|

Thread Number: 47366

Lady Kenmore Transmission Help |

[Down to Last] |

| Post# 687871 7/7/2013 at 21:02 (3,944 days old) by lebron (Minnesota) | ||

So my '71 Lady Kenmore needed a new transmission and our webmaster Robert was kind enough to provide me one. I was able to remove the old transmission without too much trouble. They had different drive pulleys so I swapped them. I also transferred the control magnet from the old transmission to the new one. (These could be potential clues to the problem). Unfortunately after I installed the new transmission I ran into a rather large Snafu. The entire transmission is locked up. The washer will not spin, agitate or drain. I can turn the drive pulley slowly in one direction but nothing in the other direction. I have poked a run for awhile hoping to see something glaringly wrong but I have found nothing. I have no experience working with WPs so I have no idea where to go from here. Calling all Kenmore experts to help me out.

| ||

|

| Post# 687888 , Reply# 1 7/7/2013 at 23:36 (3,944 days old) by lebron (Minnesota) | ||

All right so I found this post in the archives (link below) and in it Gordon had some advice. He said that the spin tub bearings can become misaligned and cause pinching (in my case the pinching was severe). To alleviate this problem he instructed to remove the transmission braces and loosen the transmission bolts about 6 mm then shake the transmission so that it settles and doesn't pinch. I did all this and the machine spun. Thinking I had solved the problem I put the machine back on its side and tightened the transmission back up but it still didn't spin. So I loosened the transmission and shook it again. This time I left it upright and tightened each bolt slightly at a time until it was tight. Still didn't spin. Then I decided to get really serious. I loosened every bolt until the machine was spinning. I then did just one single revolution of each bolt, shook the machine, and checked for spin. I thought that maybe this would be enough to keep it spinning but it doesn't take very long until the spin binds up, and the bolts still have a substantial way to go till they are completely tight. Could this possibly have something to do with the brake? Again I am not good with WPs but the part of the transmission that a spring which connects to the brake deal looks a little different. I don't know if that is what is binding. Also when I removed the transmission I found a small spring that I did not know where it came from. I put it on the metal rod connecting to the brake deal on the side opposite the long connecting spring. Maybe that is in the wrong place and causing it.

CLICK HERE TO GO TO lebron's LINK | ||

| Post# 687898 , Reply# 2 7/8/2013 at 00:41 (3,944 days old) by lebron (Minnesota) | ||

Further investigation reveals that the original 71 transmission had a black plastic thick bushing around the agitator shaft while the replacement transmission has a silver metal thin bushing around the agitator shaft. Attempts to place the black bushing on the replacement transmission did not work. I was not able to get the transmission back into the machine. I think the problem has something to do with this

| ||

Post# 687917 , Reply# 3 7/8/2013 at 07:16 (3,943 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

BD KM Help The black plastic thing you are referring to is the T bearing, it supports the entire basket and wash basket itself, and the machine will not spin with the wrong combination of parts. WP used several different styles of TBs over the years and it sounds like you are using a earlier style steel TB support with the newer 1970s style TB that did not use a steel support collar. Instead the original one on your 71 LKM was supported by a tiny steel clips that were clipped around the agitator shaft. You either need to use the original bronze TB that sat on the steel collar or remove the collar and use a new later style white plastic TB that uses a little steel support ball bearing that fits into the hole in the agitator shaft where the set screw from the steel color is currently. The little clips that were on your LKM original are almost impossible to remove and reinstall correctly.

