|

Thread Number: 48869

Mobile Maid Akron OH rebuild |

[Down to Last] |

Post# 707830 10/7/2013 at 20:39 (3,846 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

here's the link to the original find, but this here thread will be repairs.

HOLY SH%T. IT knocks glasses over, I can hear the plates banging against one another rhytmically as that spray arm sweeps around the machine! That is a powerful spray system, very glad I don't own fine china.

But it ain't without problems. JB Weld solved the small rust-through hole, about 3/16 dia. The impeller came right off the motor shaft and I inspected the seal but didn't take pics. It had a perfectly smooth surface and was just like a small diameter version of Norge washer and Frigidaire 1-18 washer tub seals. I prayed that the previous leak had only been the rust hole, and 3 loads of wash later it seems I was right, so the impeller/shaft/seal/motor stays assembled for now.

The link is my first thread,when I got the machine

But I had lots of problems getting the spray arm to rotate. The pic shows how the machine was when I got it. After a few turns of spray, the arm ended up tightenening that large nut agiainst the arm and all rotation stopped. This happened TONS of times. Finally I put an internal tooth #10 washer and a #10-32 small bolt on the top of that, tightened like a jam nut against the original large nut while checking it had maybe 1/16 of play and free movement, and 3 loads later it's spraying up a storm.

And I mean a storm!!! Loud water tons of water Niagara! it knocks plates against each other in a perfect cadence, turns over small cups in the top racks, etc, holy crap

CLICK HERE TO GO TO akronman's LINK

| ||

|

Post# 707836 , Reply# 1 10/7/2013 at 20:53 (3,846 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

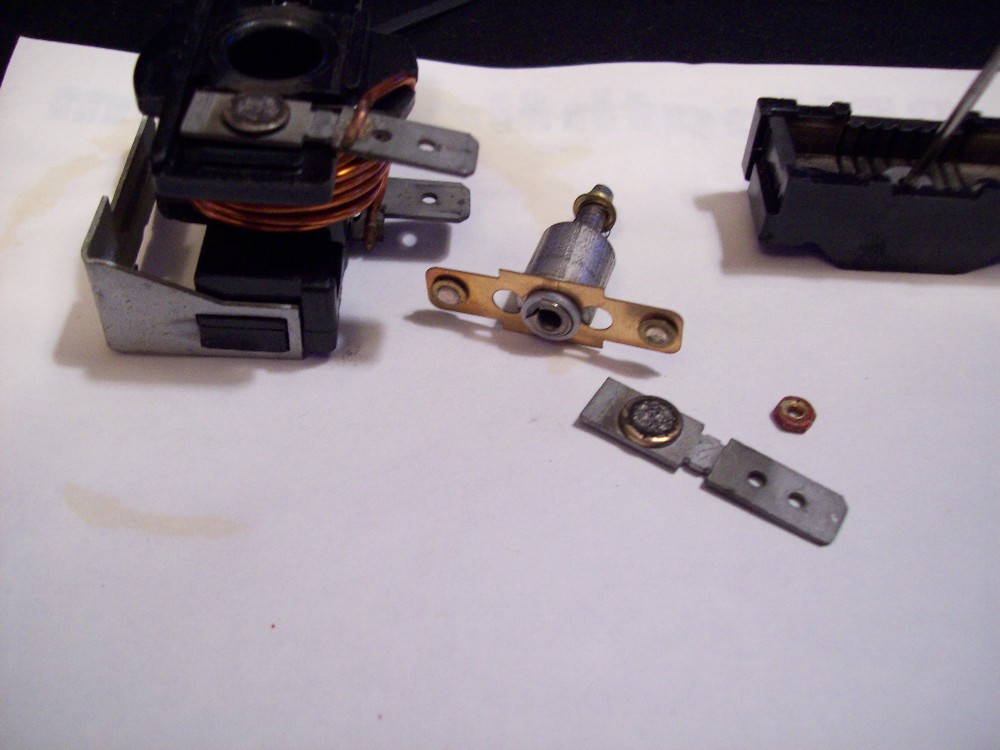

questions 1) Relay------during all the problems with spray arm rotation, I kept opening the lid frequently to see if the arm was at 2 oclock then 7 oclock then wherever, needed to check it's movement. Most of the times, the wash re-started immediately. BUT once or twice it immediately went into drain, then paused, then another drain with almost no water left. It occured to me the relay must stick a bit, sending it on the wrong direction, finishing an interrupted wash on drain instead? And once or twice it buzzed for 3 seconds before going into drain, then again stop, then immediate drain again. Sounds like sticky relay when it's supposed to wash. John Combo mentioned oiling it, rebuilding it? Or for a GE bi-directional motor relay, is there a PN for new?

