|

Thread Number: 48797

KDS-58 Rack odd question |

[Down to Last] |

| Post# 706734 10/2/2013 at 08:25 (3,852 days old) by jkbff (Happy Rock, ND) | ||

Hey all!

It is apparent that I have too many odd sized objects that I want to cram into my KA and am wondering if I can use commercial standard plastic racks like the ones from Vollrath or something like that? I need a rack with no tines.

The vollrath's I've been looking at supposedly measure to 19.75" square, my rack measures wheel edge to wheel edge 20" if I am measuring it correctly... I need 1/8th inch on each side... Unless the 19.75 will fit? Has anyone tried this? Or does anyone know of a carrier I can use to hold the rack?

I suppose I could always order the racks and see if I can find a way to mount pegs on it or something so the rack can slide?

I am too used to loading a commercial washer rack to the gills and haven't quite adjusted to this rack... I'd probably order a rack with tines as well.

I still am hoping the part numbers and what-not pop up for that Undermount Hobart wash-arm conversion, I hadn't used my DW for a few days and when I did last night, the wash arm wouldn't spin.. I took the arm off, put it back on and it spun freely... something must have gotten in the bushing or something, but I have a feeling the arm is going to need replacing at some point... The arm feels like there is a slight bit of play while on the peg and the one from my donor machine is cracked...

With all of this said, I am surprised with all the SubZero and Wolf type appliances on the Market (brands made to mock commercial equipment) that someone hasn't made a consumer dishwasher that uses commercial racks... If I could find a machine like an under counter hobart that would let me use general consumer grade cascade and had a dry cycle, I'd be all over it. | ||

|

Post# 706972 , Reply# 1 10/3/2013 at 10:42 (3,851 days old) by jeff_adelphi  (Adelphi, Maryland, USA) (Adelphi, Maryland, USA) |

||

Dish rack--- | ||

| Post# 707111 , Reply# 3 10/3/2013 at 23:14 (3,851 days old) by jkbff (Happy Rock, ND) | ||

jeff_adelphi, please please post more pictures!!!

If you have an extra carrier, I'll purchase it from you if you don't need it.

That being said, I am going to try to make one... A family member owns a metal shop so I'm gonna put my resources to work...

SteveT, I don't suppose you have a cad drawing of that carrier do you? :P What is this European 18 you are talking about, how do you mean dumbed down and I didn't know the WM series existed... I have to find one of those now, that stainless tank is beautiful! What are the timer cycles, does it have a water heater?

With that, as far is this machine being worth all the money for conversions... Baring anything catastrophic happening to the tank, I should be able to get parts for almost everything except the timer, right? I mean, Hobart still makes a pump that fits this machine if I read correctly, and if I converted to the new style commercial wash arm, those parts would be available, the seals are still available, no? Given the way the constant rinse arm is, that is a wash either way if I ever replace it, and I have two middle racks now though one has a broken china guard.

If the timer fails, I know enough in electronic engineering to get my self in trouble.. Given how this machine was mechanically timed to begin with, it could be electronically controlled and customized and programmed because all it really would be is relays clicking on and off driven by an arduino controller. If the dispensers failed, I could seal those off or even put a glass window in the door and run a commercial chemical dispensing pump to flow in with the water fill, all driven off of that controller...

All of that said, the answer is yes, because this 'tank' of a dishwasher still cleans better than anything I've experienced today and it has so much potential once things start failing... Granted I can get the main parts that matter... Seals and pump housings mostly.

