|

Thread Number: 53340

Need Oil Recomendation for Maytag Wringer Motor Bearings |

[Down to Last] |

| Post# 756824 5/13/2014 at 21:21 (3,633 days old) by scoots (Chattanooga TN) | ||

I just pulled the motor out of a Maytag E2L (Serial 141472W 1950-53?) Looks to be the original GM Delco Motor. I need to replace the original and ungrounded power cord with something that won't kill me on contact.

As long as I have the motor out, does anybody have an recommendation on what oil I should use on the bearings? There are two apertures where you'd expect with fabric wadding. Is there anything else I can do for a quick service other than push compressed air through it? | ||

|

Post# 756834 , Reply# 1 5/13/2014 at 22:08 (3,633 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

SAE 20W Electric motor oil. Zoom Spout or 3 in 1 motor oil would be what I'd reach for on the shelf. John quotes twenty drops. I'd say that's good start if they weren't bone dry to start with.

I'd also take a look at the centrifugal switch contacts. If the are totally scorched/black I'd rub them LIGHTLY with some emery cloth. No need to file them down. Ben | ||

| Post# 757016 , Reply# 2 5/14/2014 at 20:50 (3,632 days old) by scoots (Chattanooga TN) | ||

Thanks | ||

| Post# 757099 , Reply# 3 5/15/2014 at 04:18 (3,632 days old) by scoots (Chattanooga TN) | ||

Pictures, Pictures, Pictures | ||

| Post# 757100 , Reply# 4 5/15/2014 at 04:20 (3,632 days old) by scoots (Chattanooga TN) | ||

Motor Pulley End | ||

| Post# 757101 , Reply# 5 5/15/2014 at 04:22 (3,631 days old) by scoots (Chattanooga TN) | ||

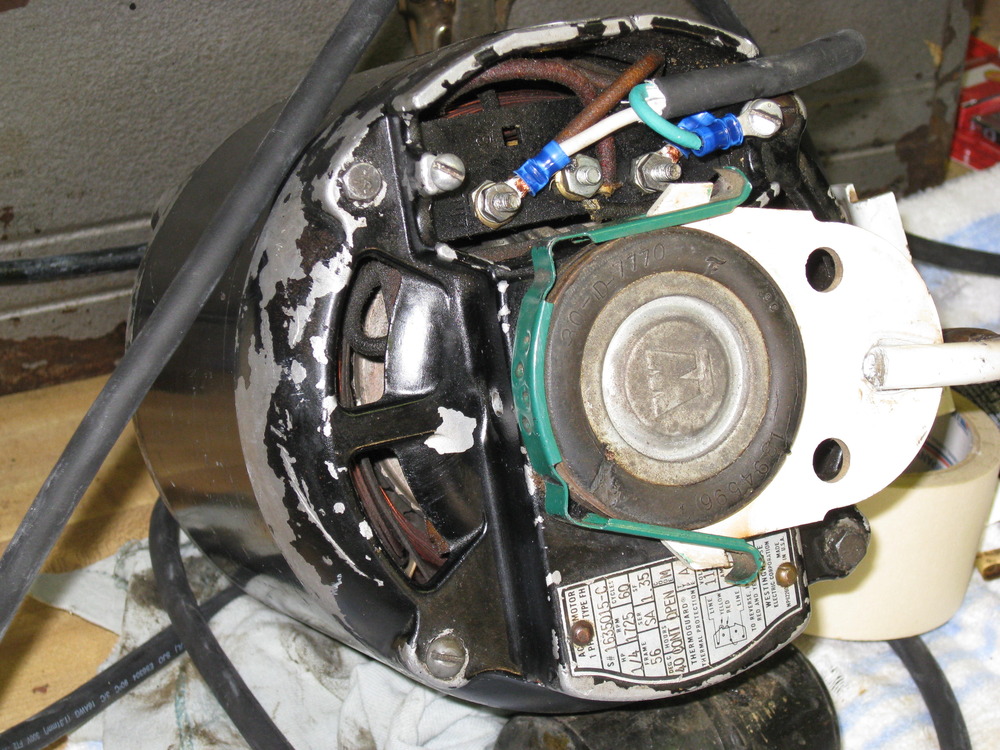

Butt End | ||

Post# 757122 , Reply# 6 5/15/2014 at 07:18 (3,631 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Early To Mid 50s Delco Motor

These were great motors in their day and hopefully it will continue to work for a long time.

