|

Thread Number: 49745

Colston Ariston Automatic Wash and Tumble Dry 850 XD |

[Down to Last] |

| Post# 718824 12/2/2013 at 14:58 (3,787 days old) by sesteve (London, UK) | ||

Hi folks

I recently acquired one of these machines - an old favourite of mine. It's in great cosmetic condition with just a bit of rust around the dispenser but the chrome, paintwork and controls are in good nick. However, it's not working properly - I'll come on to that in a minute. First here are a few pics

| ||

|

| Post# 718825 , Reply# 1 12/2/2013 at 14:59 (3,787 days old) by sesteve (London, UK) | ||

| ||

| Post# 718826 , Reply# 2 12/2/2013 at 14:59 (3,787 days old) by sesteve (London, UK) | ||

| ||

| Post# 718827 , Reply# 3 12/2/2013 at 15:01 (3,787 days old) by sesteve (London, UK) | ||

| ||

| Post# 718828 , Reply# 4 12/2/2013 at 15:02 (3,787 days old) by sesteve (London, UK) | ||

| ||

| Post# 718829 , Reply# 5 12/2/2013 at 15:05 (3,787 days old) by sesteve (London, UK) | ||

| ||

| Post# 718830 , Reply# 6 12/2/2013 at 15:06 (3,787 days old) by sesteve (London, UK) | ||

| ||

| Post# 718833 , Reply# 7 12/2/2013 at 15:11 (3,787 days old) by sesteve (London, UK) | ||

| ||

| Post# 718834 , Reply# 8 12/2/2013 at 15:12 (3,787 days old) by sesteve (London, UK) | ||

| ||

| Post# 718837 , Reply# 9 12/2/2013 at 15:17 (3,787 days old) by sesteve (London, UK) | ||

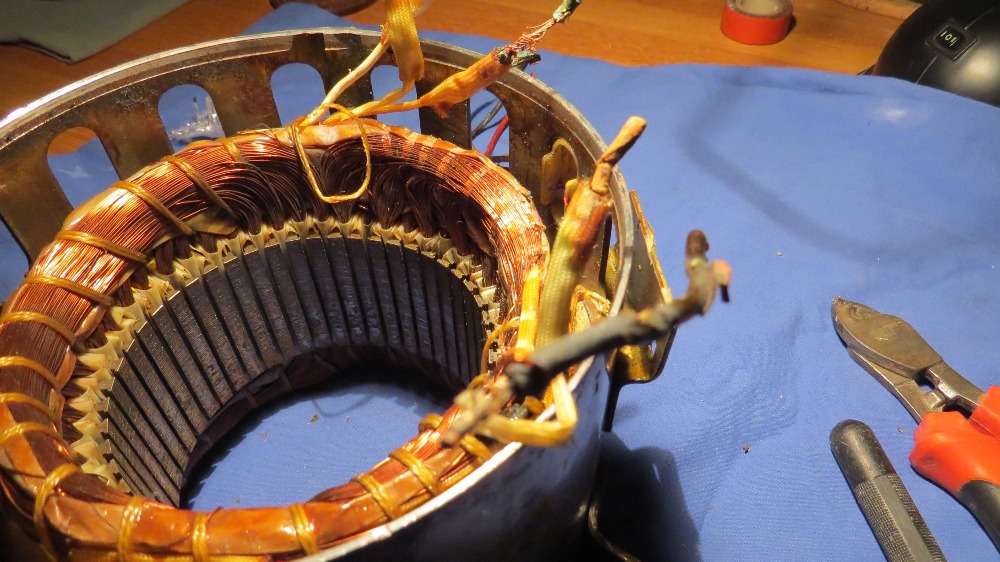

The big question is how. This is as far as I have been able to go with the motor strip down. Not sure how the core comes out. I did speak to a motor rewind place but they wanted silly money. I think they were a bit dodgy though.

