|

Thread Number: 37803

Help with wiring a motor |

[Down to Last] |

Post# 562200 12/9/2011 at 18:40 (4,514 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

So the good news is I rencetly got a beautiful new vintage machine which I will share with everyone once its up and running properly.

The bad news is after a few washloads the motor gave out. The motor starts just fine (the centrifugal switch is working perfectly) but in ten or so seconds you can hear the voltage drop and it cuts back into the start winding, click-click click click and is intermittent every few seconds after that. I suspect it needs to be rewound which is an expensive ordeal. I know for sure its not the timer because I wired it up with a test cord and it did the same thing.

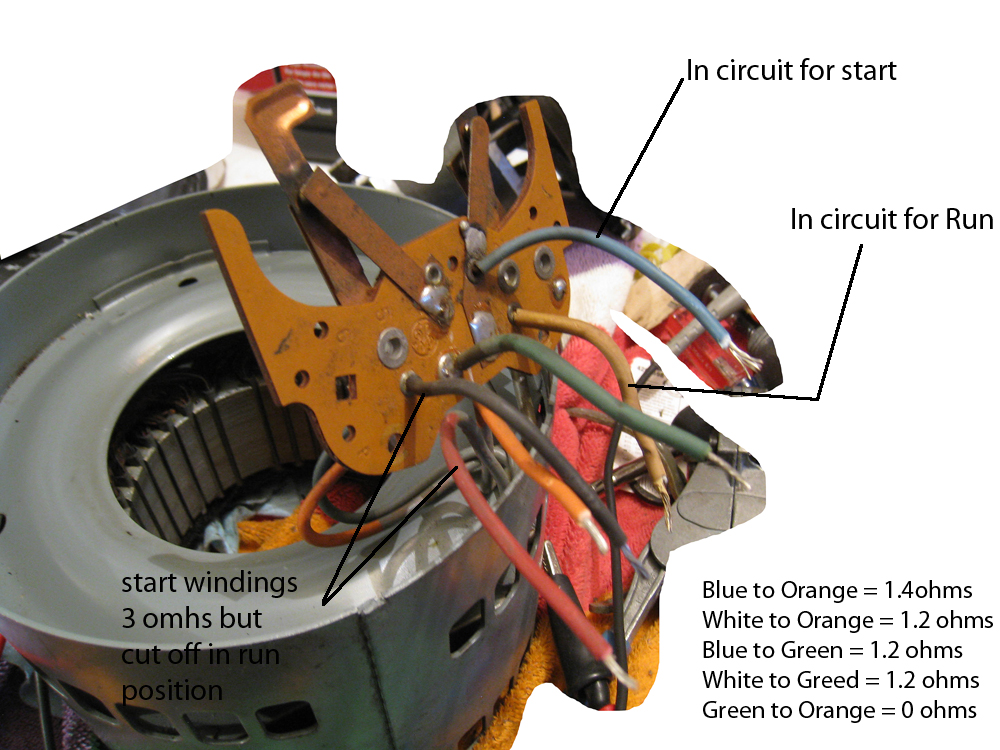

The machine uses a 1 speed reversing motor. I have a spare two speed reversing GE motor from a Kelvinator washer but I have absolutely no wiring diagram to go along with it. So I took the motor new motor apart to examine the connections.

I obviously do not need to use the low speed winding in the circuit, all I want to be able to do is to figure out which wires will enable it to turn clockwise and then later reverse the polarities for counter-clockwise rotation in high speed only. I suspect the white wire is one side of the low speed winding (odd that they would have used the color beige/off-white for that).

Here is an image of the motor terminal board. I suspect the motor is made to start in high speed and if the low speed winding is called for it the centrifical switch will energize that winding once the motor switches from start to run. The centrifical switch seems to energize the blue wire in start mode and the white wire in run mode but these two wires are not part of the start winding (black and red are the start winding).

I know this is hard to analize (if not impossible) from a far but I thought I would throw it out there. The motor is model # 5KH47JR47S. By chance would anyone have a wiring diagram for this motor or guesses on which wires should go to one side of the line and which ones to the other? I really don't want to guess and short it.

