|

Thread Number: 42915

"New" GE Filter Flo owner here :) Questions and strange noises . . . |

[Down to Last] |

|

Post# 631257 , Reply# 2 10/13/2012 at 10:29 (4,206 days old) by bajaespuma  (Connecticut) (Connecticut) |

||

Your machine is from the late Eighties, early Nineties. They changed the design of the backsplashes, slightly, to be consistent with the new GE "Corporate" design specs. I think it's a smart looking panel and yours looks like a very respectable MOL unit.

The scale on the bottom of your outer tub is perfectly normal for a well-used machine in a hard water area. It's very easy to clean with de-scaler. The bad news is that it sounds like your transmission will require replacing. GE trannys usually leaked oil when they were ready to sh*t the bed, but yours sounds like it's beginning to fail. FF's rarely struggle to agitate on any sized load and the noise you're hearing during the spin might be a harbinger of death. On the other hand, it could be that the spin brake is out of whack and engaging when it shouldn't. Are you avoiding a service call? You might want to save yourself the grief and the grime. Fortunately, trannies for Filter-Flo's seem to come up once in a while on eBay and some of the techies on this site may have one for sale. I'm told it's an easy job to replace them. The only thing is you'll have to identify your machine as either standard capacity or extra-large.

Other more service-knowledgeable members will weigh in on this so listen to them. Good luck and welcome! | ||

Post# 631268 , Reply# 3 10/13/2012 at 10:57 (4,206 days old) by goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

| ||

Post# 631309 , Reply# 5 10/13/2012 at 14:47 (4,206 days old) by goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

| ||

Post# 631310 , Reply# 6 10/13/2012 at 14:54 (4,206 days old) by bajaespuma  (Connecticut) (Connecticut) |

||

There were only two sizes of Perforated tub Filter-Flo's made, "Standard capacity" which includes V-12, 14 & 16 and was later called "Large Capacity" and "Extra-large capacity " which began as "Heavy Duty 18" .

The components of there machines are largely interchangeable, but the wash-baskets, activators, mini-baskets, outer tubs and transmission assemblies are available in the two different sizes. I suppose you could get away with rebuilding a transmission with a large activator post, but I wouldn't know how to do that. | ||

Post# 631330 , Reply# 7 10/13/2012 at 15:54 (4,206 days old) by yogitunes  (New Jersey) (New Jersey) |

||

There can be a trick to some of this time frame as far as capacities......meaning, they were using the largest capacity tubs, and small capacity, short post transmissions, thus adding a 2 inch adaptive extention to the top of the agitator for the difference to compensate......this was more seen in the next version of the tilted monochromatic control panel......

its best to take measurements when considering replacements of the exact one......not that you couldn't put a Regular Largest Capacity tranny in, but you would also need the larger agitator....you can interchange alot, but keep in mind some things have to be matched together..... just pay attention to sizes......but for the most part, anything can be done! | ||

| Post# 631331 , Reply# 8 10/13/2012 at 15:57 (4,206 days old) by redcarpetdrew (Fairfield, CA) | ||

| ||

| Post# 631358 , Reply# 9 10/13/2012 at 17:59 (4,206 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

| ||

| Post# 631359 , Reply# 10 10/13/2012 at 18:02 (4,206 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

| ||

| Post# 631361 , Reply# 11 10/13/2012 at 18:06 (4,206 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

| ||

| Post# 631391 , Reply# 13 10/13/2012 at 21:09 (4,205 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

| ||

| Post# 631394 , Reply# 14 10/13/2012 at 21:20 (4,205 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

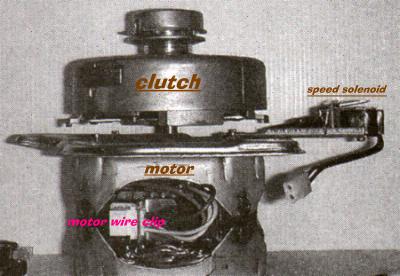

.In this picture the 2 small cams can be seen sticking out on either side of the round clutch drum above the motor. When the speed solenoid is in it's resting position or Regualr/Fast, springs pull the actuator arm down so as not to activate the cams. Basically it's OFF (just like in the picture). Select gentle and the solenoid is energized, lifting the arm from its resting position, upwards to make contact with the clutch cams and thus engage Gentle/slow. It's very hard to see, but when it's making that noise, look through the peep hole in the black motor yoke to see if the arm is up or down. I hope this helps. -Alex

| ||

| Post# 631395 , Reply# 15 10/13/2012 at 21:22 (4,205 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

| ||

Post# 631449 , Reply# 17 10/14/2012 at 04:58 (4,205 days old) by goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

| ||

| Post# 631471 , Reply# 18 10/14/2012 at 08:13 (4,205 days old) by RWIndiana () | ||