I have always liked appliances and gadgets and what have you, but hobart and kitchenaid have always been the most fascinating machines/companies (granted kitchenaid was a division) to me... I wished I could find spec sheets and users guides from the machines that were made that crossed over to eachother. That still has my heart just pounding away that there is a commercial version of the KDS. Thank you so much for posting that PDF.

| ||

| Post# 707146 , Reply# 4 10/4/2013 at 05:56 (3,850 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

WMs

Great Machines

Uncomplicated unlike the LX series. Here's a link to Bobbin's WM rebuild. I wonder how he's doing with the UM-4 rebuild ? CLICK HERE TO GO TO toploader55's LINK | ||

| Post# 707176 , Reply# 5 10/4/2013 at 09:15 (3,850 days old) by william637 (Damp pants? Not a chance. ) | ||

I have several KAs | ||

| Post# 707179 , Reply# 6 10/4/2013 at 10:09 (3,850 days old) by jkbff (Happy Rock, ND) | ||

William637,

Would you be willing to post a picture of one of the racks in it? What KA do you have? If you got back to me with a pic, I could have my racks here by monday :-)

I miss catering... I'm 26 and have had way too many jobs that I should ever admit to, but cooking has always been a passion of mine and I loved catering... Did it for 2 years almost... I only took the job because the lady I worked under was very well known for her food and I wanted her to teach me everything. When I finally left (didn't get along with the greedy owner anymore) she gave me 8 binders of recipes she had created that he stole from her and started his business with... Told me to take them and start a business someday. I'll get back to my true passion someday...

I've always found it easier to cook for 200 than for 1... ... | ||

| Post# 707181 , Reply# 7 10/4/2013 at 10:15 (3,850 days old) by jkbff (Happy Rock, ND) | ||

toploader,

After just learning these machines existed, I spent all of last night scouring through the archives (via search) and through hobarts resource library to find out as much as I can... These are beautiful!!!

I appreciate the link!

| ||

Post# 707187 , Reply# 8 10/4/2013 at 10:57 (3,850 days old) by jeff_adelphi  (Adelphi, Maryland, USA) (Adelphi, Maryland, USA) |

||

My Hobart,

Is a model WMP-CL, It was built in the early 70's. It had a chlorine injection system that I have removed, so it had no booster heater. It has a 4 minute cycle, wash and two rinses. It cleans very well, but the dishes must be freshly soiled, no dried or baked on soil. It's great for large dinners, as it can do several loads in short order.

| ||

Post# 707188 , Reply# 9 10/4/2013 at 11:10 (3,850 days old) by jeff_adelphi  (Adelphi, Maryland, USA) (Adelphi, Maryland, USA) |

||

KitchenAid Parts,

The tub is the same as a KitchenAid KDSS-16, but no dispenser in the door. As you can see I have made several modifications, I blocked up the overflow drain in the right rear corner with a air vent from a later KA, and installed a float switch in the left front corner. I also use a KA filter as it requires much less cleaning then the much more protective Hobart filter. When I rebuilt this DW about 10 years ago, I was told by the local Hobart office that they had no parts except the plastic racks. I was able to get what I needed from Whirlpool, except a timer that Midwest timer had.

| ||

| Post# 707249 , Reply# 10 10/4/2013 at 16:25 (3,850 days old) by jkbff (Happy Rock, ND) | ||

| ||

| Post# 707304 , Reply# 11 10/4/2013 at 22:02 (3,850 days old) by jkbff (Happy Rock, ND) | ||

SteveT,

I was looking again at the wash arm support, the white round plastic diverter or what ever it is is fixed into place... I am not sure what caused the arm to not spin, but when I tried to manually spin it, it took a lot of force to turn it... like turning a steering wheel while parked. After I lifted it up and put it back down, it spun freely with no resistance... I'm hoping it was just a freak occurrence.

If I knew the condition of the pump/seals on the KDI-58 I used as a donor, I'd start messing around with it this winter and make an electronic controller for it... It showed signs of a leak when I was robbing parts. The more I keep thinking about these WM machines, the more I want to find one or two just so I can rebuild one and make a completely custom interface for it and get rid of the short timer.. I'd just want one with the sump heater and no the booster heater so I could stay with 125 volt... Swap out the temp probe with one I could get variable resistance readings on (assuming the ones that are used are a 180 on / off type thermometer) and have it fill, heat to 140 wash / 180 rinse then run for how ever long, drain and repeat... I could control everything, make it use a bit less water by having less cycles than the domestic machines, it'd heat the water like the stupid new front load washers and run...

