|

Thread Number: 31610

/ Tag: Vintage Automatic Washers

Taking apart a 1964 Montgomery Wards/Norge Plus-Capacity Washer |

[Down to Last] |

|

Post# 476806 , Reply# 1 11/21/2010 at 23:08 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476807 , Reply# 2 11/21/2010 at 23:10 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476808 , Reply# 3 11/21/2010 at 23:13 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476809 , Reply# 4 11/21/2010 at 23:14 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476810 , Reply# 5 11/21/2010 at 23:17 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476811 , Reply# 6 11/21/2010 at 23:18 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476813 , Reply# 7 11/21/2010 at 23:20 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476814 , Reply# 8 11/21/2010 at 23:21 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476815 , Reply# 9 11/21/2010 at 23:22 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476816 , Reply# 10 11/21/2010 at 23:24 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476817 , Reply# 11 11/21/2010 at 23:25 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476818 , Reply# 12 11/21/2010 at 23:28 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

After I removed the ring and washer, I removed the set screw in the spanner nut and used a pipe wrench to turn the nut counter-clockwise and unscrewed it off the shaft. Then I took my pipe wrench and unscrewed the Basket Tube Hub off the shaft as well.

Norge made special spanner wrenches to do this, but a pipe wrench works just as well.

| ||

Post# 476819 , Reply# 13 11/21/2010 at 23:30 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476820 , Reply# 14 11/21/2010 at 23:31 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476821 , Reply# 15 11/21/2010 at 23:33 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476822 , Reply# 16 11/21/2010 at 23:33 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476823 , Reply# 17 11/21/2010 at 23:36 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 476825 , Reply# 18 11/21/2010 at 23:38 (4,896 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 476855 , Reply# 19 11/22/2010 at 03:45 (4,896 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

Thank you Robert | ||

| Post# 476872 , Reply# 20 11/22/2010 at 06:59 (4,896 days old) by norgeway (mocksville n c ) | ||

|

Fantastic!! Fantastic work on ..In my humble opinion...the finest washer ever made. | ||

Post# 476875 , Reply# 21 11/22/2010 at 07:31 (4,896 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

NORGE WASHER TEARDOWN

Robert fantastic job tearing down the Wards washer I glad you decided to fix this one. Now everyone can see why I had often said these machines were not practical to repair in the field. Norge continued to use 1950s technology into the 1980s with all the pot metal parts that were exposed to water and detergent. I also always though it was a poor idea to use a sealed ball bearing so close to the water seal, this design still caused major problems for Maytag with the Amanatags and the Norgetags with all those leaking roaring washers. Having sleeve bearings are part of the reason that Maytag helical drive, GE Filterflow and Whirlpool washers lasted so long. But in any case I am sure that you will have it running like new again, I think you are probably the only person the site to rebuild one of these. Congratulations.

| ||

Post# 476879 , Reply# 22 11/22/2010 at 08:10 (4,896 days old) by bajaespuma  (Connecticut) (Connecticut) |

||

Very timely indeed | ||

| Post# 476892 , Reply# 23 11/22/2010 at 09:32 (4,896 days old) by autowasherfreak () | ||

|

Robert, you are AMAZING. I'm positive you will have her running as good as new! | ||

Post# 476912 , Reply# 24 11/22/2010 at 11:20 (4,896 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

| Post# 476918 , Reply# 25 11/22/2010 at 11:29 (4,896 days old) by mickeyd (Hamburg NY) | ||

Hi Robert, Thank you for kicking off Thanksgiving week with

Last month you showed us brain surgery on the AW 6, and now we see into the core of the Wards, the pelvis, I suppose. It's so amazing. Laying in bed last night, one of the pre-sleep meditations was: why doesn't he quit his day job, then publish and market these fabulous repair clinics. You must be up to at least thirty since I joined on Jan 1, 06. They make the process so understandable, even doable if you have the strength, parts, and skill.

