|

Thread Number: 54481

Rusty tub repair tips |

[Down to Last] |

Post# 768623 7/7/2014 at 00:13 (3,573 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Something that I wish there were more of are repair workshops for amateurs like myself who want to revive an otherwise piece of scrap metal. I figure maybe we can use this forum to talk with those of you who are experts and experienced at the art of rusty tub repairs.

I haven't work on a washer in a few years so I'm the rusty one to say the least. In addition, I am looking at a particularly challenging outer tub repair on the GE washer I recently picked up. I'm hoping that you who wish to will chime in with tips, products, photos etc. that will help in this sort of repair. The area of the tub (photo attached) is the GE's outer tub. Significant rust formed around one of the hoses and corroded completely through the tub. I'm not sure where to begin as far as patching this area in a manner that will allow for the hose to be reinstalled and sealed. I did check out a local hardware store and noticed one of the products for repairing holes in various types of material was using fiberglass "cloth" and then painting on layers of a sealant? type of liquid which I guess forms a hard waterproof patch. Is this something that would work? I look forward to the discussion and thank you in advance! | ||

|

Post# 768689 , Reply# 1 7/7/2014 at 07:46 (3,573 days old) by turquoisedude  (.) (.) |

||

Jon, I have successfully used that fiberglas patching fabric and compound combined with JB Weld and POR15 to repair and reinforce rusty tubs. The photos here of of the rusted tub from a 1957 Whirlpool dishwasher - the motor mount and heating element mounting holes had rusted through and tub leaked pretty convincingly. I started by removing the loose rust, then sanded the surfaces. I gave the holes a coat of POR15, then applied the fibreglas patch. I built up a layer of JB Weld around the holes to strengthen them and then drilled out the fibreglas patch. IA little sanding down, a top coat of POR15 and new grommets used as seals were installed and that did it. The tub is now water-tight!

I hope this helps! | ||

Post# 768695 , Reply# 2 7/7/2014 at 08:05 (3,573 days old) by Yogitunes  (New Jersey) (New Jersey) |

||

| ||

Post# 768730 , Reply# 3 7/7/2014 at 10:11 (3,573 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Nice work guys!

I take it this fiberglass w/ compound ends up forming a pretty sturdy surface and edges so a rubber hose pressing against it shouldn't cause it to buckle or break? I haven't actually seen or used POR-15 before but I know you can't find it at the typical places like Lowes or HD. The POR-15 website at least gives locators for dealers that sell their stuff and looks like there are a handful around me thank goodness.

BTW, interesting reading the instructions about POR-15. Apparently even a single bead of sweat falling into a full can of fresh POR-15 renders the entire can useless! | ||

| Post# 768774 , Reply# 4 7/7/2014 at 13:05 (3,573 days old) by beekeyknee (Columbia, MO) | ||

POR-15 reacts and cures with humidity, as I recall. I was chatting with Alan from Salt Lake last night about POR-15 and commented that I thought if you didn't use the whole can it would ruin. Some else chimed in and said when you're done to put plastic over the can and bang the lid down hard. When reopened, peal the film off the top of the product and continue using.

| ||

Post# 768836 , Reply# 5 7/7/2014 at 15:47 (3,573 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

| ||

Post# 768863 , Reply# 6 7/7/2014 at 17:44 (3,573 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Time to go to work

I think I have what I need to get started!

View Full Size

| ||

Post# 768898 , Reply# 7 7/7/2014 at 19:15 (3,573 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

And we are off!

So I dove into this old thing and started cleaning with a wire brush. Looks like the too wasn't the only thing sealed. The tub bolts were sealed hence why part of one is still in the tranny. Also, the entire boot was sealed down using a plumbers putty. Word to the wise...don't use that stuff for a metal washing machine tub. Major rust starting everywhere that the putty was placed. Luckily the boot was sealed water tight so no leaks or rust. I cleaned off what there was on the outside and the first layer of POR15 is now in place. Luckily it's hot and dry in portland so this should dry pretty quickly.

| ||

Post# 768913 , Reply# 8 7/7/2014 at 20:31 (3,573 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

One last coat and that should do it. Will let this set until the morning and then I will start patching the hole. So far so good! Thanks for the input too!

View Full Size

| ||

| Post# 768941 , Reply# 9 7/7/2014 at 22:25 (3,572 days old) by roto204 (Tucson, AZ) | ||

Great job! | ||

Post# 769218 , Reply# 10 7/8/2014 at 19:17 (3,572 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

A new hole...

Ok so the fiberglass cloth and resin is in place. Smells like a new boat! Hopefully this stuff hardens and creates a sturdy new surface.

View Full Size

| ||

| Post# 769258 , Reply# 11 7/8/2014 at 21:47 (3,571 days old) by brainardcooper (Columbia, SC) | ||

|

Jon Thanks for asking this question. I have the same type of issue with the outer tub on my '63 Kenmore washer. I am looking at removing the inner tub this weekend to access the problem. Your thread gives me some confidence! | ||

Post# 769804 , Reply# 12 7/10/2014 at 19:08 (3,570 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Getting closer...

