|

Thread Number: 47440

Australian Market Hoover 455 Washer & 155 Dryer |

[Down to Last] |

|

| Post# 688978 , Reply# 1 7/12/2013 at 16:32 (3,939 days old) by crouzet951 () | ||

|

The 'chrome' plating on the bezel never lasts.

| ||

| Post# 688979 , Reply# 2 7/12/2013 at 16:33 (3,939 days old) by crouzet951 () | ||

|

Open wide! The machine originally came with a grey door seal.

| ||

| Post# 688984 , Reply# 5 7/12/2013 at 16:55 (3,939 days old) by crouzet951 () | ||

|

The detergent dispenser and water valves.

| ||

| Post# 688985 , Reply# 6 7/12/2013 at 16:58 (3,939 days old) by crouzet951 () | ||

|

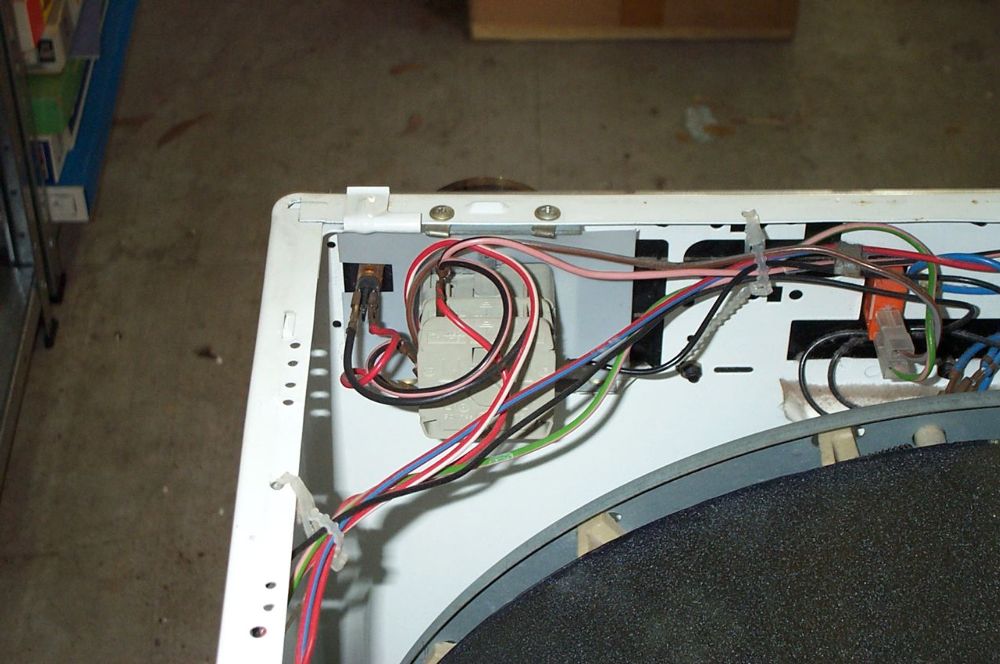

Water level pressure switch, relay, and timer.

| ||

| Post# 688988 , Reply# 7 7/12/2013 at 17:21 (3,939 days old) by ronhic (Canberra, Australia) | ||

| ||

| Post# 688991 , Reply# 9 7/12/2013 at 17:27 (3,939 days old) by crouzet951 () | ||

|

Thanks ronhic. I've realised just how much knowledge there is here after reading threads for the last few days. The many UK machines are fascinating. | ||

| Post# 688992 , Reply# 10 7/12/2013 at 17:29 (3,939 days old) by crouzet951 () | ||

|

The dual water level pressure switch.

| ||

Post# 688995 , Reply# 12 7/12/2013 at 17:43 (3,939 days old) by mayfan69  (Brisbane Queensland Australia) (Brisbane Queensland Australia) |

||

Hi John | ||

| Post# 688996 , Reply# 13 7/12/2013 at 17:46 (3,939 days old) by crouzet951 () | ||

|

The motor, pump, and module - the latter being Mullard of course. The fish-oil paint is sure ugly, but it's stopped any rust in the metal joints and spot welds.