I was gonna snoop through Ephemera and see what I could find about the WM's and there isn't anything lol... But the resource library has given me a lot... Just confused about the booster's vs sump heaters..

*edit* Found this... Please send the pdf! Please lol... Post# 240758 , Reply# 12 10/6/2007 at 8:04pm (2,190 days old) by stevet (palm coast florida) posts: 1,456 This post was last edited 10/04/2013 at 22:19 | ||

| Post# 707335 , Reply# 12 10/5/2013 at 05:42 (3,849 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

Jeff...

That's one beautiful WM. Just Pristine.

When they were around because of the pump drain, they could be installed anywhere. Any kitchen I ran, I always had my Chemical Guy find and rebuild a WM and put it under the soiled dish table for washing glasses only. I bet there are a few in Church, VFW, or American Legion Basement kitchens throughout the country that have only washed the "Pancake Breakfast" dishes or the "Schpaghetti Dinner" Fund raisers etc. Most of those machines are used 3-4 times a year if that. | ||

| Post# 707390 , Reply# 13 10/5/2013 at 14:43 (3,849 days old) by william637 (Damp pants? Not a chance. ) | ||

pica of a commercial rack in a residential ka | ||

| Post# 707391 , Reply# 14 10/5/2013 at 14:45 (3,849 days old) by william637 (Damp pants? Not a chance. ) | ||

and the other pic | ||

| Post# 707410 , Reply# 15 10/5/2013 at 17:29 (3,849 days old) by jkbff (Happy Rock, ND) | ||

William637 You have made my weekend!! My racks are ordered and should be here next week. Thanks so much for posting those pics!!

So the racks don't move side to side and fall on the wash arm or anything? That really was my concern was that they fit but would slip or something... This is awesome!! I am absolutely excited to be able to wash my decanters and tea jars that won't fit over the tines!! OOO and my stock pot! I just hate having to bend the tines slightly for that thing... I'm still going to see if I can find a carrier just to have it cause who knows maybe a WM will be in my near future but this takes the urgency off. That and I'm not finding the time to go down and make one after hours... jeff_adelphi, if you wanna sell one of your carriers, I'd be interested.. (LOL why am I so excited over this?) | ||

Post# 707417 , Reply# 16 10/5/2013 at 17:50 (3,849 days old) by jeff_adelphi  (Adelphi, Maryland, USA) (Adelphi, Maryland, USA) |