I think for the most part the less you do the better unless you really want to make servicing this motor into a major project. The rubber mounts look OK but if you want to replace them you may be able to find from a motor shop, online etc. While you have the motor out I would get all the rust off the motor pulley however, the rust will cause the drive belt to wear more quickly. Good luck with your project and DO add a ground wire attached directly to the motor. | ||

| Post# 757552 , Reply# 7 5/16/2014 at 19:53 (3,630 days old) by scoots (Chattanooga TN) | ||

Need wiring advice

Thanks John for your suggestions.

I have a quick question about wiring. The motor has had a non-maytag non-polarized, non-grounded plug attached. My concern is the power cord's black (power) wire is soldered to a wye with a white lead and a brown(with possible red underneath) lead. The cord's white neutral is soldered to a black wire and a brown wire. I think this is just sloppy work on the part of the original electrician. I want my new power cord's black to go to motor black, and cord's white to go to motor white. Is this correct?

| ||

| Post# 757568 , Reply# 8 5/16/2014 at 20:57 (3,630 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

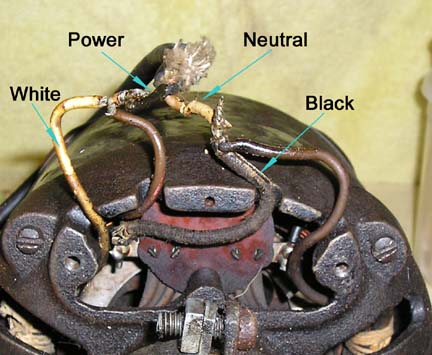

|

I don't know if this will help But here's what my Westinghouse motor looked like when I added a grounded plug.

| ||

Post# 757761 , Reply# 9 5/17/2014 at 20:07 (3,629 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Motor Power Connections | ||

| Post# 758079 , Reply# 10 5/19/2014 at 08:33 (3,627 days old) by scoots (Chattanooga TN) | ||

Thanks for the input. | ||

| Post# 758466 , Reply# 11 5/20/2014 at 20:08 (3,626 days old) by scoots (Chattanooga TN) | ||

Possible Current leak to Case

I lubed the bearings and hooked the Power and Neutral wires up as suggested and the motor started and ran fine under no load on the bench.

There may be a problem, however. I connected the ground to a voltmeter and the case is reading 30 volts. I have a buddy that's an electrician and I'm going to have him confirm what I found, but my question is, what's the next step? Are motors this old "Leaky"? (I have a Sunbeam mixer that I had to retire because the case had picked up a 50 volt leak, and yes, you will feel that.) I'd really like to keep this motor (that's code for money is no object)(almost). What are my options? Thanks | ||

| Post# 758503 , Reply# 12 5/20/2014 at 23:05 (3,626 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Sounds like you'd prefer the original but . . . There's one on EBay right now for $29.99 with zero bids. That's where I'd head. You can always keep your original until you find an electric motor repair/refurbish place. But that'll likely cost a lot more than $29.99! | ||

Post# 758544 , Reply# 13 5/21/2014 at 07:06 (3,625 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Current leakage from an older motor

Bill I would go ahead and ground the motor and use it, yes older motors are often leaky, if the leak is bad enough it will trip the houses circuit breaker. For greatest safety on older appliances I prefer a 15 Amp breaker, not a 20 Amp breaker and DO Not use a ground fault breaker on older washers, refrigerators Etc, but do be sure that these older appliances are properly grounded.

| ||

| Post# 758724 , Reply# 14 5/21/2014 at 20:39 (3,625 days old) by scoots (Chattanooga TN) | ||

Larry & John:

Thanks again for your input on the subject of this motor.

John, I wanted to ask where the current is leaking from? Is an insulator breaking down, or is there gunk in the motor that's acting as a bridge for the current? What would be needed to fix this and do motor shops even bother to look at a unit this old? For what it's worth, I checked for continuity between both plug prongs and the case and couldn't find anything. | ||

Comes to the Rescue!

Comes to the Rescue!