Have any other AW ers had a similar issue? Not sure what to do as would love to get this up and running again.

| ||

| Post# 718838 , Reply# 10 12/2/2013 at 15:19 (3,787 days old) by sesteve (London, UK) | ||

| ||

| Post# 718839 , Reply# 11 12/2/2013 at 15:20 (3,787 days old) by sesteve (London, UK) | ||

| ||

| Post# 718860 , Reply# 12 12/2/2013 at 16:55 (3,787 days old) by robliverpool (england Liverpool) | ||

| ||

| Post# 718866 , Reply# 14 12/2/2013 at 17:23 (3,787 days old) by hotpoint9534 (UK) | ||

|

Great machine. My grandparents used to have the washer only version of this machine until about 1992, unfortunately I can't remember the model number. I've only seen examples of the washer-dryer version since though, so I guess it was more common. Tom | ||

Post# 718871 , Reply# 15 12/2/2013 at 17:32 (3,787 days old) by vacbear58  (Sutton In Ashfield, East Midlands, UK) (Sutton In Ashfield, East Midlands, UK) |

||

Colston | ||

Post# 718873 , Reply# 16 12/2/2013 at 17:34 (3,787 days old) by vacbear58  (Sutton In Ashfield, East Midlands, UK) (Sutton In Ashfield, East Midlands, UK) |

||

@Mathew | ||

| Post# 718895 , Reply# 18 12/2/2013 at 18:41 (3,787 days old) by optima (Cumbria England) | ||

Colston | ||

| Post# 718908 , Reply# 19 12/2/2013 at 19:42 (3,787 days old) by mrx () | ||

|

This is its slightly older 1974 washer-only predecessor Coleston, Thor and a few other brands seem to have simply been purchasing and rebadging Riber machines. | ||

| Post# 718942 , Reply# 20 12/3/2013 at 01:14 (3,787 days old) by Docker (Cape Town, South Africa) | ||

|

"They're made by Riber of Italy" These were sold as Indesit 525 in SA & Oz.

| ||

Post# 718944 , Reply# 21 12/3/2013 at 01:27 (3,787 days old) by ozzie908  (Lincoln UK) (Lincoln UK) |

||

Lines on the rotor | ||

| Post# 718955 , Reply# 22 12/3/2013 at 03:58 (3,786 days old) by hotpoint9534 (UK) | ||

|

I remember the washer only version of the Colston had a very odd final spin cycle, where it would continuously speed up, slow down, speed up etc. Never seen anything like it before or since. | ||

| Post# 718956 , Reply# 23 12/3/2013 at 04:43 (3,786 days old) by electron1100 (England) | ||

Man and Machines

Hello Steve what a great machine, all mechanical, these sort of machines tick my boxes, engineering and engenuity, i love it.

I can only endorse what Mat has said about replacing the failing motor wires, take your time keep a clear head, and it can be done. Als comment about Mats professional tool kit is well spotted, I always have a "Universal Adjuster" or "Harry the Hammer" close at hand as do others that I know ;-) the only extra tool I have is a packet of fags and an ashtray. Good luck Gary

| ||

| Post# 718973 , Reply# 25 12/3/2013 at 08:26 (3,786 days old) by Docker (Cape Town, South Africa) | ||

|

Indesit 2527 Chris, Those South African orphan imports were Indesit serie 2000 machines.

| ||

| Post# 718977 , Reply# 26 12/3/2013 at 09:52 (3,786 days old) by mrx () | ||

|

I still can't remember what the A and B buttons did. S was just on/off. | ||

| Post# 719043 , Reply# 28 12/3/2013 at 16:57 (3,786 days old) by statomatic (France) | ||

| ||

Post# 719051 , Reply# 29 12/3/2013 at 17:21 (3,786 days old) by ozzie908  (Lincoln UK) (Lincoln UK) |

||

A and B buttons were I believe... Short spin was one and the other raised the water level for delicates and wool etc.

Does anyone remember the predecessor of this machine and it had the dryer unit built into the door?

They were good for their time !

Oh and if you look at the bundle of wires in the pics above they are not as hard to trace as you think as each has a unique number that is on each end !

Austin | ||

| Post# 719052 , Reply# 30 12/3/2013 at 17:22 (3,786 days old) by hotpoint9534 (UK) | ||

|

Thanks for the information, Chris. I'd wondered for years about the reason for this, and now I know at last. Very interesting! Tom | ||

| Post# 719053 , Reply# 31 12/3/2013 at 17:25 (3,786 days old) by sesteve (London, UK) | ||

Thanks chaps for all your comments. Just spent ages putting a reply together and then lost it all so will start again and post a bit at a time grrrrr

Mathew - thanks matey you have given me the encouragement to give it ago. I don't think the coils are going to come out easily so I will give it a go from the top even though I have sausage fingers so not too good with the fiddly things! Do I need to use heat resisting wire or anything special - I was thinking of using sone old Hoovermatic wiring that I have if it would work. I might be able to spend some time on it at the weekend and I am looking forward to seeing the pulley in full operation so that's a good incentive for me to get this back up and running. Love the precision tools too - I'll be using something similar I'm sure! Will keep you posted. S :) | ||

