|

Thread Number: 34355

Cracking Open My Westy |

[Down to Last] |

| Post# 515644 5/4/2011 at 13:17 (4,734 days old) by takacedon (Salt Lake City) | ||

|

The Laundromat has cleaned up nicely, a bit of rust here and there, but otherwise, looking good.

| ||

|

| Post# 515645 , Reply# 1 5/4/2011 at 13:18 (4,734 days old) by takacedon (Salt Lake City) | ||

|

A good tug got that access panel off...but It looks like we may have a leak, or at least evidence of one in the past.

| ||

| Post# 515646 , Reply# 2 5/4/2011 at 13:19 (4,734 days old) by takacedon (Salt Lake City) | ||

|

In what I assume was the drain part of the cycle... The machine made this terrible noise, I ran it with the panel off and this piece here seems to be mal-shaped and grinding against the housing....do I need a new pump?

| ||

| Post# 515647 , Reply# 3 5/4/2011 at 13:20 (4,734 days old) by takacedon (Salt Lake City) | ||

|

Well this doesn't look good Where can I get a new belt?

| ||

| Post# 515648 , Reply# 4 5/4/2011 at 13:21 (4,734 days old) by takacedon (Salt Lake City) | ||

|

I wasn't too sure what this was, stuck in the cold water I later learned I shoulda left it alone

| ||

| Post# 515649 , Reply# 5 5/4/2011 at 13:22 (4,734 days old) by takacedon (Salt Lake City) | ||

|

I hooked up a hose and WOOSH water everyplace! So what did I do wrong? Since I was uncerimoniously let go yesterday, I have a lot of time to focus on this project....What do I do from here?

| ||

| Post# 515650 , Reply# 6 5/4/2011 at 13:23 (4,734 days old) by takacedon (Salt Lake City) | ||

|

Picture of the tub and pump Post hose fiasco

| ||

| Post# 515692 , Reply# 7 5/4/2011 at 19:47 (4,734 days old) by jeb (Mansfield Ohiio) | ||

|

Westinghouse The evidence of water leak down the front of the tub is very common, All the ones that I've seen look just like that. JEB | ||

| Post# 515751 , Reply# 8 5/5/2011 at 00:46 (4,734 days old) by arbilab (Ft Worth TX (Ridglea)) | ||

Whoa, you've actually GOT a mid-50s Westy? Rare, best I can tell. Had one just like it, back then.

Pump hose: Standard vinyl tubing, goes to the waterlevel diaphragm. Pump noise: Well there's a bearing in the back (that cast piece connected to the solenoid) and one in the pump housing, and that flex shaft in between. I've replaced the shaft, not the bearings, BUT that was back when parts for these were OTC. The shaft is a stout spring, which may have corroded onto itself and no longer flexing or it may have been kinked by the pump being blocked at some point. There's also the rubber motor pinion the plastic wheel runs on, which can't possibly NOT be cracked by now. Wish I could advise on parts but I haven't a clue. If you get the dimensions on the belt it can be substituted (I *think*). | ||

Post# 515775 , Reply# 9 5/5/2011 at 07:09 (4,734 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

MID 50s SLANT FRONT WH Hi Trevor the machine looks good overall and seems to have arrived with no shipping damage. The little black rubber thing that you removed from the water inlet is a back flow preventer, it is not important and they never work when the valves are are old anyway. The drive belts on this machine are not special so any belt that is the same size should work fine. You may want to look for a complete new water pump assembly, the pump that was used on all full-sized WH FL washers through 1988 used the same pump kit, Larry @ Modern Parts in Ohio had some a while ago or do an internet search. Good Luck keep us posted, John. | ||

| Post# 515794 , Reply# 14 5/5/2011 at 09:50 (4,733 days old) by 3beltwesty () | ||

|

.

