|

Thread Number: 50185

1959 Kenmore - Restoration |

[Down to Last] |

Post# 724128 12/31/2013 at 16:49 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Hey gang!

I know I've been quiet lately, but it doesn't mean I haven't been lurking in the basement, working and tweaking on different appliances hiding down there. In fact, there is SO much down there, that some stuff needs to go! That's where this 1959 Kenmore Eighty comes into play. After bringing home the '59 Lady Kenmore set earlier this year, I don't have a need for TWO 1959 model Kenmore washers, so I made the quick decision that this one had to go. Here she is, back in 2007.

| ||

|

Post# 724129 , Reply# 1 12/31/2013 at 16:50 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724130 , Reply# 2 12/31/2013 at 16:52 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724133 , Reply# 3 12/31/2013 at 16:54 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724134 , Reply# 4 12/31/2013 at 16:56 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724135 , Reply# 5 12/31/2013 at 16:59 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

The first project was to rebuild the basket drive, by installing a new spin tube. I had never taken one of these apart, so I photographed the process.

First, remove the 5/32" set screw.

This post was last edited 12/31/2013 at 20:02 | ||

Post# 724136 , Reply# 6 12/31/2013 at 17:00 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724137 , Reply# 7 12/31/2013 at 17:01 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724138 , Reply# 8 12/31/2013 at 17:03 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724139 , Reply# 9 12/31/2013 at 17:04 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724140 , Reply# 10 12/31/2013 at 17:05 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Now, things are a bit accelerated here, but this is the drive pulley, after being removed from the spin tube. A ring retainer and thrust bearing are removed to free the pulley, but I'll get to that during the re-assembly. Notice the bad scoring of the bearing. This is not a good thing!

The mating area of the spin tube was also in pretty bad shape as well.

This post was last edited 12/31/2013 at 20:03 | ||

Post# 724141 , Reply# 11 12/31/2013 at 17:08 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

I was stuck between a rock and a hard place at this point. I didn't want to re-use the drive pulley with a bad bearing on an NOS spin tube, and I didn't want to use a 1971 and later drive pulley (which I had plenty around) because I wanted to retain the earlier clutch design.

The only logical solution was to source the NLA bearing for the drive pulley. I got lucky and found a place that had two on the shelf. After waiting a week or so for one to arrive, here I am pressing out the old bearing. I used a 2" socket to hold the pulley, and I drove the old bearing out with a 1" socket.

| ||

Post# 724142 , Reply# 12 12/31/2013 at 17:09 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724143 , Reply# 13 12/31/2013 at 17:10 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724144 , Reply# 14 12/31/2013 at 17:12 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724146 , Reply# 15 12/31/2013 at 17:16 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Ok, here is where things were wonky when I took the basket drive apart. It was totally missing the retaining clip and the upper thrust bearing! I suspect that the pulley was floating on the spin tube, and possibly caused the spin tube to lift higher than designed and crushed the T-bearing below. It still amazes me that the washer had a pretty decent sounding spin! I guess you never know the true condition of things until you tear them apart.

Here I've scavenged a retaining clip from another basket drive, but they are available from most fastener and industrial suppliers (1-1/8 size Crescent Retaining Ring, Grainger PN is 5CU51).

This post was last edited 12/31/2013 at 20:04 | ||

Post# 724147 , Reply# 16 12/31/2013 at 17:19 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

The rest of the basket drive assembly is the reverse of the dis-assembly. The only tricky part is getting the set screw lined up with the hole in the spin tube. I used a Sharpy to mark the location of the hole, which allowed me to line things up using the reference point.

Here is the replacement transmission and rebuilt basket drive assembly, all ready to go! I used a 1978 and later transmission. John mentioned that these are good donors as the agitator shaft wears at a much lower point than the earlier ones, making them good donors for 1977 and earlier standard capacity machines. I also used the later white plastic T-bearing, in place of the broken bronze one.

| ||

Post# 724149 , Reply# 17 12/31/2013 at 17:20 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724150 , Reply# 18 12/31/2013 at 17:21 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

