|

Thread Number: 51238

1968 Frigidiare Custom Imperial (Restoration) |

[Down to Last] |

Post# 736151 2/18/2014 at 19:18 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

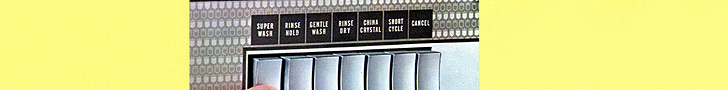

After a long break from working on washers I felt ready to take the plunge again. Here we have a beautiful 1968 WCIL gifted to me by a fellow club member. I am working on issues that need addressing slowly as I have time and I will detail my efforts here as they develop, which should be over the next few months.

If you will notice the control panel has a turquoise tint to the light. There are no trick shadows here as I ordered and wrapped the fluorescent tube in a turquoise gel.

| ||

|

Post# 736152 , Reply# 1 2/18/2014 at 19:20 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 736153 , Reply# 2 2/18/2014 at 19:21 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 736154 , Reply# 3 2/18/2014 at 19:23 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

Got the top off, sealing the balance ring plug and cleaning the tubs. Notice the grey upper cone transplanted at some point from a coin op machine. I can change it to a blue one but I like this hybrid setup so I'll be keeping it and add a new blue cap to the top.

This post was last edited 02/18/2014 at 19:43 | ||

Post# 736157 , Reply# 4 2/18/2014 at 19:25 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 736158 , Reply# 5 2/18/2014 at 19:27 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

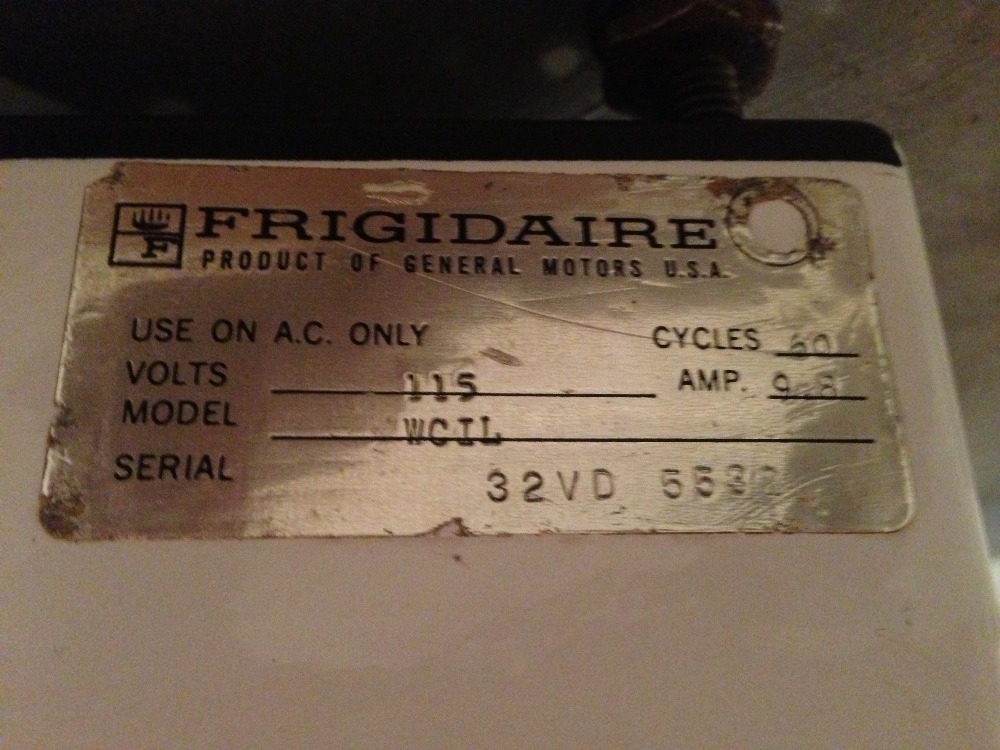

At this point our top side has been finished and reassembled, there are still a few small cosmetic issues to attend to later on. Now we'll move on to bigger things. Ben this photo is for you and I soon hope to get you my other tags for your database.

