|

Thread Number: 40858

Winning the Dyson CR01 Battle |

[Down to Last] |

|

| Post# 604526 , Reply# 1 6/18/2012 at 14:03 (4,326 days old) by ANDYVIVO (Essex) | ||

|

The main bearing by comparison to 6204zz

| ||

| Post# 604527 , Reply# 2 6/18/2012 at 14:06 (4,326 days old) by ANDYVIVO (Essex) | ||

|

And another

| ||

| Post# 604529 , Reply# 3 6/18/2012 at 14:10 (4,326 days old) by aegokocarat (United Kingdom) | ||

|

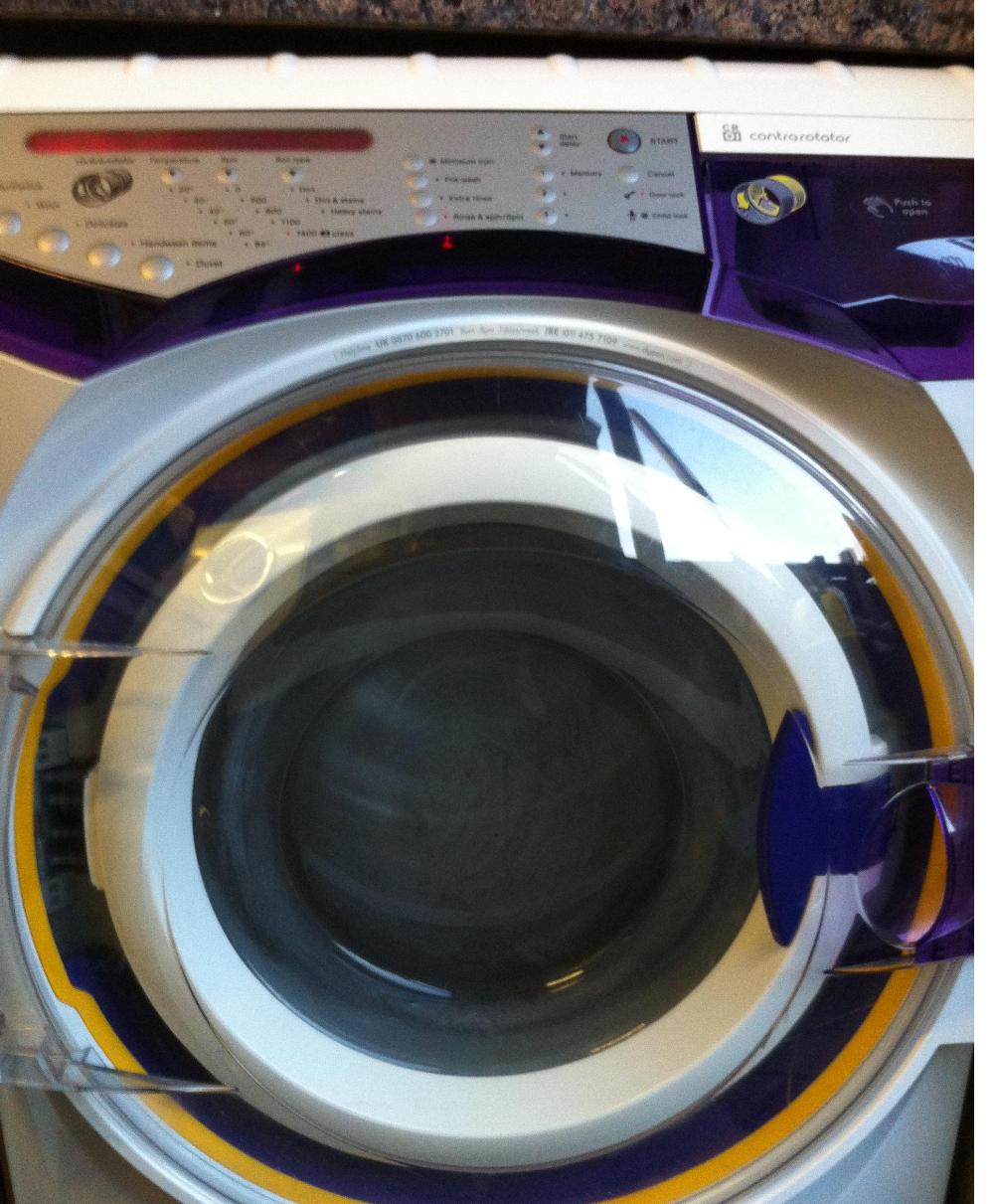

i'd love a purple dyson washer :) Tom :) | ||

| Post# 604561 , Reply# 4 6/18/2012 at 16:18 (4,326 days old) by arbilab (Ft Worth TX (Ridglea)) | ||