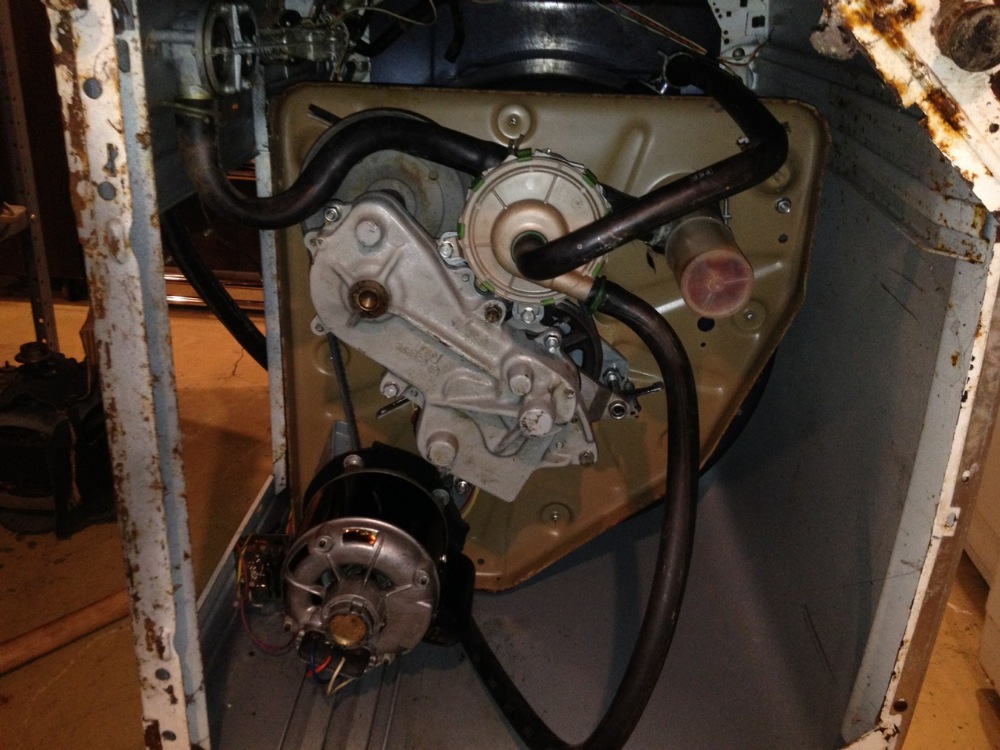

After swapping in the replacement base plate, the new transmission was ready to go in. Notice I upgraded the plumbing by installing a 1961 and later drain trap. A new 4 port pump was also installed, along with a new belt.

The motor pulley was seized on the shaft, denying access to the centrifugal switch, but I was able to lubricate the bearings.

This post was last edited 12/31/2013 at 20:06 | ||

Post# 724151 , Reply# 19 12/31/2013 at 17:23 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Here she is, ready for the wash tub to be installed.

I had broken the plastic dome in the hose dome assembly. Thankfully I found a supplier that still had one the shelf. After doing some research, it seems that they changed to the all plastic dome assembly in 1969.

This post was last edited 12/31/2013 at 19:34 | ||

Post# 724152 , Reply# 20 12/31/2013 at 17:25 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724153 , Reply# 21 12/31/2013 at 17:26 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724154 , Reply# 22 12/31/2013 at 17:27 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724155 , Reply# 23 12/31/2013 at 17:29 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724156 , Reply# 24 12/31/2013 at 17:30 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

AND.... I threw together a film. Enjoy!

It might be one of the quietest, non Quiet-Pak, belt drive Whirlpool/Kenmore washers I've heard. It's not quite 1080p HD, but it should look great at 720p. This post was last edited 12/31/2013 at 20:07 | ||

Post# 724157 , Reply# 25 12/31/2013 at 17:31 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724159 , Reply# 26 12/31/2013 at 17:33 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724167 , Reply# 27 12/31/2013 at 18:28 (3,761 days old) by Kenmoreguy64  (Charlotte, NC) (Charlotte, NC) |

||

GREAT job Ben, it really looks as though you have all the bases covered here for lots of service to come from this machine.

