|

Thread Number: 77138

/ Tag: Vintage Automatic Washers

Look What Happened to My 1958 General Electric Washer |

[Down to Last] |

Post# 1010633 10/13/2018 at 09:51 (2,011 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Now that's strange, two new knobs have been discretely added to the side of the control panel?

| ||

|

Post# 1010637 , Reply# 1 10/13/2018 at 10:14 (2,011 days old) by super32  (Blackstone Massachusetts) (Blackstone Massachusetts) |

||

| ||

Post# 1010643 , Reply# 2 10/13/2018 at 10:49 (2,011 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

I've been working on this project for over five months now and it's officially completed. I'll start with saying all the original parts have been saved and I could if I ever desire easily return the machine to it's original design.

So let's start with what I removed from underneath the machine: #1 Original Motor (1/3hp, 1750rpm) #2 Original Pump #3 Original Clutch #4 V-Belt Here's what I replaced them with... Brand spanking new 21st century 3-phase motor (3/4hp, 3600rpm). Variable Frequency Drive (VFD) to run the motor Relays to communicate the original timer to the new motor drive, I didn't want to add any computer to the machine I wanted it run off of it's original control panel timer, Two electric pumps one for Filter-flo the other for drain, Changed the drive belt to a cogged belt from a standard belt, I also added an extra 1950's version Kenmore washer off-balance relay switch So what exactly did this do to this machine? lol you're not going to believe this, let's just say the performance is amazing. Video to come shortly. | ||

Post# 1010644 , Reply# 3 10/13/2018 at 10:57 (2,011 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Here we go, watch this in full screen mode for the full effect...

CLICK HERE TO GO TO Unimatic1140's LINK | ||

Post# 1010645 , Reply# 4 10/13/2018 at 11:03 (2,011 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 1010647 , Reply# 5 10/13/2018 at 11:10 (2,011 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Yup, that's all Paul! | ||

| Post# 1010649 , Reply# 6 10/13/2018 at 11:34 (2,011 days old) by golittlesport (California) | ||

Awesome!!!

Thanks, Robert! It's raining here in So Cal this morning and your video was perfect entertainment to watch with a cup of coffee! Such a beautiful machine! I just love fast spins and that fast activation is almost like a pulsator action. You are amazing!! Thanks again for documenting what you are up to these days! You are the "washer wizard!"

P.S. Very cool that you saved old parts and can return this machine back to original condition if you ever wanted to. (But it looks a lot more fun like this!) | ||

Post# 1010655 , Reply# 7 10/13/2018 at 12:12 (2,011 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

This Machine Is Amazing

I have seen it run in person and this may be the most amazing washer creation you have done yet Robert.

This update is really what this washer needed, it always amazed me that GE started out with such a great performing AW and then went to such an anemic design, the basic agitation was always weak on GE solid tub AMWs but then they slowed down the spin to only approximately 550 they lost any real advantage in overall performance. All this is even more interesting that they slowed the spin down so much as you have proved that the machine is capable of spinning at over 1000 RPMs without problems. I doubt that you would ever want to convert this washer back to its original design. John L. | ||

Post# 1010657 , Reply# 8 10/13/2018 at 12:58 (2,011 days old) by appnut  (TX) (TX) |

||

|

Wow!!!!! Is this tub constructed different or same as the original GE automatic such that it can withstand that 1150 rpm spin speed? This post was last edited 10/13/2018 at 14:07 | ||

| Post# 1010660 , Reply# 9 10/13/2018 at 13:47 (2,011 days old) by bradross (New Westminster, BC., Canada) | ||

She's a beauty! | ||

Post# 1010661 , Reply# 10 10/13/2018 at 13:56 (2,011 days old) by pdub  (Portland, Oregon) (Portland, Oregon) |

||

Great job Robert... | ||

Post# 1010665 , Reply# 11 10/13/2018 at 15:09 (2,011 days old) by pulltostart  (Mobile, AL) (Mobile, AL) |

||

Dayum!!! Fun video, beautiful machine! I think this 1958 (in turquoise, no less) is my favorite machine in your collection. When watching it agitate at full speed I thought of a new name for the washer - Filter-Shred.

So now the only functions that the Piano Keys control is water temps? You found a way to bypass the controls for wash/spin speed that the keys had?

So very cool.

lawrence | ||

Post# 1010680 , Reply# 12 10/13/2018 at 17:25 (2,011 days old) by chetlaham  (United States) (United States) |

||

|

Took the idea right out of my head

Been meaning to do something similar, though much less well thought out, but money has been tight for while and kept pushing it back.