||

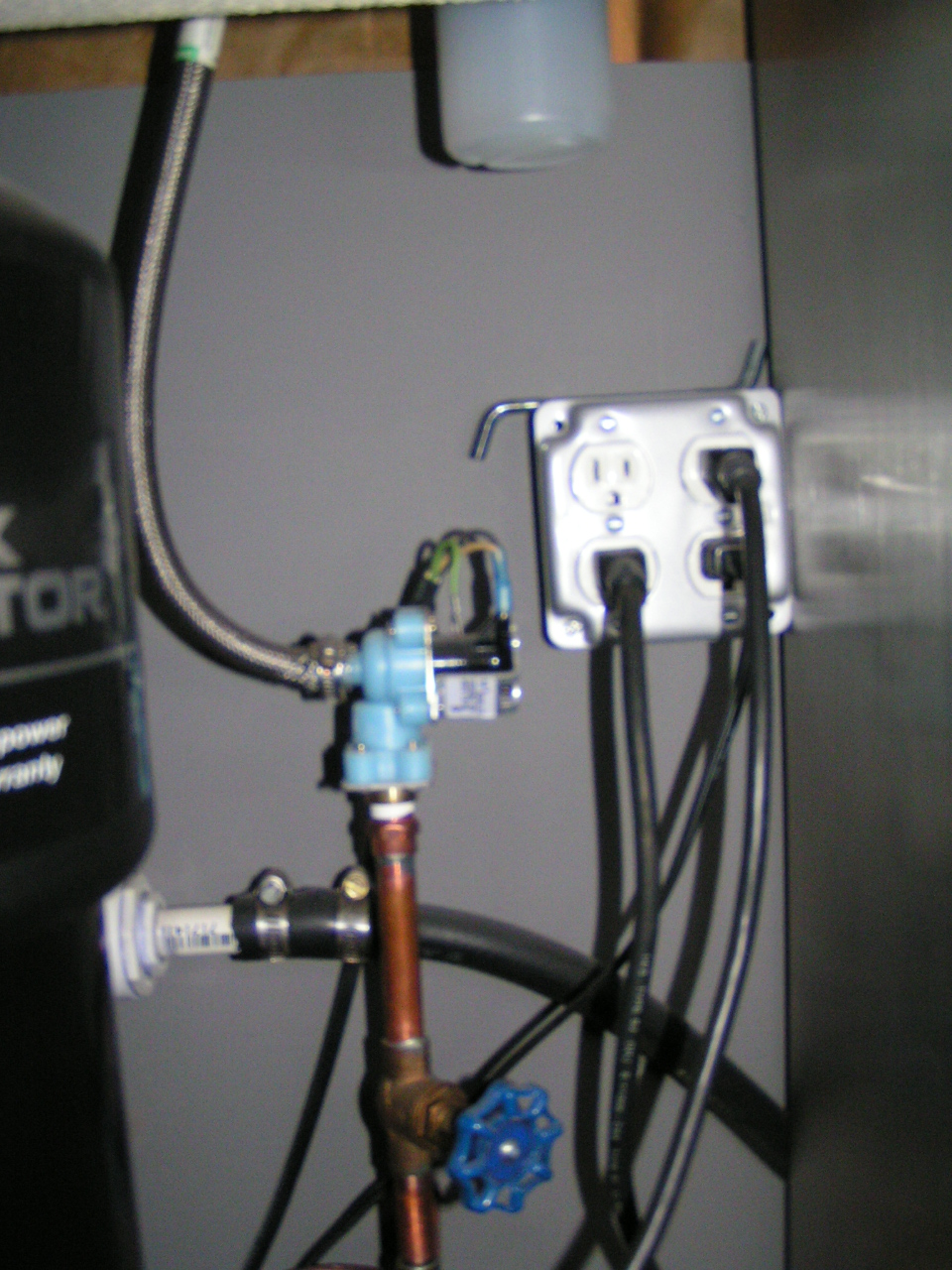

Foot pedals---

The foot pedals control the hot and cold water at the sink faucet. It's just two dishwasher valves connected to the supply lines of the faucet. I have wired it to turn on the cold water when the disposer is running.

I have thought about installing a sump heater and thermostat in the Hobart. The nice thing about stainless steel is when you need to drill extra holes.

| ||

| Post# 707660 , Reply# 17 10/6/2013 at 21:26 (3,848 days old) by jkbff (Happy Rock, ND) | ||

You just gave me an idea how I wanna do my timed tempering valve for my 'modern' washer that doesn't get hot...

Anyways, how do you guys do the shower curtain or plexiglass to watch the inside of the machine? I wanna see how this machine runs because I'm wondering if something isn't wrong with the middle arm... For the life of me, I can not get plastics clean in the top rack and they seem to warp in the bottom with the heated dry... This machine doesn't seem to like plastics or I have something wrong lol..