Using a 1978 and newer gearcase in a pre-1978 machine really is an excellent thing to do. Not only is the agitator shaft essentially all-new where it counts when swapped this way, it allows parts to be re-used which otherwise can be questionable when used again in a post 1978 machine (those grooves on the shaft can prematurely wear-down new seals if the seal winds up in the same or nearly same spot). Agitator shafts are getting hard to find, so this is a great way to recycle them without using NOS parts. Great score on the NOS filter - it realy jazzes up the appearance of the machine. Question - was that an original metal pump? I'm surprised it survived all this time in the machine, but probably well past time for the new one. I can't see from the pics, but if the pump bolts don't have the washers with them, you'll want to add them. For some time in the 70s and 80s, WP/FSP was including two washers to be added to original bolts with their new pumps in case they were used in original metal bodied installations. The plastic pump needs these washers to be fully secure when installed. Someone will surely be glad to acquire this great machine for their collection. It looks ready to wash up the great un-washed! Gordon | ||

Post# 724182 , Reply# 28 12/31/2013 at 20:12 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Hey Gordon, I was hoping you'd chime in. Yes, I love the idea of recycling later transmissions on earlier machines, and visa versa (if needed). I also liked the idea of having a transmission that was full of honey-looking oil, and it also has a tight agitator shaft seal. No leaks!

Thanks for the tip on the pump bolts. I used the pump bolts from the '78 and later trans as I do recall the washers on the bolts. I was shocked to see the metal pump still in use. When I first got this machine the pump was working fine, and worked even back in 2011 when I filmed the 'Pissy Kenmore' clip. But, it was frozen solid when I tore the machine apart. I may take it apart and see if I can free it up and throw a new seal in it. Or maybe it will just collect dust in the parts bin. :) You know I'm a Maytag guy, but I've got to admit, I do like working on these washers. They are a lot of fun! Ben | ||

| Post# 724183 , Reply# 29 12/31/2013 at 20:14 (3,761 days old) by hippiedoll ( arizona ) | ||

you did an amazing job!!! | ||

Post# 724214 , Reply# 31 1/1/2014 at 00:54 (3,761 days old) by abcomatic  (Bradford, Illinois) (Bradford, Illinois) |

||

|

Wow Ben, I am so impressed. Gary | ||

| Post# 724224 , Reply# 32 1/1/2014 at 02:54 (3,761 days old) by toploader55 (Massachusetts Sand Bar, Cape Cod) | ||

As always Ben | ||

Post# 724238 , Reply# 33 1/1/2014 at 04:46 (3,761 days old) by goatfarmer  (South Bend, home of Champions) (South Bend, home of Champions) |

||

| ||

| Post# 724240 , Reply# 34 1/1/2014 at 05:01 (3,761 days old) by alr2903 (TN) | ||

|

Ben, as always a beautiful restoration job. Thank You for posting. Happy New Year! | ||

Post# 724245 , Reply# 35 1/1/2014 at 06:12 (3,761 days old) by peteski50  (New York) (New York) |

||

Kenmore! | ||

Post# 724258 , Reply# 36 1/1/2014 at 08:11 (3,761 days old) by Frigilux  (The Minnesota Prairie) (The Minnesota Prairie) |

||

A standing ovation for you from the frozen prairie of Minnesota, Ben! What a beautiful machine.

I haven't the skills or patience to perform such a wonderful transformation, so the sequential photos and explanations are fascinating. I once took these old Kenmores for granted (having grown up with a 1960 Model 80 while enduring a severe case of Frigidaire envy), but they now hold a very soft spot in my heart. Two questions and a comment: 1) The photo at the top of the thread shows the lid reversed (handle on left; opening to the right), while the post-repair photos show the lid in its standard position (handle on right; opening to the left). Did you acquire the machine with the lid reversed? 2) The lint filter shown is the same as on our Model 80, though it was my understanding machines prior to that had a filter with two cylindrical "bottle brushes" attached to chrome front-piece. Was the original filter one of those, or did it also sport the wraparound metal screen? 3) You mentioned the '59s were the last tubs to have four rows of holes at the bottom. I'm 99% sure our 1960 had four rows, as well. However, I had custody of a '59 LK for a year, so perhaps that's what I'm remembering. Calling Gordon: Can you clarify this for us? | ||

Post# 724287 , Reply# 37 1/1/2014 at 11:15 (3,761 days old) by Yogitunes  (New Jersey) (New Jersey) |

||

| ||

Post# 724294 , Reply# 38 1/1/2014 at 11:51 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Thanks for the kind comments everyone!