| ||

| Post# 515796 , Reply# 15 5/5/2011 at 10:15 (4,733 days old) by takacedon (Salt Lake City) | ||

|

Leak I believe it is leaking at the drive shaft, so since it's easy to disassemble would it be possible to replace seals in the pump...if there are any. Oh an ok, so water coming directly out of the pump if I add it to the tub is normal, got it. | ||

| Post# 515797 , Reply# 16 5/5/2011 at 10:19 (4,733 days old) by 3beltwesty () | ||

|

I am not sure if you pump uses the same seal as the newer white pump. Today folks often replace the pump. The seal at Bell is 1.40 ; item 32. CLICK HERE TO GO TO 3beltwesty's LINK | ||

| Post# 515801 , Reply# 18 5/5/2011 at 10:49 (4,733 days old) by takacedon (Salt Lake City) | ||

|

Yeah, that drive spring does look like it has been leaked on for a while, maybe a new pump might be in order, and the base of my machine is coated in rust, which I plan on sanding away and coating in primer today. | ||

| Post# 515829 , Reply# 21 5/5/2011 at 12:59 (4,733 days old) by Travis () | ||

|

Whatever They have appliance and tool cords right by the extension cords. I would go with 16 gauge. Take a pic of what you're working on and tell them to stick it. | ||

| Post# 515887 , Reply# 25 5/5/2011 at 18:11 (4,733 days old) by takacedon (Salt Lake City) | ||

|

Unfortunately... There's always an unfortunately. As I tried to get the small air hose off, I broke the #$@%ing thing. Can this be fixed with an epoxy? I tested to see if the water level sensor was working, I blew in the tube and heard the click, so I'm good there.

| ||

| Post# 515888 , Reply# 26 5/5/2011 at 18:12 (4,733 days old) by takacedon (Salt Lake City) | ||

|

One last image for today Here's how rusty the inside was before I got to work sanding and putting down a primer specifically for rusty metal, hopefully tomorrow I'll get to paint it up with an off white enamel.

| ||

Post# 515900 , Reply# 27 5/5/2011 at 19:08 (4,733 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

WH FL WASHERS WOW that machine is not very rusty for an old WH washer. The flat floor pan should be a light gray the cabinet should be white, you don't want to loose points during the judging LOL.

The pump impeller has serious cracks, the water seal is shot so the main bearing can't be too great and the cover is broken. As I said earlier get a new pump, I guess I am not very patient, but I hate to see some waste 5 hours fooling with a bad pump and yes if you can find all those parts you can fix the one you have. | ||

| Post# 515922 , Reply# 29 5/5/2011 at 21:50 (4,733 days old) by arbilab (Ft Worth TX (Ridglea)) | ||

Thanks for that great nostalgia shot in frame 26. That must be the last of the gearbox slantfronts. I had no idea any of these had survived. That's hardly rusted at all for something ~60yo that runs on water.

Anybody remember the earlier Westys that measured water by how far down the bottom spring was compressed? Now THAT'S nostalgia. | ||

| Post# 515984 , Reply# 32 5/6/2011 at 09:46 (4,732 days old) by 3beltwesty () | ||

|

The short hose that is the input to the pump or may not "be sort of bonded" to the old pump body; thus use caution when removing the hose so it is not ruined. | ||

| Post# 516111 , Reply# 34 5/6/2011 at 22:25 (4,732 days old) by stan (Napa CA) | ||

restoration  | ||

| Post# 516224 , Reply# 38 5/7/2011 at 15:02 (4,731 days old) by 3beltwesty () | ||

|

Many times a belt can be placed on via leaving the pulleys all in place. One uses a thin 3/16" screwdriver's shaft between the belt and pulley and rotates the largest dia pulley by hand and the belt rolls over the pulley edge. | ||

| Post# 516235 , Reply# 39 5/7/2011 at 15:43 (4,731 days old) by takacedon (Salt Lake City) | ||

|

No dice I just ran down and tried that, couldn't get it to work. I'll attribute it to my exhaustion and the heat lol | ||

| Post# 516303 , Reply# 40 5/7/2011 at 23:07 (4,731 days old) by stan (Napa CA) | ||

Paint

Trevor. I can tell you how I repainted my Maytag E2L. not sure if you want to go to this much work, but here goes... I wet sanded it first and washed down good. Since I hate water based spray paint, I decided to use oil based Rustolium (white can) (high gloss) thinned slightly, and applied with a 2" high density foam roller, waited a couple of days. and lightly re wet sanded with 000 sandpaper, wiped down well (tack cloth) gave a second coat, Two more days went by, re wet sanded, 000 sand paper, wiped down, and finished with Meguiar's fine cut-cleaner, and later buffed. I was able to get a new decal and such to give the finishing touch.