2)-cycle buttons-----the previous thread shows 3 cycle switch, Daily loads, pots-pans, china. It seems electrically stuck on China: it skips the first wash and rinse, just give a rinse wash rinse rinse, and the Calrod only heats for maybe 1/4 of the drying. I don't mind the stuck apsect of limited Calrod drying, but I surely want the Normal load or PotsPans cycling, Wash-Rinse-Wash-Rinse-Rinse.

The pic shows the switch, it's actually 3 buttons but hard to see the break in the long one. 6 blades, 4 contacts, GE#ASP3224-08. Anyone know a replacement or source? Ebay brings up ASP 3224-????? many variations, not mine.

But overall, the wash system/motor/arm/pump all works with no leaks, potent washing action. Once I solve the minor issues, I'll tackle the horrid Formica top and the paint job.

Does Jet-Dry still sell those netted plastic baskets you clip on a rack? My machine lacks only the Rinse-Glo GE sysetm of the 60's. Other than that, it's a TOL Power Shower 3 cycle machine(stuck on one cycle and painted like crap, lol)

| ||

Post# 707838 , Reply# 2 10/7/2013 at 21:06 (3,846 days old) by turquoisedude  (.) (.) |

||

Hmmmm... the China/Crystal AND the Pots and Utensils have a 'dead space' on the timer for the first pre-wash. The timer will run through to what would be the first pre-rinse on the Normal cycle and the washing cycle will begin at that point. This is not a problem, as far I as I can recall from my '62 Mobile Maid.

Feeling the need to get that machine back out of deep storage and play with it when I get back from Brazil.... | ||

Post# 707842 , Reply# 3 10/7/2013 at 21:15 (3,846 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

Paul Paul Turquoise---trouble is that no matter what button I press, with all fingers and thumbs and 220 lbs of weight, I get the short cycle, That switch is internally stuck. And to push one button, I have to lift like hell on the others. Mechnically/springs DEAD, electrically stuck on one exact cycle. I took it off and cleaned as best I can, it's a rusted mess of a switch, each of those six blades is about ready to rust through.. If I can't find a replacement, I'll see about wiring past it on the diagram, to get only the daily load cycle, WRWRR. Who knows | ||

Post# 707857 , Reply# 4 10/7/2013 at 23:11 (3,846 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

2 more things The water level is nearly half way up the metal spray arm, nearly to its holes. OK?

Also, what is this thing? should it be rotating or is it stationary? At times while trying to get the arm to rotate, this was loose and sort of spun, but poorly because of the 3 nibs you can see, seem to match up with 3 ribs in the outer black casing. But by the time I finally got things in place and a jam nut to keep the arm from self-tightening, this no longer moved. Hmmmm....

| ||

Post# 707890 , Reply# 5 10/8/2013 at 07:00 (3,846 days old) by turquoisedude  (.) (.) |

||

Long shot here, Mark, but you might want to try asking Larry at Modern Parts if he might still have a pushbutton selector for this model. I don't remember seeing any while I was there in May, but I do remember that there were LOTS of GE and Hotpoint parts still and that there were some pushbutton switch banks...

He's in Parma, Ohio - Modern Parts House on Brookpark Road. I don't have the number handy, but I'll look it up. | ||

Post# 707967 , Reply# 6 10/8/2013 at 13:28 (3,846 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

relay John--I have the relay off the machine, it's #wd21x194, there's a supply house one for $10 plus $10 shipping. There's also a tiny screw at the bottom and a nut on top----what do I do inside once it's open. When I shake it, you can hear some metallic solenoid moving up and down.

Weird thing is, while I did tons of opening and closing the washer while testing and probably under 20% of the time it wrongly gave me rinse directon of the motor partway thru an interrupted wash, but----when I just turn it on and let it cycle thoughout the dial, this relay gives me the correct direction at the correct time. It never gave me a wash instead of rinse when interrupted.

For only $20 for a new one, it doesn't scare me to open this to either repair or ruin it. I get braver or dumber with each old machine.

Well, before I posted this, I took a screwdriver in my hands..........now what? Just emery paper on the 4 contacts and the tiniest drop of oil on the main center spring post and another tiny drop on the silver sleeve? I've rebuilt centrifugal switches on a 1951 Hamilton and a 62 Frigidaire, this is less worrisome than I thought. But no, I don't know what to do now I'm inside it. That's what he said! Tissue paper wipe out the center opening? everything is dust free, no sign of lube ever, contacts not great but I've seen worse and repaired them. My guess is delicate sanding only, no oil.

| ||

Post# 707983 , Reply# 7 10/8/2013 at 14:30 (3,845 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

done John--I sanded the contacts, didn't use a drop of oil anywhere, put the relay back together, and all is well? I noticed it only does accidental drain in the last 20 or so seconds of a wash. I must have opened the lid 30 times and it washed washed washed. When it does accidental drain, it's only at the tail end, and it then does accidental drain each time I open and close. Then it pauses and does scheduled drain. Methinks it's not a relay problem. Instead could the timer already be "ready" for the next part of the cycle, contacts in the timer are already set to send the reverse direction next time the motor starts, and by stopping the machine at that tail end of wash, I'm confusing the timer by 15 seconsd? If that's the only problem, I'm just leaving it alone.