| ||

| Post# 688999 , Reply# 14 7/12/2013 at 17:51 (3,939 days old) by crouzet951 () | ||

|

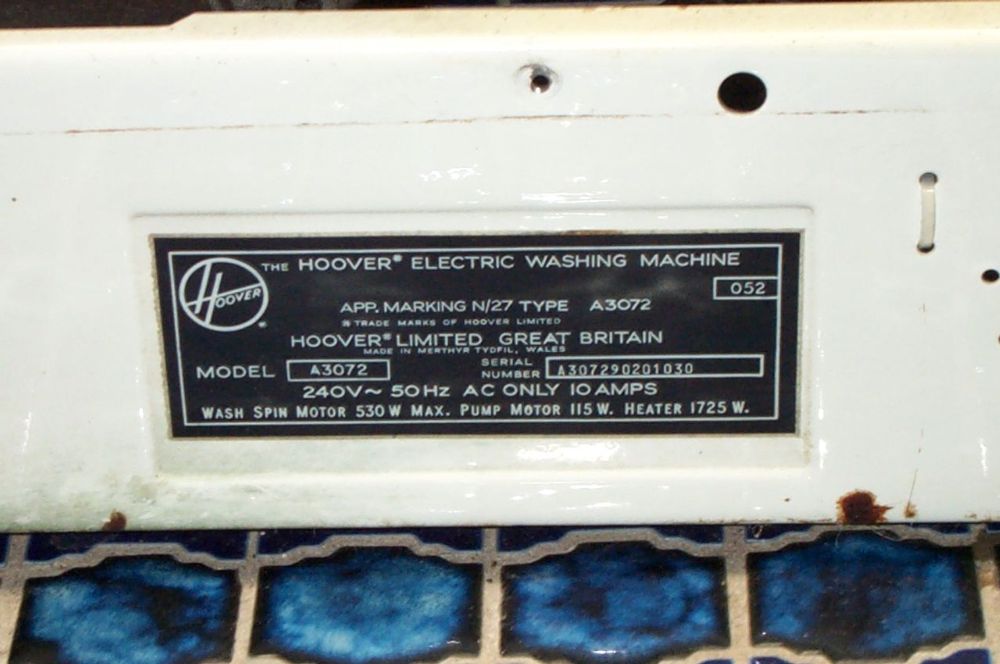

Model A3072 manufactured February 1979. Presumably the 052 in the top right corner is Hoover's internal code for Australia, as it's the same on my dryer. All the British market machines seem to have 001, which is logical, being the home market.

| ||

| Post# 689002 , Reply# 16 7/12/2013 at 18:00 (3,939 days old) by crouzet951 () | ||