This post was last edited 02/18/2014 at 19:44 | ||

Post# 736160 , Reply# 6 2/18/2014 at 19:30 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 736161 , Reply# 7 2/18/2014 at 19:30 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 736162 , Reply# 8 2/18/2014 at 19:32 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

| Post# 736164 , Reply# 9 2/18/2014 at 19:34 (3,718 days old) by cornutt (Huntsville, AL USA) | ||

|

Nice work If I have my Frigidaire lore straight, this model is a Rollermatic, is it not? | ||

Post# 736165 , Reply# 10 2/18/2014 at 19:34 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 736166 , Reply# 11 2/18/2014 at 19:36 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 736168 , Reply# 12 2/18/2014 at 19:38 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 736169 , Reply# 13 2/18/2014 at 19:39 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 736171 , Reply# 14 2/18/2014 at 19:41 (3,718 days old) by joelippard  (Hickory) (Hickory) |

||

The end of the road for now. Here is the mechanism removed. I have removed the bearing and will source a new one soon. Then the total reassembly process can begin. I'm hoping this will resolve all issues and I will not need to reopen the top of the machine. I'll keep posting photos and updates over the next few weeks.

| ||

| Post# 736190 , Reply# 16 2/18/2014 at 21:18 (3,718 days old) by PhilR (Quebec Canada) | ||

| ||

| Post# 736207 , Reply# 17 2/18/2014 at 22:16 (3,717 days old) by norgeway (mocksville n c ) | ||

|

Mothers cousin.. Had these when I was a kid, they were truly wonderful, beyond compare in my book!! | ||

Post# 736248 , Reply# 18 2/19/2014 at 05:32 (3,717 days old) by Frigilux  (The Minnesota Prairie) (The Minnesota Prairie) |

||

| ||

Post# 736323 , Reply# 19 2/19/2014 at 11:12 (3,717 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

| Post# 736332 , Reply# 20 2/19/2014 at 11:47 (3,717 days old) by PhilR (Quebec Canada) | ||

| ||

Post# 736579 , Reply# 21 2/20/2014 at 16:49 (3,716 days old) by joelippard  (Hickory) (Hickory) |

||

Back at it. Here is today's work, a partial reinstall of the mechanism and wiring. New gasket cut for pump and new seals in place. Having trouble sourcing a bearing, Grainger ordered one but the outer diameter was wrong, went to a local bearing shop and they gave me what they thought would work, said it may be a little tight. Well the tolerances on this don't allow for anything even remotely too small on the inner diameter. I'll be going back to visit them tomorrow. Suggestions from people who have done this before or who know a lot more than me are certainly appreciated and respected as I navigate this process.

| ||

| Post# 736581 , Reply# 22 2/20/2014 at 17:00 (3,716 days old) by retromania (Anderson, South Carolina) | ||

|

Love the washer! | ||

Post# 736626 , Reply# 23 2/20/2014 at 19:02 (3,716 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 736634 , Reply# 24 2/20/2014 at 19:35 (3,716 days old) by joelippard  (Hickory) (Hickory) |

||

Hi Ben, On each side it simply says NICE PHILA USA I would assume this is the NICE bearing company in Philadelphia. I don't imagine it's standard either. Grainger said they probably could get it but to try Bearing Distributors. I mentioned to them having a new one made custom, I also considered that it could be rebuilt. | ||

Post# 736640 , Reply# 25 2/20/2014 at 19:51 (3,716 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 736647 , Reply# 26 2/20/2014 at 20:08 (3,716 days old) by ovrphil  (N.Atlanta / Georgia ) (N.Atlanta / Georgia ) |

||

Photo breakout excellent and re: Reply #18 | ||

Post# 736648 , Reply# 27 2/20/2014 at 20:14 (3,716 days old) by joelippard  (Hickory) (Hickory) |

||

Ben, they did measure it with calipers but I don't have those numbers, they say the outer is metric. Grainger did get one in with the proper inner diameter. I suppose if it came down to it I could make a surround to compensate but with this being a rapidry machine that bearing is going to get a workout.

Thanks ovrphil for the compliments. I am purposely being detailed about this for the forum archives, hopefully someone else will be helped by it someday. | ||

Post# 736650 , Reply# 28 2/20/2014 at 20:21 (3,716 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Joe - your findings are similar to what Phil mentioned to me in a PM. He said that the outer diameter was metric but the bore diameter was a standard size. Odd that GM would spec a bearing that could have been easily fitted in a casing that could have been sized accordingly.

Did you grab the PN/SKU of the bearing that Grainger originally sold you? Phil had found a possible replacement with an NDH number of 77504CJ. If you drop the CJ that crosses to a 6204ZZ, but we'd still need to know what the sizes are to see if something matches up.

EDIT - the 6204ZZ translates into a 20MM bore/ID, x 47MM outer diameter, and a 14MM Width, double shielded. Grainger PN for the shielded for NTN is a 1L017, and the sealed version was a 6L026. I'm wondering how far off the original outer diameter is from 47MM.