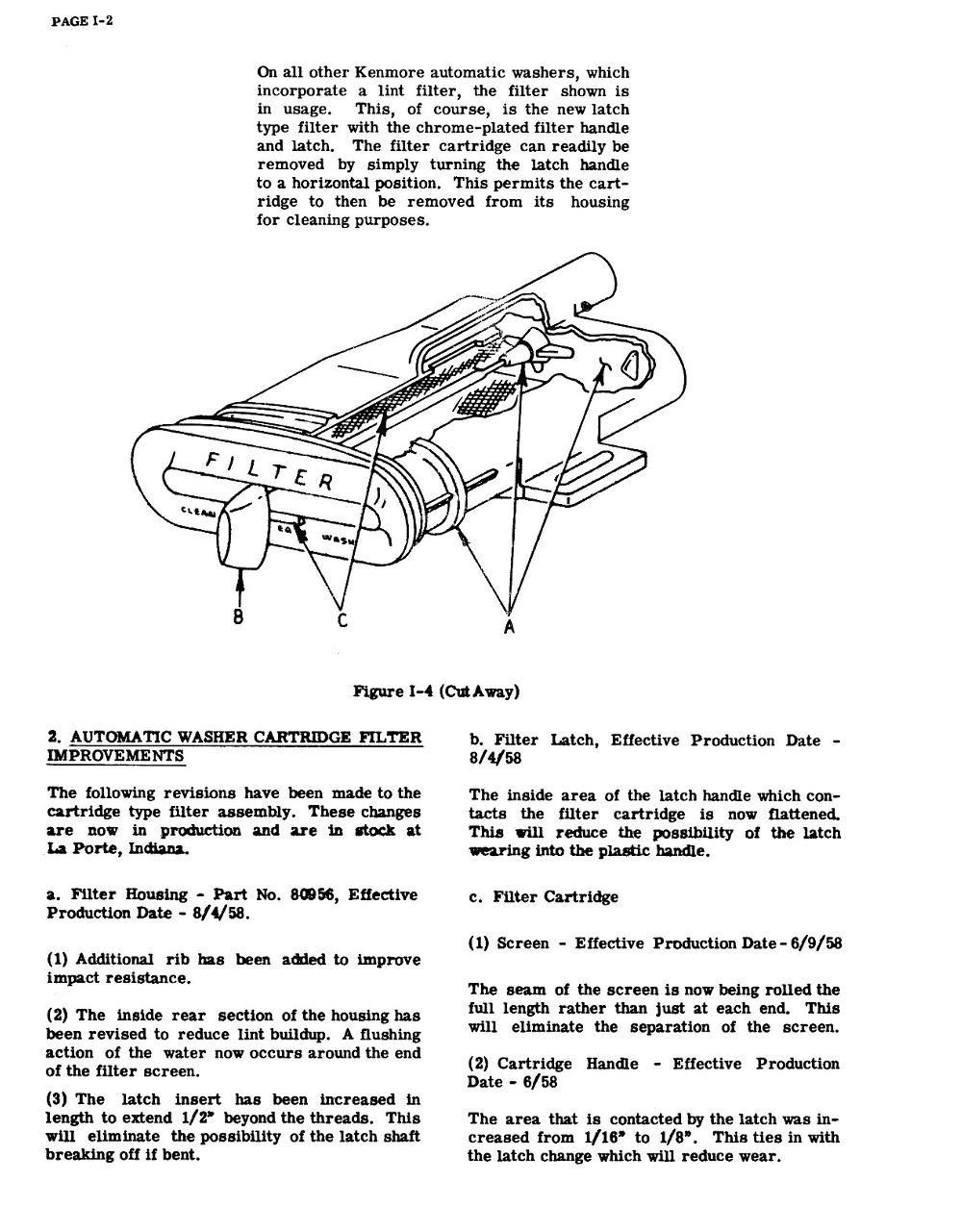

The cycle selector can be rotated in both directions. Once you've picked the cycle you want, you pull the timer dial out, turn the dial clockwise until it mechanically locks in the cycle, then push in to start the wash. The dispenser is for fabric softener. Whirlpool could have done a better job designing the reinforcement for the dispenser, as this one has cracked up quite a bit. With the cabinet changes in 1961, it was much easier for them to suspend a reservoir in this corner. I did acquire the washer with the lid reversed. I believe one of the former owners was a member, and they mentioned their preference for the reversed lid. I personally couldn't stand it, LOL. The washer came with what I think was an early style lint filter cartridge. The mesh for the filter was a flexible material, where the later ones are stamped stainless steel. The later versions are much easier to clean. I've attached two pages from the Kenmore manual, discussing the changes to the chrome filter. My reference for the 4 holed tubs goes to a response from Robert years ago. They may have used up some of the stock in '60, or maybe they made the change when they changed the cabinets in 1961. Anyone else out there have a pretty original 1960 Kenmore? Ben

| ||

Post# 724295 , Reply# 39 1/1/2014 at 11:51 (3,761 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 724356 , Reply# 40 1/1/2014 at 17:39 (3,760 days old) by jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Wow Ben | ||

| Post# 724385 , Reply# 41 1/1/2014 at 19:24 (3,760 days old) by mrb627 (Buford, GA) | ||

Sweet Machine  | ||

Post# 724430 , Reply# 42 1/2/2014 at 00:45 (3,760 days old) by jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

I love the 4 hole tubs | ||

Post# 724484 , Reply# 43 1/2/2014 at 09:12 (3,760 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

59 KM Washer Restoration

Great job Ben, it would seem like you have done this many times before.

It ia always fun to do a something like this because you always see something new, in all my years I have never seen a broken Tee Bearing, I have seen the clutch pulley retainer clip missing many times however. When the new bearings are pressed into the cast iron pulleys there is a grove behind the bearing that can be filled with lubebrcant. Someone will get lots of use out of this washer, hope you have fun using it. I am out in Ohio and going to be heading to Minasota the next two days, it is cold and snowing. Yesterday Bob and I spent all day taking pictures of parts and machines at his shop, when I get back I am going to post lots of pictures of stuff he wants to sell or just get rid of. Happy New Year to all, sorry about the spelling, I am using the oldest coumpter I have seen in years and it does not seem to have spell check, LOL. John. | ||