| ||

| Post# 604562 , Reply# 5 6/18/2012 at 16:18 (4,326 days old) by ANDYVIVO (Essex) | ||

|

What the full purple one? I'd quite like the silver one But this was a bargain. This one is a standard CR01, but I found a Memory key panel on ebay and fitted that. The switches that are on the memory are on the standard console board, just hidden. =) | ||

| Post# 604815 , Reply# 6 6/19/2012 at 16:34 (4,325 days old) by ANDYVIVO (Essex) | ||

|

Some more pics So tonight it was time to tackle separating the inner drums

| ||

| Post# 604817 , Reply# 7 6/19/2012 at 16:38 (4,325 days old) by ANDYVIVO (Essex) | ||

|

The main shaft assy needs a bit of a clean

| ||

| Post# 604819 , Reply# 8 6/19/2012 at 16:39 (4,325 days old) by aegokocarat (United Kingdom) | ||

|

Yup id love the full purple one! Lol The purple one looks sooo cool! :-) Tom :-) | ||

| Post# 604820 , Reply# 9 6/19/2012 at 16:43 (4,325 days old) by ANDYVIVO (Essex) | ||

|

Inner shaft Fair bit of congealed fabric softner to clean off

| ||

| Post# 604821 , Reply# 10 6/19/2012 at 16:45 (4,325 days old) by ANDYVIVO (Essex) | ||

|

The main outer drum

| ||

| Post# 604823 , Reply# 11 6/19/2012 at 16:48 (4,325 days old) by ANDYVIVO (Essex) | ||