Should email this next part so no one can see me be dumb(er) ;'D but I don't care~ the gray water seal in #13 looks fine to me, but you say that you can tell that it's bad. How? Is it supposed to be flush around the shaft? At what age did your gift manifest, and what was the first machine you operated on? | ||

Post# 476927 , Reply# 26 11/22/2010 at 11:59 (4,896 days old) by washerlover  (The Big Island, Hawai’i) (The Big Island, Hawai’i) |

||

| ||

Post# 477177 , Reply# 27 11/23/2010 at 23:46 (4,894 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

the gray water seal in #13 looks fine to me, but you say that you can tell that it's bad. How? Is it supposed to be flush around the shaft?

Hi Mike, its as its carbon face type seal so its not suppose to be flush. I knew it was bad because its obvious that the bearing it was suppose to protect has water damage. At closer inspection of the original seal shows the split that let water through...

| ||

Post# 477178 , Reply# 28 11/23/2010 at 23:48 (4,894 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 477179 , Reply# 29 11/23/2010 at 23:52 (4,894 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

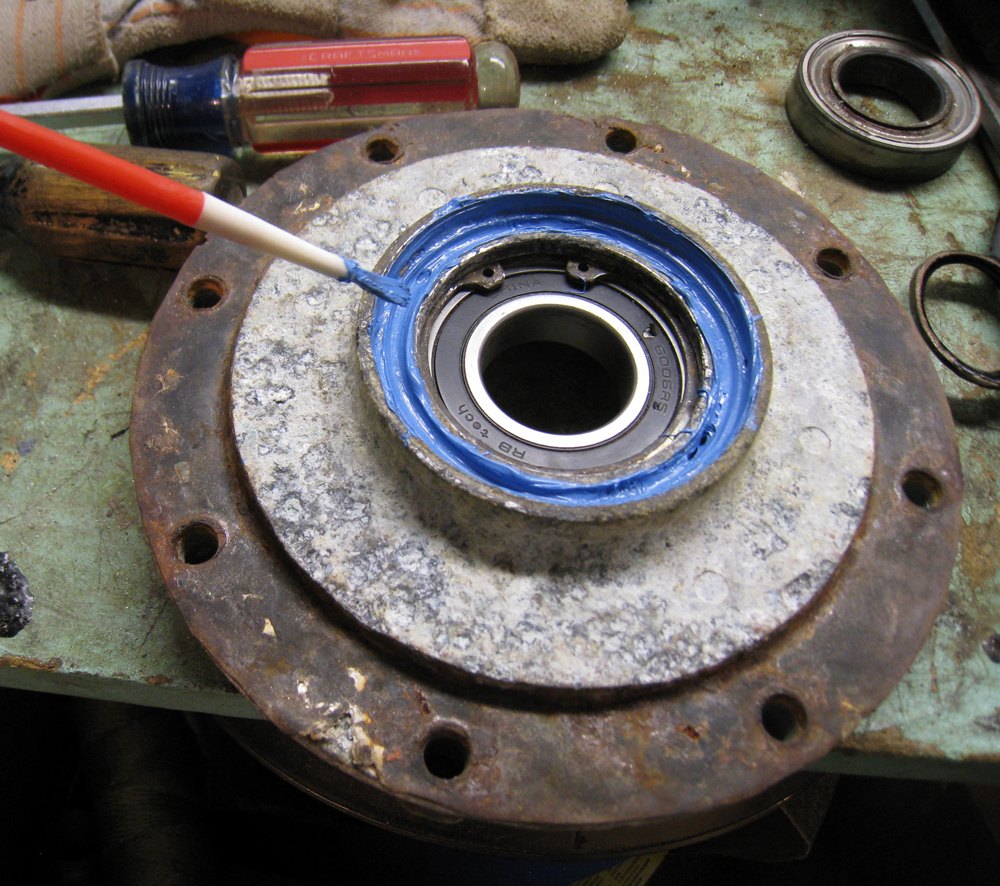

A closer inspection of the seal show the carbon face on the left side and the metal ring on the right. The metal ring faces downward on the carbon face, the carbon is soft and does not wear down the metal as they press together and spin. The carbon face is stationary and the metal ring spins along with the wash basket, it sits under the Spin Tube Hub.