Post# 719055 , Reply# 32 12/3/2013 at 17:30 (3,786 days old) by ozzie908  (Lincoln UK) (Lincoln UK) |

||

Why not use insulating tape? | ||

| Post# 719056 , Reply# 33 12/3/2013 at 17:36 (3,786 days old) by sesteve (London, UK) | ||

I've attached a link to the instruction book for this and the 800VS washer only courtesy of Chestermike for anyone who is interested. The A button is the rinse hold and B is for bio wash. The book also mentions a venting kit although there will be no chance of tracking one of these down now and it still wouldn't address access to the filter. Strange that the advert for the machine shows it under a worktop - perhaps the Formica was stronger in those days.

I wonder if the high pump failures were done to that filter Ronan. The one on this machine was totally clogged with fluff. The instruction book also mentions the soap dispenser switch - my mum's old neff used to have this but there was no chance of that jumping around lol. CLICK HERE TO GO TO sesteve's LINK | ||

| Post# 719057 , Reply# 34 12/3/2013 at 17:45 (3,786 days old) by sesteve (London, UK) | ||

Hi Austin

If only it were that simple. The problem with the wires is that the actual core has frayed apart as well so in some cases it's down to a couple of strands. It's also really brittle so it's just going to snap and the insulation has broken at the point were they pass through the casing. I would have preferred to have been able to do the shrink tube but alas it's a full on challenge instead. Thanks for the note on the rotor - it's a relief to know its deliberate.

| ||

Post# 719058 , Reply# 35 12/3/2013 at 17:53 (3,786 days old) by ozzie908  (Lincoln UK) (Lincoln UK) |

||

Sorry Steve | ||

| Post# 719060 , Reply# 36 12/3/2013 at 17:59 (3,786 days old) by sesteve (London, UK) | ||

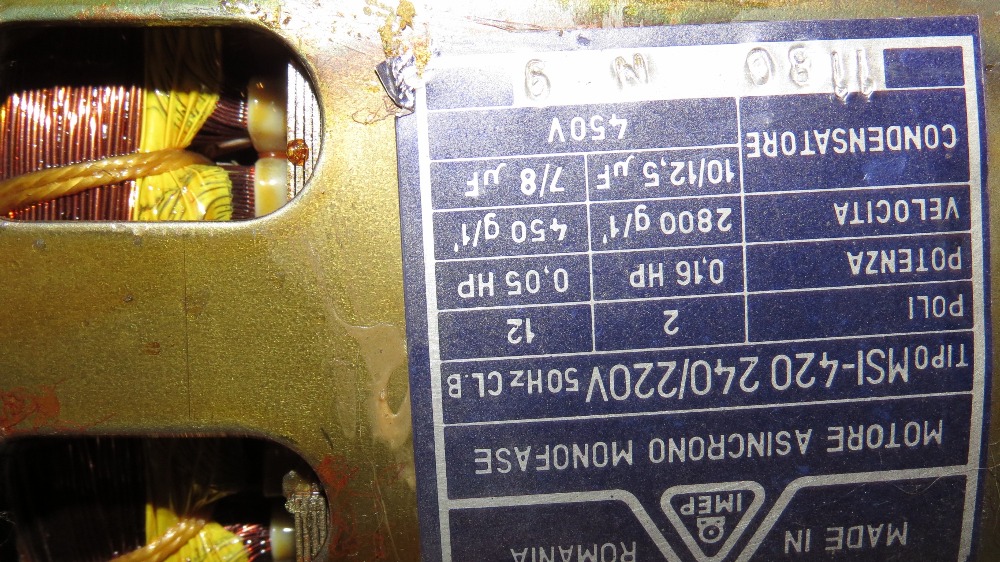

Meant to say I will look out for the numbers too! That spin is an interesting way of doing things. I know the way the motor is mounted is unique to enable the belt to keep its tension when it's washing or spinning.