|

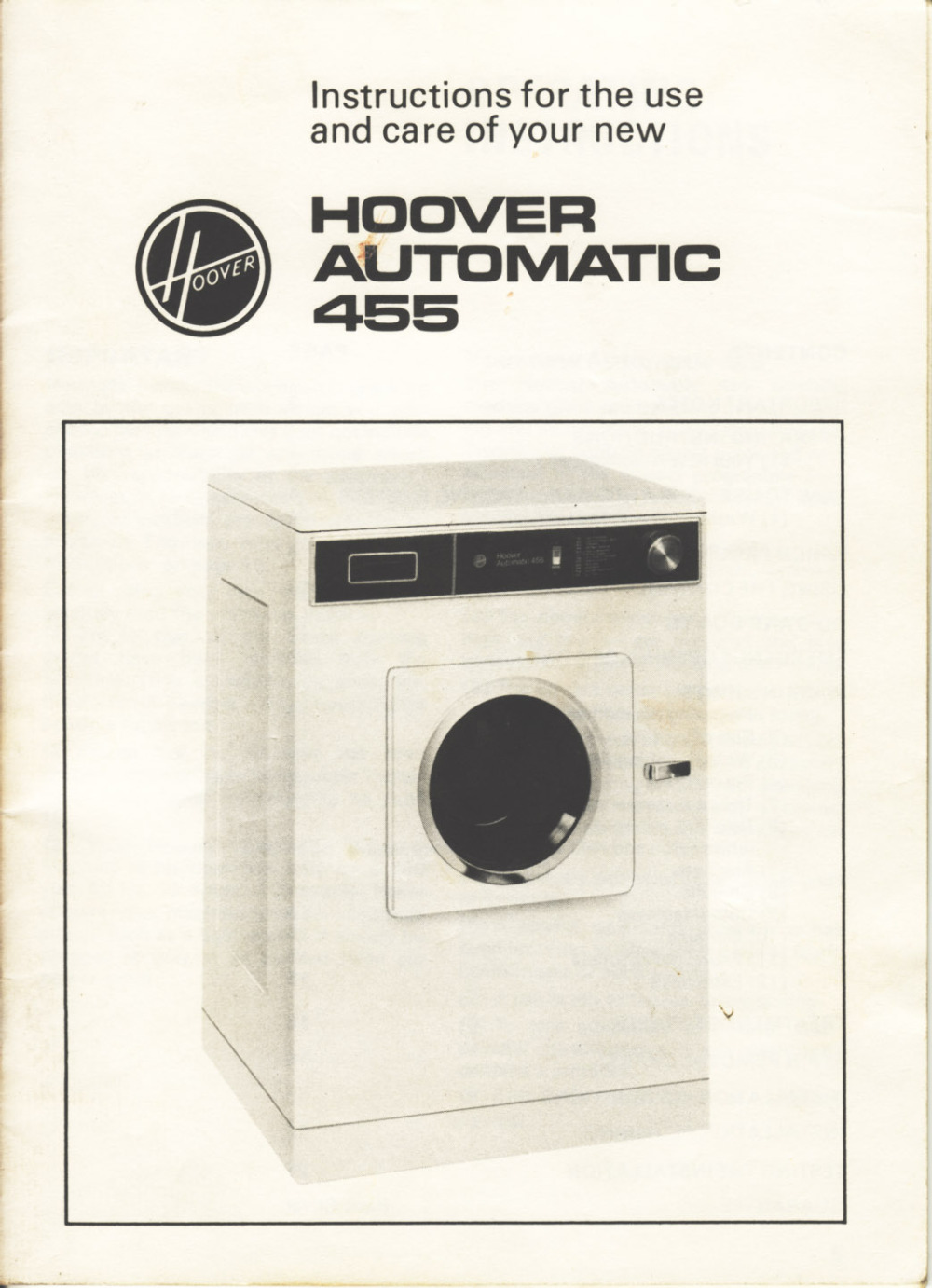

The owner handbook.

| ||

| Post# 689003 , Reply# 17 7/12/2013 at 18:02 (3,939 days old) by crouzet951 () | ||