Of course you have a lot more trim, and details to mask, and watch out for on your Westy, so you'd have to use your own judgement. I know the factory used oil based enamel, so that's why I did (tying to get the same look and durability, or as close as I could) I'm sure someone here will chime in with a better idea on how to do this, This is just how I did it. Take your time, I know you can get her up and running, with a fresh new face. I'll be watching LOL Stan | ||

| Post# 516304 , Reply# 41 5/7/2011 at 23:16 (4,731 days old) by takacedon (Salt Lake City) | ||

|

Ee gads Nertz to that! I'll just touchup the rusty spots (which aren't in the visible places.) | ||

Post# 516381 , Reply# 43 5/8/2011 at 14:30 (4,730 days old) by syndets2000  (Nanjemoy, MD) (Nanjemoy, MD) |

||

|

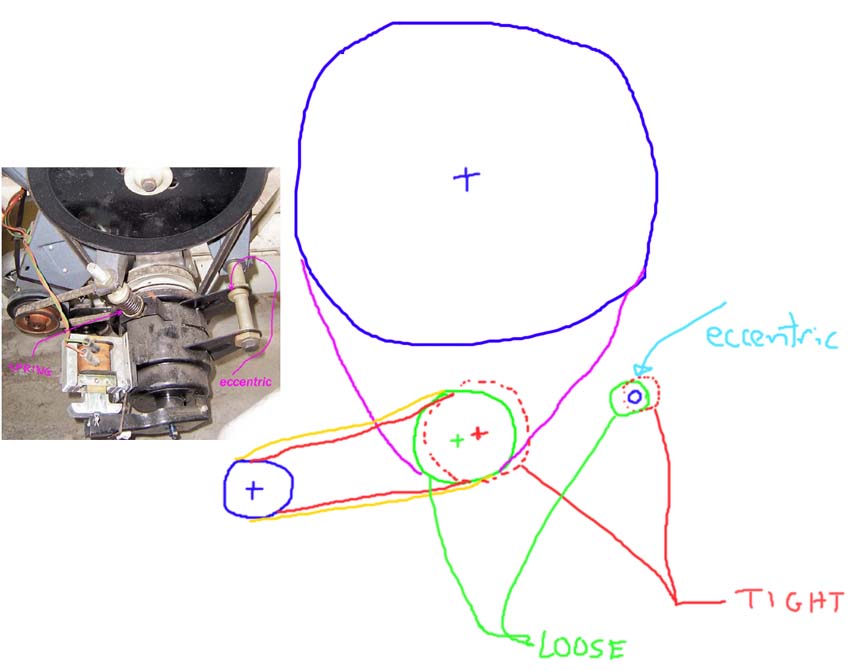

motor pully this is what it can look like- I have wondered about using the newer slider clutch pully, but I have not found a belt to fit it, & the rpms the tub makes might be different

| ||

Post# 516383 , Reply# 44 5/8/2011 at 14:34 (4,730 days old) by syndets2000  (Nanjemoy, MD) (Nanjemoy, MD) |

||

|

My Westinghouse lab ha ha

| ||

| Post# 516391 , Reply# 45 5/8/2011 at 15:34 (4,730 days old) by HiLoVane (Columbus OH) | ||

|

I like the way you've "Frankestein'ed" the '57 with the turquoise kick panel, and the '53, with the '54-'55 top and turquoise door. | ||