Either way, THANK YOU! This means a lot to me, I love seeing machine enhancements or anything adding to a machine. Making myself comfortable for the video. BTW, no fun! You should have let us guess more! :P | ||

Post# 1010681 , Reply# 13 10/13/2018 at 17:28 (2,011 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Congrats! | ||

Post# 1010687 , Reply# 15 10/13/2018 at 19:09 (2,011 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Thanks everyone for your kind words and encouragement. One of the things I love about this machine is it's water flow-through fabric softener dispenser, the best design of any early machine in my opinion. I just always wish it spun faster like the very early GEs washers and Frigidaires, and now it does!

Is this tub constructed different or same as the original GE automatic such that it can withstand that 1150 rpm spin speed? Hi Bob, the major difference between the earlier 1947-1950 GE washers that spun at 1140rpm and the later models is the tub sat in a cast iron cradle in the early machines. The tub in the later machines are still pretty solid metal and porcelain so I wasn't so worried about that. The suspension system is similar to the early GE fast spinning washers so I knew it could handle it. My only real concern is the cast-iron balance ring that sits on top of the tub has welded brackets. If I see any sign of those brackets loosening I will take the ring out and drill through it and the brackets and secure them with stainless steel bolts. But after five months of high speed spinning they seem to be holding up just fine. So now the only functions that the Piano Keys control is water temps? You found a way to bypass the controls for wash/spin speed that the keys had? Hi Lawrence, yes the piano keys now only control the water temperature. Since they way GE reduced the speed for low speed operation was a simple solenoid to the clutch, I took that wire out of the circuit. All speeds are controlled through the two variable knobs on the side of the control panel. The VFD only allows for one variable speed control (a potentiometer) so I used two separate relays to switch the signal from the knobs into the speed control terminals of the VFD. One relay is for the upper activation knob and the other for the spin knob, that way I could control the agitation and spin speeds separately. With the high-speed spin, have you made any tests to see how much more water is extracted? Something like running a full spin cycle with factory original speed; removing and weighing the clothes - and then repeating the test with 1150 RPM spin? I bet a lot more water is removed. Hi David, I haven't done an actual test but I certainly could, I can tell there is a HUGE difference now in the water extraction ability of this machine. According to the service manual for this machine, the original spec spin speed was 610rpm, although my meter showed it originally was only spinning at 598rpm, but that probably was due to clutch wear. I knew nothing about VFD's before this project and learned a lot about them, they offer endless possibilities of how one could control a washing machine. When I have more time I make a post about what a VFD is and how to wire and program it for others who may not know anything about them. | ||

Post# 1010690 , Reply# 16 10/13/2018 at 19:35 (2,011 days old) by Gyrafoam  (Wytheville, VA) (Wytheville, VA) |

||

|

Fun! Would be really splashy with a load of bib-overalls. I do wonder how well the fins and drive block area will hold up under the stress. Seems like the old brittle Bakelite might be unforgiving of the extra stress. | ||

Post# 1010695 , Reply# 17 10/13/2018 at 20:15 (2,011 days old) by chetlaham  (United States) (United States) |

||

|

VFDs

"they offer endless possibilities of how one could control a washing machine. When I have more time I make a post about what a VFD is and how to wire and program it for others who may not know anything about them."

I would certainly be interested! I know little about applying them to washing machines. Let alone how to program them. I watched your video twice, and all I have to say is that I can not believe a modern manufacturer does not have a machine like this. The concept of infinite independent speed is control priceless. The way you varied the speed at the start of agitation and spin is spot on to. Aside from all that I personally like the sound of the high speed agitation, and the up/down varying of the speeds. Its like a cartoon washer but with seriously enhanced performance. I just want to ask one thing- can the gear case break 1150 rpm? I noticed you let the motor gradually slow down the spin? | ||

| Post# 1010698 , Reply# 18 10/13/2018 at 20:42 (2,011 days old) by Spinmon (st. charles mo ) | ||

|

Somebody's channeling Tim Allen-''More POWER'' Erh,Erh,Erh! Very cool Hi-Po GE! | ||