|

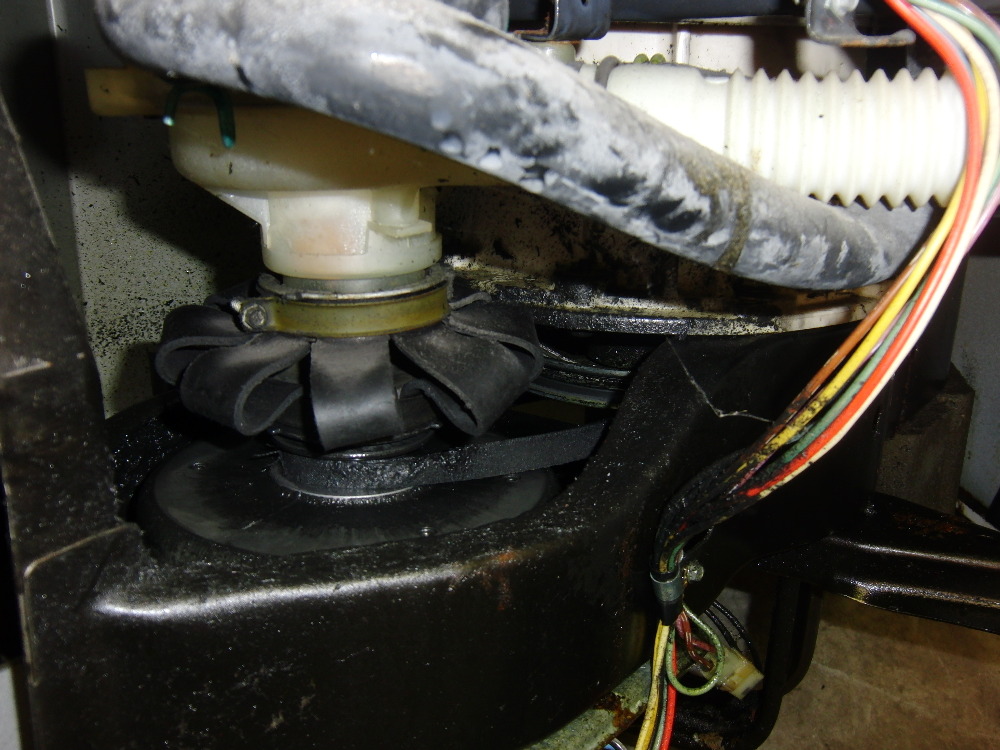

Some pictures I'm gonna try posting some pics of the grease. Don't know if it will be a good representation or not:

| ||

| Post# 631475 , Reply# 20 10/14/2012 at 08:18 (4,205 days old) by RWIndiana () | ||

|

So I guess I'd better be looking for a new tranny? Who knows how long this one will last. :( | ||

| Post# 631477 , Reply# 21 10/14/2012 at 08:23 (4,205 days old) by RWIndiana () | ||

|

Forgot to mention, you can also see the damage to the belt in these photos. | ||

| Post# 631515 , Reply# 23 10/14/2012 at 11:38 (4,205 days old) by rwindiana () | ||

|

Thanks for the info. Any ideas what I might be spending on a new transmission, or where I can get one (along with a belt)? | ||

Post# 631517 , Reply# 24 10/14/2012 at 11:48 (4,205 days old) by goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

| ||

| Post# 631521 , Reply# 25 10/14/2012 at 12:22 (4,205 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

I would try using some degreaser like simple green and get all of that built up gunk out of there to see what's really going on. This way you can see if there is any fresh evidence of oil being blown around. Maybe the grease was there from a prior breakdown and the person that fixed it didn't bother to clean it up?

| ||

| Post# 631522 , Reply# 26 10/14/2012 at 12:30 (4,205 days old) by redcarpetdrew (Fairfield, CA) | ||

It's also possible to replace the lower seal and change out the oil. If the trans is in otherwise good shape, I've done this. Pull the trans, flip it upside down (either hold it by securing the agitation shaft in a bench vise or use a jig made from a piece of plywood with a hole cut in it so that the trans case sits nice and pretty in it...), then access the lower cover. The shaft seals used to be pretty easy to find and put in.