| Post# 516393 , Reply# 46 5/8/2011 at 15:43 (4,730 days old) by takacedon (Salt Lake City) | ||

|

ah HA! So that pulley DOES come off! My machine was allegedly in use up until 8 months ago, and the pulley looks just fine, I guess more WD40 is in oder. | ||

| Post# 516411 , Reply# 47 5/8/2011 at 18:41 (4,730 days old) by 3beltwesty () | ||

|

PB nut blaster or Kroil works better than WD40 to remove a stubborn stuck item | ||

| Post# 516429 , Reply# 48 5/8/2011 at 20:01 (4,730 days old) by takacedon (Salt Lake City) | ||

|

Nut Oil & Kroil Are these to be found at Lowes or a more traditional hardware store (and I totally found one in Houston!) | ||

| Post# 516468 , Reply# 49 5/9/2011 at 02:14 (4,730 days old) by 3beltwesty () | ||

|

PB nut blaster is at Walmart in the automotive area, it is in Auto parts stores sometimes too. Kroil is on ebay; at Johnston Supply and sometimes at gun stores. It is better but harder to find. | ||

| Post# 516642 , Reply# 50 5/9/2011 at 17:26 (4,729 days old) by takacedon (Salt Lake City) | ||

|

Changing the belt Ok I STILL can't get this new belt on, what the hell am I doing wrong? I got the service manual, loosened the adjusting nut on the spring, no dice. Anyone? | ||

Post# 516957 , Reply# 51 5/10/2011 at 23:16 (4,728 days old) by appnut  (TX) (TX) |

||

|

usage Guide | ||

| Post# 516968 , Reply# 52 5/11/2011 at 00:29 (4,728 days old) by 3beltwesty () | ||

|

Bonderized "Bonderized steel is simply galvanized steel that in the process of manufacture, the steel is put through a phosphate bath and chromate dry. " CLICK HERE TO GO TO 3beltwesty's LINK | ||

| Post# 517094 , Reply# 53 5/11/2011 at 17:06 (4,727 days old) by takacedon (Salt Lake City) | ||

|

Belt Well, unless I can get the speed changer pulley off or that nut loosened I'm at an impass. That bolt is just not moving....unless maybe I go out and get a torque wrench. | ||

Post# 517192 , Reply# 57 5/12/2011 at 09:10 (4,726 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

REMOVING AND REINSTALLING THE BELTS | ||

| Post# 517205 , Reply# 59 5/12/2011 at 11:16 (4,726 days old) by 3beltwesty () | ||

|

Isn't adjustment (1) more for the vertical belt that goes for to the Large pulley; and 2) more the eccentric for the horizontal belt ( motor to gear changer) ? | ||

| Post# 517223 , Reply# 61 5/12/2011 at 13:04 (4,726 days old) by 3beltwesty () | ||

|

The eccentric looks like it moves the shifter to remove or tighten your belt to the motor

| ||

| Post# 517226 , Reply# 62 5/12/2011 at 13:14 (4,726 days old) by 3beltwesty () | ||

|

shifter to MOVE or tighten your belt to the motor | ||

| Post# 517245 , Reply# 65 5/12/2011 at 14:55 (4,726 days old) by 3beltwesty () | ||

|

Here is how a v belt can go on a pulley. Yours of course is a small pulley. The shaft of the screwdriver prevents the belt from coming out of the pulleys groove; as you revolve the pulley by hand. Have the washer un-plugged for safety.

| ||

| Post# 517397 , Reply# 68 5/13/2011 at 08:52 (4,725 days old) by takacedon (Salt Lake City) | ||

|

I'll try that Last night it was just warmer than the larger belt, I could still touch it, nothing insanely hot, but maybe I'll run it for around 15 minutes to simulate a wash and see how it feels then. I willing to bet there's over-spray of grease on those pulley's, drat! | ||

| Post# 517564 , Reply# 69 5/13/2011 at 21:12 (4,725 days old) by stan (Napa CA) | ||

| ||

| Post# 517566 , Reply# 70 5/13/2011 at 21:30 (4,725 days old) by takacedon (Salt Lake City) | ||

|

Ran it So I ran the machine for about 30 minutes, against, still warmer than the larger belt, but could touch it just fine, didn't burn me or anything. On to the pump I guess! And thanks Stan! I can't wait for the maiden wash! | ||