Ben This post was last edited 02/20/2014 at 20:37 | ||

Post# 736659 , Reply# 29 2/20/2014 at 21:10 (3,716 days old) by joelippard  (Hickory) (Hickory) |

||

Ben, here is a link to what they got in. I never bought it from them. I paid the local bearing shop $3 for the one they sold me but the bore is definitely not correct. CLICK HERE TO GO TO joelippard's LINK | ||

Post# 736662 , Reply# 30 2/20/2014 at 21:15 (3,716 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Ok, that's a start. The 5u498 has a 20MM bore, so we know that's good. The outer diameter lists at 42MM, vs. the 47MM we saw from the possible cross Phil found. Also, the width is slightly smaller at 12MM, vs 14MM.

If you have a metric ruler on hand, you could get a rough estimate of both the outer diameter and the width. | ||

Post# 736663 , Reply# 31 2/20/2014 at 21:21 (3,716 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 736665 , Reply# 32 2/20/2014 at 21:26 (3,716 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

After going through the Rollermatic parts stash... ... I found an NOS 7524183 bearing! We can confirm finally that the number Phil saw on his box is probably the correct number - the New Departure number of 77504CJ.

I measured the bearing and came out really close to the measurements from the cross reference bearing number - the 6204ZZ.

www.vxb.com/page/bearings/PROD/62...

With a cheap metric ruler, I measured out a 20 MM bore, 14MM width, and what looked to be a 46 or 47MM outer diameter. The Grainger 1L017 or 6L026 should be really close.

Ben CLICK HERE TO GO TO swestoyz's LINK

| ||

Post# 736668 , Reply# 33 2/20/2014 at 21:33 (3,716 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

| Post# 736702 , Reply# 34 2/21/2014 at 00:40 (3,715 days old) by PhilR (Quebec Canada) | ||

Let me know if that works, I'll order some spares too!

Edit: I just checked the metric dimensions on mine with a cheap electronic caliper (a bad bearing removed from a machine in a new Delco NDH bearing box) and the inside diameter is 20.64 mm, the outside diameter is 47.00 mm and width is 13.99mm. The 20.64 translates into 0.8125" or 13/16"... On the box, there is the Frigidaire part number: 7524183, 1# 77504CJ and "XY1343 C" This post was last edited 02/21/2014 at 02:07 | ||

| Post# 736707 , Reply# 35 2/21/2014 at 01:25 (3,715 days old) by PhilR (Quebec Canada) | ||

My bearing is from a Canadian-made Rollermatic machine and it says: "SKF MADE IN CANADA" and the numbers are really hard to read but it seems to be written "K7004J9".

There's no way to fit a 20mm I.D. bearing on that shaft. The place who sold me the wrong replacement bearing suggested that I have the shaft machined to fit that smaller I.D. bearing they sold me but I showed them the shaft and they understood I couldn't do that! Then I asked if it was possible to have the I.D. Of the bearing bored out to 13/16" and they told me it wouldn't be good... So I had the used bearing back in place and just replaced the upper Torrington bearing which was bad. BTW, Joe, can you show a picture of the old upper spin bearing you have on your washer? This post was last edited 02/21/2014 at 01:53 | ||

| Post# 736760 , Reply# 36 2/21/2014 at 07:59 (3,715 days old) by Lightedcontrols () | ||

|

Grasshopper.... ...I remember the day when you were so afraid of these machines and now you're an expert! Very proud of you!!! | ||

Post# 736762 , Reply# 37 2/21/2014 at 08:06 (3,715 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

I have a spare '66 2 speed Rollermatic transmission sitting around. This weekend I'll tear it apart, pull the bearing, and compare the original (bad) one to the NOS replacement I have, and take some measurements.

I find it odd that the ND 77504 NOS replacement crosses to an industry standard number that has a bore too small. I should note that all Rollermatics from 64-69 used the same 7524183 lower shaft bearing.

Ben

This post was last edited 02/21/2014 at 08:37 | ||

Post# 736770 , Reply# 38 2/21/2014 at 09:07 (3,715 days old) by bajaespuma  (Connecticut) (Connecticut) |

||

| ||

Post# 736793 , Reply# 39 2/21/2014 at 11:35 (3,715 days old) by joelippard  (Hickory) (Hickory) |

||

Phil, does this mean that what I have ordered will not work? I don't have the top side of the machine opened to get a picture of the top bearing because it doesn't seem to be the problem. I'll have to see how things are up top after I complete the bottom end work.

Ben, thanks for checking into that man, you've gone out of your way to be helpful to me. Thank you!