A sticker on the timer says 20-69. Week and year of production? No other signs anywhere, and I have a 63 sales brochure and 68 owners manual, they sure made minor changes in buttons and lids and Uni-coupler and timer knob, kinda hard to exactly identify.

I can live with and wash with the bad switch for a while as I search for a fix or replacement, other than that I believe I am done with repairs, now moving on to the "Textolite" top, uglier than hell. So far this cost $20 for the long-unused machine, $5.95 Home Depot faucet adapter, that's all. So the ugliness of the lid and paint job don't seem so bad from that standpoint.

And some of the trim and handles are now being washed in a KitchenAid! | ||

| Post# 708003 , Reply# 8 10/8/2013 at 16:43 (3,845 days old) by xpanam (Palm Springs California ) | ||

parts machine

Hey Mark check this out! Probably 500 miles?

CLICK HERE TO GO TO xpanam's LINK on Chattanooga Craigslist | ||

Post# 708028 , Reply# 9 10/8/2013 at 19:28 (3,845 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

cleveland Cleveland OH to Cleveland TN is 563 miles! Too far for a parts machine, but thanks for the link. Now I know my Model #.. This one is EXACTLY my model. All the others in these forums show the decades GE built this and the numerous options and decor changes, but this listing is EXACT. All I need right now is that Formica lid, mine sucks.

hopefully someone gets this | ||

Post# 708112 , Reply# 10 10/9/2013 at 07:09 (3,845 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

GE DW Relay Mark it sounds like you did well with the relay, you basically just clean them up, file the contacts if pitted and use the tiniest bit of a non-sticky lubricant.

It is normal for the machine to switch from wash-rinse run direction if the machine is stopped near the end of a W or R period by either opening the lid or plugging the plug and then starting it again. The GE built timer advances continuously so the timer contacts for the motor preset themselves to reduce arching. | ||

Post# 708129 , Reply# 11 10/9/2013 at 08:57 (3,845 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

Model I scraped some paint off, this is #SP390B1. Timer says 20-69, and there's a Craigslist ad for an SP390B3 where the seller claims 1970, exact match to mine, so I am saying it's a 69 or 70 model, I think near the end of Mobile Maids. I think the only missing options are Rinse-Glo dispenser and some unicoupler that allowed for running water in the sink, called "Faucet-Flo."

I think the lid can be renewed by just flipping it over and gluing down a new sheet of Formica. Currently, "Textolite" top is 18ga steel with about the same thickness, 1/32, laminate fully glued. In my business travels I'll keep an eye out for Kitchen/Bath Remodelers stores, all I need is 2 ft square. I'll also cut and glue some wood shims for under the lid so it won't bow down again. The metal frame around the edges looks to have enough flex and space to allow a marginally thicker lid.

| ||

Post# 708322 , Reply# 12 10/10/2013 at 09:19 (3,844 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

switch Larry at Modern Parts took my model#SP390B1 while searching thru listings and immediately told me it's a 1966 model, I trust his paperwork. HE HAS THE SWITCH!!! Of course, price is more than the entire machine, but that's part of the hobby madness. Any idea if the "B3" model number I've seen elsewhere just refers to color?

I already jumpered one set of contacts on my dead one and got the full cycle of 3min wash, rinse, 9 min wash, R R. I will wait for Calrod testing once the new switch is installed. It does work for drying, no Calrod problems, but I am pretty sure it hasn't yet turned on for heated washes or rinses. I'll see what the new switch does. Other shcematics for other models make some reference to Calrod wash and rinse, other schematics have no notes, some literature for other models mentions heated wash, most don't, etc, way too many models thru the years on this machine. And various 2 button models, 3 and 4 button also, RInse and Hold. Hopefully I get heated main wash at least, I would never use heated dry.

This GE is similar to Filter Flos and GE dryers in that on the same basic design, they have so many iterations and options, very BOL to super TOL and all in between, nearly as many models as Kenmore did.

The same week I get a new toy fun dishwasher, I have been out to eat with family and friends nearly every evening, and daytime businees travel lunch on the road, darn little eating at home. I want a fattening weekend with tons of home-cooked dirty dishes, pots, pans | ||

Post# 708325 , Reply# 13 10/10/2013 at 09:44 (3,844 days old) by turquoisedude  (.) (.) |

||

It's coming along very nicely, Mark!!