Just an idea... RCD | ||

| Post# 631526 , Reply# 27 10/14/2012 at 12:58 (4,205 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

.GE doesn't make it easy to see, but the solenoid is behind the motor, pointing towards the center of the machine. Follow those 2 wires branching off of the maim motor wiring harness back to it. The noise I heard when mine was acting up was like someone rapping on an empty coffee can. Click, click, click.

| ||

| Post# 631539 , Reply# 28 10/14/2012 at 14:20 (4,205 days old) by arbilab (Ft Worth TX (Ridglea)) | ||

| ||

| Post# 631570 , Reply# 29 10/14/2012 at 17:11 (4,205 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

| ||

Post# 631576 , Reply# 30 10/14/2012 at 17:53 (4,205 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

2 speeds, 2 sets of windings

....would have been easier, but GE wanted to filter and pump well regardless of agitaton and spin speed, and they accomplished it with this contraption. Many other brands have anemic recirculation filtering at low speeds, and poor pumping ability, either slow pumpout or it won't lift the water very high for unique drainage applications. Only with the Filter-Flo can you get excellent filtering and high speed pumping even if your cycle is all delicate and gentle. It has its advantages.

| ||

Post# 631593 , Reply# 31 10/14/2012 at 19:03 (4,205 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

GE FF Washers With a 2 Speed Clutch Instead Of a 2 Speed Mot Mark is correct as to why GE had these stupid and troublesome 2,3,4 and variable speed clutches in their washers instead a multi-speed motor. The irony is that GE is one of the woulds biggest electric motor makers, and every other washer maker made great performing washers without these clutches. The higher speed of the motor really wasn't necessary for good washer performance, in fact Frigidaire 1-18 washers always started their spin cycle on the low speed of the motor, and even had a smaller drain hose and always worked fine [ they did this to reduce the amount of dirty water that can be thrown back over the wash tub and threw the clothing as the machine goes into the spin&drain cycle. which turns the clean clothing into a dirt and lint filter ].

As I have said before you can change the speed selector on a GE FF washer back and forth from Hi to low and low to Hi while the motor is running all you want without harm to the clutch and I invite any of you to come do this on any of my GE FF washers. | ||

| Post# 631601 , Reply# 32 10/14/2012 at 19:35 (4,204 days old) by arbilab (Ft Worth TX (Ridglea)) | ||

Thanks for your perspectives gentlemen. I have very little hands-on with GE. I replaced a pump coupler once in 1981.

I understand the desire to have the pump run at full speed, but it would have made more mechanical and economic sense to put the gearbox/clutch on the pump where the load is light than on the main drive. Or just let the pump choke some on high, there is little deficit to doing that. I have also owned 2-speed Maytags which don't seem to suffer overtly from running the pump at lower motor speed. | ||

| Post# 631726 , Reply# 33 10/15/2012 at 02:05 (4,204 days old) by redcarpetdrew (Fairfield, CA) | ||

It must just be me... | ||

Post# 631766 , Reply# 34 10/15/2012 at 06:52 (4,204 days old) by yogitunes  (New Jersey) (New Jersey) |

||

Been there.....Done that.........while at John's, I had the chance to play with his filterflo, at first was a little worried about shifting speeds while running.....but guess what?...you can!.....the speed won't change from fast to slow while running, but the switch can be flipped back and forth with NO issues.....actually the fingers that are held by the solenoid, retract while the machine is running at high speed.....so no damage could occur while running......

probably the most damage that may occur is when trying to shift speeds, the operator will shut the machine off, flip the switch, and turn back on, not allowing enough time for the clutch to slow down to a stop before restarting the machine..... | ||

| Post# 631807 , Reply# 36 10/15/2012 at 10:58 (4,204 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

I am going to go ahead and take the transmission apart and s | ||

| Post# 631892 , Reply# 38 10/15/2012 at 18:09 (4,204 days old) by rwindiana () | ||

|

The gears look alright to me. There were metal grounds down in the seal which I cleaned out, but nothing substantial. I think my original agitator problem was simply the oil covered belt slipping.

| ||

| Post# 631905 , Reply# 39 10/15/2012 at 18:43 (4,204 days old) by redcarpetdrew (Fairfield, CA) | ||

| ||

| Post# 631963 , Reply# 41 10/15/2012 at 22:35 (4,203 days old) by redcarpetdrew (Fairfield, CA) | ||

How about this? | ||

| Post# 631978 , Reply# 42 10/15/2012 at 23:47 (4,203 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

| ||

Post# 632061 , Reply# 44 10/16/2012 at 07:51 (4,203 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

GE Transmission on Ebay Is the last style that GE used, it will fit either the standard or extra large tub washers. It would fit in your washer but you would have to use a different agitator from one of these last GE washers.

If I were you I would consider getting either a factory rebuilt transmission or a good used one, a new one should be around $100, used 1/2 as much. If you want to fix yours I would flush out all the old oil and metal particles before refilling and replacing the bottom seal. GE transmissions were notorious for leaking oil either at the bottom seal or the top seal into the clothing load so the condition of the top seal should also be considered when refurbishing these transmissions, Good Luck John. | ||

Post# 632067 , Reply# 45 10/16/2012 at 08:04 (4,203 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

I've replaced the lower seal on my 1960 GE transmission, not a bad job at all. John is right though, replacing the entire transmission is so easy since they are still around.