Post# 1010699 , Reply# 19 10/13/2018 at 20:55 (2,011 days old) by whirlykenmore78  (Prior Lake MN (GMT-0500 CDT.)) (Prior Lake MN (GMT-0500 CDT.)) |

||

WOW JUST WOW! | ||

Post# 1010704 , Reply# 20 10/13/2018 at 21:41 (2,011 days old) by earthling177  (Boston, MA) (Boston, MA) |

||

|

Wow!!! Congratulations and enjoy it in good health!!! | ||

Post# 1010707 , Reply# 21 10/13/2018 at 22:51 (2,011 days old) by peteski50  (New York) (New York) |

||

supped up GE! | ||

Post# 1010709 , Reply# 22 10/14/2018 at 00:18 (2,011 days old) by tolivac  (greenville nc) (greenville nc) |

||

|

Very nice and CLEVER!!!Now if only we could get a NEW machine like this!In one of the Dennis the Menence episodes it begins with Dennis making a milkshake in his washer-the high agitate speed in this would be perfect!! | ||

Post# 1010715 , Reply# 23 10/14/2018 at 00:53 (2,011 days old) by GELaundry4ever  (Nacogdoches, TX, USA) (Nacogdoches, TX, USA) |

||

|

If GE did... If GE were to come out with the filter-flo reincarnation, I'd be the first one onboard! | ||

Post# 1010716 , Reply# 24 10/14/2018 at 01:16 (2,011 days old) by askolover  (South of Nash Vegas, TN) (South of Nash Vegas, TN) |

||

|

| ||

Post# 1010722 , Reply# 25 10/14/2018 at 03:10 (2,011 days old) by Frigilux  (The Minnesota Prairie) (The Minnesota Prairie) |

||

| ||

| Post# 1010753 , Reply# 26 10/14/2018 at 05:23 (2,011 days old) by arbilab (Ft Worth TX (Ridglea)) | ||

As Darth Vader said, "Impressive. Most impressive."

As the opening narration of 6 Million $ Man said, "We can rebuild him. We can make him better than he was."

N-i-i-i-i-i-c-e. That's what I'd like to do if I had the space, time, money, attention span, energy, fabrication talent, and about 20 fewer birthdays. | ||

Post# 1010755 , Reply# 27 10/14/2018 at 05:48 (2,011 days old) by Easyspindry  (Winston-Salem, NC) (Winston-Salem, NC) |

||

|

Fascinating video and ideas. Just another example of your abilities and genius. Thanks for sharing a wonderful video. Jerry Gay | ||

Post# 1010756 , Reply# 28 10/14/2018 at 05:59 (2,011 days old) by foraloysius  (Leeuwarden, Friesland, the Netherlands) (Leeuwarden, Friesland, the Netherlands) |

||

| ||

Post# 1010759 , Reply# 29 10/14/2018 at 07:28 (2,010 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

| ||

Post# 1010764 , Reply# 31 10/14/2018 at 09:03 (2,010 days old) by TrainGuy  (Key West, FL) (Key West, FL) |

||

Excellent Job Robert! | ||

| Post# 1010777 , Reply# 32 10/14/2018 at 13:35 (2,010 days old) by StrongEnough78 (California) | ||

|

| ||

| Post# 1010783 , Reply# 33 10/14/2018 at 14:36 (2,010 days old) by bajaespuma (Connecticut) | ||

Vintage Versatronicalness!!

Are two of your photos hinting that you might also customize your WA-755W? I'm wondering if/why you picked the solid tub model over the later one for the maiden flight.

You realized and achieved what GE/Hotpoint TRIED to accomplish but, ultimately, failed because their attempt was half-assed; you went full Monty. What you built is what these machines (which came and went very quickly because the range of speeds was minimal and made little or no difference to the consumer{I only wish that CU had had the cohones to rate either of these machines during their time})should have been. I wish I had a WWA8800L to donate for enhancement; the extra knobs are already there. I'd like to find the Hotpoint "All-Fabric", but I balked at the GE's when I knew what MAX WASH and MAX SPIN amounted to: | ||

Post# 1010793 , Reply# 34 10/14/2018 at 16:20 (2,010 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

I just want to ask one thing- can the gear case break 1150 rpm? I noticed you let the motor gradually slow down the spin?