Mark, I remember those days too! I have no fear of any Frigidaire now but I will say that pulsator nuts and water bellows never seem to be my friend! | ||

Post# 736870 , Reply# 40 2/21/2014 at 20:36 (3,715 days old) by joelippard  (Hickory) (Hickory) |

||

Another thought If I can't locate something that works I got the notion this afternoon that I could replace the inner workings of the bearing with good parts from a new bearing that is within a few mm of the proper size. I can't imagine it would be that huge of a difference in the ball/holder size versus the inner bore size. | ||

| Post# 736900 , Reply# 41 2/21/2014 at 23:26 (3,714 days old) by PhilR (Quebec Canada) | ||

I'm not a bearing specialist (Ben certainly knows much more about that!) but maybe a 7/8" (22.23mm) x 47mm x 14mm bearing would work if you could have a sleeve to widen the shaft from 20.64 to 22.23mm

CLICK HERE TO GO TO PhilR's LINK | ||

| Post# 736901 , Reply# 42 2/21/2014 at 23:27 (3,714 days old) by PhilR (Quebec Canada) | ||

| ||

| Post# 736902 , Reply# 43 2/21/2014 at 23:28 (3,714 days old) by PhilR (Quebec Canada) | ||

If it ain't too expensive, I'd order a few myself!

Another link from the same site

I sent them an email with a request and I copied it to Ben and Joe. CLICK HERE TO GO TO PhilR's LINK This post was last edited 02/21/2014 at 23:57 | ||

Post# 736951 , Reply# 44 2/22/2014 at 07:28 (3,714 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 737015 , Reply# 45 2/22/2014 at 16:25 (3,714 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

I wish I had better news. I bought a digital caliper today to measure both the NOS 7524183 bearing and the shaft in the transmission.

In terms of the bearing, I got pretty much the same measurements as Phil. There's no need for me to tear apart the spare transmission at this point.

It seems GM used a 13/16" spin shaft and machined the bearing housing to standard metric specifications. I suspect they couldn't go with the standard metric bore sizes of either 20MM or 22MM, as they had make sure the pulsator shaft bearing had enough material to be effective (not too small), as well as fitting into a fairly tight space in terms of the housing (not too big).

My buddy at work took a look at the Bearing Interchange and mentioned that the ND 77504CJ had several bore sizes available, as well as the standard 20MM. The CJ references the type of lubrication inside the bearing, MIL-G-23827 grease. He didn't respond back with the other sizes he saw in the interchange besides saying there wasn't a 22.64MM, but it wouldn't surprise me if one was indeed 13/16"/20.6375MM.

From the looking around I've done it seems that no one makes a 13/16" bore radial bearing. If you step up to 7/8", there are a few out there that are slightly over-sized on the outer diameter, and short on the width. (Grainger 1L008, 7/8" x 47.625MM x 13.00MM). But even then, you'd need to find a way to bush the shaft, and get the larger bearing into the housing.

There is a good chance that a bearing would need to be custom made, or maybe a shop out there can take the old one apart, clean it up, and reassemble it. The problem is the shields are usually toast once you take them off.

Ben

| ||

Post# 737026 , Reply# 46 2/22/2014 at 17:08 (3,714 days old) by joelippard  (Hickory) (Hickory) |

||

Ben, thanks so much for the updated information. I'm committed to making this work somehow and I'm not above trying anything. Just for the heck of it I'm going to see if I can transplant the innards of a 47X20mm into the casing of the original and see what I've got after reassembly. I can't see that I've lost anything in trying. | ||

| Post# 737031 , Reply# 47 2/22/2014 at 18:14 (3,714 days old) by rickr (.) | ||

| ||

Post# 737059 , Reply# 48 2/22/2014 at 21:19 (3,714 days old) by joelippard  (Hickory) (Hickory) |

||

Hey Rick, the problem is not the housing but rather the sizing on the inner bore. Most bearings are standardized at 20mm, this one is 20.6. That .6mm makes enough difference since the spin shaft has those threads on the end, that prevents you from pounding a bearing up over there because you would damage the threads. I'm going to see how this bearing I have ordered works out and if necessary I'll rebuild the original bearing. I've done some reading on the subject and feel that I'm savy enough to do so. We'll see just how clever I can be ;) | ||

Post# 737134 , Reply# 49 2/23/2014 at 09:33 (3,713 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Thoughts On Finding a Bearing To Fit Your washer

Hi Joe, I am sure that you have looked for a NOS Frigidaire bearing, but I would continue on that coerce it always seems that I can find mechanical parts for FD laundry appliances.

2nd thought couldn't you install the new bearing with the over-sized inner bore with some type of epoxy like material around the shaft to fill the gap ? Ben you certainly did an impressive amount of research into looking for a replacement bearing, I wounder if my younger brother Phil whom works with a machinist would have any thoughts on how to solve this problem. | ||

Post# 737144 , Reply# 50 2/23/2014 at 10:15 (3,713 days old) by joelippard  (Hickory) (Hickory) |

||

Good idea also John! I never thought about an epoxy filler. I seem to recall finding on some web search a bearing that had a 21mm inner bore with the standard 47mm outer. I need to look for that again and maybe order it too.