Hope this helps, you can always message me or better just message me your ph# and best time to call, John. | ||

Post# 687945 , Reply# 4 7/8/2013 at 11:31 (3,943 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Jed -

I saw your first post last night and thought "wow, a nearly locked up gearcase - that's not something I've come across before." I've seen some with resistance in them, but it was due to water having fouled the gearcase oil. I didn't get a chance to reply, but that's probably good now that you've moved on to a T-bearing problem. This is the second time in a week or so that T-bearing issues have caused someone in club spin issues (the other I learned about by e-mail). T-bearings can be troublesome, especially when you don't know that much about them. The original bronze ones that John mentioned I've had the least amount of trouble with, but also the least experience since they are in the oldest machines. The black plastic ones weren't around all that long I don't think (5 or 6 years maybe??), as the cream/white colored ones replaced them and stayed. The cream color parts can be a royal pain, as that ball bearing that John also mentioned has a great knack of falling out, and when it does, there is nothing to support the t-bearing and it falls to the cover of the gearcase and interferes with spin. A servicer is lucky if the T-bearing ball falls out and hits the cabinet, then you know something has happened. Most often though, it falls out but gets stuck in the crevice next to the yoke support and you have to get it out with needlenose pliers. These are the easiest to deal with other than the ball falling out though. The best thing to do is put a small dab of grease in the hole where the ball goes, so that it holds the ball in, it won't fall out when you're reinstalling the gearcase that way. As to the advise I gave in the thread you linked, I learned that "trick" of sorts when working on a very fickle 1967 Kenmore 70. It was only the third or fourth washer I'd ever worked on, and definitely the oldest at the time. It had the bronze T-bearing in fact. The machine had very tight, low-wear bearings, but it needed a belt. I had a MAJOR problem with that machine in getting it to spin properly after the belt install. It would nearly stall the belt during acceleration. Various degrees of bind in installing the gearcase would affect the degree to which the belt would stall, but I never could get it to spin properly --- not until I replaced the bearings. Looking back now, that was all great practice but I think the bearings were simply dry. The turbine oil in these bearings over time leaks down past the oil seals. It gets absorbed by the basket drive brake pad, and/or simply flung out by the drive pulley. Once the bearings are dry, it is harder to get a tight fitting spin tube to install flawlessly, which in turn can do what my machine did. So, when you make it past the T-bearing issue, my advice is to make sure that the bearings are very well lubricated, and lube the spin tube itself very well too before re-inserting it into the centerpost. That will slow wear on the bearings, and it will give the machine a better chance for proper acceleration. Oiling these bearings is a major part of work that should be done on an older belt-drive if it is going to remain in service, so the loss of your old gearcase may have done you a favor in some ways long-term. One other tid-bit of advice --- try not to over-lubricate the surface of the T-bearing where it inserts into the spin tube. Doing so will interfere with agitator rotation during spin. Gordon | ||

| Post# 687968 , Reply# 5 7/8/2013 at 13:31 (3,943 days old) by lebron (Minnesota) | ||

Thank you for your responses guys. Unfortunately I am still stuck but I am going to continue to work on it until I get it fixed. The combination of steel collar and bronze t bearing still produces no spin. I am not sure even if this is the correct combination of parts. I may purchase the part in the link and try that. CLICK HERE TO GO TO lebron's LINK | ||

| Post# 687988 , Reply# 6 7/8/2013 at 14:49 (3,943 days old) by lebron (Minnesota) | ||

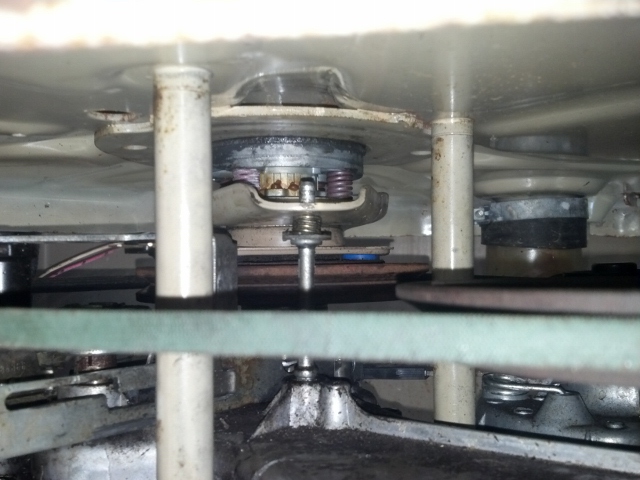

Here's what I'm dealing with | ||

| Post# 687990 , Reply# 7 7/8/2013 at 14:51 (3,943 days old) by lebron (Minnesota) | ||

| ||

Post# 688001 , Reply# 8 7/8/2013 at 15:19 (3,943 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Jed -