Hi Chet, The entire inside of the GE transmission locks and turns together when the pulley is turned counter-clockwise so speed is a non-issue as long as the bearings can take it, which 1000 to 1200rpm is perfectly within the bearings specs. As a matter of fact the upper sleeve bearing in the 58's transmission is the exact same part number as the earlier AW6 fast spinning transmissions. I do wonder how well the fins and drive block area will hold up under the stress. Seems like the old brittle Bakelite might be unforgiving of the extra stress. Hi Steve, I think it will handle it just fine mainly because I'm not using the power boost agitation speed for more than 30 seconds or so just to get the load moving, I think it would be too hard on the clothing, although I have done microfiber rags at about 100 oscillations per minute and they came out perfectly fine. As for the transmission, before I started this project I completely rebuilt it. I cleaned it thoroughly, installed brand new sleeve and roller bearings, all new seals, a brand new drive block and tub hub and then I refilled it with the proper amount of 40 weight non-detergent oil. It doesn't sound stressed at all when running at high speed. Chris you projects sounded super cool, love to see some video or pictures of those running. I really surprised to hear that a belt-drive Whirlpool spinning at 900 to 1000, how did the suspension system handle that speed??? I've heard that even at 700rpm a belt-drive Whirlpool had some major vibration issues. Are two of your photos hinting that you might also customize your WA-755W? No I won't do that to that machine Ken because it was brand new and never used and I just started using it a few years ago. I'm also not sure how the perforated tub GE machines suspension system would handle high speed spin, although it may be just fine. I suspect a Maytag would be another candidate for this and it could handle 1100rpm+ spin, but I'm not positive. Maybe we will have to find out! | ||

Post# 1010808 , Reply# 35 10/14/2018 at 18:41 (2,010 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

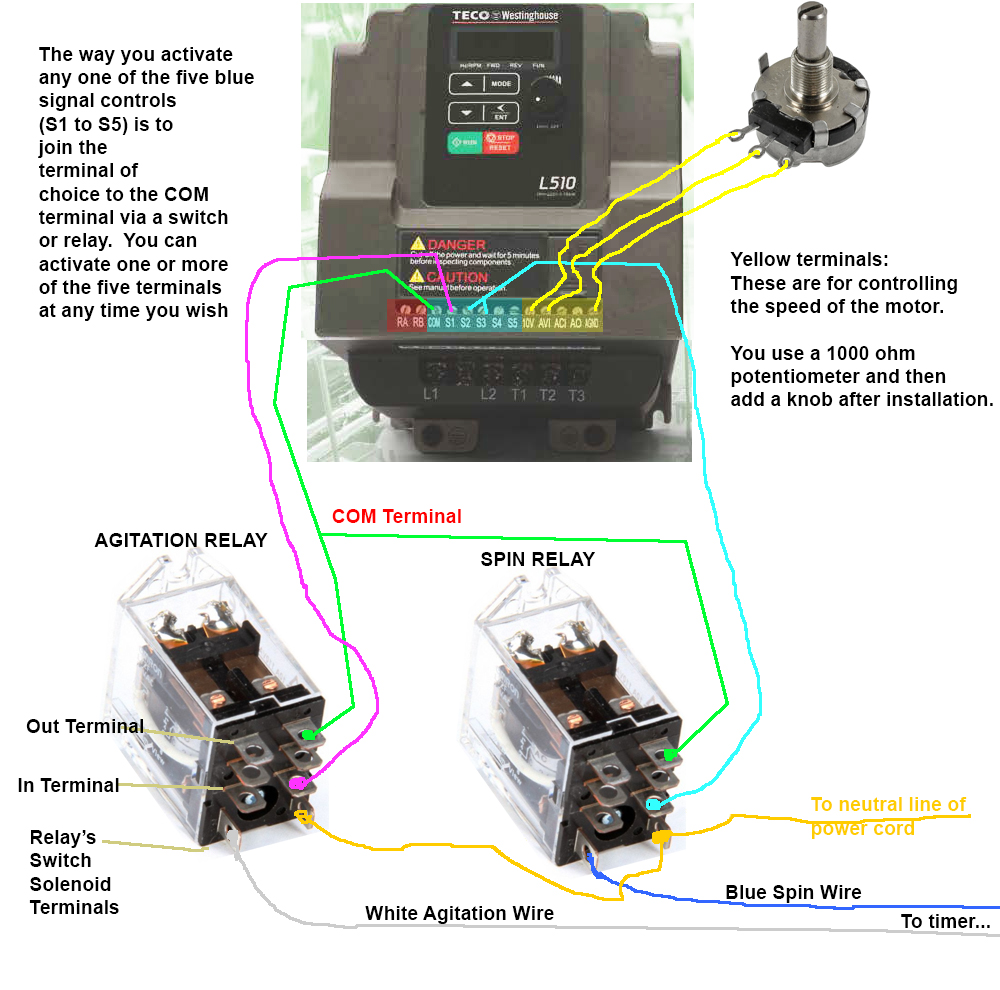

VFD Primer for those who may want to try this...