|

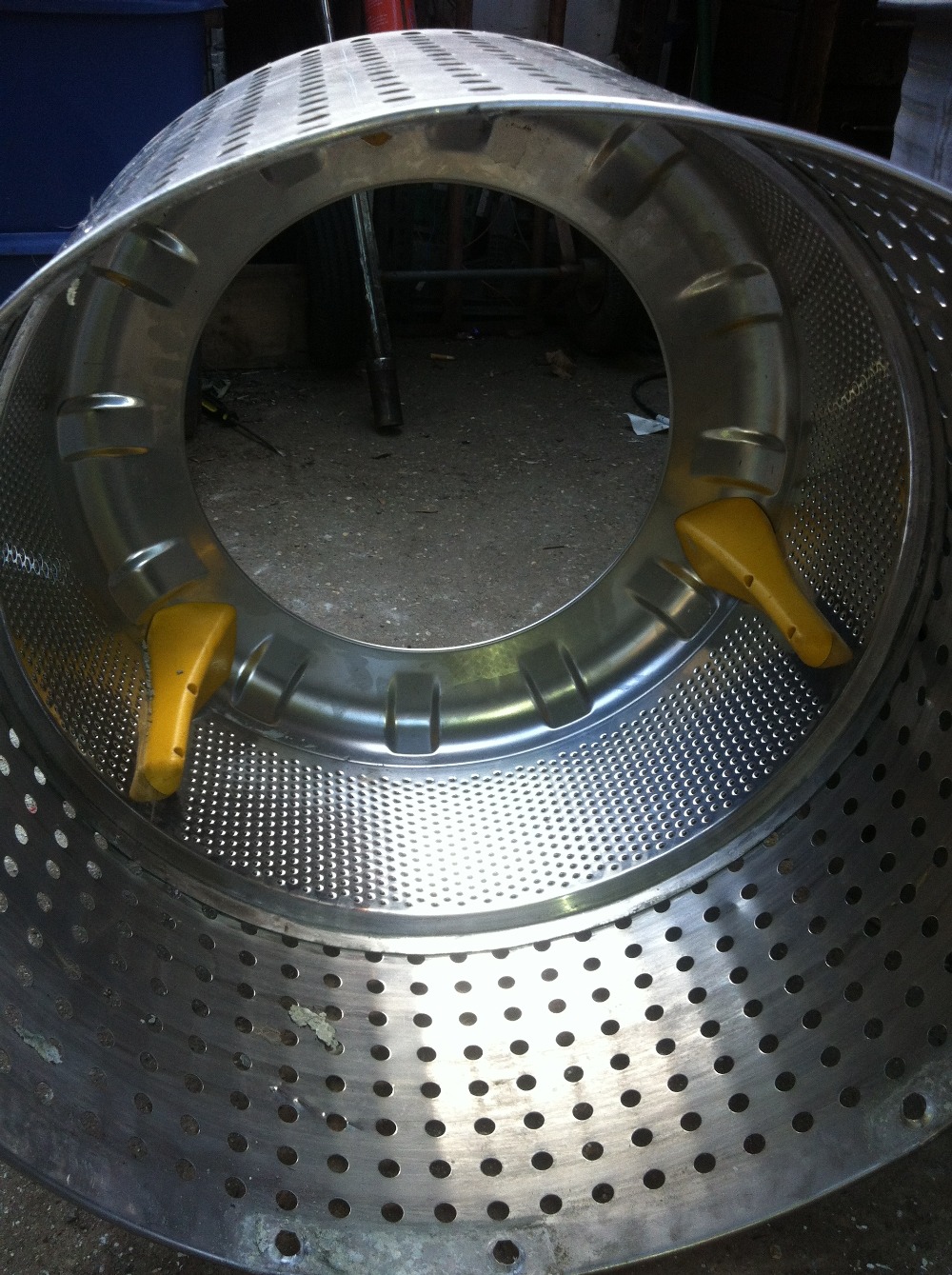

The rear inner drum with separator ring

| ||

Post# 604839 , Reply# 14 6/19/2012 at 18:04 (4,325 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Keymatic

Hi Andy , yes the Keymatic pulsator turned the opposite way to the drum, quite a drama splash action when both get going , hence only a 4 minute wash from correct temperature when on cottons, ie pulsator & drum both turning!!!

CLICK HERE TO GO TO chestermikeuk's LINK

| ||

Post# 604843 , Reply# 15 6/19/2012 at 18:06 (4,325 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Contra Rotator | ||

Post# 604903 , Reply# 17 6/20/2012 at 01:17 (4,325 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Contra | ||

| Post# 604909 , Reply# 18 6/20/2012 at 02:22 (4,325 days old) by ANDYVIVO (Essex) | ||

|

The yellow thingy these are to do with the OOB detection, they are piezo accelerometers, and are used at the 800 and 1100 rpm part of the spin phase. | ||

| Post# 605064 , Reply# 19 6/20/2012 at 15:31 (4,324 days old) by ANDYVIVO (Essex) | ||

|

The drive componants The rear pulley, primarily connects to the main drum assy, the toothed part connects to.........

| ||

| Post# 605066 , Reply# 20 6/20/2012 at 15:44 (4,324 days old) by ANDYVIVO (Essex) | ||

|

the planet hub this is sprung, a motorised ramp pushes against the spokes to initiate contrarotation. The hub is opened for the gears to engage.

| ||

| Post# 605067 , Reply# 21 6/20/2012 at 15:58 (4,324 days old) by ANDYVIVO (Essex) | ||

|

The ramp ring has two halves, the black ring is the operating ring for opening the planet hub, it locates with the slots in the outer drum.

| ||

| Post# 605068 , Reply# 22 6/20/2012 at 16:00 (4,324 days old) by ANDYVIVO (Essex) | ||

|

The white section is ramped to push against the black ramp

| ||

| Post# 605070 , Reply# 23 6/20/2012 at 16:16 (4,324 days old) by ANDYVIVO (Essex) | ||

|

Which is finally connected to the main drive pulley, this sits on the inner drum shaft. It has a geared hub with it's own set of bearings in the hub also.

| ||

| Post# 605073 , Reply# 24 6/20/2012 at 16:19 (4,324 days old) by ANDYVIVO (Essex) | ||

|

So that is all on this one until reassembly, will take some more pics as this happens to better illustrate how it all comes together =) | ||

| Post# 607476 , Reply# 26 7/1/2012 at 16:24 (4,313 days old) by andyvivo (Essex) | ||

|

More pics Rear pulley mounted

| ||

| Post# 607478 , Reply# 27 7/1/2012 at 16:26 (4,313 days old) by andyvivo (Essex) | ||

|

Ramp mount fitted

| ||

| Post# 607480 , Reply# 28 7/1/2012 at 16:30 (4,313 days old) by andyvivo (Essex) | ||

|

Just for demonstration ramp lowered (normal action)

| ||

| Post# 607483 , Reply# 29 7/1/2012 at 16:34 (4,313 days old) by andyvivo (Essex) | ||

|

Ramp raised (contra rotate)

| ||

| Post# 607484 , Reply# 30 7/1/2012 at 16:36 (4,313 days old) by andyvivo (Essex) | ||