Gary - I will have a similar tool kit out but will swap the fags for fruit gums and perhaps the tea for a gin although I'd better leave that for when I'm almost done or I'll end up crossing my wires! I love the clicks and whirs of these old beauties so hopefully I will get it back on its feet. Chris, thanks for the offer but you are right, these motors weigh a ton so no chance on shipping. I'm guess other motors of this age may be suffering the same issues as the insulation is rubber. This motor was made in Romania so that would explain why it's so robust. They don't make em like this no more!! Will keep you updated S :)

| ||

Post# 719061 , Reply# 37 12/3/2013 at 18:00 (3,786 days old) by vacbear58  (Sutton In Ashfield, East Midlands, UK) (Sutton In Ashfield, East Midlands, UK) |

||

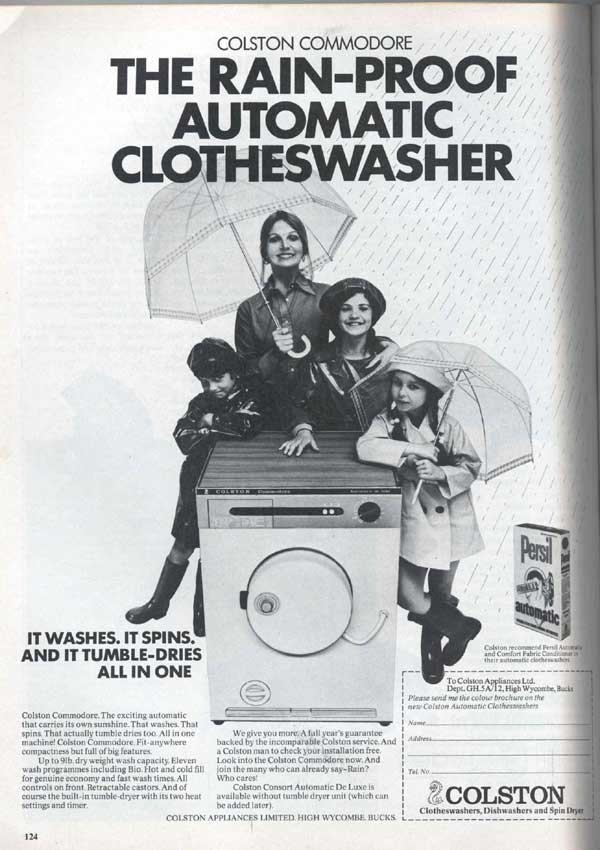

The previous version

Was the Colston Commodore, this picture is dated November 1973. It is my recollection that, after the demise of the large Bendix washer/driers this was the only combo that was around for quite some years, although Thorn did revive the large style Bendix towards the end of the 1970s.

This Colston also came as a washer only with a conventional door. Al

| ||

Post# 719062 , Reply# 38 12/3/2013 at 18:04 (3,786 days old) by ozzie908  (Lincoln UK) (Lincoln UK) |

||

Nice one Al | ||

| Post# 719063 , Reply# 39 12/3/2013 at 18:07 (3,786 days old) by sesteve (London, UK) | ||

No worries Austin. Believe me I would prefer to keep it easy but no chance with this, that's why I went to the motor rewind place as I know they could do a good job easily!

Yes the quartz boards would be great. Both quartz machines are parked in a new shed I had to get to hide the machines while the house was on sale. Should be moving out of here in January so once I'm in the new place I'll have to have another go at them so the boards could help if you are happy to hang in for a bit longer. Will keep you posted S :) | ||

Post# 719064 , Reply# 40 12/3/2013 at 18:09 (3,786 days old) by ozzie908  (Lincoln UK) (Lincoln UK) |

||

Fluff filter.. | ||

Post# 719067 , Reply# 41 12/3/2013 at 18:16 (3,786 days old) by ozzie908  (Lincoln UK) (Lincoln UK) |

||

The boards are yours  | ||

| Post# 719266 , Reply# 45 12/4/2013 at 17:40 (3,785 days old) by vivalalavatrice () | ||

|

This is its slightly older 1974 washer-only predecessor OMG! I didn't remember to have picked up such rare machine :D and I got early rid of it giving to another washers lover (rikbio77) CIAO! | ||

| Post# 719348 , Reply# 46 12/5/2013 at 03:24 (3,784 days old) by mrx () | ||

|

They were certainly distinctively styled machines. | ||

Post# 719350 , Reply# 47 12/5/2013 at 03:45 (3,784 days old) by vacbear58  (Sutton In Ashfield, East Midlands, UK) (Sutton In Ashfield, East Midlands, UK) |

||

@MRX

Just a couple of points on your last post.