I saw more than a few of these GE washers in scrap piles that had a plastic drop cloth (for painting) fashioned into a diaper under the machine to catch the oil, I can't imagine the mess they left in owner's homes. Yours could have been much worse! | ||

| Post# 632069 , Reply# 47 10/16/2012 at 08:11 (4,203 days old) by rwindiana () | ||

|

gansky, I assume that fixed the problem? How long did it last? Judging by the mess that was inside mine, I can imagine the original owner had a mess as well! | ||

Post# 632071 , Reply# 48 10/16/2012 at 08:25 (4,203 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

I did that on my '60 about five or six years ago and it's still holding fine. That was on a metal case tranny, haven't done it on the plastic case.

This was a machine I rebuilt, large capacity a year or so ago. The outer tub was in pretty rough shape and required a lot of patching of rust holes and beginning rust spots. It was pretty far gone all in all and only lasted about a year before developing more leaks. It would be wise to check that outer tub in your machine while you have the machine apart, just to be sure all this mechanical work doesn't get doused with a frustrating water leak. An ounce of prevention...

| ||

| Post# 632284 , Reply# 50 10/17/2012 at 08:11 (4,202 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

| ||

| Post# 632336 , Reply# 51 10/17/2012 at 12:04 (4,202 days old) by RWIndiana () | ||

|

Did you paint it? Do you know what metal the outer tub is? I'm thinking of a primer/metal conditioner before I paint a sealer on. | ||

| Post# 632351 , Reply# 53 10/17/2012 at 14:03 (4,202 days old) by kenmoreguy89 (Valenza Piemonte, Italy- Soon to be US immigrant.) | ||

That pics is like was my Ge after it's oil leak! your one got a massive oil leak ! This is a link I always post when someone talks about transmission or seals replacing, that is very simple and helped me alot while I had to change my lower oil seal, as said I learned GE FF sooner or later tends to leak oil when seals get worn, it does not necessarily means that your tranny is getting trash unless it is the tub seal (not the boot) that went, that would let water getting in the transmission and ruin it... Replacing a transmission on a filter is harder to expalin rather than do it actually but I know it sounds so at start, what you might meet during replacing would be stuck basket bolts from lime etc... as happened to me, it kept 3 days of continuos torching and pounding and a good amount of Wd 40 and Pb Blaster....but I managed, harder part will also be finding a good GE tranny and figure out the exact one you'll need for your model including spline for actiavtor spiral agitator and size, I found some on ebay time ago but they all were not for my model (it was when I thought I had to replace it, I didn't have need luckily)...... A kind member now became a very good friend, Eddy, helped me alot and also sent me the spare seal I needed, I will never stop thanking him!

To note that if your washer will work with a new belt and you'll discover your tranny it is still good, you might also replace the seal from the bottom it will be more easy on a side but harder from another as it is very close in there, all you need is to remove pulley unscrewing the bolt, tear out oil seal and replenish with oil enough thick with a syringue or by pouring it very slowly, dont remeber the right thicness needed but I fill rescue the info if you need it, I anyway suggest you to follow the way in the link so you will see how many oil it lost and it's left (it must not be completely full, little more than half gearbox), If you decide to do that from bottom be sure you'll have your machine on it's side with the bottow facing a little upwards Good luck! CLICK HERE TO GO TO kenmoreguy89's LINK This post was last edited 10/17/2012 at 16:19 | ||

| Post# 632362 , Reply# 54 10/17/2012 at 16:02 (4,202 days old) by kenmoreguy89 (Valenza Piemonte, Italy- Soon to be US immigrant.) | ||

You already removed it and I didn't notice before??? I a LOL Anyway changing an oil seal is not difficult! This is the part you need! CLICK HERE TO GO TO kenmoreguy89's LINK on eBay | ||

| Post# 633046 , Reply# 56 10/20/2012 at 14:22 (4,199 days old) by redcarpetdrew (Fairfield, CA) | ||

Yay for fixing it yourself!

Congrats! Now we need pics (and video, if possible) of your handy work. The trans lower seal really wasn't that bad after all, was it? Not sure about the slight imbalance. Did you check the snubber pads where the suspension comes in contact with the washer frame to make sure they were not contaminated with oil?

RCD | ||

| Post# 633059 , Reply# 57 10/20/2012 at 15:01 (4,199 days old) by tecnopolis (Ocala/Dunnellon, Florida 34481) | ||

| ||

Post# 633079 , Reply# 58 10/20/2012 at 16:07 (4,199 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Unbalanced Spinning With No Load There is no easy fix for this on a GE FF washer, but you may find it spins well with a load. On WP built DD washers with the water filled balance ring the machine usually will vibrate with nothing in the tub but is actually smother with a load. In any case it is really not important if the washer is smooth without a load. | ||

Post# 635152 , Reply# 59 10/29/2012 at 17:52 (4,190 days old) by goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

Matching dryer in Indy | ||

Comes to the Rescue!

Comes to the Rescue!