Gearbox added

| ||

| Post# 607486 , Reply# 31 7/1/2012 at 16:44 (4,313 days old) by andyvivo (Essex) | ||

|

With the ramp raised, it pushes against the gearbox fins to open for contrarotate mode

| ||

| Post# 607488 , Reply# 32 7/1/2012 at 16:49 (4,313 days old) by andyvivo (Essex) | ||

|

With the ramp lowered, the gearbox locks in to the raised edges of the rear pulley for normal drum action.

| ||

| Post# 607496 , Reply# 33 7/1/2012 at 17:36 (4,313 days old) by andyvivo (Essex) | ||

|

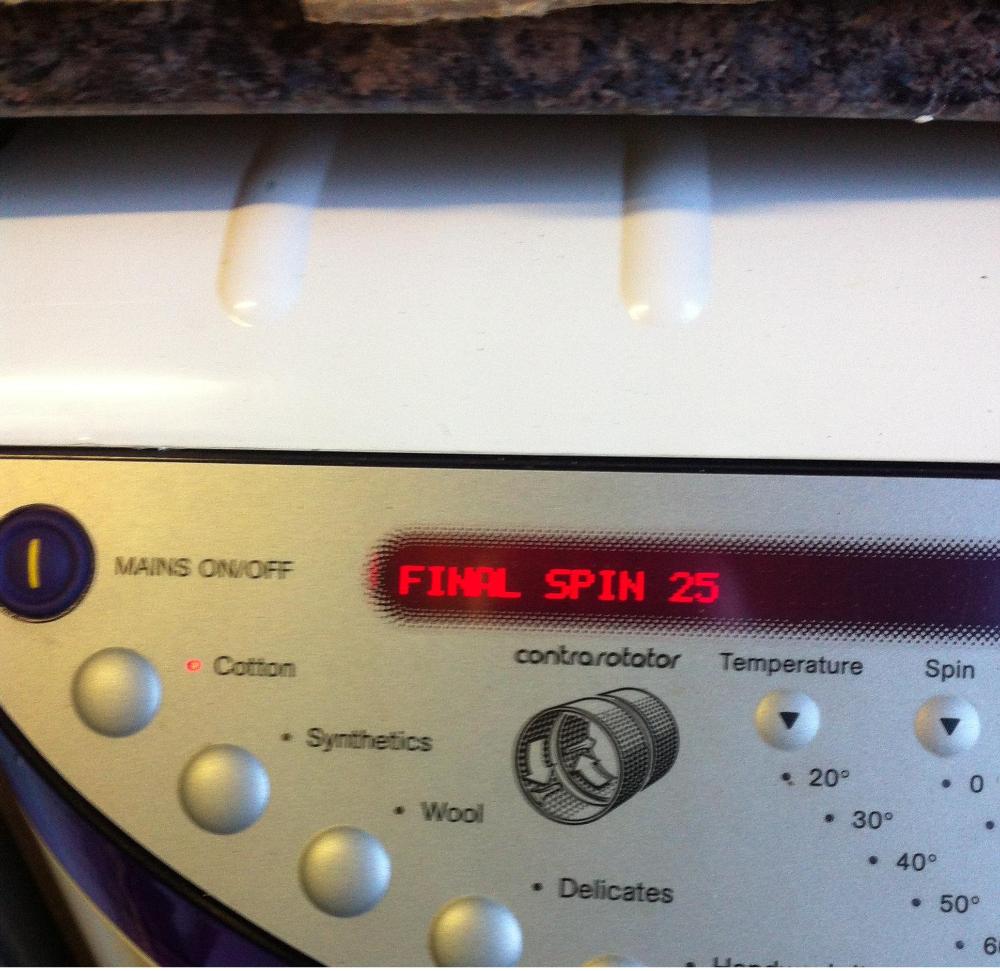

Back together and

| ||

| Post# 607500 , Reply# 34 7/1/2012 at 17:55 (4,313 days old) by andyvivo (Essex) | ||

|

Woohoo!!

| ||

| Post# 607501 , Reply# 35 7/1/2012 at 17:57 (4,313 days old) by andyvivo (Essex) | ||

|

Can't say this has been a labour of love, more of a labour of intrigue and curiosity. The purple warrior lives on, for how long though? lol | ||

| Post# 607594 , Reply# 36 7/2/2012 at 08:34 (4,313 days old) by dyson2drums (United Kingdom) | ||

Well done! I was amazed everytime the dyson engineer came to fix the washing machine, the machine surely was something different!

