|

Thread Number: 5392

What's a coaxial transmission? |

[Down to Last] |

| Post# 115240 3/14/2006 at 17:04 (6,610 days old) by roto204 (Tucson, AZ) | ||

| ||

|

| Post# 115325 , Reply# 4 3/15/2006 at 03:37 (6,610 days old) by spinout (Phoenix) | ||

|

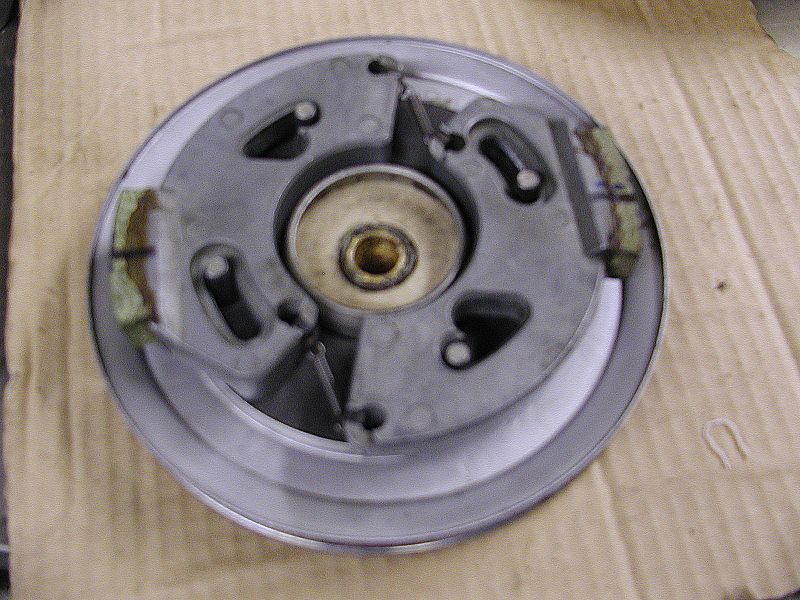

The clutch assembly Note that the clutch shoes ride on the drive pulley. This is a strong, no non-sense clutch. And with substantial weight on each of these shoes (they are made from some sort of lead alloy) it wastes no time in bringing the tub up to speed.

| ||

| Post# 115326 , Reply# 5 3/15/2006 at 03:41 (6,610 days old) by spinout (Phoenix) | ||

|

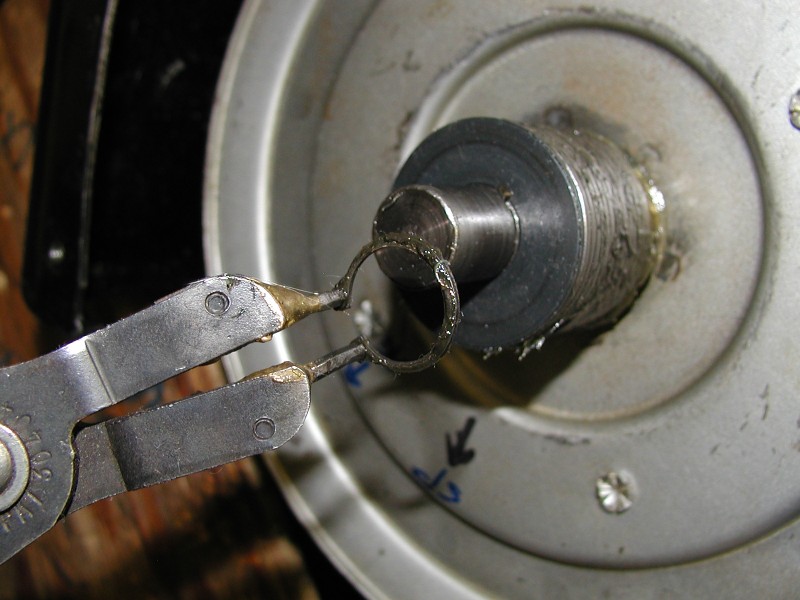

Clutch installed in transmission Here is the clutch assembly installed into the transmission. Note the large hub on the bottom of the pulley; that hub receives the agitate clutch spring.

| ||

| Post# 115327 , Reply# 6 3/15/2006 at 03:44 (6,610 days old) by spinout (Phoenix) | ||

|

And finally... Here it is with the agitate clutch spring and hub in place. Spin it in one direction to agitate, the other way for spin. Elegant, isn't it?