Post# 517618 , Reply# 71 5/14/2011 at 05:55 (4,725 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

maiden wash? | ||

Post# 517655 , Reply# 72 5/14/2011 at 08:44 (4,724 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

DRIVE BELT TEMPERTURE | ||

| Post# 517668 , Reply# 73 5/14/2011 at 09:43 (4,724 days old) by takacedon (Salt Lake City) | ||

|

Jetcone: Virgin load?! I'm not touching that. Combo52: Thanks for the info, I'm always afraid of instead of fixing something I'm slowly destroying it lol | ||

Post# 517931 , Reply# 74 5/15/2011 at 06:12 (4,724 days old) by ozzie908  (Lincoln UK) (Lincoln UK) |

||

Parts | ||

| Post# 517948 , Reply# 75 5/15/2011 at 09:12 (4,723 days old) by takacedon (Salt Lake City) | ||

|

Austin Thanks for the heads up! I've emailed him, I don't need a motor (yet) but I do need a pump, maybe I should get a motor too just to be safe, that is, if they'll fit my machines. | ||

Post# 517974 , Reply# 76 5/15/2011 at 11:07 (4,723 days old) by ozzie908  (Lincoln UK) (Lincoln UK) |

||

For the sake of your pocket | ||

| Post# 517982 , Reply# 77 5/15/2011 at 11:51 (4,723 days old) by 3beltwesty () | ||

|

Since this thread has started there has already been a dozen pumps on ebay; 3 of them the older black looking ones. | ||

| Post# 518002 , Reply# 78 5/15/2011 at 13:21 (4,723 days old) by takacedon (Salt Lake City) | ||

|

Pumps Guilty of being lazy here lol, I've actually been focusing on working on a manuscript, guess I'd better get my ass back on the line here and peruse some pumps! | ||

| Post# 518210 , Reply# 79 5/16/2011 at 08:35 (4,722 days old) by 3beltwesty () | ||

|

Pumps vary widely in pricing on Ebay . Larry at Modern Parts is a brick and mortar actual parts store; buying one there too helps keep a great parts house open. | ||

| Post# 518211 , Reply# 80 5/16/2011 at 09:11 (4,722 days old) by takacedon (Salt Lake City) | ||

|

Pump Got one off of ebay for 30 bux with shipping. | ||

| Post# 519944 , Reply# 81 5/23/2011 at 12:07 (4,715 days old) by takacedon (Salt Lake City) | ||

|

Here's the new pump Which I won't be installing today as I nurse an awful hangover.

| ||

Post# 520069 , Reply# 82 5/23/2011 at 19:56 (4,715 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

NEW WH WASHER PUMP | ||

| Post# 520089 , Reply# 83 5/23/2011 at 22:00 (4,715 days old) by takacedon (Salt Lake City) | ||

|

It looks exactly like the original one on there, but not nearly as heavy duty plastic....perhaps the original is Bakelite. Anywho, where do I lubricate it before I install it? I'm hoping to be able to figure out how to remove the old one and install the new one easily. | ||

| Post# 521075 , Reply# 84 5/28/2011 at 15:16 (4,710 days old) by takacedon (Salt Lake City) | ||

|

Success? I got the new pump in, but the drive shaft spring thing is making a noise like it's hitting against the motor housing. I tried adjusting it and this is as quiet as I could get it. Any tips anyone? The link below is to a vid of it. CLICK HERE TO GO TO takacedon's LINK | ||

| Post# 522784 , Reply# 85 6/5/2011 at 23:28 (4,702 days old) by stan (Napa CA) | ||

Westy | ||

Comes to the Rescue!

Comes to the Rescue!