Thanks everyone, the new machine is a rare beauty btw. :-)

| ||

|

Post# 562201 , Reply# 1 12/9/2011 at 18:41 (4,514 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 562207 , Reply# 2 12/9/2011 at 19:16 (4,514 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Robert,

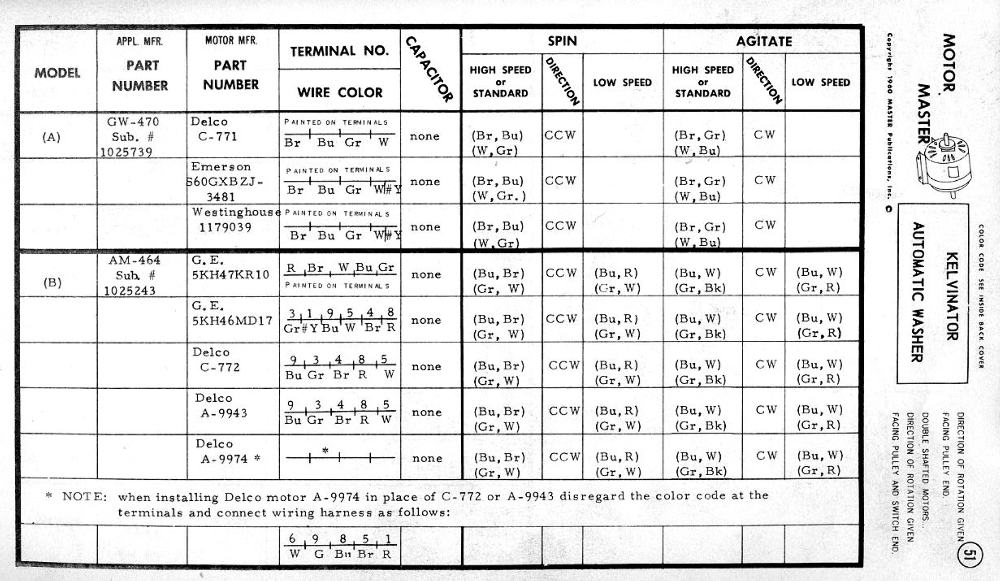

I have an older Motor book from Master, but it ends at 1960. I suspect the motor is post-1960. The 'B' section of the table is for two speed Kelvinator motors. Hopefully this is helpful. I suspect the stripped ends of the wires was to the original harness plug. I'm not sure if the wire is black or blue. Otherwise the GE motor diagrams on this table may be useless. Ben

| ||

Post# 562211 , Reply# 3 12/9/2011 at 19:33 (4,514 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 562213 , Reply# 4 12/9/2011 at 19:43 (4,514 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

| Post# 562232 , Reply# 5 12/9/2011 at 21:01 (4,514 days old) by supremewhirlpol () | ||

|

Ok I'm confused...The two pictures above: Is that the old motor, or the motor that you are trying to fit to the machine? | ||

Post# 562235 , Reply# 6 12/9/2011 at 21:26 (4,514 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 562237 , Reply# 7 12/9/2011 at 21:47 (4,514 days old) by tlee618 () | ||

|

Well if anyone can figure this out I know that you can Robert!! Now you are going to keep us all wondering what this "new" machine is....

Terry | ||

| Post# 562238 , Reply# 8 12/9/2011 at 21:50 (4,514 days old) by supremewhirlpol () | ||

|

Ok, it looks like: Blue + Black or red is for CW or CCW start windings White + orange looks like a run winding White + green looks like the other run winding Do you have a low AC voltage source, or a variac? | ||

| Post# 562241 , Reply# 9 12/9/2011 at 22:15 (4,513 days old) by arbilab (Ft Worth TX (Ridglea)) | ||

Just to cut the fog a little, and more-knowledgeable correct me if I'm wrong:

H and L are main/run windings and use the same start winding. H and L encompass a different number of poles, have the same resistance, and the same common. To reverse, either winding changes "polarity" with respect to the other. Probably the start winding as H and L run windings are already having to switch for speed. Not that that helps you sort brown, blue, orange, green, grey, white. Except whatever wire goes to the centrif switch and opens when the weights extend, is start. In a reversing motor only one wire should read continuity to the start winding, as BOTH ends have to swap WRT the run winding at the timer. And if you got the speed wires backwards, just reverse them again. | ||

Post# 562246 , Reply# 10 12/9/2011 at 22:29 (4,513 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Thanks Everyone

Do you have a low AC voltage source, or a variac?