Firstly, as far as is known Colston did NOT go under in 1964, you are confusing it with Rolls who primarily manufactured twin tubs although they also did sell Colston dishwashers under the Rolls name. The name Colston appears to have emerged in the very late 1950s - a Colston dishwasher appeared in the Which December 1960 report. I have often wondered if there is any relationship with the 1950s Hoover MD (NOT Sir Charles who basically set up Hoover in the 1920) and indeed if the dishwasher could have been a design that Hoover had been developing but dropped. THIS IS JUST MY SPECULATION, AND I MAY BE MAKING 2+2 = 5. Anyway, Rolls emerged about the same time, into the burgeoning UK twin tub market. Initially they imported these from Holland but shortly began manufacturing them here in the UK. They bought the motors for these machine from a company called Bylock whom they took over in late 1963. Bylock first appeared in the 1930s manufacturing hair dryers but they expanded after WW2 into vacuum cleaners & polishers - the vacuum cleaners, initially, where based on designs from the US Apex company. I believe that there was also a Bylock twin tub which presumably was a Rolls design. When Rolls went bust in 1964 they took Bylock with them. After Rolls went bust the manufacturing facility was taken over by a company called Tallent, who had a relationship with Rolls as one of their suppliers (from memory) and the machines continued to be produced under a variety of well known names (including English Electric, Goblin, HMV and many others) before being consolidated (and restyled) under the Colston name. During this period Colston increased their range to include a more "squared off" counter-top model and a floor standing machine although these were fundamentally the same machine as the older model under the skin. And so it continued into the 1970s with the addition of the automatic washer & washer/dryer and also a more conventional (12 place) floor standing dishwasher. Steve's washer drier above must be a later one as it is branded Colston Ariston (so post Ariston takeover), I think I have also seen these branded as Colston only. It was in the early 1980s (maybe even 1980) that Colston were taken over by Ariston, God knows why as their dishwashers had disappeared in the mid 1970s and the twin tubs were certainly very long in the tooth, in a market that was (and had been for several years) shrinking rapidly. They even brought out a single tub and spin drier (fair enough based on the old technology) at the end of the 1970s when this market was even smaller. Initially branded as Colston-Ariston the Colston name was soon dropped and shortly after that the whole lot disappeared for ever - by my reckoning about 1982 or so. And a final note, this time on the Thor. I had a Philips branded washer drier purchased (new) in around 1984 or maybe early 1985 which was similar to the Thor 950. This seems to have been a development of 850 (so maybe manufactured by Riber) which vented out the back - mine did have a vent hose. It had one curious thing about it in that there was a little L shaped hose which drained out the door boot into the (outer) wash drum. A gimmick for, which a very short time, with all the movement & vibration it had split sending waster all over the place. I have an ad for the 950 which I recorded on RTE back when you were still in your pram which I will try and get onto YouTube this weekend Al | ||

| Post# 720092 , Reply# 49 12/9/2013 at 11:55 (3,780 days old) by matchboxpaul (U.K) | ||

|

closer up ...

| ||

| Post# 720093 , Reply# 50 12/9/2013 at 11:57 (3,780 days old) by matchboxpaul (U.K) | ||

|

and here is the version2 850XD that we have - version2 as it is branded COLSTON ARISTON, picked up from Blackpool a couple of years ago ....

| ||

| Post# 720095 , Reply# 51 12/9/2013 at 11:58 (3,780 days old) by matchboxpaul (U.K) | ||

|

then we move to pure ARISTON branding, in the form of the 950XD with additional button. This machine is model number 2559, whilst the original 850XD was model 2558....

| ||

| Post# 720097 , Reply# 52 12/9/2013 at 12:01 (3,780 days old) by matchboxpaul (U.K) | ||