A couple things: Your link is indeed the newest T-bearing design, and it should work using the older gearcase. I think WP managed to use the same hole for the new-style retainer ball that originally was used for the set screw from the metal T-bearing assembly. My experience has been that these newest T-bearings are rather forgiving once they are installed and seated correctly. When e-mailing with the other member last week, I remembered what I called a lot of "sweat equity" aka trial and learning by error, when I was doing this originally. Belt-drives are really cool in some ways as many new parts were engineered for current production, they were made so they can often be used to update older machines as well. We don't have the benefit of the in-field or factory training to know how to fit these parts though, thus we wind up doing a lot of assembly and dis-assembly. Second thing --- a note of concern. Your replacement gearcase is surely a pre-1971 transmission if it had the bronze T. These machines were made with the original brake design. When UL Labs required the fast-brake in 1971, some very significant changes were made to the basket drive to accomodate the new seven second brake time limit. First, the drive pulley itself was changed, the brake springs were greatly strengthened, and the spin cam bar was re-specified to be made out of hardened metal as the new basket drive can deform the old cam bar due to the brake spring pressures. For many years, replacement basket drives that might be useful on older machines came with a new cam bar for this very reason because the new drives were made to post 1971 standards, even for older models. You may want to look at the set-up you're trying to use to make sure the cam bar can move under the pressure of your '71's brake system, that the support post roller is not frozen and that the support itself rides up and down in the channel provided for it. All those moving parts should be well lubricated with a light grease (I use white lithium). If not, the machine won't disengage the brakes, so to speak. If the cam bar is original to a pre-1971 machine and it isn't already deformed, using it will eventually damage it in this application, though I don't know how long that will take. Of of curiosity, can you get us a picture of the install as you currently have it? I'd like to see both sides of the yoke plate in reference to the sliding support shaft on the left and the fixed one on the right mounted atop the gearcase. If these aren't installed correctly, you could have improper spin that way as well. Gordon | ||

Post# 688003 , Reply# 9 7/8/2013 at 15:32 (3,943 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Jed -

Great pictures --- you posted them while I was composing. Questions: 1) Are you attaching the cotter pin on the gearcase support that mounted on the cover? It goes atop the little spring. Are you also installing the much larger spring on the other side, attached to the yoke support and the corner of the gearcase? 2) Have you placed a couple of flat washers atop the replacement yoke support (they will wind up under the drive yoke) on the replacement gearcase? These are usually quite necessary for proper spin, and take the place of the adjustment nut on the original trans. If I were you, I'd take the spin cam bar and yoke support off the original gearcase, clean them, lube the crap out of them at every point where they contact other parts, and put them on the new/old transmission, see if that makes any difference. Incidentally, are you doing all this will the pump and manifold trap coming in an out of the machine? That is not necessary if so. Gordon | ||

Post# 688008 , Reply# 10 7/8/2013 at 15:42 (3,943 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Jed -

Sorry to keep responding, but I just remembered something else I wanted to share. My rebuilding hobby was spurred by buying a 1980 Kenmore used from a rebuilder for my sister in fall 1989. That machine went into my storage trailer in 2000 after 11 years additional service. It sat in that trailer (just a retired trucking trailer) for 8 years until I brought it home to put it back into service. It went into the trailer working fine. It did not spin at all when I brought it home in 2008. I found out that the cam bar and yoke support assembly were absolutely frozen, and not moving at all. I'd hear the click of the control magnet, but absolutely no spin or even an attempt at it. It turned out that the rebuild shop had used some heavy grease, which turned into a hardened sticky smear while sitting in that truck for 8 hot summers. I had to clean and almost polish everything for the parts to move freely again. If everything else is assembled properly, check that the spin cam bar moves when spin is engaged and that the yoke support can go up and down. Out of curiosity, what is wrong with the original gearcase? Gordon | ||

| Post# 688017 , Reply# 11 7/8/2013 at 16:01 (3,943 days old) by lebron (Minnesota) | ||

Here is how I have the transmission in the machine currently. I am not sure if the springs are in the correct position (the long one I know is but I don't know about the other one). I assume that the spin cam bar is functioning properly because the machine spins fine when the transmission is lose? I don't have any washers on the yoke supports. Are these original parts? If not I have some washers that I can use.