I think you can still buy sheet laminate for counters at Home Depot. I remember they had a 'boomerang' pattern (in turquoise, natch) back in '09 when I was redoing the Ogden kitchen (hubby put the kibosh on that though...) If you don't have a specific pattern or style in mind, look in the 'reject cut' area of one of the home improvement stores - they often have a piece or two of counter top material that nearsighted fools like myself gave them the wrong measurements for.... LOL | ||

Post# 708331 , Reply# 14 10/10/2013 at 09:59 (3,844 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

Home D So far 2 Home Depots and one Lowes only want to sell me a 4 x 8 sheet at $68 to $85. I am very colorblind and none of these portable's lids ever matched anyone's kitchen counters. Boomerang would be nice but Wilsonart only "re"produced it for a few years, and my kitchen re-do with pale blue boomerang was maybe 6 years ago? I will likely just gladly use the first $10 scrap piece of any style I find. The switch is the real price-gouger here, now I gotta save on the lid. You are correct, I will keep checking kitchen/bath remodeler stores, something priced right will appear, then I'll know the top color and can decide what paint(s) for the cabinet. | ||

Post# 709000 , Reply# 15 10/13/2013 at 11:12 (3,841 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

repairs Larry at Modern Parts had a switch, it's GE#WD21X211, and then ReStore had lots of laminate sheets, so now all that's left to do is the cabinet painting. You can see 2 screws in the lid chrome edge. Also, next to the Mobile Maid is my Chambers range. Both the griddle and the broiler pan fit inside this dishwasher, that's my very ultimate dishwasher test.

| ||

Post# 709001 , Reply# 16 10/13/2013 at 11:16 (3,841 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

more The original lid edge assembly was glued together, and had bowed out, warped through the years. I did a complete dissasembly of the top, cleaned up and sanded the underside of the Textolite top, then Gorilla glued and clamped and weighed down the new sheet of red formica. For re-assembly, I drilled right through the chrome and into the metal tub lid's upper flange, then installed stainless steel self-tapping screws. It shouldn't come apart again.

A fellow AW person kindly offered a switch from his dead Mobile Maid, but I already had LArry get me this one and various washer/dryer parts, I just went through with that deal. But thanks to Alan for the kind offer. This 3 cycle machine Nomal--PotsPan--China uses WD21X211. I've seen other MM's here with usually 3 positions, but some only Normal and China, one with 3 + Rinse Hold, so there's a slight variance in switches. Then once I had the switch and PN, I Ebayed and found I paid a logical price, wtf. I still need to hook up a test lamp to prove that the Calrod does or doesn't heat for the wash portion, it's easier than sticking my fingers in there.

With the cabinet already having a poor brush coat, difficult to entirely get down to a smooth finish, I may just decide to use leftover dark blue and yellow paint from my kitchen and do a two-tone matching job!

This post was last edited 10/13/2013 at 11:34 | ||

Post# 710275 , Reply# 17 10/19/2013 at 18:03 (3,834 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

Numerous loads washed This Mobile Maid is EXELLENT! I am very happy with it, powerful washing no matter how I load it, dishes and pans sit for days and come out perfectly clean.

But the calrod does NOT heat for any wash or rinse, regardless of what buttons I press. This is a SP390B1, from 1966. The 3 postion button is as follows: Normal---2 washes, 3 rinses, Calrod heats entire 20+ minutes of drying Pots---2 washes, 3 rinses, Calrod on for just first 5 minutes of drying(approx) China--skips first W and R, then gives Wash-Rinse-Rinse, Calrod on same 5 minutes only like Pots cycle.

Some literature and electric diagrams FOR OTHER MODELS, OTHER YEARS makes reference to the Calrod ON for Wash/Rinse, other literature and diagrams make no such claim or reference. And GE made many many versions, differences in racks and rack lifting arrangements, Power Shower or no, single cycle, 2 buttons, 3, 4 buttons, etc, Rinse and hold feature, etc Way too many optional models for such a one-design machine. Could I have a model that only heated the Calrod for drying, and left it off for energy conservation during water action? But 1966 was before the 73 energy crisis, we just didn't worry as much as now.

Should I look into the timer? Should I leave well enough alone? I am not afraid of timers, but aware I'd likely never find another one.

It is an extremely impressive toploader, but a heated wash would be the icing on the cake.

| ||

Post# 711040 , Reply# 18 10/23/2013 at 11:57 (3,831 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

bump | ||

Post# 711053 , Reply# 19 10/23/2013 at 13:05 (3,831 days old) by bajaespuma  (Connecticut) (Connecticut) |

||

According most of the literature I have that covers many years, the Calrods are supposed to remain on for most of the cycle except for the drain/fill intervals and for the OPEN-circuit periods during the China/Crystal and Pots & Pans cycles.