And I agree about the stainless, it would be nice to be able to drill some holes if I wanted to modify something... I've got to find me a WM... | ||

| Post# 707787 , Reply# 19 10/7/2013 at 17:46 (3,847 days old) by jkbff (Happy Rock, ND) | ||

SteveT,

When I put that wash arm support on, I stole it off of a KDI-58 that seemed to be in rougher shape than my KDS. The wash arm support on the KDI had been replaced because it seemed like it was a re-designed one from the one I took off my KDS... The point of all of this was that there was a seal on the KDI's support and there wasn't an area for me to put the seal on my KDS... would this be part of my problem? Seal/gasket I guess.. A round piece of rubber which of course ripped when I lifted the support off the pump. I ask because I checked the impeller when I replaced the support and felt for nicks etc, and didn't see a crack either.. (I'm used to working on direct air vacuums, so I thought I'd go through that part at least.) I wished I would have taken pictures when I did all of this but I was so excited to get the wash arm going I just did it in a hurry. By the way, Thanks for all the replies everyone! -- Josh | ||

| Post# 708732 , Reply# 21 10/12/2013 at 03:32 (3,843 days old) by jkbff (Happy Rock, ND) | ||

OK, so I got my racks today.. ... They don't fit :( Mainly because all 3 said they had specs of 19.75" and none of them matched each other. One is 19 11/16" one is 19 1/4" and the last is 19 5/8".

All is not lost. I am going to bolt strips of acrylic as shims/rails for the racks to slide on... Hopefully my plan will work.. I just need to figure out a solution that won't rust or mold when its all together. I imagine sealing it or bonding it will be involved some how...

In the back of my mind I keep thinking I should just go get a few packs of those cheap flex cutting boards from walmart and cut strips and make layered support shims on the sides.. They'd be NSF etc... I think....

SteveT, I guess the reason I didn't think there was a gasket in the arm support was because I didn't see the one that was already there... The one that came off of the donated support was stuck to it, I presumed it went around the top part... So, there is indeed a seal there... I'll have to order the shims and get an impeller from you or some where at some point though because when I spun the impeller by hand it was rubbing on the housing on one side. | ||

| Post# 708878 , Reply# 24 10/12/2013 at 21:10 (3,842 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

Peg type rack

You can also purchase what is called a Open Cup and Bowl Rack

It has large openings to let maximum water pressure through. I use this rack for washing 5 gallon pails in the AM 14. CLICK HERE TO GO TO toploader55's LINK | ||

| Post# 710517 , Reply# 25 10/21/2013 at 00:09 (3,834 days old) by jkbff (Happy Rock, ND) | ||

I modified my rack tonight.. This was just as a test fit with some random parts I fould at the vacuum shop I work at but it turned out pretty well!

It looks like I need to clean my door... Also, I noticed a chip in the porcelain. What can I fill that with? I put a few more pictures in the album but this is the one that is most on point! I was one nylon spacer short on this side, but have a parts order coming in with another tube of spacers. I've gotta finish the other two racks (the one with pegs and the combo open rack). | ||

| Post# 714978 , Reply# 26 11/12/2013 at 21:51 (3,811 days old) by jkbff (Happy Rock, ND) | ||

| ||

| Post# 715005 , Reply# 27 11/12/2013 at 23:45 (3,811 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

flea bay | ||

| Post# 715208 , Reply# 28 11/13/2013 at 21:54 (3,810 days old) by jkbff (Happy Rock, ND) | ||

| ||

| Post# 715230 , Reply# 29 11/14/2013 at 00:10 (3,810 days old) by rustyspaatz () | ||

|

You could try simply cutting all or most of the tines out of your existing rack, and coating the newly exposed metal nubs with dishwasher rack coating. Let it dry thoroughly before using again. It might cost you $30+/-

| ||

| Post# 715940 , Reply# 31 11/17/2013 at 21:12 (3,806 days old) by jkbff (Happy Rock, ND) | ||

And there's the magical phrase I was looking for!

"that will never wear out" Lets not forget this is a KDS-58, so when I move, it goes with me... And truly, to me, it is a timeless piece :) I'll get to this setup eventually.. I suppose if I am going that route though, I should find someone to do it for me so they can make sure everything else will fall under the 'never wear out' category.. Too bad there aren't any (as I haven't found any yet) kitchenaid collectors around here ... A second or third set of eyes never hurt anything. Think the Hobart guy makes house calls? LOL | ||

Comes to the Rescue!

Comes to the Rescue!