UPDATE: I did find one spec'd as a deep groove ball bearing (shielded) that was 47mm x 14mm x 21mm for $10. I ordered that too. Something tells me that .4 mm will not make much of a difference, but since this is trial and error we shall see. | ||

Post# 737508 , Reply# 51 2/24/2014 at 22:06 (3,712 days old) by kb0nes  (Burnsville, MN) (Burnsville, MN) |

||

A bit late to the party here Joe, I was just talking to John and he just mentioned the thread to me.

I'm not sure I fully understand all you are dealing with so bear with me. From what I have gathered you have a possible replacement bearing that would work bit its inner bore is .0625" over your shaft diameter. You could conceivably use some form of metal filled epoxy paste to build up the shaft, but the material would have to be machined after the epoxy kicks hard. I would think it would need to be machined to fit the bearing to insure there isn't excessive runout. If you just assembled with the epoxy soft and let the paste set up in place alignment may be off. I would think that the easy/simple fix is to simply create a sleeve to resize the shaft. A piece of stainless bored to press fit onto the shaft, then machine the OD of the bushing to slip fit into the replacement bearing. Perhaps you could get a sleeve machined to just slip onto the shaft and fit the bearing without the need of sending the shaft to the shop. If you handle it in this manner it would make sense to size the sleeve to be a proper fit into the replacement bearing bore, then have the sleeve ID made to be a slip fit onto your shaft. A drop of Locktite 609 retaining compound will create an artificial friction fit without altering the OD of the sleeve, thereby eliminating the need to machine the outer diameter to size after the press fit. There are a number of companies that sell stock shaft repair sleeves to give a new surface for a lip seal to bear against. I looked for a few minutes and was unable to find any that would work in your application with your dimensional constraints. | ||

| Post# 737531 , Reply# 52 2/24/2014 at 23:31 (3,711 days old) by PhilR (Quebec Canada) | ||

Phil, The inner bore of the bearing is smaller than the shaft by 20 mm ID on the bearing vs 13/16" or 20.6375mm on the shaft...

Bearings with larger ID seem available but they are 22 mm or 22.23 mm (7/8") and not as common as those with 20mm ID.

I also thought about something like a Speedi-Sleeve held in place with Locktite 609 but I don't think they'd fit either as most are not wide enough and probably not the correct thickness anyway. And 22mm ID bearings with the correct width and OD seem to be rare too. Do you know if there's a way to machine a 20mm bearing to 20.63mm? If I understand well, the place in the UK in a link I sent above seems to do things like that. I emailed them last weekend but haven't heard from them yet...

Also, non-metric bearings with an ID of 13/16" don't seem to be very common either. I have searched for them but didn't find any. It's either 3/4" or 7/8"... Maybe that's the reason why GM used a metric bearing size for that application and they specified to have the ID slightly enlarged to 13/16". | ||

Post# 737537 , Reply# 53 2/25/2014 at 00:33 (3,711 days old) by d-jones  (Western Pennsylvania (Pittsburgh Area)) (Western Pennsylvania (Pittsburgh Area)) |

||

Have a look at the bearing in this link. With the exception of the ID, the quoted dimensions match the new old stock bearing that was measured above. The seller lists the ID on his bearing as 25/32", which is essentially 12.5/16ths instead of the required 13/16ths, but that could be due to the way he way holding his calipers. I'd ask him to measure that again and see if he can come up with 13/16ths. The listed part number is 77504XIC. CLICK HERE TO GO TO d-jones's LINK on eBay | ||

Post# 737541 , Reply# 54 2/25/2014 at 00:58 (3,711 days old) by kb0nes  (Burnsville, MN) (Burnsville, MN) |

||

Machining from 20mm to 13/16"

Phil

In theory opening up the 20mm center race .025" to .8125" shouldn't be all that difficult. Holding the bearing and stabilizing the inner race is the first hurdle. To do one bearing I think it would be easiest to just clamp it to a plate, indicate on the ID and Jig Bore to the new size. If one were to need a few made then a clamping fixture would made to hold them in the lathe to bore them. The only fly in the ointment is if the inner race is very hard. Typically the races are induction hardened then ground to finish. If the material is too hard boring (especially in the Jig Bore) may be problematic. Even if they were really hard the ID could be Jig Ground to size but that is a slow process that isn't too common today, i.e. read pricey... If possible I'd rather find a bearing with an over size ID that was usable otherwise and sleeve the shaft up in size but perhaps bearings in this size aren't common. Modifying the bearing is possible but it could risk contaminating the race so it would be my 2nd choice. | ||

| Post# 737551 , Reply# 55 2/25/2014 at 06:27 (3,711 days old) by dnastrau (Lords Valley, PA) | ||

|

RBC Nice bearings RBC Nice is still in business. You might want to contact them to see if they can still supply that bearing. CLICK HERE TO GO TO dnastrau's LINK | ||