|

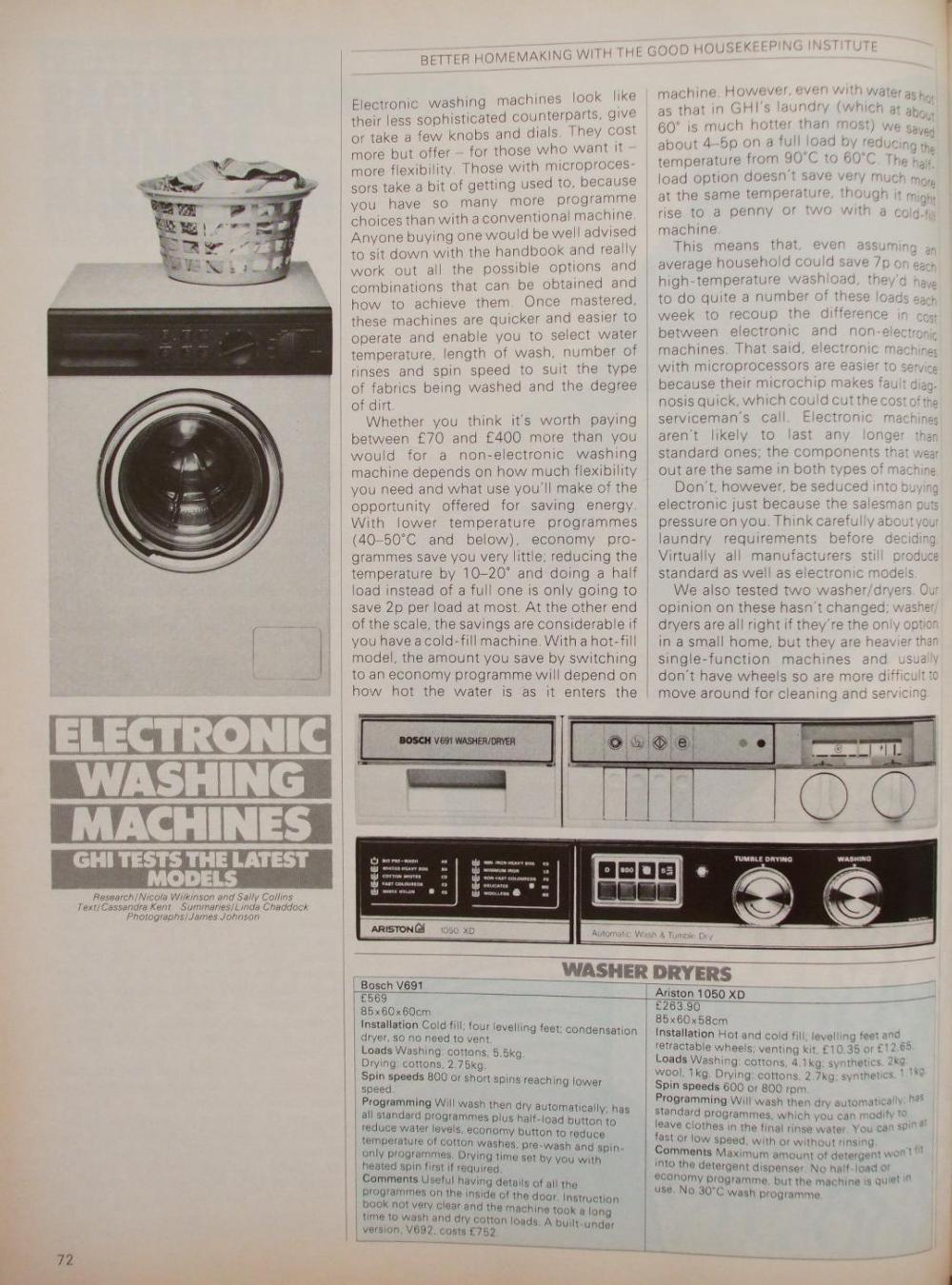

then on again, with a further restyle for 1984, to produce the ARISTON 1050XD ...

| ||

| Post# 720098 , Reply# 53 12/9/2013 at 12:04 (3,780 days old) by matchboxpaul (U.K) | ||

|

Al mentioned that he had a Philips branded machine, that was derived from the Colston. That machine will probably have been the PHILIPS AWB089 Washer-Dryer, that was available circa 1984. Subtle tweaks, nips and tucks, but its filter cover is the give away ....

| ||

| Post# 720100 , Reply# 54 12/9/2013 at 12:08 (3,780 days old) by matchboxpaul (U.K) | ||

|

The 850XD is a great machine and interesting to watch with, as mentioned in the thread, its up and down spin cycles. Fingers crossed you get it going again steven. Regards Paul

| ||

| Post# 723222 , Reply# 55 12/26/2013 at 16:16 (3,763 days old) by sesteve (London, UK) | ||

