 80707 , Reply# 12 8/28/2005 at 19:35 (6,808 days old) by Spiraclean (UK) | ||

|

Adobe Photoshop CS2

Hi Corey, I have Adobe Creative Suite 2.0 which includes Photoshop CS2 V9.0, Adobe Go Live CS2 V8.0, Adobe Illustrator CS2 V12, Adobe Acrobat 7.0 Professional, Adobe Version Cue CS2 file manager and Adobe Bridge. I love Adobe Software and Photoshop in particular is my favorite Software itís just amazing what you can do in Photoshop CS2. All the best. Hugh

| ||

Comes to the Rescue!

Comes to the Rescue!