Post# 724518 , Reply# 44 1/2/2014 at 12:11 (3,760 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Jon, you are right about the whistling. Not only does this tub have the four rows of holes along the bottom of the tub, but it also is an early tub that has large holes along the top of the tub. It makes a pretty impressive sound when the top is off! I used some OLD Sears Ultra Plus that I had sitting around, knowing that I wanted to showcase the agitation action, rather than a tub full of suds. However, I don't think Ultra Plus ages gracefully as there were flecks of white granules left on the clothes after using it in a few loads.

Malcolm, all the major wear items like bearings/spin tube/agitator shaft are either brand new or were in pristine shape. I did re-seat the motor mounts and made sure to not over tighten the four mounting bolts after cleaning and lubricating the motor. The rubber insulators are doing their job. John, thanks for your stamp of approval! I've torn down at least a dozen, if not more, belt drives over the years. I had the privilege of restoring Don's '59 and '65 Kenmores over the last few years, which helped put all the tear down experience and manual reading to good use. I also have learned a lot from Gordon and yourself, as well as studying Robert's '57 rebuild time and time again. I do like working on Whirlpool/Kenmore belt-drives and wouldn't hesitate on restoring another one. You are right about their being grooves in the spin pulley. The grease in the pulley looked sufficient for pressing in a new bearing so I didn't bother packing more into the grooves. Safe travels as you trek to Minnesota, and I'm looking forward to seeing what Bob might be interested selling. Ben This post was last edited 01/02/2014 at 14:16 | ||

Post# 724567 , Reply# 45 1/2/2014 at 17:04 (3,759 days old) by mayfan69  (Brisbane Queensland Australia) (Brisbane Queensland Australia) |

||

Looks fantastic Ben | ||

Post# 724597 , Reply# 46 1/2/2014 at 19:44 (3,759 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

| ||

Post# 724631 , Reply# 47 1/2/2014 at 21:40 (3,759 days old) by jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

oooo ooooo  | ||

| Post# 724646 , Reply# 48 1/2/2014 at 23:41 (3,759 days old) by 70series ( Connecticut.) | ||

|

Fantastic job Ben on restoring this beautiful Lady. I remember the video you had posted in 2007. Best of luck in finding her a good and worthy home. Have a good one, James | ||

Post# 724698 , Reply# 49 1/3/2014 at 09:13 (3,759 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Wash 'N Wear cool down sequence

A few weeks ago, Mark (kenmore71) had posted the Perm Press booklet from Whirlpool, and also posted a video of his 1970 Kenmore's cool down cycle. It dawned on me after watching it that I had never seen the first generation of cool down sequence.