I wish my new machines were designed this way but, I would suppose for current energy efficiency requirements, they take about 5 times as long to heat the water to 150 when that option is selected. One of the reasons I love these Mobile Maids is that they do was my modern dishwasher does in about 1/3 of the time. | ||

Post# 711061 , Reply# 20 10/23/2013 at 13:24 (3,831 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

Ken Thanks for info, and yes I think it is supposed to be on. I want to fix/figure out or leave alone before I paint the machine. I'm going to first get my multi-meter and start labeling all the wires leaving the timer, then open it a bit to see what I might find. Everything else about the machine and the timer and that 3-cycle switch works, this is the final repair needed and I gotta be able to figure it out. Since it's only 600 watts and can be chosen to heat for 23 minutes of drying, I doubt that energizing it throughout the entire cycle could damage anything. I load plastics away from it and I always open the machine to steam dry instead of that heat cycle anyhows, so the energy usage would likely be about the same if I instead powered it throughout water cycles. That's wondering out loud, but first various timer inspections are the way to go. So far it is giving excellent results, I just want it perfected and painted before the Thanksgiving crowd arrives. And yes it's lots quicker than my 92 KA and 82 Hotpoint. | ||

Post# 711063 , Reply# 21 10/23/2013 at 13:43 (3,831 days old) by bajaespuma  (Connecticut) (Connecticut) |

||

Be careful!!

I forgot that when we owned a GE pull-out almost 99% of the load was always china, glasses and silverware. Mom INSISTED on hand-washing all utensils, cookware and anything else that didn't fit easily in the dishwasher pins. Back in the sixties we had very little in the way of plastics (other than melamine)that I wash in my dishwasher all the time.

One of the first washes I did in a restored Mobile Maid, I made the mistake of putting one of my color-coded plastic cutting boards in the lower rack as I do all the time in my contemporary machine. The heat from the 600-watt heater melted one end of the board. If you turn the lights off, you can see those Calrod heater elements glow. There was a reason GE and other manufacturers made it very clear that certain plastic items like baby bottles needed to be secured in the upper racks. These machines weren't exactly careful with energy outputs. If you have a China/Crystal cycle, use it; it's the safest option because the heater is off for almost all of the cycle. | ||

Post# 711064 , Reply# 22 10/23/2013 at 14:00 (3,830 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

care and caution Ken--trust me I fully remember melting Melmac and handles and plastic when we had a MM and a 1960 GE pullout. So far I've loaded this well and then open it up to steam dry anyhows. I'm looking to figure out and perfect the timer, other heat ideas are pretty unlikely. I'll keep you posted on timer inspections. I may also have a chance on an impeller model MM, we'll see if the deal goes through. When I was a kid and it was all we had, it was great. But nowadays with 3 level-washing and even this 66MM with 3 levels, I bet the impeller version and its exact loading needs would wear me out. | ||

Post# 711259 , Reply# 23 10/24/2013 at 20:46 (3,829 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