Gordon and John, thank you so much for your help. The knowledge you have of these machines is incredible and I won't be able to fix this without you. However the amount of information I am trying to process is very high so please just bear with me. Thank you.

| ||

| Post# 688018 , Reply# 12 7/8/2013 at 16:03 (3,943 days old) by lebron (Minnesota) | ||

| ||

| Post# 688019 , Reply# 13 7/8/2013 at 16:06 (3,943 days old) by lebron (Minnesota) | ||

| ||

| Post# 688020 , Reply# 14 7/8/2013 at 16:07 (3,943 days old) by lebron (Minnesota) | ||

| ||

| Post# 688022 , Reply# 15 7/8/2013 at 16:07 (3,943 days old) by lebron (Minnesota) | ||

| ||

| Post# 688023 , Reply# 16 7/8/2013 at 16:10 (3,943 days old) by lebron (Minnesota) | ||

| ||

Post# 688037 , Reply# 17 7/8/2013 at 16:34 (3,943 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Yep - you can't go wrong swapping the cam bar. Its easy, and you'll know everything is moveable and properly lubricated when you do that.

I do see one issue in the pictures...the spring on the right/front side of the yoke is on the wrong side. The yoke should sit flat on the support collar with nothing in between. The spring goes on the top side of the yoke, and the little cotter pin holds the spring down and fits into that impression on the top of the post. They are a bit tricky to install if doing it while in the machine unless you hit it just right. This may well be most of your explanation for the non-spin. When the drive yoke is not secured, there isn't enough pressure when the parts move and the clutch pads contact the drive surface to hold it all together and cause the pads to grip and start moving the basket. Do you still have the cotter pin? I've had them go flying, usually never to be found again when trying to compress that spring. Gordon P.S. - sorry for the information overload before! | ||

| Post# 688043 , Reply# 18 7/8/2013 at 16:55 (3,943 days old) by lebron (Minnesota) | ||

| ||

| Post# 688044 , Reply# 19 7/8/2013 at 16:59 (3,943 days old) by lebron (Minnesota) | ||

| ||

Post# 688053 , Reply# 20 7/8/2013 at 17:31 (3,943 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Yes indeed, that is it!!!

You may have to loosen the gearcase quite a few turns on the bolts, but bring it down enough that you can lift up on the yoke, get the spring out of there, put the yoke back, and put the spring on top. My trick to getting the cotter pin in: Put the tip of the pin securely in a pair of needlenose pliers. Use your left hand fingers or a long flat bladed screw driver to hold the spring, and compress it a bit if you can. With the cotter pin still in the pliers, push until it snaps into the groove. Make sure it doesn't get threaded into the spring itself, it needs to be on top of the spring. I find this easiest to do with the gearcase and basket drive out of the machine. If you can't or don't want to do that, it is doable just awkward while the drive is still installed. Good luck!! G | ||

| Post# 688059 , Reply# 21 7/8/2013 at 18:03 (3,943 days old) by lebron (Minnesota) | ||

Here is how I have the machine now. I couldn't get the cotter pin on with the drive in the machine so I had to take it out and I was successful. Unfortunately the spin still binds to a stop when the bolts are tightened albeit a little less so. How does the brake look now? Would adjusting this nut help anything?

| ||

| Post# 688060 , Reply# 22 7/8/2013 at 18:04 (3,943 days old) by lebron (Minnesota) | ||

| ||

Post# 688067 , Reply# 23 7/8/2013 at 19:01 (3,943 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Jed -