I sure do have a variac, would that be a good way of testing to prevent shorts if I crank the voltage up slowly? I want to get this hooked up first with a test cord, once I figure out the connections the timer will be easier. Blue + Black or red is for CW or CCW start windings White + orange looks like a run winding White + green looks like the other run winding Hey Melvin thanks! I'm a bit confused, so to begin testing are you saying you think: One side of the line (L1) = Blue, Black and White Other side of the line (Neutral) = Orange and red?? Now you are going to keep us all wondering what this "new" machine is.... Terry not a peep until its working lol :-D This post was last edited 12/09/2011 at 22:45 | ||

Post# 562255 , Reply# 12 12/9/2011 at 22:53 (4,513 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Thank you very much Melvin, I'm 90% sure that the start windings are black and red. What I wasn't sure was exactly how the run windings are wired. | ||

| Post# 562261 , Reply# 13 12/9/2011 at 23:01 (4,513 days old) by supremewhirlpol () | ||

|

Hey no problem! Did you ohm the red and black wires too? | ||

| Post# 562264 , Reply# 14 12/9/2011 at 23:03 (4,513 days old) by roto204 (Tucson, AZ) | ||

Why rewire? | ||

Post# 562266 , Reply# 15 12/9/2011 at 23:03 (4,513 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 562323 , Reply# 17 12/10/2011 at 01:37 (4,513 days old) by roto204 (Tucson, AZ) | ||

Hee-hee! | ||

Post# 562588 , Reply# 18 12/11/2011 at 09:05 (4,512 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Robert | ||

| Post# 562750 , Reply# 19 12/12/2011 at 05:41 (4,511 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

OMG Nate... | ||

Post# 562760 , Reply# 20 12/12/2011 at 07:32 (4,511 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

| ||

Post# 562765 , Reply# 21 12/12/2011 at 09:45 (4,511 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 562775 , Reply# 22 12/12/2011 at 11:55 (4,511 days old) by kenwashesmonday  (Carlstadt, NJ) (Carlstadt, NJ) |

||

|

I'm not sure I like the idea of using a variac on an AC motor, low voltage can cause it to draw too much current and burn up, as often happens in a brown-out. I would certainly use an ammeter to watch what it draws.

Ken D. | ||

| Post# 562783 , Reply# 23 12/12/2011 at 12:29 (4,511 days old) by mickeyd (Hamburg NY) | ||

Robert, | ||

Post# 562821 , Reply# 24 12/12/2011 at 14:33 (4,511 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Using the variac worked because its fused and popped its fuse long before enough voltage made it to the motor to cause any harm when I was experimenting with the wires. When I saw that I finally got the wiring set up correctly and the rotor started to turn slowly I immedialtey cranked it up to 120 volts to prevent any low-voltage issues from harming the motor.

Now the problem is the new motor wont fit in the space of the old motor because of the motor end bell sticking out further in the new motor. I'm going to try and switch the motor end bell that doesn't contain the start controls, but one is a GE motor and the old bad motor that fits properly is a Westinghouse motor so I'm not sure that they are going to be compatible, but we will see. | ||

| Post# 562828 , Reply# 25 12/12/2011 at 15:28 (4,511 days old) by supremewhirlpol () | ||

|

That's great! You got the motor working. Would the surprise get ruined if you posted pictures of the old motor? You never know what I may have lurking about. | ||

Post# 562933 , Reply# 26 12/12/2011 at 23:26 (4,510 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Unfortunately the new Kelvinator motor is just about 1/2" too big to fit in the motor cradle of our mystery machine, so it wont work. ***sigh***

So I'll figure out something, here is the original motor to the machine. What is unusual about it is the bearing housing for one of the end bells is on the inside of the motor.