Update

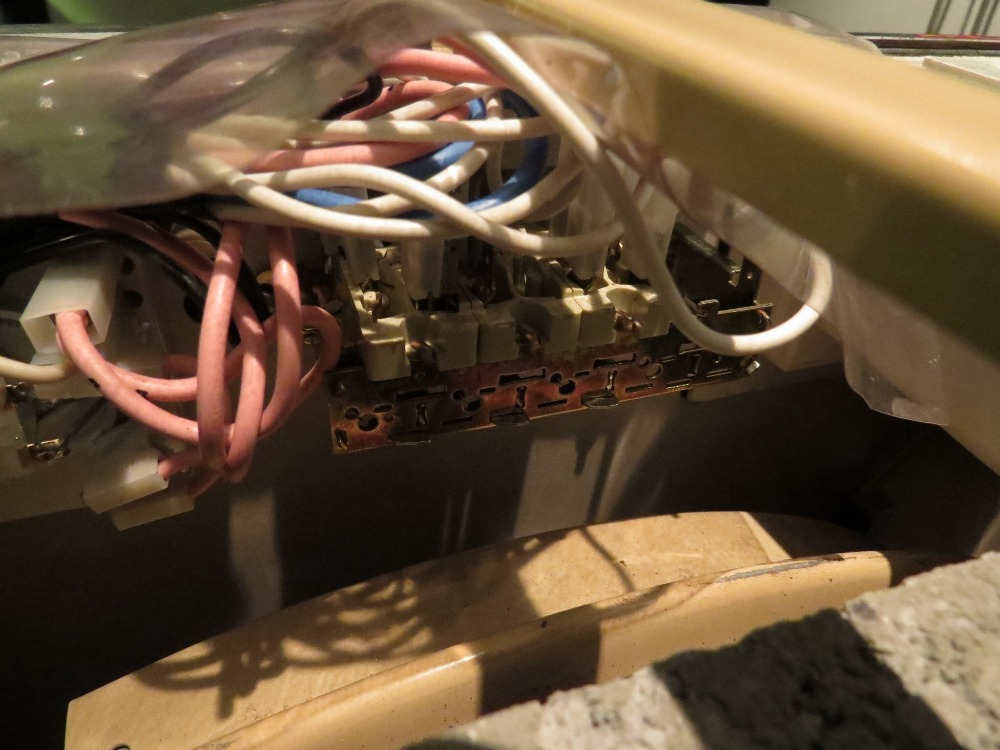

After getting back from the rellies I had a bit of time today to work off some of the Christmas overeating and tackle the motor. I wasn't looking forward to it but it turned out to be much easier than I expected. I followed Mathew's instructions and didn't need to remove the coil. I used spare wiring from some Hoovermatic parts I have and used some heat shrink tubing and solder. Here's a pic of the wiring released before I renewed the wires

| ||

| Post# 723223 , Reply# 56 12/26/2013 at 16:19 (3,763 days old) by sesteve (London, UK) | ||

| ||

| Post# 723225 , Reply# 57 12/26/2013 at 16:29 (3,763 days old) by sesteve (London, UK) | ||

The motor fan does have a crack but is firmly attached to the shaft so should be ok. I popped it back into the machine and did a test. The drum would only rotate clockwise and wouldn't spin either which turned out to be me mixing up two connections. It was difficult to see which colour was which on two of the old wires when I was replacing them as they had discoloured.

Have done a quick test spin and it works a treat doing the on off spin thing for the first few minutes before a constant spin. Will do a full test wash tomorrow and hopefully some videos too. :)

| ||

| Post# 723389 , Reply# 58 12/27/2013 at 13:39 (3,762 days old) by dj-gabriele () | ||

|

Nothing short of amazing! That machine sure is lovely! Plus, I ADORE the fact that is a vented combo! | ||

| Post# 723883 , Reply# 59 12/30/2013 at 12:41 (3,759 days old) by sesteve (London, UK) | ||

I have now done a couple of washes in it and it seems to be working fine. There is a bit of a squeak which I think is coming from the pulley but it doesn't seem too bad. The machine has had a repair carried out as there is a sticker on the side and someone has drawn on the soap drawer. It relates to the switches which now seem to be the opposite of the instructions. Button B has to be pushed in to get the machine to spin!

| ||

| Post# 723884 , Reply# 60 12/30/2013 at 12:48 (3,759 days old) by sesteve (London, UK) | ||

I took the switches out and they are different. The B switch has less terminals than A so not sure what is going on! Impossible to fathom out without a wiring diagram. Paul - if you are able to note the numbers and positions of the connections and let me know that would be fantastic.

Anyway, have made a video of the whole wash cycle which I've shortened and hopefully will be able to upload soon. It shows the unusual spin cycles too. I have tried the dryer and it works well but I really need the vent kit as it fills the house with condensation!

| ||

| Post# 723890 , Reply# 61 12/30/2013 at 13:07 (3,759 days old) by paulc (Edinburgh, Scotland) | ||

| ||

| Post# 723900 , Reply# 62 12/30/2013 at 13:38 (3,759 days old) by sesteve (London, UK) | ||

| ||

| Post# 724770 , Reply# 63 1/3/2014 at 16:41 (3,755 days old) by sesteve (London, UK) | ||

Video

At last. Here is the video of a shortened wash cycle. Not the best quality and 12 mins long. I'll try and improve for the next one!