Last night I threw 6 button up shirts in the '59 Kenmore, and recorded the 1st Generation of the cool down sequence, used between 1958 and 1963. I've included both videos for comparison. Enjoy. | ||

Post# 724702 , Reply# 50 1/3/2014 at 09:56 (3,759 days old) by Revvinkevin  (Tinseltown - Shakey Town - La-La Land) (Tinseltown - Shakey Town - La-La Land) |

||

|

| ||

| Post# 724705 , Reply# 51 1/3/2014 at 10:18 (3,759 days old) by washman (o) | ||

|

Marvelous Job well done! | ||

| Post# 724706 , Reply# 52 1/3/2014 at 10:20 (3,759 days old) by ken (NYS) | ||

Cool Down Cycle Questions | ||

Post# 724707 , Reply# 53 1/3/2014 at 10:27 (3,759 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Ken - take a moment to read through the link below. It provides a nice explanation of Permanent Press/Wash 'N Wear items and the special treatment required.

CLICK HERE TO GO TO swestoyz's LINK | ||

| Post# 724709 , Reply# 54 1/3/2014 at 10:56 (3,759 days old) by ken (NYS) | ||

| ||

| Post# 724749 , Reply# 55 1/3/2014 at 14:17 (3,758 days old) by mrb627 (Buford, GA) | ||

WOW | ||

Post# 724761 , Reply# 56 1/3/2014 at 15:36 (3,758 days old) by Frigilux  (The Minnesota Prairie) (The Minnesota Prairie) |

||

Our 1960 Model 80 had the identical cool-down process. Mom wouldn't use the Wash 'n' Wear cycles because she thought the cool-down process was actually a malfunction. It really does use a lot of water to accomplish its goal. I far prefer the later method that used agitation to distribute the cold water throughout the tub, ultimately using less water for the cool-down.

If you choose the 'Sturdy' W'n'W cycle with its medium wash temp (between hot and warm) the water opposite the fill flume didn't get as cool as other areas of the tub. The 8-minute wash consisted of 4 minutes of fast agitation followed by 4 minutes of slow, which was cool. Thanks for posting this, Ben. Many here have probably never seen the original version of the cool-down process. This post was last edited 01/03/2014 at 17:50 | ||

| Post# 724771 , Reply# 57 1/3/2014 at 16:42 (3,758 days old) by boboh1 (California) | ||

|

Very Nice This would be a great match for my 1961 Kenmore dryer.I will be looking for the post when this is for sale. | ||

Post# 724908 , Reply# 58 1/3/2014 at 23:36 (3,758 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

WnW Cool Down Squence

Ben thanks for posting the cool down operation of the 59 KM you just rebuilt this brought back memories of the 59 LKM my brothers and I rebuilt back in 1967. Our family used that washer for several years and it did a great job on permanent press shirts etc.

This earlier WnW cycle worked as well as the later agitated but used a lot more water, I would estimate that a Non-Suds machine will use between 20-30 gallons in the cool-down period, the suds-saver machines used about 25% less water due to the restriction the two-way valve places on the water being pumped from the machine. It would be really interesting Ben if you could measure the amount of water your machine uses for the Cool-Down sometime, Thanks John. | ||

| Post# 724910 , Reply# 59 1/4/2014 at 00:49 (3,758 days old) by barcoboy (Canada) | ||

Very interesting 1st Gen Permanent Press... thanks for posting!