Post# 737552 , Reply# 56 2/25/2014 at 06:33 (3,711 days old) by joelippard  (Hickory) (Hickory) |

||

I also had considered a sleeve if it became necessary. You all must have missed my post above where I talked about locating and ordering a bearing with a 21mm inner bore. I sincerely don't believe that .4mm will make much of a difference in this case. We'll see how it is when it arrives, that will be the real proof. I think I'd come quicker rebuilding the original with good parts rather than having machine work done since I don't have ready access to those abilities. You all tell me what you think, I'm enjoying this discussion! | ||

Post# 737565 , Reply# 57 2/25/2014 at 10:10 (3,711 days old) by kb0nes  (Burnsville, MN) (Burnsville, MN) |

||

Joe, My apologies,I did miss the part where you had ordered a 21mm ID bearing.

Indeed 21mm is a lot closer to the 13/16" shaft diameter, but still you are left with .014" clearance. As they say close only counts for dancing and hand grenades. While I don't have a perfect idea of how this assembly works or the loading, my hunch is that the loading is significant otherwise they wouldn't have used a hefty bearing like that. How much spacing is there between the upper and lower bearings? I'm curious as to how much angular shaft displacement the lower bearing play might cause. It might be possible to fill the gap with something like Locktite 660 Quick Metal Retaining Compound. I'm not sure how you'd apply it as it probably doesn't wick like Locktite 609 does. The 609 product is rated for gap fill up to .2mm so it might work, at least for a while. The drawback for any of these adhesives is that you will effectively glue the bearing to the shaft, although the bond is easily broken by heating to about 400F. Hope you find something to work. With these vintage machines and parts made of unobtanium, it may be helpful to let your fingers do the walking through Google and find a sympathetic local machine shop. They are out there! | ||

Post# 737610 , Reply# 58 2/25/2014 at 16:57 (3,711 days old) by joelippard  (Hickory) (Hickory) |

||

I'm itching for that 21mm bearing to get here so I can try it. I'm ready to get moving!

Phil, I've taken a pretty exhaustive study of these machines and it's mechanism and I've come to the conclusion that while it would seem the bearing is really taking a bulk of the load I tend to believe that Frigidaire actually did a good job in engineering how weight would transfer through the different parts of the mechanism. It seems to me from a physics standpoint that the tub (mechanism) support carries a great deal of the weight load, part of this load is distributed right down through the spin shaft which then ultimately transfers load through the mechanism brace into the snubber system. I would imagine weight loads diminishing the further it traveled down through the mechanism, leaving the upper and lower bearings in the spin shaft to by and large provide stabilization of the spin shaft itself.

One thing I'm curious about that someone here might be able to answer is what kind of bearing is in the upper end? I've never been any farther in top of one than to change a tub out. I've drawn assumptions from schematics I've studied that is a bronze sleeve type bearing? If anyone knows please tell us. I want to use this thread to dispense as much information as possible for others to use in the future which is why I'm being so detailed with photos about everything I do that is common to many of us. | ||

| Post# 737636 , Reply# 59 2/25/2014 at 20:27 (3,711 days old) by PhilR (Quebec Canada) | ||

Joe, the upper bearing is a needle bearing. Torrington J-1812 if I remember well... In my machine, it was a caged bearing and that's what replaced it I was told that some old techs probably replaced them with a full complement bearing (B-1812). I can't tell if this was a good practice or not! When I replaced the bearing in my 1965 Custom Imperial washer, I asked for both caged and full complement bearings but they just had the caged type in stock at the local bearing store. Since that was the type already in the machine, I felt confident to install one like it but that's also why I asked earlier in this thread if you could show us what kind of bearing is in your machine (if you need to get there). | ||

Post# 737655 , Reply# 61 2/25/2014 at 21:04 (3,711 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

| Post# 738219 , Reply# 62 2/28/2014 at 08:54 (3,708 days old) by PhilR (Quebec Canada) | ||

Joe and Ben,

I got a reply from the place in the UK and transferred it to both of you. It might be a bit expensive with the shipping... (or there's the option to try those NOS bearings with similar numbers on eBay). I don't know how important it is to have the same type of lubricant for the bearing either. Also, I'm still waiting for a reply from guy from SKF Canada to see if he has something else to offer, his first suggestion was to modify the shaft so it fits the 20mm bearing (but that can't be done)...