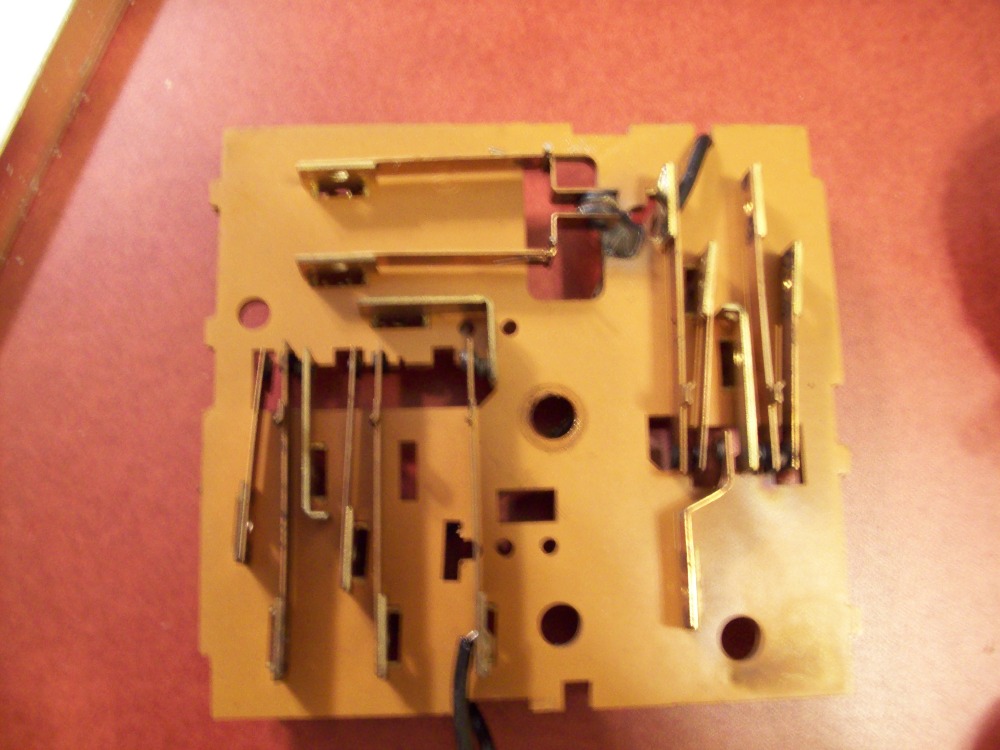

No water heating I figured out the Calrod wires and checked for power throughout a cycle, no heat except for dry cycle. Then I took out the timer, took it apart, everything looks fine except wear on the motor contacts, easily sanded to shiny and flat again, no problems.

In the picture, the heater contact is the third from the left, and stationary, pretty much halfway up the board. The next one outboard, much longer and moving on cams, is the positive power lead. The most outboard on the left is the water valve. So left to right it's Water----power----Heater. Also, this POWER one rides on the outside cam'd(spelling?) edge of the single cam you'll see in the next pic. Therefore very easy to watch. The outer cam has 3 levels-----5 high spots for 5 water fills, lots of middle space with no contact to the left or right, then finally a long lowest level for heater contact for the last half of the cycle, drying only after all 5 water bumps are passed. Pictures might be bad, but this timer really only powers the Calrod for the dry cycle, not the water cycles.

| ||

Post# 711261 , Reply# 24 10/24/2013 at 20:56 (3,829 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

poor photography pic is bad, but this one disc, with all its grooves and ridges and bumps, does it all. You can sort of make out the very outermost edge has some external bumps visible in the lower left, that's 2 of the water cycles. Once the timer was all the way apart, I could see how it operates, and now I do believe I have a rare model with no Calrod water heating. Only heated drying.

The cams for limiting the heater timing for the various cycles is very near the center of the board, and simply breaks the neutral, and I can follow the contact wires back to the cycle switch. So the only positive power is the one descibed one post back, and only is on for the entire heating part of the cycle. Pics are bad but bright kitchen lights made it clear as a bell.

| ||

Post# 711264 , Reply# 25 10/24/2013 at 21:07 (3,829 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

and It turns out the constant positive/cam-broken neutral operates in this way for the cycles:( Model SP390B1, 1966) Regular 20 minutes heat, 3 minutes no heat til end of cycle. Pots Pan 10 minutes heat, 13 minutes broken neutral. China 5 minutes heat, 18 minutes broken neutral.

Now that I've had it apart and back together and it ran one perfect cycle, if anyone has ideas on how to heat for some washes or rinses, I'll listen and ain't afraid to dig back in to the timer again, but otherwise I'm done. It's a wonderful washer with clean results, Power showering all the time, potent arm spray.

Now to decide on new colors for painting....

| ||

Post# 711319 , Reply# 26 10/25/2013 at 07:25 (3,829 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Very Rare ENERGY STAR 1966 MM DW, LOL It does look like you have a rare model Mark, it probably would not be to difficult to use a timer from a similar reversing motor GE DW to get wash and rinse heating. You could just add a relay and turn the heater on whenever the main motor is on or even as you suggested wire the relay to the timer motor circuit so the heater runs the full cycle. I would probably wire it with two relays so the heater would be on all the time the timer motor is running and the main motor is running, this way you will get an automatic air-dry and protect the fragile old plastisol coating in the bottom of the tub from the Calrods heat. | ||

Post# 711326 , Reply# 27 10/25/2013 at 08:40 (3,829 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

Hiya John John--good to hear from you------I think relays are easier to wire in than finding some other timer---I am semi-familiar with relays, but only the style where low volt turns on high volt, not here where it's all 120, but 1/3 amp or so timer motor versus 5.5 amp heater, so I might ask for Ebay or Grainger advice from you for the relays to buy. I lokked on Ebay a few day ago and got quickly confused.

It's approximately impossible to get heat only for the wash, so my best wish is heat whenenver the main motor runs, and then never for the dry cycle. Give me a few days to think out your 2 relay idea, but throw me some relay PN's any time you want.

Thanks-----I was quite surprised going thru the timer and contacts and wires, but it nows seems truly obvious that this model doesn't heat the water.

I realize what I'm doing will make most of that $60 replacement switch useless, but you live and learn. The machine itself was only $20, lol, and $2 for the new Formica top.

Thanks for your help-- Mark

| ||

Post# 711468 , Reply# 28 10/26/2013 at 08:49 (3,828 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

relay John and other pro's----the link is for a 120V coil relay, I believe it's what I want.