Did you know by pressing the soil type button in the mode you had it in it will go to the next step in the program sequence. 24 stands for final spin, 25 for slowing down, 26 for anti crease tumble etc. We do miss the dyson for one reason, we can't wash our king size duvets at home anymore as the LG only has a 69litre drum so we have to go to the launderette and the machines aren't very good (Ipso with the clock dial). It was a good machine, excellent washing and very fast too. I want to ask what does Hz stand for on the display in diagnostic mode? When it was spinning it would hit 1750Hz, 64Hz (ish) on normal tumbling and 400Hz on contraroration. Happy washing :) | ||

| Post# 607622 , Reply# 38 7/2/2012 at 10:57 (4,312 days old) by electron1100 (England) | ||

Hello Andy you must be pleased as punch to have won over one these possible nightmare machines, I am pleased for you and the machine.

You will be one of the few people in England i would think with a fully working one, whenever they came into work it was always the gear box that had gone for the umpteenth time. I used to be tempted at times to take one home and have a fiddle, but i backed out Well Done Gary | ||

| Post# 607635 , Reply# 39 7/2/2012 at 11:30 (4,312 days old) by dyson2drums (United Kingdom) | ||

I always thought it'd be the speed the machine is running at, if that is the case then the final spin is shown as 1750Hz!

The only way I could get all that to display during the wash was to put it into diagnostic mode by pressing soil type and temperature button simultaneously upon pressing the on/off button and then starting a wash without switching it off. It displayed the temperature in degrees, Hz(most likely the rpm) and water level with (mm) as some sort of measurement from what I remember. The link below shows what is displayed on the display, I took this video over 4 years ago. CLICK HERE TO GO TO dyson2drums's LINK | ||

| Post# 607697 , Reply# 41 7/2/2012 at 16:39 (4,312 days old) by dyson2drums (United Kingdom) | ||

| ||

| Post# 607704 , Reply# 43 7/2/2012 at 16:49 (4,312 days old) by andyvivo (Essex) | ||

|

Just though I would add this link for good measure lol CLICK HERE TO GO TO andyvivo's LINK | ||

| Post# 607710 , Reply# 44 7/2/2012 at 17:24 (4,312 days old) by dyson2drums (United Kingdom) | ||

| ||

| Post# 607729 , Reply# 46 7/2/2012 at 17:58 (4,312 days old) by dyson2drums (United Kingdom) | ||

It definitely was a really good daily driver. It did a lot of washing and was easy to use and the quick washing times were a bonus. However it had a few problems.

We had it repaired out of warranty when the motors, interlock, planet carrier assembly were replaced and the drums were locked. After that 1 years cover expired from the repair it was causing problems by getting stuck on programs, it was very loud on spins so we decided to opt for a new washing machine. We needed something big and preferably graphite or silver so got the LG F1479FDS5 which we're very happy with :) | ||

| Post# 607731 , Reply# 47 7/2/2012 at 18:01 (4,312 days old) by andyvivo (Essex) | ||

|

Ah well I suppose all good things come to an end. I do like the LG machines, ven if sometimes they light up like a christmas tree lol | ||

| Post# 607734 , Reply# 48 7/2/2012 at 18:15 (4,312 days old) by dyson2drums (United Kingdom) | ||

Well lets just say the start up tune and end tune plus the lights always intrigue visitors or family especially kids as they can't keep their hands off.

We've had the machine switched off half way into a wash by a child as the power button isn't included in the child lock which i'd say is a design fault as it is the case with the LG at grans. | ||

| Post# 607736 , Reply# 49 7/2/2012 at 18:19 (4,312 days old) by andyvivo (Essex) | ||

|

Yes that is daft, hopefully this will get revised on future machines. Does yours have steam cycle? | ||

| Post# 607849 , Reply# 50 7/3/2012 at 04:03 (4,312 days old) by dyson2drums (United Kingdom) | ||

| ||

Post# 607856 , Reply# 51 7/3/2012 at 05:13 (4,312 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Contra

Great pics there Andy, such a complicated machine, similar to the Hoover keymatic using the hollow shaft to in the Hoover case driving the pulsator in Dysons case driving the contrarotator!!