| ||

Post# 739055 , Reply# 63 3/3/2014 at 16:10 (3,705 days old) by joelippard  (Hickory) (Hickory) |

||

Waiting for the paint to dry... A quick update, still waiting for the 21mm bearing to arrive and try it out. Today is one of those days where I could get a lot done if I had the part, and I'm itching to do so... Today I repainted the snubber brace and rear service cover panel. I got a feeling when done this will be something of true greatness! | ||

Post# 747323 , Reply# 64 4/3/2014 at 13:58 (3,674 days old) by joelippard  (Hickory) (Hickory) |

||

An Update Still nothing happening here. I am awaiting the .21mm bearing to arrive, it apparently has been back ordered and is coming from China. I spoke with a man in California recommended to me by fellow member djones but he says he cannot locate the part but will keep trying.

At this point I'm at a standstill unless someone here has a NOS bearing they'd like to sell me. | ||

Post# 748474 , Reply# 66 4/7/2014 at 14:19 (3,670 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

| Post# 748579 , Reply# 67 4/7/2014 at 20:45 (3,670 days old) by dnastrau (Lords Valley, PA) | ||

|

Great news! Glad to hear it! Fingers crossed...

Andrew S. | ||

Post# 748921 , Reply# 68 4/9/2014 at 17:18 (3,668 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

| Post# 748944 , Reply# 69 4/9/2014 at 18:21 (3,668 days old) by mickeyd (Hamburg NY) | ||

| ||

| Post# 748995 , Reply# 70 4/9/2014 at 22:50 (3,668 days old) by dnastrau (Lords Valley, PA) | ||

|

Sorry to hear that Too bad - hopefully an NOS bearing will turn up - or a way to make something else work. | ||

Post# 751490 , Reply# 71 4/20/2014 at 17:27 (3,657 days old) by joelippard  (Hickory) (Hickory) |

||

Another Update I have had absolutely zero luck in finding a replacement bearing that I feel will work properly. A light bulb went off and I remembered a spare mechanism that I had way back in my parts collection. I removed the bearing from it and found it to be in good condition. As an aid and precaution I performed a oil submersion in a sealed hot water bath to re-lubricate the bearing without breaking the seals. This process took care of some of the dryness I could feel in it.

Tomorrow I am off work so the beginnings of the re-assembly process will begin. I'm shooting for a month or less to get this machine fully restored.

I'm still going to continue looking for a good replacement bearing for future use with the hope that I never need to use them. | ||

Post# 751534 , Reply# 72 4/20/2014 at 21:25 (3,657 days old) by d-jones  (Western Pennsylvania (Pittsburgh Area)) (Western Pennsylvania (Pittsburgh Area)) |

||

| ||

Post# 751535 , Reply# 73 4/20/2014 at 21:27 (3,657 days old) by joelippard  (Hickory) (Hickory) |

||

RE: let me remind you. | ||

Post# 751538 , Reply# 74 4/20/2014 at 21:35 (3,657 days old) by d-jones  (Western Pennsylvania (Pittsburgh Area)) (Western Pennsylvania (Pittsburgh Area)) |

||

| ||

Post# 751599 , Reply# 75 4/21/2014 at 07:02 (3,656 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 751718 , Reply# 76 4/21/2014 at 18:28 (3,656 days old) by d-jones  (Western Pennsylvania (Pittsburgh Area)) (Western Pennsylvania (Pittsburgh Area)) |

||

OK Joe, I just got back from visiting Larry. It turns out that he'd forgotten where he'd found that bearing, so when he went looking for it again he didn't call the place in Mission Hills that said they had it a few weeks ago. This time he gave me the contact info for them to pass on to you, so check your inbox. I just hope this doesn't turn into a wild goose chase. | ||

Post# 751721 , Reply# 77 4/21/2014 at 18:38 (3,656 days old) by joelippard  (Hickory) (Hickory) |

||

Thanks so much David, I got your PM and I'll call them tomorrow after they open. Today I spent the day buttoning up and got more done than I expected. The bearing I did the water/oil bath on feels very good and sounds good too in the machine. Tomorrow evening I'll water test the pump before I move on to other small cosmetic items. Here is a picture of the cleaned and restored mechanism.

| ||

Post# 752401 , Reply# 78 4/24/2014 at 15:36 (3,653 days old) by joelippard  (Hickory) (Hickory) |

||

More news Passed the water test and everything else is good except... We've got clutch issues, it seems it preferred being dirty because it doesn't want to slip and acts as if it were an impact clutch. I adjusted the tension down to the lowest setting with only slight improvement. Agitation under load is good so I know it's not the motor. The clutch is so sticky that it's throwing the overload protection. My plan? I'm going to dirty the clutch up a bit with some dry graphite blown up through the adjustment holes, I think this will correct things. I certainly I hope I don't have to remove the clutch again because this means undoing the pump. | ||