| ||

Post# 477180 , Reply# 30 11/23/2010 at 23:53 (4,894 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 477181 , Reply# 31 11/23/2010 at 23:57 (4,894 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Since the hub has some corrosion damage I put a thin bead of silicone around where the outer rubber part of the seal sits to prevent leaks around the outer edge of the seal. If the hub was new and the metal was smooth this wouldn't be necessary. Its all part of 50 year old washer restoration that they don't cover in the service manuals.

| ||

Post# 477182 , Reply# 32 11/23/2010 at 23:58 (4,894 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 477184 , Reply# 33 11/24/2010 at 00:18 (4,894 days old) by hydralique  (Los Angeles) (Los Angeles) |

||

|

Super-Cool Writeup! Thanks for posting this Robert, it's really interesting to actually see these parts, how they failed and are subsequently repaired. Oh, and a handsome machine too! | ||

Post# 477218 , Reply# 34 11/24/2010 at 10:28 (4,894 days old) by bigalsf  (Salt Lake City) (Salt Lake City) |

||

|

Cool pics! And a great explanation of the process. I've never worked on a Norge design before, so it's great to actually see how they are put together. Thanks for sharing the info. Have a good holiday! | ||

| Post# 477222 , Reply# 35 11/24/2010 at 10:39 (4,894 days old) by supremewhirlpol () | ||

|

Very nice work Robert! I'll keep that Silicone in mind. | ||

| Post# 477262 , Reply# 36 11/24/2010 at 12:51 (4,894 days old) by mickeyd (Hamburg NY) | ||

You're such a good teacher.

Yeah, the main spin bearing looks like a space craft part after re-entry. Grins. Learned that to look that bad, only a leaky seal could have let water in long enough to cause such damage. Fire and water, so bad in the wrong place. I understand now. And the close-ups show the seal damage clearly. Must be the light in #13 that makes the "gray" look so nice.... nice, that is, till you see the rich dark new one and the bright brass ring in the middle... ORRRR... is that the bearing? LOL Thanks.

| ||

| Post# 477318 , Reply# 37 11/24/2010 at 16:31 (4,893 days old) by roto204 (Tucson, AZ) | ||

Joy!

Congratulations on the joy of maximum wash action! That's a beautiful machine, and it represents some of my favorite Montgomery Ward aesthetics, stacked "M|W" logo with a ring of dots and all.

I enjoyed reading about your repairs and the whys and wherefores of what was making it misbehave--amazing that a faulty motor could do all that. I'm so glad you kept at it and fixed her up--she's beautiful! To answer a question you asked long ago and I missed, the Wards Roger and I found lives on to this day. My then-boss inherited it, preferred it over her Kenmore, and did all her wash in it. The torque spring issue is nil if there is a full load of clothes in the tub to hold the agitator down. It only caused issues with small loads, where the agitator batted and tangled the clothes prior to spin, causing grievous out-of-balance conditions. Speaking of which, we washed a rug in our MW the other night, and it was completely out of balance--but never knocked or did anything out of the ordinary. All I noticed was that the clothes were wet after the spin, and I sussed out the rest. I guess if it's out of balance during spin, it has a way of never coming up to speed--the tub oscillates wildly, but it stays put. Weird. But cool! David is so totally attached to the Wards that he has told me it's the only washer he'll use. So, I guess I'd better keep my eyes peeled to keep us in a steady supply of them. (He hated the Whirlpool.) He enjoys the monster capacity and aggressive wash action. The neighbors enjoy the way it rearranges picture frames on their side of the wall and shakes loose plaster dust out of the ceiling. :-)

| ||

Post# 477422 , Reply# 38 11/25/2010 at 00:16 (4,893 days old) by rp2813  (Sannazay) (Sannazay) |

||

Well, I'm going to have to admit that I'm a sucker for the agitator design on the '64. That's the same type as on the first washer of my mom's that I'm able to remember, which was a mid-to-late 50's vintage Norge.