I often wondered if they had also offered a "Stripped back" version sleek & sophisticated with subtle colour, would they have sold more!! Most kitchen I`ve seen them in look like they are sat in the middle of the room given how much they stuck out from under worktops in small kitchens etc!! | ||

| Post# 607906 , Reply# 53 7/3/2012 at 09:49 (4,311 days old) by andyvivo (Essex) | ||

|

Found the link Last paragraph and written last year. I doubt that this will happen for a good few years yet. CLICK HERE TO GO TO andyvivo's LINK | ||

| Post# 607939 , Reply# 54 7/3/2012 at 12:57 (4,311 days old) by fido () | ||

|

Hi Andy, if a customer asked you to do bearings on a Dyson: a) would you do it? b) how many hours would you charge? | ||

Post# 607994 , Reply# 55 7/3/2012 at 15:52 (4,311 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Blogs | ||

| Post# 608022 , Reply# 56 7/3/2012 at 16:28 (4,311 days old) by matchboxpaul (U.K) | ||

|

Blimey Andy. Thats one unusual and rather complicated looking machne Dyson designed! Really good to be able to see photos of the internal components of these unique machines. Thanks for updating us all along the way. Paul p.s the machine looks in superb condition. | ||

| Post# 608028 , Reply# 58 7/3/2012 at 16:49 (4,311 days old) by dyson2drums (United Kingdom) | ||

Hey glenfieldmathk1

I have tried putting the king size duvet into the washing machine but it just won't fit, a third or quarter of the duvet will stick out which means I can't even shut the door. I don't know what tog it is but its a thick duvet. I've fitted double duvets and they were washed very well with steam wash being selected. As far as i'm aware my old dyson had a 78l drum which is what it says on the poster I have which is the actual size of the machine. Maybe if it was a thinner (lower tog) duvet it would've fitted. | ||

| Post# 608030 , Reply# 59 7/3/2012 at 16:52 (4,311 days old) by glenfieldmathk1 (Glenfield-Leicester-UK) | ||

|

oh right, I am just thinking maybe LG is not true to size. I am sure I read on there website the LG can handle Kingsize duvets of up to 11.5 tog. Maybe thats the 11Kg Model though!! Yes, sorry meant 78l. | ||

| Post# 608031 , Reply# 60 7/3/2012 at 16:54 (4,311 days old) by dyson2drums (United Kingdom) | ||

| ||

| Post# 608047 , Reply# 63 7/3/2012 at 17:58 (4,311 days old) by paulc (Edinburgh, Scotland) | ||

| ||

| Post# 608048 , Reply# 64 7/3/2012 at 17:59 (4,311 days old) by paulc (Edinburgh, Scotland) | ||

BTW | ||

| Post# 608049 , Reply# 65 7/3/2012 at 18:05 (4,311 days old) by andyvivo (Essex) | ||

|

Thanks Paul, been nice to find somewhere to share it too =) | ||

| Post# 608248 , Reply# 66 7/4/2012 at 13:57 (4,310 days old) by dyson2drums (United Kingdom) | ||

I used to wash all the duvets in the house when we had the dyson, they always went through a max spin cycle once the cycle had ended for quicker drying.

Even in the LG, the duvets were put through a seperate spin at 1400 once the standard 1000rpm on the duvet cycle is done. Only the dyson CR02 allergy (silver model) had a 60 degrees duvet wash. | ||

| Post# 608257 , Reply# 67 7/4/2012 at 14:29 (4,310 days old) by andyvivo (Essex) | ||

|

Hmmm I may see how much a cr02 control panel is...... | ||

| Post# 709848 , Reply# 69 10/17/2013 at 13:31 (3,840 days old) by jameseyboy (uxbridge, london UK) | ||

|

cr01 bearing hi guys i was just wondering where i would buy a replacment drum bearing for a cr01 i have looked everywhere :-( thanks guy's james | ||

Post# 709849 , Reply# 70 10/17/2013 at 13:38 (3,840 days old) by henene4  (Heidenheim a.d. Brenz (Germany)) (Heidenheim a.d. Brenz (Germany)) |

||

|

You could try to get the old ones out, go to any kind of hardware store that sells bearings like these and get some with the same size. So you could "Upgrade" you washer with more resistant bearings. But as Dyson stopped serviceing them you don't have any other chance, I guess. | ||

| Post# 709947 , Reply# 71 10/18/2013 at 06:56 (3,840 days old) by jameseyboy (uxbridge, london UK) | ||

|

i think thats what i will have to i havent even taken the back off the machine yet but i will keep you guys updated when i do cheers james | ||

| Post# 761969 , Reply# 72 6/6/2014 at 17:28 (3,608 days old) by mia () | ||

|

dyson drums Andy, having difficulty separating inner and outer drums, any help? | ||

Comes to the Rescue!

Comes to the Rescue!