CLICK HERE TO GO TO sesteve's LINK | ||

| Post# 724778 , Reply# 64 1/3/2014 at 17:00 (3,755 days old) by Hoover1100 (U.K.) | ||

|

Fantastic video That spin is so bizarre! If I didn't know that was normal I would certainly think it was faulty! How dry would you say it gets the clothes compared to other 800 spin machines? Matt | ||

| Post# 724783 , Reply# 65 1/3/2014 at 17:22 (3,755 days old) by sesteve (London, UK) | ||

Hi Matt

It is weird and the motor makes a different noise to any other! The spin is ok but you can see how much more water I got out of the washing in the Spinarinse video I've just posted so would cost a fortune if you just went straight onto the drying cycle not to mention all that condensation if you didn't use a vent kit! S :) | ||

| Post# 724818 , Reply# 66 1/3/2014 at 18:40 (3,755 days old) by OPTIMA (Cumbria England) | ||

Colston | ||

| Post# 724888 , Reply# 67 1/3/2014 at 22:12 (3,755 days old) by paulc (Edinburgh, Scotland) | ||

Thank you...... | ||

| Post# 725148 , Reply# 69 1/5/2014 at 04:37 (3,753 days old) by electron1100 (England) | ||

Chuffed

Steve I am so pleased you got the motor sorted and working, this is a lovely machine to listen too and watch

maybe the suspension needs looking at, but if that was one off bad spin I wouldn't worry, these machines are built to take this sort of action. If it used dampers like the older Hotpoints you might be able to strip them and re-grease them inside I don't know as I have never investigated them. Enjoy enjoy Gary | ||

| Post# 725356 , Reply# 70 1/5/2014 at 18:53 (3,753 days old) by statomatic (France) | ||

Hi and happy new year !

Good job on fixing the motor wiring. When I find an unknown asynchronous motor I make measurements with ohmmeter on all of the possible combinations of the motor terminals and report the measurements on a list like this : 1/2 = 78 Ohms. 1/3 = 87 Ohms. 1/4 = 44 Ohms. 1/5 = 56 Ohms. 2/3 = 78 Ohms. 2/4 = 35 Ohms. 2/5 = 47 Ohms. 3/4 = 44 Ohms. 3/5 = 56 Ohms. 4/5 = 13 Ohms. By deduction it's possible to find how to connect the motor for wash or spin speed: 1 = Low speed (CCW, same as high speed). 2 = High speed (starting winding) 3 = Low speed (CW) 4 = Common (neutral). 5 = High speed (main winding). I did this on 3 or 4 motors I've found. | ||

Post# 725445 , Reply# 71 1/6/2014 at 04:38 (3,752 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Colston Washer Dryer

Congrats Steve, lots of hands on work finally pays off, I do remember the dryer was very effective with the big blower unit, it shifted some air through that back vent!!

I wonder if the vent is the same size as the Hoover in the 80`s model as their vented combo had a similar vent system? Glad you got the motor sorted, they usually last forever apart from the frayed wiring. Look forward to seeing more vids... | ||

| Post# 726999 , Reply# 72 1/11/2014 at 15:58 (3,747 days old) by chanceskydiver (West Linton) | ||

|

That's one machine which is very tasty to see and will be a pleasure to use 😄 Never used one but have seen picture of them in past | ||

| Post# 727460 , Reply# 73 1/13/2014 at 15:01 (3,745 days old) by sesteve (London, UK) | ||

Thanks for the comments guys.

Gary - I'm chuffed too. Didn't think I'd be able to do it so I'm really glad Mathew posted his encouragement or the machine might have just been left in the shed! It has friction damper suspension so it might be a bit worn - I haven't checked it out yet. You can't lubricate this but you are right as the machine doesn't flinch even when it was spinning towels! Mike - you are right. The dryer is very effective so much so that I had to wheel the machine near to the cooker so I could use the cooker hood to extract the air. Not sure how people managed to use it without a vent kit! It's back in the shed for now as I decided to tackle another machine at the weekend. More of that in a bit ...... S :) | ||

Comes to the Rescue!

Comes to the Rescue!