Robert, I hope you'll post a video of the washer going through its cycles once it's up and running again. Truly a labor of love that you've documented above. Ralph | ||

Post# 477426 , Reply# 39 11/25/2010 at 02:33 (4,893 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Nothing better,

Than seeing a minty new fresh bearing fitting into an old well used casing!!! and you do make it look easy, but that comes with practice & patience....AND having the correct spanners and wrenches...and the nouse to improvise!!!

Along with a good silicone, rust treatment and enamel paint, thats in every restorers toolkit, looking forward to the vids!!! Are those bearing kits just for washers etc or generic for other uses?? and what is the cost?? Cheers, Mike | ||

Post# 477459 , Reply# 40 11/25/2010 at 11:33 (4,893 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Are those bearing kits just for washers etc or generic for other uses?? and what is the cost??

Mike those bearings are used in all kinds of applications and that is why they are so easy to get yet today. This bearing cost right under $11. The large double main bearing I bought for my Apex Wash-a-Matic was used by Ford apparently in engine applications. | ||

| Post# 477461 , Reply# 41 11/25/2010 at 11:39 (4,893 days old) by PeterH770 (Marietta, GA) | ||

| ||

| Post# 477760 , Reply# 42 11/26/2010 at 19:59 (4,891 days old) by mrb627 (Buford, GA) | ||

Second That... | ||

Post# 477775 , Reply# 43 11/26/2010 at 20:23 (4,891 days old) by appnut  (TX) (TX) |

||

|

| ||

Post# 477790 , Reply# 44 11/26/2010 at 21:22 (4,891 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 478171 , Reply# 45 11/28/2010 at 20:47 (4,889 days old) by rollermatic (cincinnati) | ||

|

very informative | ||

| Post# 478177 , Reply# 46 11/28/2010 at 20:59 (4,889 days old) by qsd-dan (West) | ||

|

i have yet to tear down a washer that is not frigidaire | ||

| Post# 478189 , Reply# 47 11/28/2010 at 21:49 (4,889 days old) by rollermatic (cincinnati) | ||

|

i don't know

but i would feel a lot more confident tearing down a frigidaire rollermatic or even 1-18 than doing what robert pictorialized above!

i just picked up a 1978 speed queen solid tub machine and i am hoping and praying that the water seal is good on it! i can't even get the agitator to come out! gonna let it warm up in the house a couple days then try it out here! one good thing about solid tubs is that the main tub seal is only submerged in water when the tub spins and drains unlike the constant wear and tear on the seal that comes in a perforated tub machine. probably why none of my rollermatics needed a new tub seal but my 1-18 did. | ||

Post# 478202 , Reply# 48 11/28/2010 at 22:32 (4,889 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 478211 , Reply# 49 11/28/2010 at 23:37 (4,889 days old) by lebron (Minnesota) | ||

| ||

Post# 478212 , Reply# 50 11/28/2010 at 23:45 (4,889 days old) by appnut  (TX) (TX) |

||

|

That's a BobLoad of jeans & darks if I ever saw one. Intense wash action for sure. As an adult, I can see why our W'n'W/Durables cycle was set for 7 minutes of wash time. That's pretty much what a load of towels in our Norge15 looked like when I was doing laundry. All sounds very "normal" and "familiar" Robert. Oustanding job--yeah I'm biased, but have a right to be.

| ||

Post# 478213 , Reply# 51 11/28/2010 at 23:46 (4,889 days old) by appnut  (TX) (TX) |

||

|

| ||

| Post# 478259 , Reply# 52 11/29/2010 at 07:45 (4,889 days old) by tlee618 () | ||

|

Wow Robert, I bet that machine wasn't that quiet when it was brand new. Thanks for sharing the fun video. | ||