The cotter pin installation looks good from what I can see. You're missing the big spring on the other side now. It goes in the hole on the yoke, and the hole immediately under the cam bar. You'll need a pair of pliers for that too. I wouldn't adjust the nut if you can avoid it unless it got moved during the work. If you're using the same cam bar, same support shaft, same basket drive, the position of that nut should be left where it was I think. Are the bearings well oiled? I know the spring will have a lot to do with proper spin, but I can't say for sure its causing all the remaining issue or not --- I don't know if I ever tried a machine without one. | ||

| Post# 688088 , Reply# 24 7/8/2013 at 20:03 (3,943 days old) by lebron (Minnesota) | ||

All right well I got that spring back on and even with both springs installed correctly the machine still won't spin. I've pretty much exhausted all my ideas and since I've never worked on a bd KM I don't know where to go from here.

Mb order that new white T bearing? Right now I have been trying with the metal collar and bronze t bearing. | ||

Post# 688090 , Reply# 25 7/8/2013 at 20:20 (3,943 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Jed -

Here is what I would do if this were my problem: 1) Remove the basket and drive block if they're attached. 2) Remove the belt from the pulleys 3) Lower the gearcase and make sure that both bearings are liberally seeped in turbine oil. Skip this if you know there is enough oil in there. 4) With the transmission down about 1/2 inch from tight, set the machine upright and follow my suggestion in the link you found last night. 5) Raise the gearcase and re-tighten the bolts in a pattern like you'd tighten the bolts on a tire (the tire bolt tightening pattern is meant to avoid the same binding that you may be experiencing here). 6) Put it back together and make sure the belt is TIGHT. This belt needs to be quite a bit tighter than the big belt that most BDs use. Without seeing the machine in person, I suspect you have the spin tube in a bind. An idea - move the machine from neutral to the spin position by holding up the spin plunger and rotating the drive pulley. Make sure the cam bar moves all the way in both directions and that the yoke support is moving with it. | ||

| Post# 688093 , Reply# 26 7/8/2013 at 20:26 (3,943 days old) by lebron (Minnesota) | ||

| ||

Post# 688096 , Reply# 27 7/8/2013 at 20:37 (3,943 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Jed -

The bearings are at the top and lower end of the centerpost. The lower one is just a few inches up from where you insert the spintube / transmission. The top bearing is just below the top rim of the centerpost. You can feel them with your fingers - they're just solid sleeve bearings. They're going to be black and goopey most likely when you check them. I would wipe them down, and put the turbine oil ABOVE each bearing so that when the machine is upright, the oil coats the spin tube and seeps into the space between the bearing and the spin tube. Good luck tomorrow. Maybe John has some other suggestions? By the way - take a picture for me of the basket drive spin tube when you can. I want to see if it is corroded at all. Gordon | ||

| Post# 688101 , Reply# 28 7/8/2013 at 21:05 (3,943 days old) by lebron (Minnesota) | ||

| ||

| Post# 688102 , Reply# 29 7/8/2013 at 21:05 (3,943 days old) by lebron (Minnesota) | ||

| ||

| Post# 688103 , Reply# 30 7/8/2013 at 21:06 (3,943 days old) by lebron (Minnesota) | ||

| ||

| Post# 688104 , Reply# 31 7/8/2013 at 21:07 (3,943 days old) by lebron (Minnesota) | ||

| ||

| Post# 688106 , Reply# 32 7/8/2013 at 21:08 (3,943 days old) by lebron (Minnesota) | ||

| ||

| Post# 688107 , Reply# 33 7/8/2013 at 21:09 (3,943 days old) by lebron (Minnesota) | ||

| ||

| Post# 688181 , Reply# 35 7/9/2013 at 09:03 (3,942 days old) by lebron (Minnesota) | ||

Hi alan thank you for your response. Im not sure about it not agitating. I filled it once with water and it wouldnt with the transmission comepletely tight. I assume it would work when it was lose but maybe that is a poor assumption. Interesting comment concerning the t bearing. Right now i am using the steel collar and bronze t that came with this transmission. Maybe i should order the new white one? Finally which bolt are you referring to that is missing the spacer? The large bolt that has the clutch adjustment nut? What can i use as a spacer? Where does the spacer belong?

| ||

Post# 688192 , Reply# 36 7/9/2013 at 11:03 (3,942 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Good morning Jed --- what's left of it...