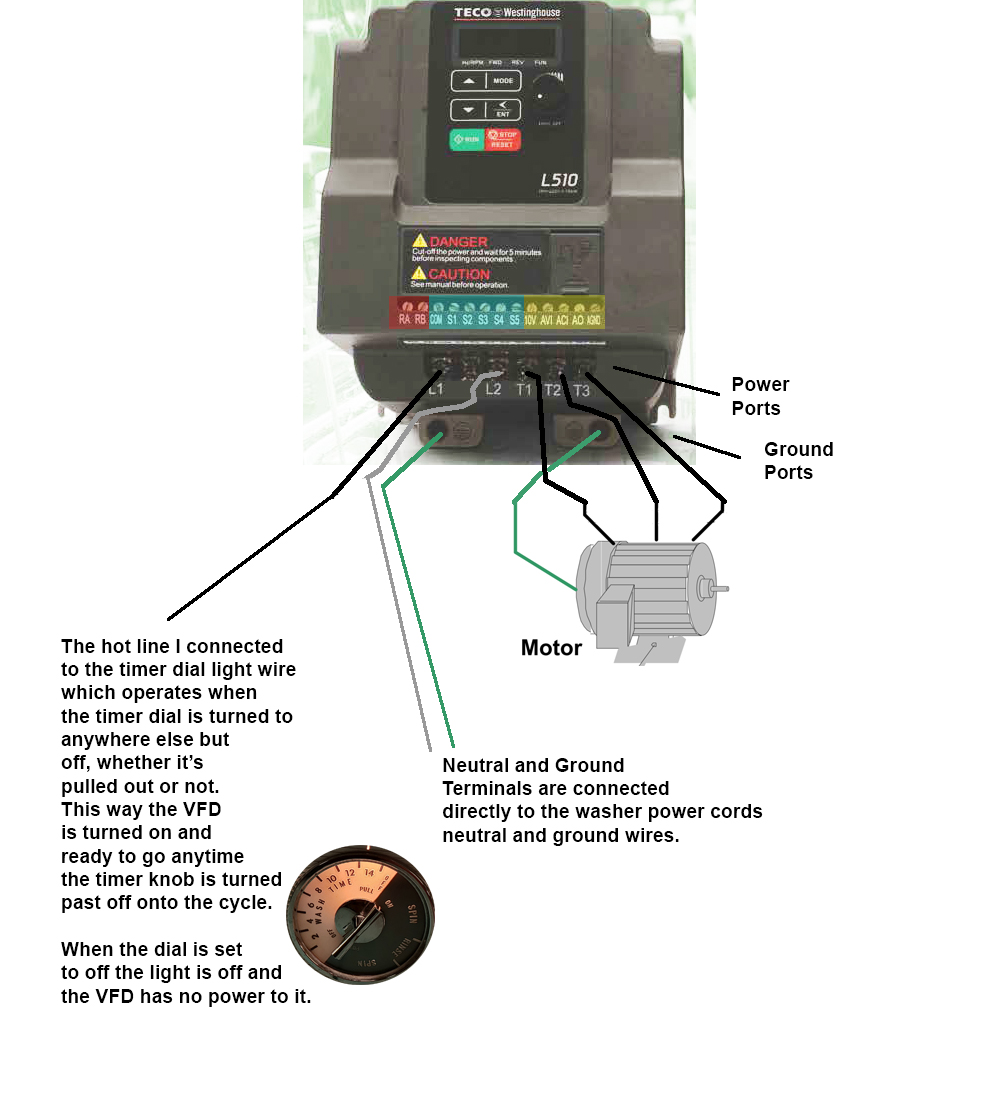

A variable frequency drive or VFD is used to run 3-phase motors on standard residential electrical outlets without needing 3-phase power. It has many settings and inputs and outputs to allow you to do many different things such as control the motors rotation direction, speed, acceleration and deceleration time, etc.

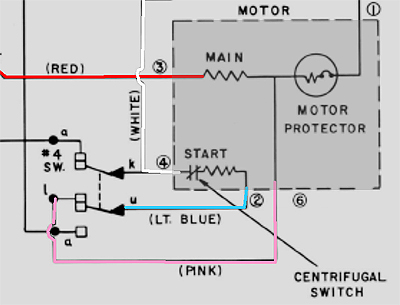

Here is how I set up my VFD to control new motor in the washer... Step 1: I had to figure out is how am I going to tell the difference between the agitation and spin signal coming out of the washer's timer. So I studied washer's the wiring diagram. I found four wires going to the original motor. Red, Pink, Blue and White. Since the original motor was a reversing motor, clockwise for agitation and counter-clockwise for spin it was clear on the washers wiring diagram that the Blue and White wires do the reversing in the start winding. For agitation the White wire is energized and the Blue wire is neutral. For spin the timer reverses the polarity between those two wires and the Blue wire is now energized and the White wire is now neutral. I confirmed this with my electrical meter that during agitation the White wire has 120 volts on it and the Blue wire was neutral and when I set the dial to spin and pulled it out they reversed and the Blue wire now has 120 volts on it and White became neutral. So it was settled, the Blue and White wires will give the signal to the VFD and the Red and Pink wires can be removed as they are no longer needed for the new motor.