| ||

| Post# 562935 , Reply# 27 12/12/2011 at 23:35 (4,510 days old) by lebron (Minnesota) | ||

| ||

Post# 562936 , Reply# 28 12/12/2011 at 23:37 (4,510 days old) by peteski50  (New York) (New York) |

||

new machine! | ||

Post# 562941 , Reply# 29 12/13/2011 at 00:50 (4,510 days old) by whirlykenmore78  (Prior Lake MN (GMT-0500 CDT.)) (Prior Lake MN (GMT-0500 CDT.)) |

||

Someone to help

Robert: you may want to enlist the help of Electric Motor Repair. They are located @ 2010 N. 4th St. In Minneapolis Ph# 612-588-4693. We used them at my work last summer when the motor on our Hobart Dw was damaged by a power surge. These guys are good, the motor came back like new.

New motor from Hobart= $1400 Repair by EMR= $450 I hope this helps. Nick | ||

| Post# 562943 , Reply# 30 12/13/2011 at 01:39 (4,510 days old) by arbilab (Ft Worth TX (Ridglea)) | ||

Just blowing smoke out my arse, but I wasn't far off. Single start winding, polarity reversed by timer, separate H and L run windings with common return. Only thing I missed was the centrifugal switch between H and L. Oh, and you should be able to tell a start winding from a run, the start is smaller gauge or at least it was in the 1/4HP motor I built from a kit when I was 10 (1956).

| ||

Post# 562965 , Reply# 31 12/13/2011 at 07:12 (4,510 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

WESTINGHOUSE MOTOR Hi Robert it would best best to repair this motor by using parts from a similar WH motor from another washer or send it to a motor repair shop. WH appliances motors were never great motors and if fact we always said the worst thing about WH washers and dryers was that they used WH motors LOL. Usually only smaller second tier appliance manufactures ever used WH motors in thier washers and dryers.

Robert it would be helpful if you pictured the complete motor and said what it is out of as someone may have a good one laying around, also have you run the motor for a period of time while detached from the transmission to be sure that something is not binding in the transmission? | ||

Post# 562986 , Reply# 33 12/13/2011 at 09:15 (4,510 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Well the end bells between the two motors do not work, so I'm back to square one.

Robert: you may want to enlist the help of Electric Motor Repair. Thanks Nick, I actually went there with the motor last week, they said it needs to be rewound at a cost of around $450. That will be the last ditch effort. also have you run the motor for a period of time while detached from the transmission to be sure that something is not binding in the transmission? Yes, although it doesn't stop and restart when there is no load attached, it clearly does not sound right when being run on the bench. Sounds like waves slowly moving through the motor. Robert it would be helpful if you pictured the complete motor and said what it is out of as someone may have a good one laying around The complete motor John is pictured a few posts above in #562933 and as for saying what its out of, NO lol. :-D Is there a problem with the cap? No cap problem, the problem with the motor isn't starting, it is staying running. It starts just fine, and the capacitor is out of the circuit during run mode. As far as I can tell there are no shorts to ground. | ||

Post# 562995 , Reply# 34 12/13/2011 at 10:29 (4,510 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

WESTINGHOUSE MOTOR Robert it sounds like it has bearing problems, not electrical problems, bearings were one of the frequent problems with WH motors. You could just take the end bells off another WH washer motor and switch them. I will look around and see if I can find a similar WHM. Also would the motor fit from your other similar washer? that you were thinking about parting out. | ||

Post# 562996 , Reply# 35 12/13/2011 at 10:44 (4,510 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 562997 , Reply# 36 12/13/2011 at 10:46 (4,510 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

WESTINGHOUSE MOTOR | ||

Post# 562998 , Reply# 37 12/13/2011 at 10:53 (4,510 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 563000 , Reply# 38 12/13/2011 at 11:18 (4,510 days old) by mickeyd (Hamburg NY) | ||

I have never seen a motor shaft so short either. | ||

| Post# 563012 , Reply# 39 12/13/2011 at 12:41 (4,510 days old) by alr2903 (TN) | ||

|

MickeyD,,, I like your style. MickeyD, thats a great idea, most of us log onto the man's website everyday. Let's give to someone who's given to every one of us everyday. alr | ||

Post# 563017 , Reply# 40 12/13/2011 at 13:09 (4,510 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 563019 , Reply# 41 12/13/2011 at 13:19 (4,510 days old) by mickeyd (Hamburg NY) | ||

Art, that's what I thought So I did it. Click UPGRADE at the top of the page, then you scroll down to unimatic 1140--he's way the hell down the page, tsk! (you'd think he'd make himself more accessible, hahaha )--and donate. I gave him 15 bucks towards the rewire. It took only seconds to accomplish. High time we gave the man a Christmas present.