| ||

| Post# 115424 , Reply# 7 3/15/2006 at 15:27 (6,610 days old) by roto204 (Tucson, AZ) | ||

| ||

Post# 115452 , Reply# 8 3/15/2006 at 20:22 (6,609 days old) by jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Thanks Joseph | ||

| Post# 115860 , Reply# 12 3/17/2006 at 11:28 (6,608 days old) by spinout (Phoenix) | ||

|

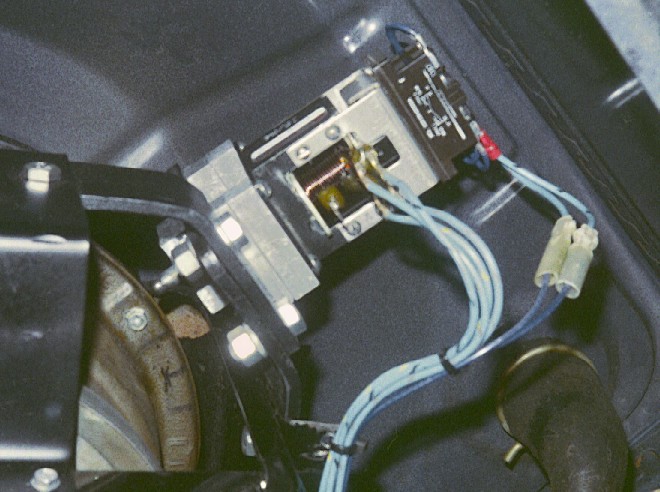

Hey Austin, Here is the anti-indexing mechanism I put on the machine:

| ||

| Post# 115861 , Reply# 13 3/17/2006 at 11:34 (6,608 days old) by spinout (Phoenix) | ||

|

A close up of the latch pin... During agitate, the solenoid is pulled in, extending the pin which engages the notch on the transmission case.

| ||

| Post# 115862 , Reply# 14 3/17/2006 at 11:37 (6,608 days old) by spinout (Phoenix) | ||

|

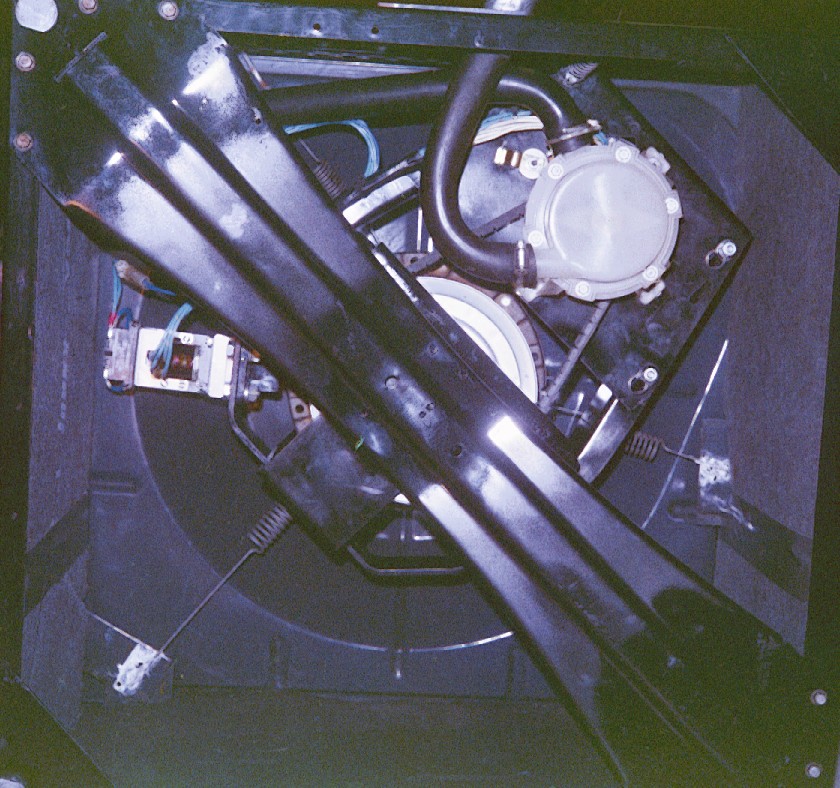

another view the bottom of the machine

| ||

Post# 115864 , Reply# 15 3/17/2006 at 12:20 (6,608 days old) by unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Comes to the Rescue!

Comes to the Rescue!