Step 2: Wire the VFD from the Washer's Power Cord to the New Motor-- The VFD power input get's wired directly to the washers power cord, however I made one exception. I wired it so the hot line is powered by the wire that power's the control panel dial light. This way the VFD is energized and ready to go when the timer dial is set to anywhere but off. So whenever the timer dial is lit the VFD is turned on a waiting for a run signal when the dial is pulled out to start...

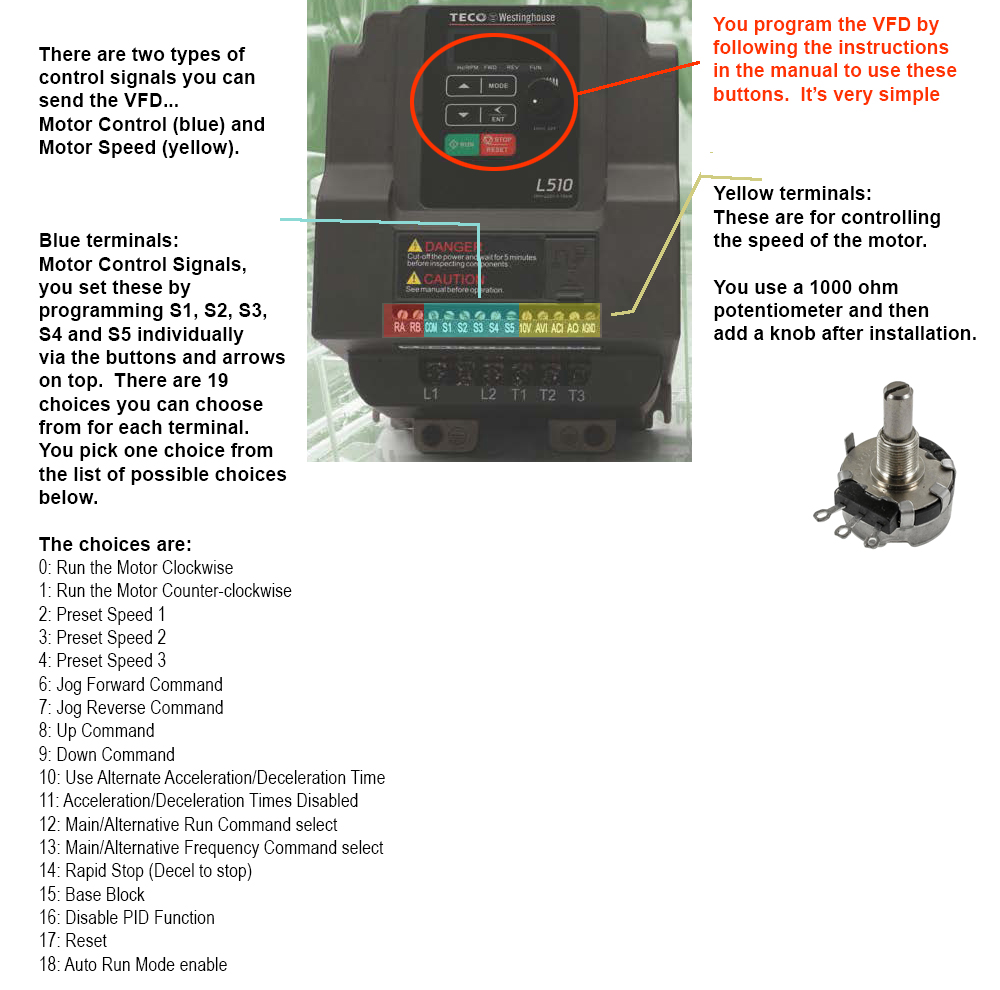

Step 3: Program the VFD functions via it's control panel and decide on how to set up the blue control terminals. They use the word "programming" but it's really not anything more than just setting options on the VFD's digital display--