I only hope that extra upgrade money doesn't go to Jetcone. LOL and hiding from the crate.

Thanks, Art, you opened up my heart. | ||

| Post# 563022 , Reply# 42 12/13/2011 at 13:24 (4,510 days old) by mickeyd (Hamburg NY) | ||

UH-OH | ||

| Post# 563088 , Reply# 44 12/13/2011 at 20:44 (4,510 days old) by nmassman44 (Brooksville Florida) | ||

| ||

| Post# 563104 , Reply# 45 12/13/2011 at 22:20 (4,509 days old) by HooverWheelAway () | ||

|

I know what it is! A bottle of Jack Daniels and the answer is yours! :-)

Just kidding!

| ||

Post# 563108 , Reply# 46 12/13/2011 at 23:02 (4,509 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 563111 , Reply# 47 12/13/2011 at 23:39 (4,509 days old) by golittlesport (California) | ||

ooooh! aahhhh! | ||

Post# 563112 , Reply# 48 12/13/2011 at 23:39 (4,509 days old) by pdub  (Portland, Oregon) (Portland, Oregon) |

||

WOW! | ||

| Post# 563113 , Reply# 49 12/13/2011 at 23:44 (4,509 days old) by alr2903 (TN) | ||

|

that's "EASY" Thats something i have never seen, in the home version, I do remember their coin ops some survived into the 1970's. Robert it looks brand new. Please let us know about that motor. I will tune in tommorrow for the rest of the story. LOL @ Fred.. alr | ||

Post# 563130 , Reply# 50 12/14/2011 at 01:08 (4,509 days old) by mayfan69  (Brisbane Queensland Australia) (Brisbane Queensland Australia) |

||

Gorgeaus! | ||

| Post# 563140 , Reply# 51 12/14/2011 at 04:08 (4,509 days old) by aldspinboy (Philadelphia, Pa) | ||

| ||

| Post# 563151 , Reply# 52 12/14/2011 at 07:31 (4,509 days old) by tlee618 () | ||

|

Robert you must have been an especially good boy this year!! Santa brought you something really special. Looks to be in mint condition as well. Please do tell us the story behind it. Glad to that you think you have the motor issue solved. | ||

Post# 563155 , Reply# 53 12/14/2011 at 07:45 (4,509 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 563159 , Reply# 54 12/14/2011 at 07:56 (4,509 days old) by gizmo  (Victoria, Australia) (Victoria, Australia) |

||

|

that is a thing of beauty...I'll be holding my breath till tomorrow for the full story. Can you please give us some background on these machines - Who made them, are they a unique design to Easy or a rebadged something else, you know the stuff. Thanks Chris. | ||

Post# 563161 , Reply# 55 12/14/2011 at 08:13 (4,509 days old) by Pulsator  (Saint Joseph, MI) (Saint Joseph, MI) |

||

OMG!!! | ||

Post# 563163 , Reply# 56 12/14/2011 at 08:19 (4,509 days old) by bajaespuma  (Connecticut) (Connecticut) |

||

Aferim! You have wonderful automatic washer Karma. A very adorable BOL-ish machine with an Easy Spirolator!! I've enjoyed this thread and want to know more about what a "variac" is although it seems like it's some sort of voltage regulator. Sounds very "Desk Set".

It's looking like husbands in the Twin Cities used to buy their wives automatic washers that would sit in basements unused while they wore out the old wringer machines.

Oh wait, I get it! Vary + AC! right? (serves me right for being AC-DC). | ||

Post# 563194 , Reply# 57 12/14/2011 at 10:19 (4,509 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Comes to the Rescue!

Comes to the Rescue!