I looked at your pictures, I don't see anything glaring at me in regard to the install of the basket drive on the gearcase, and I looked at the centerpost inside pics too. It looks like you may have some rust developing inside the centerpost, but some of the grease WP used was reddish orange, so that stuff immediately above be bearing may be grease, I can't say for sure. You may be wise to replace the centerpost seal at the very top, that is a large part of what allows water into the centerpost, that and the spin tube seal. Your spin tube is not damaged or corroded, which is great. Clean it well and re-lube it, it looks VERY dry, as do the bearings. Drop about a teaspoon of turbine oil above each bearing, and put more on the bearing surfaces and liberally all over the spin tube (once you clean it). Oil the bearings with the machine on its side and don't upright it until the spin tube is in or the oil will run out. In pic number 31, that circular spot is the braking surface for the brake pad to rub against. The brake pad is on the top of the basket drive. Clean both well and you'll have a more effective brake. Don't be surprised if when you finally have the machine running properly, that you hear a bit of grit during the braking process. This happens sometimes after "major surgery". Little grains of dirt leftover from all the work amplify themselves seemingly 1000 times when they're in between the brake components, and you hear it all over the machine. They work themselves out eventually. The reason the machine spins with the gearcase loose is because the basket drive parts are tightly gripping each other until the final few turns of the trans bolts. These last few turns do the same thing as pushing in a car clutch pedal. This last distance is what brings the clutch pads off the pulley surface. It will also engage the brake. Al brings up an interesting point --- the spacer should have fallen out as soon as you removed the lowest of the three gearcase bolts. It often makes a racket on the cabinet when that bolt comes out. Out of curiosity, how many unused parts do you have left? If you haven't been using the spacer on the short leg of the three gearcase mounting rods, chances are very good that you'll have the gearcase in a major bind. The short one of the three is the one facing the front of the cabinet. Put the spacer in the gap between the transmission and the mounting stud, and thread the bolt though the gearcase hole and the spacer. It should properly tighten together. Let us know what's next Jed! Gordon | ||

| Post# 688202 , Reply# 37 7/9/2013 at 11:49 (3,942 days old) by lebron (Minnesota) | ||

| ||

Post# 688261 , Reply# 38 7/9/2013 at 15:53 (3,942 days old) by bigalsf  (Salt Lake City) (Salt Lake City) |

||

|

Bob Dylan! That's a good reason to put off the project. Great musician! Enjoy the concert! :) | ||

Post# 688750 , Reply# 39 7/11/2013 at 13:50 (3,940 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

| ||

| Post# 688770 , Reply# 40 7/11/2013 at 15:45 (3,940 days old) by lebron (Minnesota) | ||

| ||

Post# 689577 , Reply# 42 7/15/2013 at 16:45 (3,936 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

Mark -

I haven't heard from Jed in the last couple days, but we took the discussion off-line as you can see above. Turns out the culprit was the T-bearing retaining collar, which was stuck on the agitator shaft about 5 milimeters above its normal position (even without the set screw), thus the whole drive was being forced to sit too high by the same distance. We discussed cleaning and lubing the spin tube, bearings, etc. I don't know what the final result is or was. Gordon | ||

| Post# 689668 , Reply# 43 7/15/2013 at 20:48 (3,936 days old) by lebron (Minnesota) | ||

| ||

| Post# 689904 , Reply# 44 7/16/2013 at 19:05 (3,935 days old) by bendixmark (Winchester Mass) | ||

|

collar stuck Heat it with a torch. | ||

Comes to the Rescue!

Comes to the Rescue!