For the washer project I only needed three signals. Here is how I set them up: S1 = 0: Run the Motor Clockwise for Agitation S2 = 1: Run the Motor Counter-clockwise for Spin S3 = 10: Use Alternate Acceleration/Deceleration Time S4 and S5 Not used For the motor acceleration times I set the primary acceleration time to 0.1 seconds as for agitation doesn’t need any delay in getting the motor up to full speed. But for Spin I set up the alternate acceleration time to 80 seconds to bring the tub up to speed slowly and not causes suds locks with the water being violently thrown around in the outer tub before the pump has time to drain it away. The '58 GE isn't like an earlier AW6, Frigidaire or other solid tub washers where the outer tub was huge and could hold the entire tubs worth of water below the spinning tub, so you have to be careful with acceleration time in this machine. As for the deceleration times, I disabled them and set the VFD to always coast the motor to a stop. Step 4: Wire the Relays and VFD Control Terminals The diagram below is a simplifed version so you get the idea, however I actually wired the speed selector potentiometers into the agitate and spin relays as well, but I didn't show that as I didn't want it to get even more busy.

Okay who's gonna soup-up the next washer? ;-D | ||

| Post# 1010814 , Reply# 36 10/14/2018 at 19:06 (2,010 days old) by 300C (Jonesboro, GA) | ||

|

My Dream Machine Beautiful work Robert!!! A 1957 or '58 Filter-Flo is my dream machene. My Mom had a 1960 model and eventually passed it on to my Grandmother. The machine was still going strong in 1988 when my Grandmother died. Yes, my Mom DID get a new Filter-Flo to replace the one she handed down. | ||

Post# 1010821 , Reply# 38 10/14/2018 at 20:32 (2,010 days old) by joelippard  (Hickory) (Hickory) |

||

| ||

| Post# 1010825 , Reply# 39 10/14/2018 at 21:19 (2,010 days old) by IowaBear (Cedar Rapids, IA) | ||

| ||

| Post# 1010826 , Reply# 40 10/14/2018 at 21:29 (2,010 days old) by stricklybojack (South Hams Devon UK) | ||

| ||

Post# 1010856 , Reply# 41 10/14/2018 at 23:52 (2,010 days old) by tolivac  (greenville nc) (greenville nc) |

||

|

Be interesting to try a ramp agitator in the modified machine.--Just for fun! | ||

Post# 1010872 , Reply# 42 10/15/2018 at 08:21 (2,009 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

"We Bring Good Things to Life"

Wow - the GE has morphed into a beast of a washer. Great job working through solutions for the Filter Flo system and the off balance switch from a Kenmore. Genius!

What are the specs of the motor? Frame number? I've had dreams of doing this exact thing to a Maytag for years. Your work here is some good inspiration... Ben | ||

| Post# 1010878 , Reply# 43 10/15/2018 at 10:02 (2,009 days old) by vacerator (Macomb, Michigan) | ||

|

Good engineering Robert. In the the early to mid 20th century, most industrial motors were 3 phase. In the rail industry etc., gate turn off thyristor's became the new technology. | ||

Post# 1010879 , Reply# 44 10/15/2018 at 10:26 (2,009 days old) by Yogitunes  (New Jersey) (New Jersey) |

||

| ||

Post# 1010892 , Reply# 45 10/15/2018 at 12:18 (2,009 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

What are the specs of the motor? Frame number?

Hey Ben, here are the specs and a image of the old motor/clutch and the replacement motor... | ||

Post# 1010940 , Reply# 46 10/15/2018 at 20:57 (2,009 days old) by jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

WOW~ | ||

Post# 1010952 , Reply# 47 10/15/2018 at 23:55 (2,009 days old) by tolivac  (greenville nc) (greenville nc) |

||

|

One of our 500Kw transmitters uses GTO devices in its modulator stage. | ||

Post# 1010953 , Reply# 48 10/15/2018 at 23:57 (2,009 days old) by tolivac  (greenville nc) (greenville nc) |

||

|

Interesting on how that VFD device converts the 120V single ph to 208V three ph without a transformer. | ||

Post# 1010965 , Reply# 49 10/16/2018 at 03:49 (2,009 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

GE Washer

Wow, Robert, you have been busy, that's a fab fun project for sure, nothing like some customisation on your fav washer !! Is that an inline water heater tube under the LH of the washtub ??

Nowthen, am just thinking how and what your "Washer Customisation Department" will come up with this time for your total project washing machine, after the splendui job they did on your previous washer ...ducks n runs ha ha !! | ||

Post# 1010989 , Reply# 50 10/16/2018 at 06:37 (2,008 days old) by Jetaction  (Minneapolis) (Minneapolis) |

||

How very cool is this! | ||

Post# 1011058 , Reply# 53 10/16/2018 at 09:43 (2,008 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

LOL Mike, you still have that Super-Unimatic picture I see! No heater in the GE, although because of its recirculation system it would be a perfect candidate for it.