|

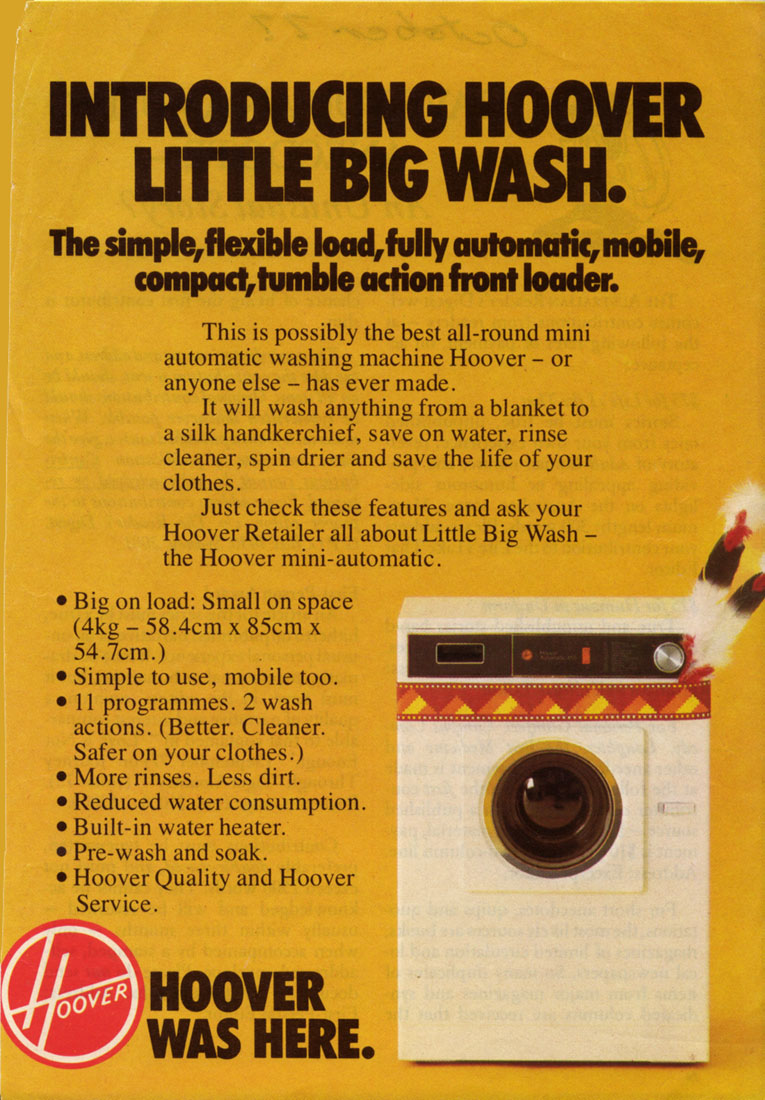

An ad from the local Readers Digest dated October 1977.

| ||

| Post# 689004 , Reply# 18 7/12/2013 at 18:04 (3,939 days old) by crouzet951 () | ||

|

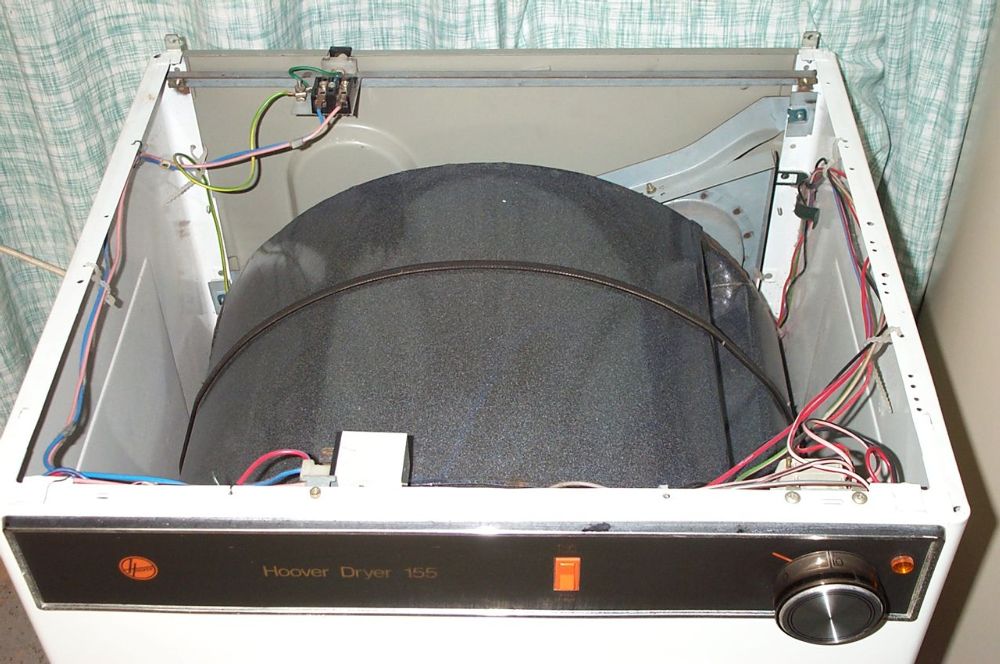

The Hoover 155 dryer. The condition throughout is quite astonishing.

| ||

| Post# 689005 , Reply# 19 7/12/2013 at 18:06 (3,939 days old) by crouzet951 () | ||

|

As mentioned previously, the timer knob is similar to the Electra D6E06 dryer.

| ||

| Post# 689006 , Reply# 20 7/12/2013 at 18:09 (3,939 days old) by crouzet951 () | ||

|

Not even deluxe! See how they treat us from the antipodes. :-)

| ||

| Post# 689007 , Reply# 21 7/12/2013 at 18:11 (3,939 days old) by crouzet951 () | ||

|

Open wide! The vitreous enamel on the drum is unmarked.