Post# 478261 , Reply# 53 11/29/2010 at 07:48 (4,889 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

NORGE WASHER REPAIR

Excellent job Robert its neat to see it running like new again. It sure doesn't sound like a MT washer, ever notice how the quieter washers and dryers are often the ones that last the longest. I do think there is sometimes a correlation between noise and longevity. As far as ease of repair goes I would rank automatic washers from the 1960s-the 1970s in this order [ this is for major repairs involving the transmission main seals and bearings etc ]. The easiest GE FFs next MT helical drive washers, next Frigidare rollermatic washers then WP BD washers and I would still place the Norges last, so again a great job Robert.

| ||

| Post# 478294 , Reply# 54 11/29/2010 at 11:04 (4,889 days old) by powerfin64 (Yakima, Washington) | ||

| ||

| Post# 478355 , Reply# 55 11/29/2010 at 15:02 (4,889 days old) by qsd-dan (West) | ||

|

| ||

| Post# 478359 , Reply# 56 11/29/2010 at 16:00 (4,889 days old) by rollermatic (cincinnati) | ||

|

me too!! | ||

Post# 478575 , Reply# 57 11/30/2010 at 19:56 (4,887 days old) by washerlover  (The Big Island, Hawai’i) (The Big Island, Hawai’i) |

||

| ||

Post# 478620 , Reply# 59 11/30/2010 at 23:28 (4,887 days old) by rp2813  (Sannazay) (Sannazay) |

||

"Maytag was rather soothing and calming compared to this | ||

Post# 478788 , Reply# 60 12/1/2010 at 21:04 (4,886 days old) by jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

WOW WHAT a

ridiculously complex basket drive system! How many bolts does it take to hold a machine together??

Wonderful job Robert!, now I know what is inside my machine. So glad they protected the transmission case from sunlight!!! They do wash well don't they! New jeans don't have a chance in these machines! | ||

Post# 478856 , Reply# 61 12/2/2010 at 00:03 (4,886 days old) by rp2813  (Sannazay) (Sannazay) |

||

So with such incontestably effective washing action, why were Norges and Warges always rated at the middle of the pack at best by CU?

Could noise and reliability have factored against them that much? Maytag held CU's top spot for years during the center dial production run, yet they offered fewer options, far less capacity, and less aggressive wash action. Could (lack of) noise and (proven) reliability have factored in their favor that much? I would think that since many homes have their laundry pairs in the garage or basement, a washer's ability to clean clothes would have weighed heavier in the ratings criteria. Perhaps the answer to CU's motivations lies in the fact that we see many more center dial Maytags showing up today that are still in fine working order, while the Norges and Warges are nearly non-existent. There is no question about which make was the better value over the very long term, and I suppose that's what CU is all about. Or at least they used to be. After seeing the work that Robert had to do, I'm conjuring up a very haggard vision of what Norge's counterpart to the Maytag Man would have looked like. Turnover of an entirely different sort with regard to Norge service personnel due to utter exhaustion. | ||

Post# 478933 , Reply# 62 12/2/2010 at 09:12 (4,886 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

I don't know, good question Ralph. To be honest that machine wasn't all that difficult to work on. Not once in this entire repair did I have to turn the machine over on its side to work on it. Had I realized that in the first place I would have not moved it out of line and into the workshop. All the bolts turned easily after some heating. The basket came out without much of a struggle, the outer tub was a cinch to remove and reinstall. If I wanted to pull the transmission out all I would have to do then is tip the machine on its side and remove the bottom pulley and the tranny would pull right up and out then. Whirlpool designed machines you have to turn over on their side to change the belt or pump or to pull the transmission, yet we see vintage WP/KM machines more often than we do Maytags and WP machines were rarely rated by CU above middle of the line. I can't speak for ease of serviceability of Maytags as the only major work I've done on those machines are the earlier AMP style. It would be interesting to see the internal documentation that CU used as they were testing these machines.

| ||

Comes to the Rescue!

Comes to the Rescue!