Also, you mention wiring through both the timer motor power and the main motor power, so the heater only works when both are running, but if i remove all the heater leads from the timer and only power the heater through a main motor relay, it'll only work when the main motor is going. I'm not sure why I need the timer motor involved. And I wonder if there's enough of the schematic left inside the machine to figure which lead is for WASH direction instead of Drain, I could get it powered only when it's washing and rinsisng, not motor running for drain.

CLICK HERE TO GO TO akronman's LINK | ||

Post# 711696 , Reply# 29 10/27/2013 at 14:49 (3,826 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

120 Coil Relay | ||

Post# 711974 , Reply# 30 10/28/2013 at 20:34 (3,825 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

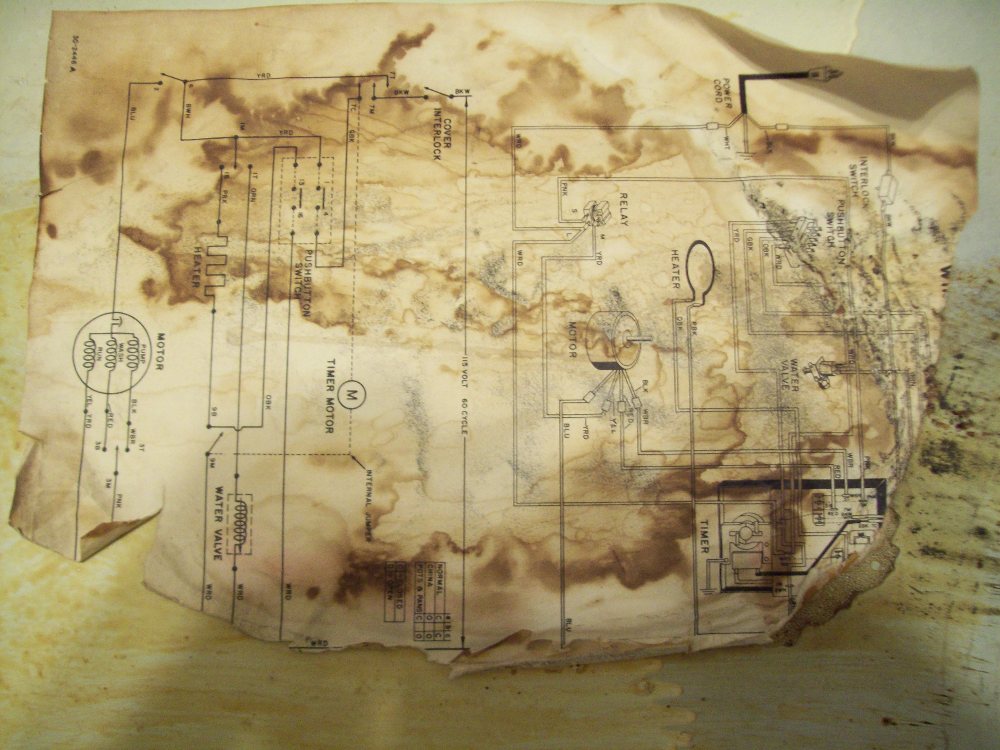

John----one last question I always have another question for John--I think I owe you a Hanukkah gift!

What's left of my schematic shows 3 windings inside the motor, Pump-Wash-Run. And the bottom of the diagram, the "ladder" section, shows the colors of wire for each. While I'd prefer to heat the Calrod for Wash instead of whenever the motor is running, if I use the WASH wire it's just the start windings and will turn off the heat once the motor is up and running? I believe I need to use the RUN wire to power my new relay, Yellow/Red joined to YEllow, and the heater will always work when the motor is running in any direction.

The top half of the diagram shows the YellowRed coming from the motor relay to the motor Yellow.

The relay is in the mail, hoping to get this done right with one more opening of the innards.

Thanks again-----this MobileMaid washes EVERYTHING. Sorry the pic is on its side.

| ||

Post# 712135 , Reply# 31 10/29/2013 at 17:39 (3,824 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

120 Coil Relay Addition | ||

Post# 712413 , Reply# 32 10/31/2013 at 11:51 (3,823 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

All good John-----it's wired up perfectly with your advice, and I even temporarily hooked up a test light to prove exactly when the heater goes off and on, exactly with the motor. And exactly with the little click from the new relay.

While I had the machine on its side, I undid the 4 motor screws, the wires left just enough slack, and wiped clean the sleeve bearing and spindle, then some 3-in-1 non-detergent oil on it, all back together now and one great load of dirty dishes done.

Also, while crawling around and scraping more paint off the cabinet, a better read of the nameplate says AMPS 6, more evidence that this rare model SP390B3 did not ever heat the water. UNTIL NOW! And the motor says 2-18-66, not as old as me but still running.

Thanks for your help, John!