| ||

| Post# 689008 , Reply# 22 7/12/2013 at 18:12 (3,939 days old) by crouzet951 () | ||

|

It could get nasty if ignored. Sorry about the blurry image.

| ||

| Post# 689010 , Reply# 23 7/12/2013 at 18:16 (3,939 days old) by crouzet951 () | ||

|

Lid off. The condition throughout is remarkable. I also modified this machine like the 455 - a neon when running, and a relay to take the electrical load of the elements, instead of the timer.

| ||

| Post# 689011 , Reply# 24 7/12/2013 at 18:21 (3,939 days old) by crouzet951 () | ||

|

The clockwork timer was replaced by a Diehl electric timer. Hoover sold conversion kits at the time. I didn't quite trust the clockwork timer. The cabinet, same as the 455, appears to have cutouts for late Keymatics, among others.

| ||

Post# 689127 , Reply# 31 7/13/2013 at 06:45 (3,939 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Aus Washers

Welcome John, looking forward to hearing more about your Hoover and washer experiences, lovely looking machines, the 455 series are like hybrids of our matchbox machines and as you say the programmers are like our "Electra by Hoover" series...just editing a video of Mathews 3243 keymatic as we speak...

CLICK HERE TO GO TO chestermikeuk's LINK | ||

| Post# 689250 , Reply# 34 7/14/2013 at 04:01 (3,938 days old) by matchboxpaul (U.K) | ||

|

A3E02...

| ||

| Post# 689258 , Reply# 36 7/14/2013 at 05:00 (3,938 days old) by crouzet951 () | ||

|

It's a little difficult to see in the images, but it's only the chrome plating beside the switch openings that is recessed, not the lip. I also have a new bezel for the 155 (at the bottom), but unfortunately no adhesive insert. Cheers John

| ||

| Post# 689313 , Reply# 37 7/14/2013 at 11:25 (3,938 days old) by SeamusUK (Dover Kent UK) | ||

Dates........

Hey Guys

It strikes me as odd on 2 counts.... firstly the fact the 455 and 155 were both Merthyr built- surely it would have made more sense for Meadowbank to have been kitted out to make them!. Secondly the fact they date from Feb 79 and Dec 78 a while after Home market machines had moved on...... Seamus | ||

| Post# 689350 , Reply# 38 7/14/2013 at 16:24 (3,937 days old) by ronhic (Canberra, Australia) | ||

Seamus

Meadowbank did eventually kit out to make them from either the 460/5 or the 470/5, but what you need to remember is that our market in general is about 35% the size of the UK market AND, at that point in time, front load machines only took about 5-10% of it.

It wasn't until around 1994-5 that front load sales started to increase and then around 2005-6 many councils introduced rebates for people who bought water efficient appliances, which had a flow on effect for front load sales. There was an 9% increase in front load usage nationally (13-22%) from 2003 to 2008, with South Australia and the Australian Capital Territory then at 28%%....I'd suggest that this could be as high as 50% today. | ||

| Post# 689417 , Reply# 40 7/14/2013 at 19:50 (3,937 days old) by optima (Cumbria England) | ||

Hoover 455 | ||

| Post# 689494 , Reply# 42 7/15/2013 at 07:21 (3,937 days old) by twinniefan (Sydney Australia) | ||

Don't forget twin tubs

Hi guys,

John your picture of the little big wash advertisement bought back memories from my childhood, indeed my mother almost purchased a 455 but decided to go with a Westinghouse top loader instead because of larger size capacity etc. Optima, I guess we collectively decided to follow America and go with large top loaders, however do not forget that twin tubs had a fair chunk of the market in those days too, especially the ever reliable Hoovermatic. Cheers Steve. | ||

| Post# 689660 , Reply# 44 7/15/2013 at 20:38 (3,936 days old) by Meadowbank () | ||

|

Unintended link Not sure what happened in my last post but a link was included which was not intended. | ||

| Post# 690628 , Reply# 46 7/20/2013 at 00:41 (3,932 days old) by twinniefan (Sydney Australia) | ||