I have to figure out how to reprogram the original mcu, or set up something different. The issue with that is the sq mcu is both the ccu, and mcu. Hi Eugene, I'm not sure exactly what you mean by mcu and ccu. I would think taking on a project like that would require a new computer interface/board unless you can somehow gain access to what has been programmed on the SQ's chip-set. That would be super fun to be able to reprogram certain machines if one could get into the code. Would take a bit of research for sure. Hey Les, those are really good questions. why is there a hesitation of the tub spinning for a few seconds when the motor first kicks on? I know in the washer's original form the tub begins spinning as soon as the motor starts. I was wondering if anyone would notice or ask about that lol. I programmed the VFD to do that purposely that when counter-clockwise rotation is called for (spin) to give a five or so seconds of delay time so the pump can pre-drain the outer tub of the extra Filter-Flo water before the main tub-full of water is thrown out in the outer tub. Also, aren't you concerned that this high speed agitation will put a strain on the old GE tub pawl that prevents the tub from rotation during wash? Not really because that part is made out of a nylon/plastic and is a perfect candidate to be 3D printed if necessary. When I rebuilt the transmission nearly 1/2 of the oil was gone, now that it is refilled I suspect the weight of a full charge of oil will help protect that part. Ahhhh there is nothing like a properly spun wash-load!!! You can tell just by looking at it.

| ||

Post# 1011069 , Reply# 55 10/16/2018 at 10:51 (2,008 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Geez I can't slip anything past you guys lol. Actually no, the rubber Filter mount I have for the copper filter pan is in perfect condition as it's brand new-old-stock and holds the pan perfectly. The last new one I had held the pan down for over 10 years but started to wear out and recently I found another brand new one on eBay. The slotted filter-mount on the picture in the post above is for the later pans. I like to have variety in my wash-day (variety prevents Monday-blues of course) so I routinely change the filter pan mount back and forth so I can use the later pans as well.

This was the pan I used last night for the fun of it, I love this one too...

| ||

Post# 1011076 , Reply# 56 10/16/2018 at 13:33 (2,008 days old) by Lorainfurniture  (Cleveland ) (Cleveland ) |

||

|

Mcu- motor control unit Ccu- central control unit. I’m going to take it apart and see. There has to be some port that will allow the software to be accessed. | ||

Post# 1011077 , Reply# 57 10/16/2018 at 14:02 (2,008 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

Just be aware Eugene that a few years ago it's wasn't legal to access the software code on products that you own, however that changed in 2015, but with some restrictions...

www.theverge.com/2015/10/... | ||

| Post# 1011080 , Reply# 58 10/16/2018 at 14:25 (2,008 days old) by hippiedoll ( arizona ) | ||

WOWZERS!! | ||

Post# 1011088 , Reply# 59 10/16/2018 at 16:39 (2,008 days old) by Mayfan69  (Brisbane Queensland Australia) (Brisbane Queensland Australia) |

||

Wow! | ||

| Post# 1013510 , Reply# 60 11/6/2018 at 11:03 (1,987 days old) by wigwag (San Diego) | ||

|

Very nice properly executed, nice work Robert. | ||

Post# 1013524 , Reply# 61 11/6/2018 at 14:28 (1,987 days old) by hydralique  (Los Angeles) (Los Angeles) |

||

|

Fantastic . . . Better than modern performance with beauty that only comes from chrome and turquoise! | ||

Post# 1013957 , Reply# 62 11/9/2018 at 21:40 (1,984 days old) by rinso  (Meridian Idaho) (Meridian Idaho) |

||

|

It would be fun to see this applied to a WP/KM belt-drive machine as well. | ||

| Post# 1016351 , Reply# 63 11/30/2018 at 19:57 (1,963 days old) by philip201 (SYRACUSE,NY) | ||

|

Briallant Santa has done it again! Most beautiful thing I have ever seen. | ||

| Post# 1016679 , Reply# 64 12/3/2018 at 13:28 (1,960 days old) by scoots (Chattanooga TN) | ||

I only just found this post.... | ||

Post# 1186357 , Reply# 65 7/30/2023 at 22:56 (260 days old) by GELaundry4ever  (Nacogdoches, TX, USA) (Nacogdoches, TX, USA) |

||

|

ideas to GE You should submit these ideas to GE. | ||

Comes to the Rescue!

Comes to the Rescue!