|

Thread Number: 40452

KDI-18 Wash Arm Pin |

[Down to Last] |

|

| Post# 598618 , Reply# 1 5/24/2012 at 06:51 (4,353 days old) by blazeword () | ||

|

Pin dropping down closing off port.

| ||

| Post# 598619 , Reply# 2 5/24/2012 at 06:52 (4,353 days old) by blazeword () | ||

|

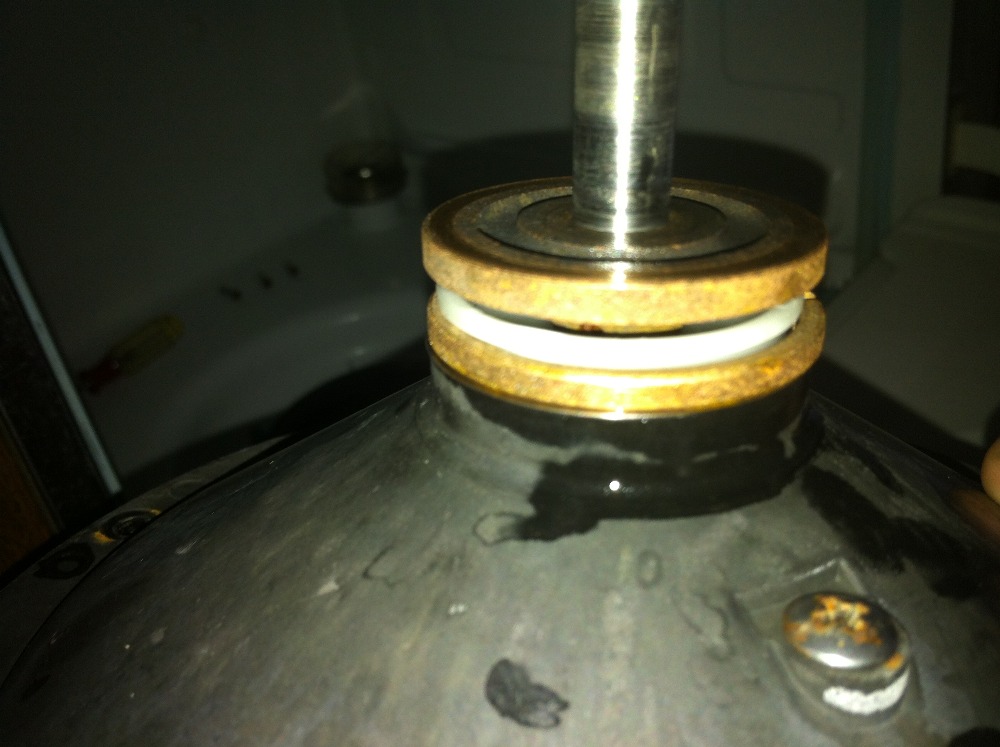

Pin protruding through bottom with weight of wash arm.

| ||

| Post# 598620 , Reply# 3 5/24/2012 at 06:53 (4,353 days old) by blazeword () | ||

|

Plan on securing pin inside housing so that pin is flush with bottom. This is the spacing when pin is flush.

| ||

Post# 598622 , Reply# 4 5/24/2012 at 06:59 (4,353 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

KD-18 washarm support | ||

| Post# 598625 , Reply# 6 5/24/2012 at 07:12 (4,353 days old) by blazeword () | ||

|

Pin flush at bottom?

| ||

Post# 598678 , Reply# 7 5/24/2012 at 11:20 (4,353 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

KD-18 washarm support | ||

Comes to the Rescue!

Comes to the Rescue!