Philips range

Hi Meadowbank,

I remember the Philips range they were called the "Gentle Care" range and it consisted of 3600F you mention, a twin tub and 2 top loaders. from memory the top loaders were simply a rebadged Hoover 720 and 730, the front loader was a rebadged Zodiac, (I think.) but the twin tub was definitely not a Hoovermatic, it was more like a Hitachi twin tub. I do remember seeing a few tv ads about them and an ad in a magazine. The advertising concentrated on how gentle these washers allegedly were because in some tests paper tissues were put in the wash and apparently did not fall apart. I kind of remember the various washing actions being described as "Pendulum washing action" for the F.L., a reversing pulsator action for the t.t. and I think "Heli-Swirl" wash action for the t.l.'s, but I could be wrong on that one. Hope this info helps. Regards, Steve. | ||

Post# 690658 , Reply# 47 7/20/2013 at 05:18 (3,932 days old) by rapunzel  (Sydney) (Sydney) |

||

|

I recall the Philips top loaders also. They had the same spiral agitator as Hoover, but, from memory, I think their wash action was intermittent agitation and soaking for gentler care and to differentiate them from their Hoover cousins. | ||

| Post# 690790 , Reply# 50 7/20/2013 at 20:49 (3,931 days old) by crouzet951 () | ||

|

Refer to posting 690789 Hi meadowbank. This is the 525 spider described in the above posting.

| ||

| Post# 691106 , Reply# 52 7/22/2013 at 07:00 (3,930 days old) by Meadowbank () | ||

|

see 691104 Picture of spider arm modifications.

| ||

| Post# 691108 , Reply# 53 7/22/2013 at 07:03 (3,930 days old) by Meadowbank () | ||

|

see 691104 Service tools for Hoover frontloader bearing replacement.

| ||

| Post# 691514 , Reply# 55 7/24/2013 at 01:46 (3,928 days old) by crouzet951 () | ||

|

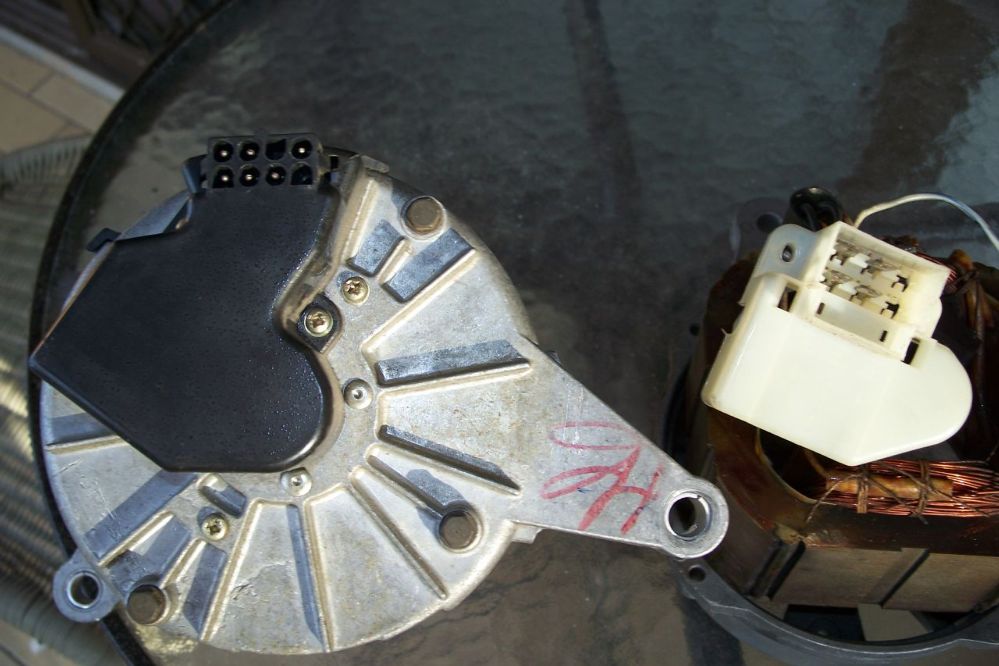

Refer to posting 691513 Original UK 455 motor on the left, Aus motor on the right.

| ||

| Post# 692418 , Reply# 59 7/28/2013 at 07:53 (3,924 days old) by matchboxpaul (U.K) | ||

|

the motor - this was just after the machine had been acquired from the schools owner...

| ||

Comes to the Rescue!

Comes to the Rescue!