All done now except for painting

| ||

| Post# 712415 , Reply# 33 10/31/2013 at 12:47 (3,823 days old) by mickeyd (Hamburg NY) | ||

Mark, the Mobile Maid looks perfectly at home and welcome in your kitchen. That's the same kitchen I LIVED IN at my Aunt Margaret's house with her Easy Spin wheeled up to an identical sink. Your sink is now coveted by newbees, paying fortunes for retro redesigns of their kitchens. Cool idea with the table cloths. I have one exactly like one of yours. But most of all, I admire and envy your mechanical skill. Good on you, Dude! Top Load Portables Rule! Can't wait for the day when you tackle a Combo. | ||

Post# 712418 , Reply# 34 10/31/2013 at 12:55 (3,823 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

Mickey Thanks-----I had a kitchen table in there for ages, and collected about 10 50's print tablecloths, and used them and loved them. When I remodeled and put a 50's Westinghouse roaster and a cabinet for a Nutone Food center in, I had to get rid of the table. All those great tablecloths had to go somewhere! The sink installation made me lose the doors under it, so more tableloths now act as curtains there. Most of the tablecloth/curtains do NOT match, but look great anyhows, I love it and appreciate your comments. Tough luck to old Martha Stewart. | ||

Post# 714487 , Reply# 35 11/10/2013 at 22:34 (3,812 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

Motor Motor problem---this machine has done a load of dishes wonderfully about every other day for 10 days------then tonight it ran through most of the cycle, got to final rinse and worked fine, paused then advanced for the final pumpout, I heard the relay click and then nothing. I advanced the timer and slowly advanced it through another cycle, each time the motor should run it clicked once, buzzed a bit, never started up. I waited for cool-down time, an hour, to see if thermal overload had kicked in, still nothing. Finally I emptied it and turned it on its side, probably 2 hours after the screwup. With no disassembly at all, you can stick your fingers into the motor bottom from underneath. At first the blades were entirely stuck, soon my fingers freed it and it turned nicely. I set it up straight and turned it on, it ran perfectly through another load of dishes.

About 2 weeks ago, doing other repairs, I had the bottom of the motor off and added 3 drops of turbine oil to the bottom bearing, but I've never seen or touched the top bearing.

| ||

Post# 714488 , Reply# 36 11/10/2013 at 22:38 (3,812 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

stolen | ||

Post# 714490 , Reply# 37 11/10/2013 at 22:39 (3,812 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

rotor | ||

Post# 714492 , Reply# 38 11/10/2013 at 22:51 (3,812 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

more stealing this pic should be the top view of my motor, but I've never had it that far apart. So yes I need to start some Ebay searches on GE motor WD26x56 or WD26X63. In the meantime, take it apart and get some cleanup done and then some turbine oil? I imagine the bearings are pretty much factory assembled to the motor, it's nothing I should think of replacing myself? Turbine oil for a sleeve bearing is correct?

Everything else is working wonderfully, this machine cleans everything, but a reliable motor is necessary.

Thanks in advance for any advice. So far I know it's a reversing motor with a sleeve bearing at the base, no capacitor but it has a relay mounted elsewhere, not much else. But I am less fearful each project of getting into motors, relays, timers, etc. That's thanks to all you guys-- Thanks Mark

PS. If I properly attribute 3 photos to Rollermatic, with thanks, I shouldn't end up as someone's prison bi&ch.

| ||

Post# 714539 , Reply# 39 11/11/2013 at 07:14 (3,812 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

GE DW Motor Problems Hi Mark, sorry your motor is having problems. These motors do use just sleeve bearings on both ends and turbine oil is great for this purpose.

I was never a big fan of this motor and pump system on GE DWs, and I always found that 3450 RPM DW motors that just had sleeve bearings to be not all that durable. D&M, WH and HP DWs also only had sleeve bearing main motors in the 1960s.

Overall the 1960s was not a time of real durable DWs [ with the exception of Kitchenaid ] even the great performing WPs were of poor long term durability [ pump and motor problems ] and WH , D&M and HP were throw away machines after a few repairs, LOL. A typical family running the DW once or more per day often got less that five years use out of a DW before replacement.

The best advice I have for DW collectors on this site is to try to find those rare machines that had little or no use if you expect to use them as everyday machines. Mark you may end up needing another motor and pump for your machine, if you do I may have a good used one, contact me if interested, John L. | ||

Post# 714547 , Reply# 40 11/11/2013 at 07:40 (3,812 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

John I always appreciate your advice. I'm gonna take the motor entirely apart and get turbine oil in both bearings, then I will use it less. This is a high-mileage machine for sure, and it's a case of "you get what you pay for" which was only $20. IT washes fantastically, but I don't want to wear it out in another month. | ||

Comes to the Rescue!

Comes to the Rescue!