One thing I noticed is that at the 8:43 mark of the first video, as the first spin is being engaged, the timer switches the motor from fast to slow without there being any break between the two speeds. That is the first time I've seen a speed change on a Kenmore without there being a 1/2 to 1 second electrical break between speeds. Is that normal with the older machines, or just specific to this timer interval or even possibly a one time random occurrence? I noticed the shift from slow to fast at the start of the cool down drain has the pause. | ||

Post# 725038 , Reply# 60 1/4/2014 at 14:46 (3,757 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

John - one of these days I'd like to rig up a flow meter to both the hot and cold taps of my future washer area. Then it would be easy to take measurements of water usage by cycle, machine, etc. But for now, I can only wish.

Todd - the washer switches to a full speed drain in the same fashion during the delicate cycles as well. I suspect the behavior relates to the timer design. Ben | ||

| Post# 725070 , Reply# 61 1/4/2014 at 17:42 (3,757 days old) by in2itdood () | ||

|

WOW! Ben !!! I'll be watching that shoppers square for sure. What a beauty! I love a good Kenmore =). | ||

| Post# 725088 , Reply# 62 1/4/2014 at 19:18 (3,757 days old) by mrb627 (Buford, GA) | ||

Cold Water Wash | ||

Post# 725092 , Reply# 63 1/4/2014 at 19:33 (3,757 days old) by Frigilux  (The Minnesota Prairie) (The Minnesota Prairie) |

||

| ||

Post# 725095 , Reply# 64 1/4/2014 at 19:39 (3,757 days old) by jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Our 1970 Imperial did  | ||

Post# 725099 , Reply# 65 1/4/2014 at 19:42 (3,757 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

| ||

| Post# 725109 , Reply# 66 1/4/2014 at 20:14 (3,757 days old) by mrb627 (Buford, GA) | ||

Awesome | ||

Post# 725158 , Reply# 67 1/5/2014 at 06:51 (3,757 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 728356 , Reply# 69 1/17/2014 at 18:19 (3,744 days old) by Frigilux  (The Minnesota Prairie) (The Minnesota Prairie) |

||

Jim-- The term is actually "preggers," as in pregnant, because it's so fat compared to later, slimmer Super Roto Swirl agitators.

I've often thought we should start an AW Terminology Thread, as acronyms like TOL, MIL, BOL, NIB, NOS, and terms such as Shredmore, BobLoad, Fraudgidaire, and Daily Driver might not mean much to the uninitiated.

:-) | ||

Post# 728435 , Reply# 70 1/18/2014 at 01:16 (3,744 days old) by jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Good Idea  | ||

| Post# 728685 , Reply# 72 1/19/2014 at 07:03 (3,743 days old) by in2itdood () | ||

|

A suds saver? Did I see "suds" on the master dial? In the words of George Takei ...OHHHH MYYYYY! | ||

Post# 764948 , Reply# 73 6/21/2014 at 12:26 (3,590 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

A pull from the archives The Kenmore is now for sale. Take a stroll over to Shoppers Square to take a look!

Ben CLICK HERE TO GO TO swestoyz's LINK | ||

| Post# 765163 , Reply# 74 6/22/2014 at 09:04 (3,589 days old) by kenmoreguy89 (Valenza Piemonte, Italy- Soon to be US immigrant.) | ||

| ||

Post# 765179 , Reply# 75 6/22/2014 at 09:29 (3,589 days old) by Frigilux  (The Minnesota Prairie) (The Minnesota Prairie) |

||

Gotta admire that washer! I see you also figured out that if you turn the agitator so the "K" on the cap is at about 4:00, it will line up perfectly when agitation begins. Used to do that all the time with our 1960 Model 80 because it looked so cool.

The dispenser also triggers memories. The one on our 1960 was for both bleach and fabric softener, depending on which way the lid was turned. If you were the right height (which I was back then) you could look through the gap between the top and the cabinet and watch the plungers lift up and dispense their contents---conveniently lit by the tub light. Boy howdy, that is one quiet machine. Excellent work and thanks for the new video footage. Soundtrack: I love, love, love pre-rock 'n' roll songs like 'Sixty-Minute Man'. It is nestled right before 'Mr. Fine' by Mable Scott on the oldies playlist on my iPod. In fact, I dare say Mr. Fine should become one of the mascot songs of AW. This post was last edited 06/22/2014 at 12:42 | ||

Post# 765213 , Reply# 76 6/22/2014 at 12:32 (3,589 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Comes to the Rescue!

Comes to the Rescue!