Post# 754745 , Reply# 79 5/3/2014 at 16:09 (3,644 days old) by joelippard  (Hickory) (Hickory) |

||

We're still all in one piece I was able to get the clutch loosened and functioning properly with a method I'd never have recommended to anyone to use. Sometimes you just got to go with what works. I'm still doing some final testing over the next few days to make the machine prove it's worth to me before it gets a final cleanup and goes into place. I think I'm closer though to completing the project. | ||

Post# 756381 , Reply# 80 5/11/2014 at 20:50 (3,636 days old) by joelippard  (Hickory) (Hickory) |

||

Complete! | ||

| Post# 756507 , Reply# 81 5/12/2014 at 12:22 (3,635 days old) by hippiedoll ( arizona ) | ||

WOOOOO HOOOOOO!!! | ||

| Post# 756539 , Reply# 82 5/12/2014 at 14:50 (3,635 days old) by PhilR (Quebec Canada) | ||

Congratulations! | ||

Post# 756759 , Reply# 83 5/13/2014 at 14:52 (3,634 days old) by joelippard  (Hickory) (Hickory) |

||

Pics! | ||

Post# 756760 , Reply# 84 5/13/2014 at 14:52 (3,634 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

| Post# 756763 , Reply# 85 5/13/2014 at 15:06 (3,634 days old) by hippiedoll ( arizona ) | ||

oooooh.... | ||

| Post# 756764 , Reply# 86 5/13/2014 at 15:11 (3,634 days old) by hippiedoll ( arizona ) | ||

oooooh.... | ||

| Post# 756767 , Reply# 87 5/13/2014 at 15:18 (3,634 days old) by mickeyd (Hamburg NY) | ||

Joe L  Just look at that thing: the color, the lights, the liquid panel, and the jet currents & swirls. If that's not washer Nirvana, I don' know what is.

So much work and effort, and the long quest & determination to find or fit the right bearing finally was finally rewarded, and you now have Heaven.

Also taken with the cleaned up shot of the mechanism from the other day: a perfectly functioning Cyborg Brain. Beautiful!

Such persistence is certainly inspiring.

If they don't have your machine in Heaven, I probably won't be attending ;'D | ||

| Post# 756771 , Reply# 88 5/13/2014 at 16:00 (3,634 days old) by richardlxixxx (Old Westbury, New York) | ||

Fabulous Frigidaire

That is a magnificent washing machine. What a tribute to the way appliances used to be manufactured in this country. Quality, design, and beauty. Modern appliances are a mere shadow of their predecessors. Aside from Speed Queen, there is no appliance manufactured today that will last as long as this one has.

Congratulations on a fantastic restoration. It should give you many years of washing pleasure. Jealous in Jupiter, Richard | ||

| Post# 756797 , Reply# 90 5/13/2014 at 19:06 (3,634 days old) by washdaddy (Baltimore) | ||

|

Great Machine! It's fantastic when your dedication and determination to get a machine back up and running lead you to the results that you achieved in restoring this machine back to life. It looks phenomenal! Enjoy! | ||

| Post# 756798 , Reply# 91 5/13/2014 at 19:07 (3,634 days old) by washdaddy (Baltimore) | ||

|

Great Machine! It's fantastic when your dedication and determination to get a machine back up and running lead you to the results that you achieved in restoring this machine back to life. It looks phenomenal! Enjoy! | ||

| Post# 756849 , Reply# 92 5/14/2014 at 00:22 (3,633 days old) by PhilR (Quebec Canada) | ||

Thumbs up! | ||

| Post# 756943 , Reply# 93 5/14/2014 at 14:03 (3,633 days old) by norgeway (mocksville n c ) | ||

|

It would just KILL! These stupid companies to make something that good today!!LOL.. | ||

| Post# 756952 , Reply# 94 5/14/2014 at 15:08 (3,633 days old) by lightedcontrols () | ||

|

Well grasshopper... you've made me proud! | ||

Post# 756960 , Reply# 95 5/14/2014 at 16:09 (3,633 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

Post# 757019 , Reply# 96 5/14/2014 at 20:51 (3,633 days old) by joelippard  (Hickory) (Hickory) |

||

To everyone... | ||

Post# 757024 , Reply# 97 5/14/2014 at 21:02 (3,633 days old) by ovrphil  (N.Atlanta / Georgia ) (N.Atlanta / Georgia ) |

||

A special machine from a special time | ||

Post# 757031 , Reply# 98 5/14/2014 at 21:50 (3,633 days old) by ultramatic  (New York City) (New York City) |

||

Congratulations Joe... | ||

Comes to the Rescue!

Comes to the Rescue!