Sorry for the delay. I had to work the last two nights so not much action. I did wake up early enough before work to get the fiberglass-resin patch in place and then plenty of time to cure. It too about 5-6 layer of the cloth quickly applied to the resin compound. That stuff dries FAST and it cures to a very sturdy surface that is water tight (so I've read).

Today's task was to cut out the new hole, replace and seal the filter-flo intake hose, replace the old pump with a new one, and reattach everything to the pump. Sounds easy right? Actually it wasn't so bad but would have been better if my Dremel hadn't decided to die on me. A drill accomplished the same result though. Tomorrow will be the first water test and I suspect I will have no leaks. Then it'll be time to tackle getting that broken bolt out of the transmission hub and getting a new bolt. I still need to clean up the rim of the outer tub and remove all of that old caulking. Once I get a new gasket then this machine will be in business for the most part. It'll just be a matter of cleaning, repairing a few other issues, and finding missing parts such as a tank, filter pan, mini basket, filter flume (this one is slightly broken), an extra rinse switch (broken) and a new timer knob (the teeth are worn off on this one). I think that just about covers it. Will keep all of you posted. Enjoy the photos! | ||

Post# 770099 , Reply# 13 7/11/2014 at 21:48 (3,568 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

update...

if anyone's even reading this...

Extracting the tub bolt was a failure to say the least. Ended up drilling a hole and supergluing a nut to the underside and then attaching a bold once the basket was in place. Tricky but it worked. Water test was successful. Not a drop!!! I'm excited about that! BUT...there's always something... The new water pump is not only noisy but doesn't seem to work. Maybe I'm doing something wrong but I got no recirculating water out of the filter-flo. Draining was spotty as well. I then thought maybe I got the filter-flo hoses backwards since it started to flow out of the flume during the spin-drain. I switched them and tried a wash again and still got no recirc. DANGIT!!! Anyone have any ideas on what's causing this? | ||

| Post# 770943 , Reply# 14 7/14/2014 at 20:40 (3,566 days old) by roto204 (Tucson, AZ) | ||

Crap impeller or blockage? | ||

Post# 771059 , Reply# 15 7/15/2014 at 13:16 (3,565 days old) by RevvinKevin  (Tinseltown - Shakey Town - La-La Land) (Tinseltown - Shakey Town - La-La Land) |

||

|

| ||

Post# 771139 , Reply# 16 7/15/2014 at 17:50 (3,565 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Pump issues

Thanks guys for the feedback! I did actually have the hoses reversed. I didn't figure it out until I put it into spin and a little water came out the flume at the same time. Switching hoses didn't fix the issue though. I'm wondering if the pump is crappy. I bought another older one just to see. It's really weak when draining too so who knows? I remember on the portable lady k having to change out that pump three times before finding a good one. I work tonight and them 4 days off so I can dive Into this some more. Good news is still not a single drop of water has leaked. I do think I spot some transmission oil inside the tub though so the tranny may need a new seal. Ugh!

Thanks again boys! | ||

Post# 771270 , Reply# 17 7/16/2014 at 08:30 (3,564 days old) by turquoisedude  (.) (.) |

||

You're making great progress! I hope that swapping out the pump will help - I've not worked on a lot of GEs (but I have two projects in the wings). Where are you seeing transmission oil in the tub? It could well be a seal, but I think I read in a GE washer repair-master that there would be two seals to change if oil is getting into the tub and onto clothes. I'll look that up this weekend and confirm what I find, if that might help. | ||

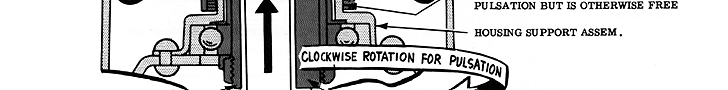

Post# 771272 , Reply# 18 7/16/2014 at 08:40 (3,564 days old) by Yogitunes  (New Jersey) (New Jersey) |

||

quirky pumps......

all pumps are not created equal.....and no reason as to why...they all appear the same....

I have had normal flow ones, some under powered, and some super powered.....no rhyme or reason, and you can't tell until their hooked up and running...even had ones that would air lock! only word of caution, on the underside of the pump, there is a little air hole, if there is a streak of black coming out, its heading for seal failure....just be on the lookout before it dribbles water on the clutch and motor.... | ||

Post# 771275 , Reply# 19 7/16/2014 at 09:18 (3,564 days old) by Yogitunes  (New Jersey) (New Jersey) |

||

for ease of aggravation....might be worth it to just install a whole new pump....

CLICK HERE TO GO TO Yogitunes's LINK on eBay | ||

Post# 771360 , Reply# 20 7/16/2014 at 19:46 (3,564 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Pumps

Turquoise: There was actually no oil on the outer tub or the boot but I wiped the top of the transmission and there was a black oily film on top. Also there was oil leaking when I tilted the machine to its side to install the new pump so I'm guessing there's a bad seal. I'm sure the easiest thing to do would be to swap out the transmission but this is the older metal housing and I think those are actually quieter so might be one I could just service and reseal.

Yogitunes: This pump seems to airlock and it's one of the new ones I found on Ebay. I found an older one so I went ahead and bought it and will see how that does instead. Definitely true that not all pumps are created equal. | ||

Comes to the Rescue!

Comes to the Rescue!